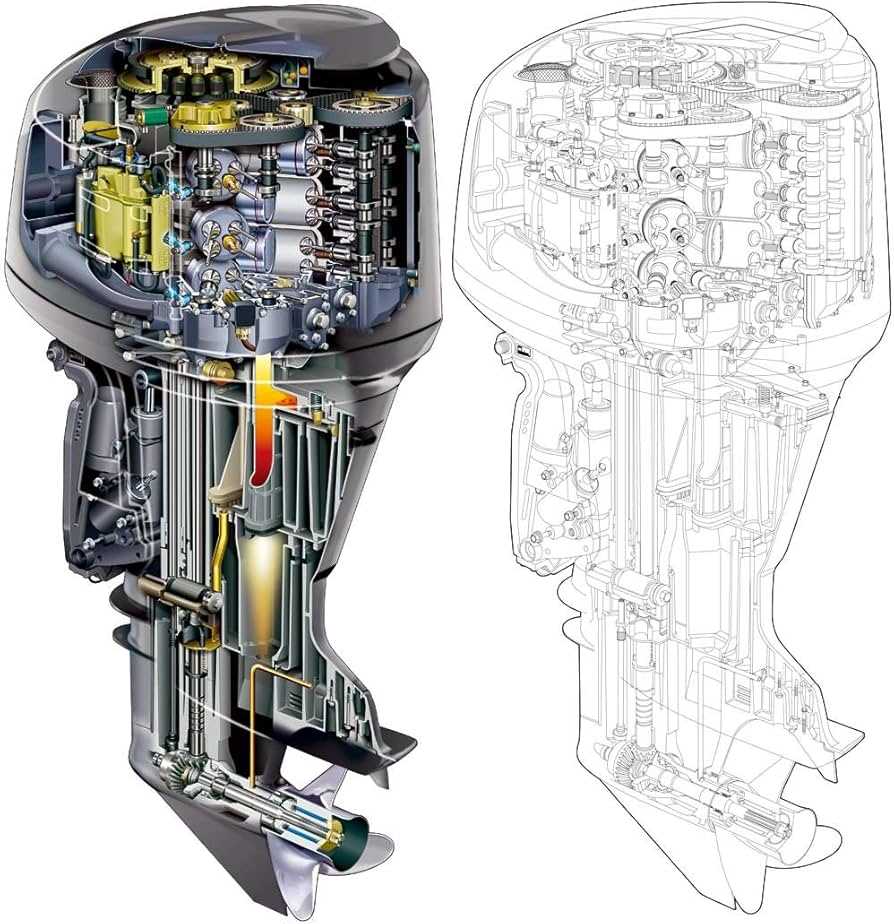

Understanding the intricacies of small marine engines is essential for ensuring optimal performance and longevity. This section delves into the various aspects of servicing and troubleshooting these vital components, providing insights that will benefit both novice and experienced users alike.

Proper upkeep plays a crucial role in enhancing the reliability of your vessel’s power source. By following detailed procedures and recommendations, you can address common challenges effectively and keep your engine running smoothly.

Knowledge of essential techniques not only simplifies maintenance tasks but also empowers you to tackle unexpected issues with confidence. This guide aims to equip you with the necessary tools and understanding to handle your engine’s needs competently.

Essential Tools for Yamaha F20 Maintenance

Effective upkeep of your outboard engine is vital for its longevity and performance. Utilizing the right tools not only simplifies the maintenance process but also ensures that each task is completed with precision. Below is a selection of essential implements that will aid in the routine care of your engine.

Basic Tool Requirements

- Socket set for various fasteners

- Wrenches for tightening and loosening components

- Phillips and flathead screwdrivers for accessing panels

- Pliers for gripping and manipulating small parts

Specialized Maintenance Tools

- Torque wrench for accurate tightening of bolts

- Oil filter wrench for easy removal

- Fuel line disconnect tool for safe fuel system access

- Multimeter for electrical diagnostics

Understanding Common Issues with Yamaha F20

This section delves into frequently encountered challenges faced by users of a specific model of outboard engine. Recognizing these issues can aid in timely maintenance and enhance overall performance.

Common problems often arise from various factors, including wear and tear, environmental conditions, and operational habits. Below are some typical concerns:

- Overheating: This can occur due to inadequate cooling water intake or a malfunctioning thermostat.

- Fuel system issues: Problems such as clogged filters or improper fuel mixture can hinder engine performance.

- Starting difficulties: These may stem from battery issues or faulty ignition components.

- Unusual noises: Sounds like knocking or grinding could indicate internal damage or insufficient lubrication.

By being aware of these potential issues, operators can take proactive measures to maintain their engine’s reliability and efficiency.

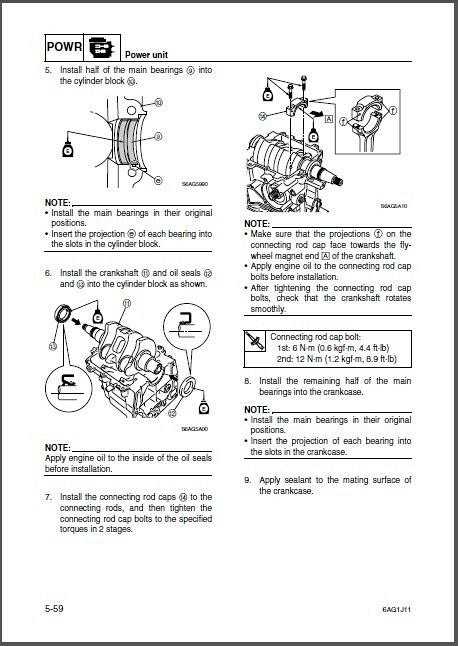

Step-by-Step Engine Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise with marine propulsion systems. By following these steps, users can efficiently diagnose problems, ensuring optimal performance and reliability of their equipment.

Identifying Symptoms

Begin by observing any irregularities during operation. Look for unusual noises, vibrations, or performance drops. Document these symptoms carefully, as they will aid in pinpointing the underlying cause.

Conducting Basic Checks

Start with a thorough inspection of the engine components. Ensure that fuel levels are adequate, connections are secure, and there are no visible leaks. Pay attention to electrical connections and fuses, as these are often sources of trouble.

Note: Regular maintenance can prevent many issues. Keep a schedule for inspections and servicing.

By following this structured guide, users can enhance the longevity and functionality of their marine propulsion systems.

Preventative Care for Optimal Performance

Maintaining a watercraft in top condition is crucial for ensuring smooth operation and longevity. Regular upkeep helps identify potential issues before they escalate, ultimately saving time and resources. Emphasizing a routine of preventative measures will enhance overall functionality and reliability.

Routine Inspections

Conducting systematic checks on various components can reveal wear and tear that may not be immediately apparent. Focus on inspecting seals, connections, and fluid levels to ensure everything is functioning as intended. Regular assessments will allow for timely interventions.

Maintenance Schedule

Establishing a comprehensive maintenance timeline is vital for keeping equipment in peak condition. Adhering to recommended intervals for servicing and part replacements can prevent unexpected failures and enhance performance. Consistency in following this schedule is key to optimal operation.

Decoding the Yamaha F20 Parts List

Understanding the components of a specific engine model is crucial for effective maintenance and troubleshooting. This section will explore the intricacies of the parts inventory, helping users identify and source necessary elements for their devices.

Comprehending the Inventory: A comprehensive list of parts provides insights into the construction and functionality of the machine. Each entry typically includes identification numbers, descriptions, and applicable specifications.

Utilizing the Parts List: By navigating through the inventory, users can ensure they procure the right components for repairs or replacements. This resource simplifies the process of finding compatible parts, ultimately enhancing the efficiency of any maintenance task.

Identifying Components: Familiarity with the terms and codes used in the parts list enables users to better understand the assembly of the engine. Recognizing each element’s role can lead to more informed decisions during service or upgrades.

Fuel System Maintenance Techniques

Regular upkeep of the fuel system is essential for ensuring optimal performance and longevity of your watercraft. Proper care not only enhances efficiency but also prevents common issues that can lead to costly repairs.

Key Maintenance Practices

- Inspect Fuel Filters: Regularly check and replace filters to prevent contaminants from entering the system.

- Check Fuel Lines: Look for signs of wear, leaks, or cracks in the fuel lines. Replace any damaged sections promptly.

- Clean Fuel Injectors: Periodic cleaning of injectors helps maintain proper fuel atomization and engine performance.

- Monitor Fuel Quality: Use high-quality fuel and avoid letting it sit for extended periods to prevent degradation.

Steps for Effective Maintenance

- Turn off the engine and allow it to cool before beginning any maintenance tasks.

- Remove the fuel filter and inspect it for dirt and debris. Replace it if necessary.

- Examine the fuel lines for leaks and replace any sections that show signs of damage.

- Utilize a fuel injector cleaning kit to ensure injectors are free from deposits.

- Refill the tank with fresh fuel to maintain quality and performance.

By following these maintenance techniques, you can significantly enhance the reliability and efficiency of your watercraft’s fuel system.

Electrical System Diagnostics Explained

Understanding the functionality of an electrical system is crucial for effective troubleshooting. This section delves into the essential processes involved in diagnosing electrical components, ensuring that users can identify issues accurately and efficiently.

Key components play a vital role in the operation of any electrical framework. Familiarity with these elements enables users to recognize signs of failure, such as inconsistent performance or unexpected behavior.

Utilizing diagnostic tools is fundamental for evaluating the health of the system. Multimeters, oscilloscopes, and specialized software can provide valuable insights, allowing for precise measurements and assessments of various electrical parameters.

Regular maintenance and testing of connections are equally important. Loose or corroded terminals can lead to intermittent problems, which may be difficult to trace without thorough examination. Keeping connections clean and secure is a straightforward yet effective strategy for minimizing issues.

In summary, a systematic approach to diagnosing electrical systems enhances reliability and performance. By understanding the components, employing the right tools, and ensuring proper maintenance, users can significantly improve their troubleshooting efforts.

Best Practices for Gearbox Repairs

Maintaining the integrity of a transmission system is crucial for optimal performance and longevity. Implementing effective methods during service can prevent future complications and ensure smooth operation. Here are some essential guidelines to follow when addressing issues related to gear assemblies.

Firstly, always begin with a thorough inspection to identify any signs of wear or damage. This includes checking for leaks, unusual noises, or abnormal vibrations. Addressing these issues early can save time and resources in the long run.

Next, ensure that you use high-quality replacement parts that meet the manufacturer’s specifications. Compatibility is key to maintaining the efficiency of the system. Additionally, proper lubrication should be prioritized; using the correct type and amount of lubricant can significantly reduce friction and wear.

Moreover, maintaining cleanliness during the repair process is vital. Dirt and debris can compromise the functionality of components, leading to further issues. Utilize clean tools and work in a tidy environment to minimize contamination risks.

Finally, follow a systematic approach to reassembly, ensuring all components are properly aligned and torqued to the recommended specifications. Taking the time to adhere to these best practices can greatly enhance the reliability and performance of the transmission system.

Propeller Inspection and Replacement

Regular examination and substitution of the propulsion unit are vital for maintaining optimal performance and safety on the water. This section outlines the essential steps for assessing the condition of the propeller and when it is necessary to replace it.

To ensure the efficiency and reliability of the propulsion system, follow these guidelines:

- Visual Inspection:

- Check for cracks, dents, or any deformation.

- Examine the blade edges for nicks or significant wear.

- Ensure the hub is free from corrosion or damage.

- Performance Evaluation:

- Monitor for unusual vibrations or noise during operation.

- Note any loss of power or decreased speed while in use.

- Measurement of Wear:

- Assess the diameter and pitch to confirm they meet specifications.

- Use calipers to measure blade thickness at multiple points.

- Replacement Criteria:

- Consider replacing if significant damage is found.

- Replace when performance issues cannot be resolved through maintenance.

- Regularly replace propellers that show excessive wear beyond tolerances.

By adhering to these inspection and replacement practices, users can ensure the longevity and effectiveness of the propulsion unit, leading to a safer and more enjoyable experience on the water.

Commonly Asked Questions about Yamaha F20

This section addresses frequently encountered inquiries regarding a specific model of outboard motors. Understanding common concerns can enhance the experience of using and maintaining this equipment.

General Maintenance Queries

- What routine checks should be performed to ensure optimal performance?

- How often should the oil be changed?

- What type of fuel is recommended for this motor?

Troubleshooting Common Issues

- What steps should be taken if the engine fails to start?

- How can overheating be prevented during operation?

- What are the signs of a malfunctioning fuel system?

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to established guidelines not only protects the individual conducting the work but also safeguards the equipment being serviced.

Before beginning any servicing activities, it is essential to follow these precautions:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Work in a well-ventilated area to avoid inhaling harmful fumes and particles.

- Keep your workspace organized and free from clutter to reduce the risk of accidents.

- Ensure that tools and equipment are in good working condition and properly maintained.

Additionally, consider the following steps to enhance safety:

- Disconnect power sources before starting any work to eliminate electrical hazards.

- Read and understand any provided guidelines or instructions thoroughly.

- Use tools specifically designed for the tasks at hand to minimize the risk of injury.

- Seek assistance if unsure about any aspect of the maintenance process.

By prioritizing safety measures, individuals can carry out their tasks effectively and minimize the likelihood of incidents during maintenance activities.

When to Seek Professional Help

Understanding when to enlist the expertise of a qualified technician can be crucial for maintaining optimal performance and safety. Certain situations may arise where professional intervention is necessary, ensuring that issues are addressed effectively and efficiently.

Signs That Indicate Professional Assistance is Needed

- Persistent performance issues that do not improve with basic troubleshooting.

- Unusual sounds or vibrations that indicate potential mechanical failures.

- Frequent error codes or warning indicators on the dashboard.

- Complex repairs that require specialized tools or knowledge.

- Inability to resolve electrical problems or wiring complications.

Benefits of Consulting an Expert

- Access to advanced diagnostic equipment for precise troubleshooting.

- Expertise in resolving intricate issues that may not be apparent to the average user.

- Warranties and guarantees on services performed, providing peace of mind.

- Potential cost savings in the long run by avoiding further damage.