Maintaining an all-terrain vehicle is essential for ensuring optimal performance and longevity. This guide aims to equip enthusiasts and owners with the necessary insights and techniques for the effective upkeep of their machines. Understanding the intricate details of your vehicle can greatly enhance your riding experience and minimize potential issues.

Key procedures and troubleshooting tips will be discussed, offering a clear pathway to resolving common problems. Whether you’re a seasoned mechanic or a novice owner, having a reliable resource at your fingertips can simplify the maintenance process and empower you to take charge of your vehicle’s health.

By delving into essential techniques and providing detailed instructions, this resource will enable you to tackle repairs with confidence. Emphasizing safety and efficiency, the information presented here will guide you through the various aspects of vehicle care, ensuring that you are well-prepared for any challenges that may arise.

Understanding Yamaha Big Bear 400

This section aims to provide insights into a specific off-road vehicle that combines durability and performance for outdoor enthusiasts. Known for its versatility, this model is a favorite among riders who seek adventure across various terrains. It is designed to handle rugged landscapes while offering reliability and ease of use.

Key Features

- Robust construction for enhanced durability

- Powerful engine ensuring strong performance

- All-terrain capabilities for diverse riding conditions

- User-friendly controls for riders of all skill levels

Maintenance Tips

- Regularly check fluid levels to ensure optimal performance.

- Inspect tires for wear and proper inflation before rides.

- Clean air filters to maintain engine efficiency.

- Follow a consistent schedule for part replacements and servicing.

Key Features of the ATV

All-terrain vehicles are designed to provide exceptional performance and versatility across various landscapes. Understanding the standout characteristics of these machines can help enthusiasts make informed decisions and enhance their riding experience.

Powerful Engine: A robust engine is at the heart of any all-terrain vehicle, delivering impressive torque and acceleration. This ensures that riders can tackle challenging terrains with confidence, whether climbing steep hills or navigating rugged trails.

Durable Suspension: Advanced suspension systems contribute significantly to ride comfort and stability. The ability to absorb shocks and bumps allows for a smoother journey, even on uneven surfaces, enhancing overall handling and control.

All-Wheel Drive: Many models feature an all-wheel drive system, providing superior traction and control. This capability allows riders to traverse mud, snow, and rocky paths, ensuring optimal performance in various environmental conditions.

Ergonomic Design: Comfort is key for long rides, and thoughtful design elements, such as adjustable seating and intuitive controls, enhance the overall riding experience. An ergonomic setup reduces fatigue, allowing riders to enjoy extended adventures.

Utility Features: Versatility is a hallmark of these vehicles. Many come equipped with racks, towing capabilities, and storage options, making them ideal for work, recreation, and exploration.

In summary, the combination of a powerful engine, durable suspension, all-wheel drive, ergonomic design, and utility features makes these vehicles a popular choice for outdoor enthusiasts and adventurers alike.

Common Issues and Solutions

When operating all-terrain vehicles, certain problems may arise that can hinder performance and reliability. Understanding these frequent challenges, along with their solutions, is essential for maintaining optimal functionality. Below, we explore some typical issues encountered and how to effectively address them.

Engine Performance Problems

A common concern among users is engine performance issues, which can manifest as rough idling or difficulty starting. These symptoms may stem from fuel system malfunctions, such as clogged filters or faulty injectors. Regular maintenance of the fuel system, including replacing filters and ensuring clean injectors, can significantly enhance engine responsiveness. Additionally, checking the spark plugs for wear can prevent misfiring and improve ignition efficiency.

Electrical System Failures

Another prevalent issue involves the electrical system, often highlighted by dimming lights or failure of the ignition system. These problems may be traced back to weak batteries or corroded connections. To remedy this, it is advisable to inspect battery terminals for corrosion and secure connections. Replacing an aging battery and ensuring proper grounding can restore functionality and prevent future electrical disruptions.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your all-terrain vehicle requires regular attention and care. By following a consistent maintenance routine, you can enhance performance, prevent costly repairs, and enjoy many hours of trouble-free riding. This section outlines essential practices to keep your machine in optimal condition.

Routine Inspections

Conducting frequent checks is vital. Examine the tires for wear and proper inflation, inspect the brakes for responsiveness, and assess the overall condition of the chassis. Early detection of issues can prevent more significant problems down the line.

Fluid Maintenance

Regularly change and check all necessary fluids, including oil, coolant, and fuel. Clean filters and ensure that levels are appropriate. Using high-quality fluids not only enhances performance but also contributes to the longevity of your vehicle’s engine and components.

Essential Tools for Repairs

When undertaking maintenance or troubleshooting tasks, having the right instruments at your disposal is crucial for achieving effective results. This section outlines the fundamental tools that are indispensable for any mechanical work, ensuring that you can handle various challenges with confidence.

Basic Hand Tools

- Wrenches: A set of adjustable and fixed wrenches is essential for loosening and tightening bolts and nuts.

- Screwdrivers: Both flat-head and Phillips-head screwdrivers are necessary for assembling and disassembling components.

- Pliers: Needle-nose and slip-joint pliers are versatile tools for gripping and manipulating objects.

- Socket Set: A comprehensive socket set allows for quick and efficient fastening tasks.

Specialized Instruments

- Torque Wrench: This tool is vital for applying the correct amount of force to fasteners, preventing damage from over-tightening.

- Multimeter: Useful for diagnosing electrical issues, a multimeter helps measure voltage, current, and resistance.

- Oil Filter Wrench: Specifically designed for changing oil filters, this tool simplifies the task significantly.

- Diagnostic Scanner: An electronic device that reads fault codes, aiding in identifying issues efficiently.

Equipping yourself with these essential tools will enhance your ability to perform various tasks, leading to successful maintenance and troubleshooting experiences.

Step-by-Step Repair Procedures

This section outlines detailed guidelines to assist you in the process of restoring your vehicle to optimal functionality. Each phase is meticulously crafted to ensure clarity and facilitate a smooth workflow. Following these instructions will help you address common issues effectively.

1. Preparation: Begin by gathering all necessary tools and materials. Ensure your workspace is organized and free of distractions. Having everything at hand will streamline the process and minimize interruptions.

2. Diagnosis: Carefully assess the vehicle to identify the specific problems. Pay attention to any unusual sounds, leaks, or performance issues. Document your findings to guide your subsequent actions.

3. Disassembly: Follow the appropriate sequence to dismantle components. Take care to label and store parts in an orderly fashion to avoid confusion during reassembly. Use a camera or notepad to record your steps.

4. Inspection: Examine all removed parts for wear and damage. Look for cracks, corrosion, or any signs of failure. Replace any components that do not meet acceptable standards to prevent future complications.

5. Repair or Replace: Depending on your assessment, either repair damaged components or replace them with new ones. Ensure that all replacements match the original specifications to maintain compatibility and performance.

6. Reassembly: Reassemble the vehicle in the reverse order of disassembly. Double-check each connection and fitting to ensure everything is secure. Refer to your documentation as needed to maintain accuracy.

7. Testing: Once reassembled, conduct thorough tests to verify that the vehicle operates correctly. Monitor for any unusual sounds or performance issues during these tests, and address them promptly.

8. Maintenance: After successful restoration, implement a regular maintenance schedule. This will help prolong the life of your vehicle and prevent future issues from arising.

Diagnosing Electrical Problems

Troubleshooting electrical issues in your vehicle requires a systematic approach to identify and resolve malfunctions effectively. Understanding the key components and their functions will help you pinpoint the root cause of any problems. This section will guide you through essential diagnostic techniques to restore optimal performance.

Identifying Symptoms

The first step in addressing electrical concerns is recognizing the symptoms. Common signs include dimming lights, difficulty starting, or inconsistent power delivery. Take note of any irregularities and make a list of the observed issues. This will aid in narrowing down potential causes during your investigation.

Testing Components

Once you’ve identified the symptoms, the next phase involves testing individual components. Use a multimeter to check voltage levels and continuity throughout the system. Start with the battery, ensuring it is fully charged and capable of holding a charge. Proceed to inspect wiring connections, switches, and fuses for any signs of damage or wear. Document your findings to track your progress and guide further troubleshooting steps.

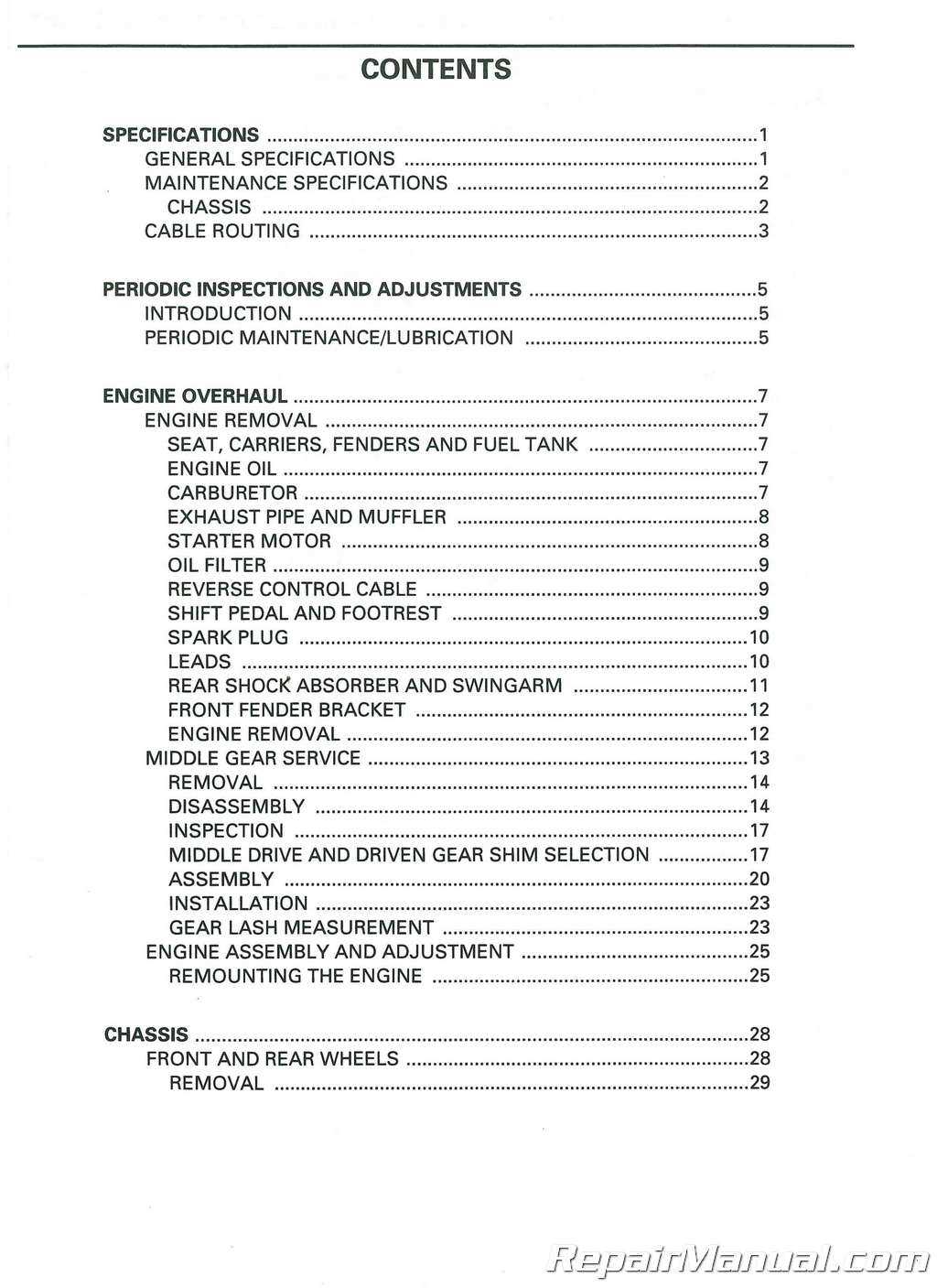

Engine Overhaul Guidelines

Revitalizing an engine involves a meticulous approach to ensure optimal performance and longevity. This process encompasses a variety of steps, from disassembly to reassembly, with the goal of restoring the power unit to peak condition. Understanding the intricacies of this undertaking is crucial for both enthusiasts and professionals alike.

Preparation and Disassembly

Before commencing the overhaul, it is essential to gather the necessary tools and components. This includes wrenches, sockets, gaskets, and replacement parts. Once adequately equipped, begin by carefully detaching the engine from the frame. Documenting each step of the disassembly process is beneficial, as it aids in accurate reassembly. Pay close attention to the orientation and condition of all components to identify wear and damage.

Inspection and Reassembly

Upon disassembly, conduct a thorough inspection of critical components such as the crankshaft, cylinder, and pistons. Look for signs of wear, cracks, or other damage that may affect performance. After evaluation, clean all parts meticulously to eliminate any debris or contaminants. When reassembling, use new gaskets and ensure proper torque specifications are met to avoid future issues. Attention to detail during this phase is vital for a successful overhaul, enhancing the reliability and efficiency of the engine.

Transmission Troubleshooting Techniques

Identifying and resolving issues within the transmission system is crucial for maintaining optimal performance and reliability. This section outlines effective methods to diagnose and rectify common problems that may arise, ensuring a smooth operation and longevity of the vehicle.

Common Symptoms of Transmission Issues

When facing potential transmission difficulties, certain signs can indicate underlying problems. Pay attention to the following symptoms:

- Unusual noises during shifting

- Delayed or harsh engagement of gears

- Fluid leaks under the vehicle

- Warning lights on the dashboard

- Unresponsive gear changes

Troubleshooting Steps

To effectively address transmission concerns, follow these systematic troubleshooting steps:

- Check Fluid Levels: Ensure that the transmission fluid is at the proper level and in good condition. Low or dirty fluid can lead to various issues.

- Inspect for Leaks: Look for signs of fluid leakage around seals and gaskets, which may require immediate attention.

- Examine the Filter: A clogged filter can restrict fluid flow, affecting performance. Regular replacement is recommended.

- Scan for Diagnostic Codes: Use a diagnostic tool to retrieve any error codes that may provide insight into specific faults.

- Test Electrical Components: Inspect wiring and connectors for damage or corrosion, as electrical issues can greatly affect transmission functionality.

By following these techniques, you can systematically identify and resolve transmission problems, ensuring your vehicle operates smoothly and efficiently.

Suspension System Maintenance

The suspension system is crucial for ensuring a smooth ride and maintaining stability on varied terrains. Regular upkeep of this system enhances performance, safety, and overall longevity of the vehicle. Proper maintenance involves a combination of inspections, adjustments, and replacements as necessary to ensure optimal functionality.

Begin by routinely checking all components for signs of wear or damage. Inspect shock absorbers for leaks, and examine bushings and bearings for deterioration. Any visible issues should be addressed promptly to prevent further damage. It’s also essential to verify that all fasteners are tight and secure, as loose parts can lead to serious handling issues.

Next, ensure that the alignment and travel of the suspension are within specifications. Misalignment can cause uneven tire wear and negatively impact handling. Adjustments may be required based on your specific model and usage conditions. Additionally, pay attention to the condition of springs; they should be free from corrosion and provide adequate support.

Finally, consider the environment in which the vehicle operates. Frequent exposure to harsh conditions such as mud, sand, or salt can accelerate wear. Regular cleaning and protective measures can help mitigate these effects, ensuring that the suspension system remains in top condition for reliable performance.

Replacing Tires and Wheels

Proper maintenance of your vehicle’s tires and wheels is essential for optimal performance and safety. Over time, wear and tear can compromise traction, handling, and overall ride quality. This section will guide you through the process of replacing tires and wheels, ensuring you have the knowledge to maintain your vehicle effectively.

1. Gathering Necessary Tools

Before starting the replacement process, make sure you have all the necessary tools at hand. Commonly required items include a jack, jack stands, a lug wrench, and a torque wrench. Having these tools ready will streamline the procedure and ensure your safety during the task.

2. Lifting the Vehicle

Begin by parking your vehicle on a flat, stable surface. Engage the parking brake and loosen the lug nuts slightly while the tires are still on the ground. Use the jack to lift the vehicle to a height that allows for safe access to the wheels. Once elevated, securely position jack stands to support the vehicle.

3. Removing Old Tires

With the vehicle securely lifted, fully remove the lug nuts and take off the old tires. Inspect the wheels for any signs of damage or wear, as this could impact the performance of the new tires.

4. Installing New Tires

Align the new tires with the wheel hubs and carefully place them onto the vehicle. Hand-tighten the lug nuts to ensure the tire is secure. It’s important to follow a star pattern when tightening to distribute pressure evenly.

5. Lowering the Vehicle

After securing the new tires, lower the vehicle back to the ground. Once it is stable, use the torque wrench to tighten the lug nuts to the manufacturer’s specified torque settings, ensuring optimal safety and performance.

6. Final Checks

Once everything is in place, conduct a final inspection to ensure that all components are secure. Regularly check the tire pressure and tread depth to maintain optimal driving conditions.

Following these steps will help you successfully replace tires and wheels, enhancing both safety and functionality of your vehicle.

Upgrading Performance Parts

Enhancing the capabilities of your all-terrain vehicle can significantly improve its overall performance, providing a more thrilling riding experience. By focusing on key components, riders can achieve better power delivery, improved handling, and increased durability, making each adventure more enjoyable.

Engine Modifications are often the first step in boosting performance. Upgrading the air intake system and exhaust can lead to improved airflow, resulting in enhanced power output. Consider high-performance air filters and aftermarket exhaust systems that are designed to optimize engine efficiency.

Suspension Upgrades play a crucial role in handling and stability. Investing in quality shocks and springs can improve ride comfort and control, especially on rough terrains. Adjustability options allow customization based on personal preferences and riding styles.

Additionally, wheel and tire enhancements can transform the vehicle’s grip and maneuverability. Choosing tires that suit your riding conditions, whether mud, sand, or rocky paths, can greatly affect traction and overall performance. Lightweight wheels can also reduce unsprung weight, enhancing responsiveness.

Lastly, braking systems should not be overlooked. Upgrading to larger rotors or high-performance calipers can improve stopping power and reduce fade during extended rides. Ensuring reliable braking performance is essential for safety, especially when tackling challenging trails.

Overall, making informed choices about performance parts can lead to a substantial transformation in how your vehicle performs, offering a customized experience that meets your specific needs and preferences.

Where to Find Replacement Parts

Locating suitable components for your vehicle can be crucial for its longevity and performance. Various sources offer parts that ensure optimal functionality, making it essential to know where to look. By exploring both online and offline options, you can find what you need efficiently.

Online Retailers are among the most convenient choices. Numerous websites specialize in automotive components, providing detailed catalogs and competitive pricing. Websites often feature customer reviews, helping you gauge the quality of the parts before making a purchase.

Local Dealerships can be a reliable source for authentic components. Although prices may be higher, the assurance of original parts can be worth the investment, particularly for critical systems in your vehicle.

Salvage Yards and Used Parts Suppliers offer a more economical alternative. Here, you can find pre-owned parts that are still in good condition, allowing you to save money while obtaining the necessary replacements.

Lastly, consider checking online marketplaces where individuals sell new and used components. These platforms can provide a wide variety of options, but it’s important to verify the seller’s reputation to ensure you receive quality items.