In the realm of off-road vehicles, ensuring optimal performance and longevity is paramount for enthusiasts and casual riders alike. This segment delves into essential practices and techniques to maintain your machine in peak condition, addressing common issues that may arise during its operation. A well-documented approach empowers owners to tackle challenges confidently and efficiently.

Equipped with thorough insights and step-by-step procedures, this guide aims to enhance your understanding of the vehicle’s intricate systems. Whether you’re a seasoned expert or a novice, having access to detailed instructions can significantly simplify the maintenance process. Empower yourself with knowledge and unlock the full potential of your trusted companion.

From routine checks to advanced troubleshooting, this resource is designed to provide clarity and support. Engaging with the intricacies of your vehicle will not only improve its performance but also enrich your experience as an owner. Embrace the journey of learning and discover how to keep your ride in exceptional shape.

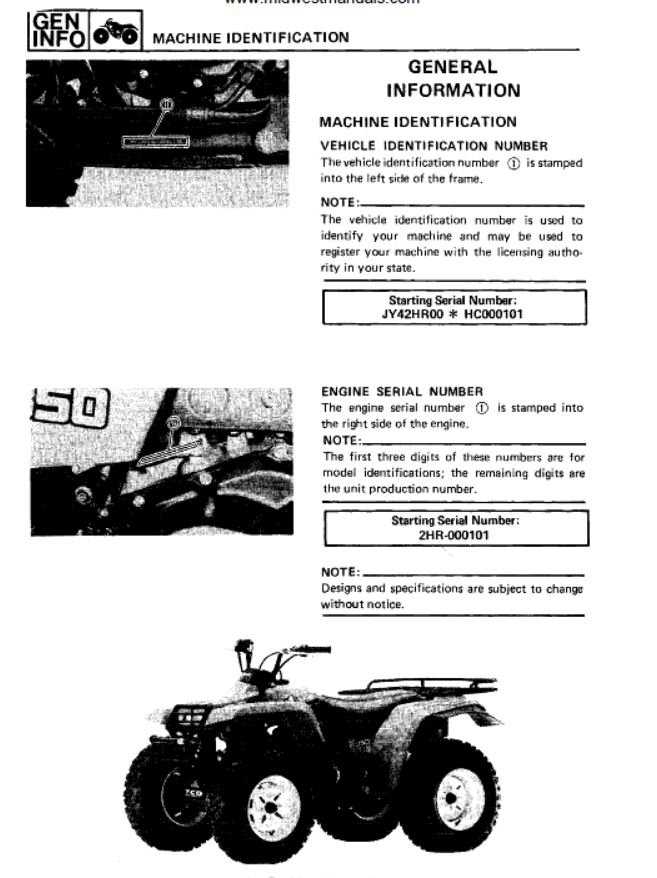

Overview of Yamaha Big Bear Models

This section provides an insight into a renowned series of all-terrain vehicles that have gained popularity for their durability and performance in various conditions. Each model within this line is designed to cater to different needs, ensuring that riders have options suitable for both recreational and utility purposes.

The lineup is characterized by several key features:

- Robust engine performance

- Advanced suspension systems

- High ground clearance

- Ample cargo capacity

- User-friendly handling

Various iterations have been introduced over the years, each boasting improvements and innovations. Below are some notable models:

- First Generation: Introduced basic functionalities and set the standard for future designs.

- Second Generation: Enhanced power and comfort, catering to a broader audience.

- Current Models: Feature cutting-edge technology and improved fuel efficiency, focusing on environmental considerations.

Overall, this series stands out for its versatility and reliability, making it a top choice among enthusiasts and professionals alike.

Essential Tools for DIY Repairs

Embarking on maintenance tasks requires a well-curated selection of instruments to ensure efficiency and effectiveness. Understanding which tools are fundamental can make the difference between a successful project and a frustrating experience. From basic hand tools to specialized equipment, having the right items at your disposal will empower you to tackle various challenges with confidence.

Basic Hand Tools

Every DIY enthusiast should start with a set of essential hand tools. These typically include screwdrivers, wrenches, and pliers. Each tool serves a unique purpose, enabling you to perform a range of tasks from loosening bolts to securing components. A well-organized toolbox not only facilitates easier access but also ensures that you can quickly find what you need when the moment arises.

Specialized Equipment

In addition to hand tools, investing in specialized equipment can significantly enhance your capabilities. Items such as torque wrenches and multimeters allow for precise adjustments and diagnostics, respectively. These tools may seem advanced, but they can greatly improve the quality of your work, making it easier to achieve professional-level results.

Common Issues with Yamaha Big Bear

This section highlights frequent challenges faced by owners of a particular all-terrain vehicle model. Understanding these common problems can help enthusiasts maintain their machines and ensure a smoother riding experience.

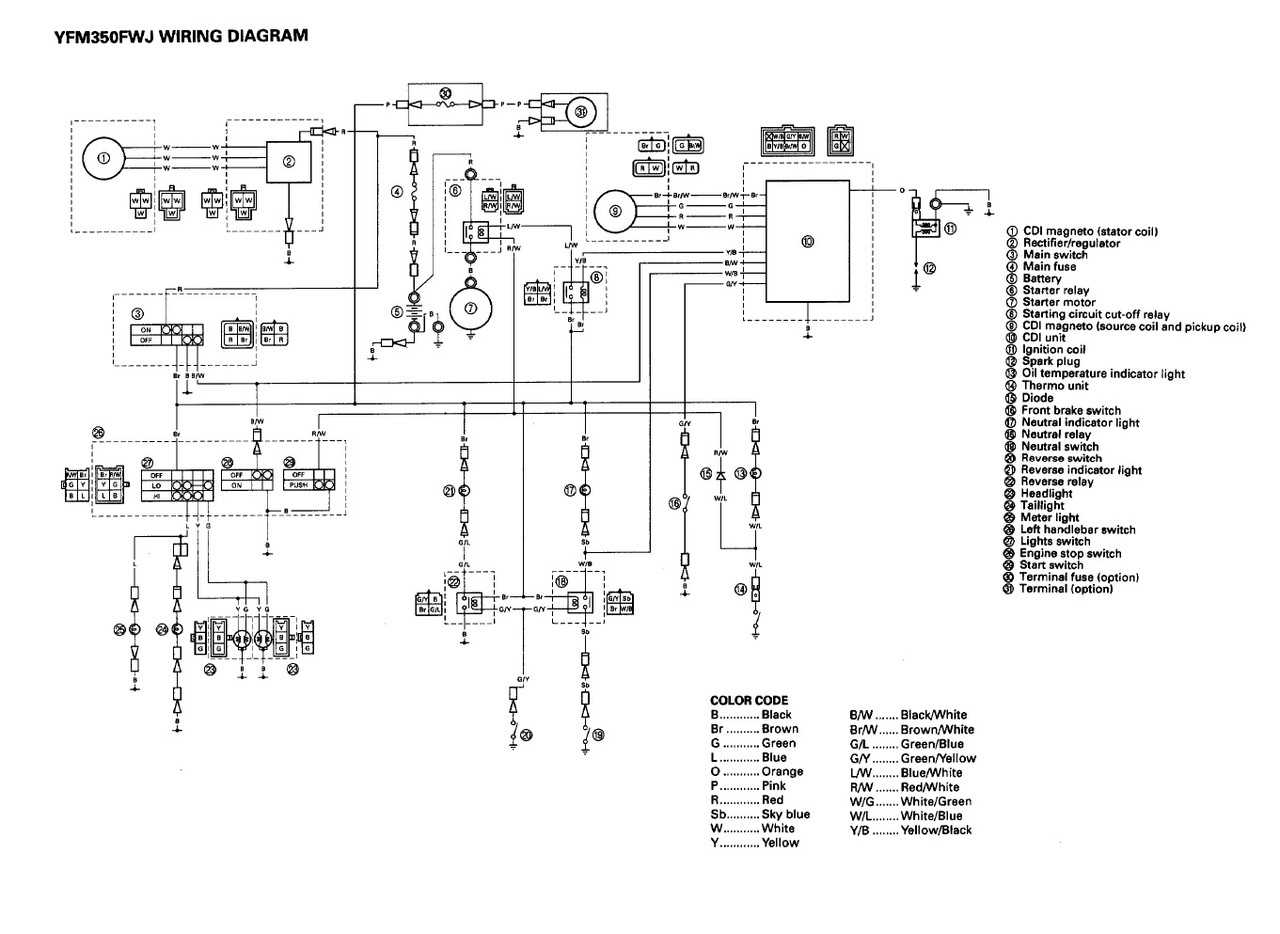

Electrical Problems

Electrical issues can often arise, affecting the vehicle’s performance. Here are some typical electrical concerns:

- Dead battery: Often caused by prolonged inactivity or insufficient charging.

- Faulty connections: Corrosion or loose wires can lead to intermittent power loss.

- Defective lighting: Headlights and tail lights may malfunction, requiring bulb replacement or wiring checks.

Engine Troubles

Engine-related difficulties can significantly impact functionality. Common symptoms include:

- Difficulty starting: Problems may stem from the fuel system or ignition components.

- Overheating: This can be due to coolant leaks or a malfunctioning radiator.

- Unusual noises: Knocking or rattling sounds may indicate internal issues needing attention.

Step-by-Step Maintenance Guidelines

Proper upkeep of your all-terrain vehicle is essential to ensure its longevity and optimal performance. Following systematic procedures not only enhances functionality but also prevents potential issues. This section outlines essential practices for regular maintenance, allowing you to keep your machine in peak condition.

Routine Checks

Conducting regular inspections is crucial for identifying wear and tear. Focus on key components that require attention. Below is a table summarizing the primary areas to monitor during routine checks:

| Component | Recommended Frequency | Key Actions |

|---|---|---|

| Oil Level | Every 100 miles | Check and top off as needed |

| Tires | Monthly | Inspect for pressure and tread wear |

| Brakes | Every 500 miles | Examine pads and fluid levels |

| Air Filter | Every 300 miles | Clean or replace if necessary |

Seasonal Maintenance

In addition to regular checks, seasonal maintenance ensures that your vehicle is ready for changing conditions. Here are key tasks to perform at the beginning of each season:

- Flush and replace coolant to prevent overheating.

- Inspect battery terminals for corrosion and ensure proper connections.

- Clean and lubricate moving parts to reduce friction.

- Check the functionality of lights and indicators.

Electrical System Troubleshooting Tips

Diagnosing issues within the electrical framework of your vehicle can be a daunting task, but with the right approach, it becomes manageable. This section provides essential guidance to help identify and resolve common electrical problems effectively.

Check the Battery: Start by inspecting the battery condition. Ensure that the terminals are clean and free of corrosion. A multimeter can be used to measure the voltage; a healthy battery should read around 12.6 volts when fully charged.

Examine Fuses: A blown fuse can lead to various electrical failures. Locate the fuse box and visually inspect each fuse for damage. Replace any that are burnt out with fuses of the same rating to avoid further issues.

Inspect Wiring and Connectors: Damaged or frayed wiring can cause intermittent electrical issues. Carefully examine all visible wiring for signs of wear. Ensure that connectors are secure and free of debris.

Test Switches and Relays: Faulty switches can disrupt the flow of electricity. Use a multimeter to test the functionality of switches and relays. Replace any components that do not operate as intended.

Ground Connections: Poor ground connections can lead to erratic electrical behavior. Check all ground points to ensure they are tight and free of rust or dirt, which can impede electrical flow.

Use Diagnostic Tools: Employ diagnostic tools such as a scan tool or voltmeter to pinpoint issues more accurately. These devices can provide valuable information about the system’s performance and help identify specific faults.

By following these tips, you can systematically address electrical problems, ensuring your vehicle remains in optimal working condition.

Engine Repair and Overhaul Procedures

This section focuses on the essential steps involved in restoring and enhancing the performance of a motor’s power unit. Understanding these procedures is crucial for maintaining efficiency and longevity, ensuring the machine operates optimally.

Preliminary Assessment

Before initiating any work, it’s vital to conduct a thorough examination of the engine. This initial assessment will help identify issues and determine the extent of the overhaul required. Follow these steps:

- Check for any visible leaks or damage.

- Inspect the oil level and condition.

- Listen for unusual sounds during operation.

- Monitor engine temperature and performance metrics.

Disassembly Process

Once the assessment is complete, the next step is to disassemble the engine carefully. This allows for a detailed inspection and repair of individual components. Follow these guidelines:

- Disconnect the battery and remove any external components.

- Label all parts for easy reassembly.

- Remove the cylinder head, piston, and crankshaft with caution.

- Inspect each component for wear, cracks, or other damage.

These procedures, when performed systematically, will ensure a successful restoration and enhancement of the engine’s functionality.

Suspension and Brake Adjustments

Proper maintenance of the suspension and braking systems is essential for ensuring optimal performance and safety. Adjustments in these areas can significantly enhance ride quality and handling, while also improving stopping power. Understanding how to fine-tune these components allows for a more tailored driving experience and prolongs the lifespan of the vehicle.

To begin with, the suspension setup should be checked for any signs of wear or misalignment. Adjusting the preload on the springs can help achieve the desired ride height and stiffness, accommodating various loads and terrain types. Additionally, ensuring that dampers are functioning correctly is vital for controlling the rebound and compression, thus providing a smoother ride.

Moving on to the braking system, regular inspection of brake pads, rotors, and fluid levels is crucial. Adjustments to the brake lever or pedal height can enhance responsiveness and comfort during operation. It’s also important to check for any air in the brake lines, as this can lead to a spongy feel and reduced braking efficiency. Properly bleeding the brakes can restore optimal performance and safety.

Overall, regular attention to the suspension and braking systems not only improves handling and comfort but also ensures safety during rides. Engaging in routine checks and adjustments fosters confidence in the vehicle’s performance under varying conditions.

Transmission Care and Adjustments

Proper maintenance and fine-tuning of the transmission system are crucial for ensuring optimal performance and longevity of your vehicle. Regular attention to this component not only enhances driving experience but also minimizes the risk of potential issues that could lead to costly repairs.

Fluid Checks and Changes

One of the primary aspects of transmission maintenance is monitoring the fluid level and condition. Regularly inspect the fluid for clarity and color; it should be a clean hue without burnt odors. If it appears dark or has an unpleasant smell, it’s time for a change. Ensuring the correct fluid level is essential for proper lubrication and cooling.

Linkage Adjustments

Over time, the linkage connecting the transmission to the control mechanism can become misaligned. Regular adjustments help maintain smooth shifting. Look for any play in the linkage and ensure it engages fully. Refer to the specifications for proper alignment and adjustment procedures to achieve optimal performance.

Inspection of Seals and Gaskets

Seals and gaskets play a vital role in preventing leaks. Regularly inspect these components for signs of wear or damage. Replacing worn seals promptly can save on fluid loss and ensure the transmission operates efficiently. A simple visual check can often highlight areas needing attention.

Regular Servicing

Adhering to a regular servicing schedule can prevent major issues. Follow manufacturer recommendations for intervals and procedures. This proactive approach ensures that all components function properly and helps identify any potential problems before they escalate.

By focusing on these key areas, you can significantly enhance the reliability and functionality of your transmission, leading to a smoother and more enjoyable ride.

Body and Frame Inspection Techniques

Regular assessment of the chassis and body structure is essential for maintaining optimal performance and safety. Proper techniques not only identify existing issues but also prevent future problems, ensuring longevity and reliability of the vehicle.

Here are some key methods to effectively inspect the body and frame:

- Visual Inspection:

- Check for visible signs of damage, such as dents, cracks, or rust.

- Inspect welds and joints for integrity and signs of wear.

- Look for misalignment or irregularities in panel gaps.

- Structural Analysis:

- Use a straight edge to assess the alignment of the frame.

- Measure critical points to verify geometric accuracy.

- Employ specialized tools to detect hidden deformations.

- Functional Testing:

- Examine suspension components for wear and tear.

- Test doors, hoods, and tailgates for proper operation.

- Assess the attachment points for any signs of looseness.

By systematically applying these techniques, one can ensure that the body and frame remain in excellent condition, thereby enhancing overall vehicle performance and safety.

Aftermarket Parts and Upgrades

Enhancing the performance and appearance of your vehicle can significantly improve your riding experience. Aftermarket components offer a wide range of possibilities for customization, allowing enthusiasts to tailor their machines to suit their specific needs and preferences. Whether you are looking for improved power, better handling, or simply a unique aesthetic, exploring these options can yield impressive results.

Performance Enhancements

Many riders seek to boost the capabilities of their machines through high-performance upgrades. Air filters and exhaust systems are popular choices that can enhance airflow and increase horsepower. Additionally, re-gearing the drivetrain can optimize acceleration and top speed, making your ride more exhilarating. Don’t forget about suspension modifications, which can dramatically improve stability and comfort on rough terrain.

Cosmetic Upgrades

Aesthetics play a significant role in personalizing your vehicle. Aftermarket body kits and decals allow riders to express their individuality. Furthermore, upgrading lighting systems with LED options not only enhances visibility but also adds a modern touch to the overall look. By combining performance and style, you can create a machine that truly reflects your personality.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance work is crucial for both the individual performing the tasks and the machinery involved. Adhering to proper guidelines not only minimizes risks but also enhances the overall efficiency of the process.

- Wear Protective Gear: Always use appropriate safety equipment, such as gloves, goggles, and helmets, to protect against potential hazards.

- Work in a Well-Lit Area: Ensure that the workspace is adequately illuminated to avoid accidents and to see details clearly.

- Maintain a Clean Workspace: Keep tools and materials organized to prevent tripping hazards and ensure easy access to necessary items.

By following these precautions, individuals can significantly reduce the likelihood of injuries and ensure a smoother workflow during maintenance tasks.

- Disconnect Power Sources: Before starting any work, make sure to disconnect all electrical and fuel sources to prevent unexpected starts.

- Use the Right Tools: Employ appropriate tools for the job to avoid damage to the equipment and ensure personal safety.

- Read Instructions Thoroughly: Familiarize yourself with the specific guidelines related to the equipment you are handling.

Staying vigilant and following these steps will promote a safer and more effective maintenance experience.