Qu

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular care and attention. Proper upkeep not only enhances functionality but also minimizes the risk of unexpected breakdowns. Adopting a systematic approach to maintenance will contribute significantly to a smoother operation and prolonged lifespan.

Regular Inspections

Frequent checks of all components are essential. Look for signs of wear, loose connections, or leaks. Addressing minor issues promptly can prevent them from escalating into more significant problems. Establish a routine inspection schedule to keep everything in top shape.

Cleaning and Lubrication

Keeping surfaces clean and free from debris is vital for performance. Use appropriate cleaning agents to remove dirt and grime. Additionally, lubricating moving parts ensures smooth operation and reduces friction, which can lead to wear and tear. Regularly assess lubrication needs and apply the right products to maintain optimal function.

Battery Care and Troubleshooting

Proper maintenance of the power source is crucial for optimal performance and longevity. This section outlines essential practices and common issues that may arise, along with solutions to ensure reliable operation.

Regularly checking the condition of the power source can prevent unexpected failures. Follow these guidelines to maintain efficiency:

| Care Tips |

Description |

| Check Fluid Levels |

Ensure the electrolyte levels are adequate. If low, top up with distilled water to maintain functionality. |

| Clean Terminals |

Corrosion can affect performance. Use a mixture of baking soda and water to clean terminals, ensuring a solid connection. |

| Inspect for Damage |

Regularly examine the casing for cracks or leaks that could lead to failures or hazardous situations. |

| Monitor Voltage |

Use a multimeter to check the voltage levels. A reading below the recommended range indicates a need for charging or replacement. |

Common issues can arise even with diligent care. Here are a few potential problems and their solutions:

| Problem |

Solution |

| Slow Cranking |

Check for poor connections or a weak power source. Clean terminals and ensure a full charge. |

| Frequent Discharges |

Assess for parasitic drains or excessive accessory use. Disconnect unnecessary devices when not in use. |

| Overheating |

Ensure proper ventilation. If overheating persists, consult a professional for further inspection. |

| Swelling |

Discontinue use immediately and replace the power source, as this can indicate a dangerous condition. |

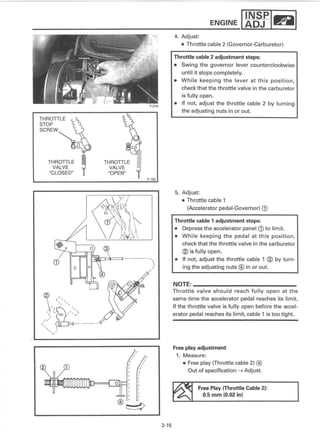

Understanding Fuel System Mechanisms

The fuel system in a small engine plays a crucial role in delivering the right mixture of fuel and air to ensure optimal performance. This intricate network of components works together to facilitate the combustion process, providing the necessary power for various applications. Understanding how these mechanisms function can help in diagnosing issues and ensuring efficient operation.

Key Components of the Fuel System

- Fuel Tank: Stores the fuel and allows for gravity or pump-assisted flow to other components.

- Fuel Pump: Moves fuel from the tank to the carburetor or injector, ensuring a steady supply.

- Carburetor or Fuel Injector: Mixtures air and fuel in the correct ratio before it enters the combustion chamber.

- Fuel Filter: Removes impurities from the fuel, protecting the engine from damage.

- Fuel Lines: Connect various components, allowing for the transport of fuel throughout the system.

Operation Principles

The fuel system operates on basic principles of physics and chemistry. When the engine is activated, the fuel pump draws fuel from the tank and sends it through the filter to remove contaminants. The carburetor or fuel injector then mixes this fuel with air, creating a combustible mixture. This mixture is drawn into the engine’s combustion chamber, where it is ignited, producing the necessary energy for operation.

Understanding these mechanisms is essential for maintenance and troubleshooting. Regular checks of the fuel lines, filters, and pumps can prevent issues that may lead to decreased performance or engine failure.

Step-by-Step Brake Adjustment Guide

This section provides a comprehensive guide to fine-tuning the braking system for optimal performance. Proper adjustment is crucial to ensure safety and enhance the vehicle’s handling capabilities. Following these steps will help you achieve precise brake functionality.

Begin by gathering the necessary tools and materials:

| Tool/Material |

Description |

| Wrench set |

For loosening and tightening adjustment bolts |

| Brake cleaner |

To clean the braking components |

| Ruler or caliper |

For measuring the gap between the brake pads |

| Safety gloves |

To protect your hands during the process |

Follow these steps to adjust the braking mechanism:

- Ensure the vehicle is on a flat surface and securely supported.

- Remove the wheel to access the brake components.

- Clean the braking system with brake cleaner to remove any debris.

- Examine the brake pads and discs for wear or damage. Replace if necessary.

- Use the wrench to loosen the adjustment bolts.

- Measure the gap between the brake pads using the ruler or caliper.

- Adjust the distance by tightening or loosening the bolts as needed.

- Recheck the gap to ensure it meets the manufacturer’s specifications.

- Once satisfied, securely tighten all bolts and replace the wheel.

- Test the brakes in a safe area before regular use.

Regular maintenance and adjustment of the braking system are essential for safe operation. Following these steps will help ensure reliable performance on the road.

Lubrication Tips for Moving Parts

Proper maintenance of machinery involves ensuring that all moving components operate smoothly and efficiently. Regular lubrication minimizes friction, reduces wear, and prolongs the lifespan of these parts. Here are some essential tips to consider for effective lubrication.

- Select the Right Lubricant: Choose a lubricant that is suitable for the specific type of material and operating conditions. Refer to manufacturer recommendations for guidance.

- Clean the Surface: Before applying lubricant, clean the surfaces of the moving parts to remove dirt, debris, and old lubricant. This ensures better adhesion and effectiveness of the new lubricant.

- Apply Lubricant Sparingly: Use an appropriate amount of lubricant; too much can attract dirt and create a sticky residue, while too little can lead to inadequate protection.

- Focus on High-Friction Areas: Identify and prioritize areas that experience significant wear and tear. These include pivot points, gears, and bearings.

- Regular Maintenance Schedule: Establish a routine maintenance schedule to check and reapply lubricant as necessary, ensuring all moving parts remain in optimal condition.

- Monitor Performance: Keep an eye on the performance of the machinery. If you notice unusual noises or decreased efficiency, it may indicate a need for more frequent lubrication.

By following these tips, you can maintain the efficiency and functionality of moving parts, ultimately enhancing the overall performance of your equipment.

Testing and Replacing Ignition Parts

Effective troubleshooting of ignition components is essential for ensuring optimal performance in any vehicle. Understanding how to diagnose and replace faulty parts can significantly improve the reliability of the starting system. This section provides guidance on how to assess these components and make necessary replacements.

To begin with, it is crucial to have the right tools for testing. Common tools include a multimeter, spark tester, and basic hand tools for removal and installation. Follow these steps to evaluate the ignition components:

| Step |

Description |

| 1 |

Check the battery voltage to ensure sufficient power supply to the ignition system. |

| 2 |

Inspect wiring connections for corrosion or damage that may disrupt the electrical flow. |

| 3 |

Use a multimeter to test the ignition coil for proper resistance values. |

| 4 |

Utilize a spark tester to verify that the spark plug is firing correctly. |

| 5 |

If any components are found to be defective, replace them with high-quality parts that meet the manufacturer’s specifications. |

After replacing any malfunctioning parts, it is advisable to recheck the system to confirm that everything is functioning as intended. Regular maintenance and timely replacements of ignition components can prevent future issues and enhance the longevity of the engine.

|