Proper upkeep of a high-performance bike is essential for ensuring its longevity and top-notch performance. This section will cover essential aspects of maintaining a powerful two-wheeled machine, offering insights into common challenges and providing detailed procedures for various tasks. Understanding these practices can help keep the vehicle in excellent condition, ready to deliver an exhilarating riding experience.

Whether dealing with engine upkeep, troubleshooting electrical issues, or adjusting the suspension, having a detailed reference at hand simplifies the process. This guide offers valuable information on key techniques, suitable for both seasoned mechanics and those new to working on powerful motorcycles. Adhering to these guidelines ensures the machine remains reliable and performs at its best on the road.

The upcoming sections will delve into essential components and procedures, from engine tuning and fluid checks to more complex tasks. Learning how to approach these maintenance routines correctly can save time and extend the lifespan of the vehicle, allowing riders to enjoy their journeys with confidence.

Common Issues with 2007 Yamaha R1

Over time, any motorcycle can develop certain recurring problems, especially as it experiences regular wear and tear. Understanding these challenges is key to maintaining smooth operation and ensuring safety on the road. Below are some frequently encountered issues that riders may come across and how they can affect performance.

Electrical System Challenges

Motorcycles of this era often face electrical concerns, such as intermittent starting problems or battery-related issues. Faulty wiring connections, aging ignition components, or inconsistent charging can all contribute to power fluctuations and affect starting reliability. Regular inspections of connectors, fuses, and the charging system can help identify and address these potential faults early.

Cooling and Overheating Concerns

Overheating is another common problem that may arise, particularly in warm climates or during extended rides. Causes can range from a clogged radiator to malfunctioning fans or insufficient coolant levels. Ensuring the cooling system remains clean and components are in working order is crucial for optimal engine temperature regulation. If left unchecked, persistent overheating can lead to more severe damage.

Preventive maintenance plays a significant role in avoiding these issues. By regularly examining key systems and addressing minor faults, riders can signifi

Basic Maintenance for Optimal Performance

Regular upkeep is essential to ensure any high-performance machine operates smoothly and efficiently. Taking a proactive approach to caring for your ride not only enhances longevity but also guarantees a safer, more enjoyable experience on the road. Consistent attention to essential components and timely inspections can prevent common issues and keep performance at its peak.

Engine Care and Fluid Levels

One of the most critical aspects of upkeep is monitoring engine health. Regular oil changes are vital for lubrication and preventing wear. Ensure that the oil used is of high quality and suited for the machine’s specifications. Additionally, maintaining proper levels of coolant and brake fluids is equally important, as these contribute to optimal engine cooling and responsive braking. Routinely checking for any fluid leaks can help identify potential problems early on.

Tire Condition and Pressure

Proper tire maintenance is essential for stability and grip. Always ensure tires are inflated to the recommended pressure, as underinflated or overinflated tires can affect handling and wear unevenly. Regularly inspect the tread for signs of damage or excessive wear, which may indicate the need for replacement. Good tire health is crucial for maintaining control, especially in challeng

Engine Troubleshooting Tips and Solutions

Understanding how to diagnose and resolve common engine issues is crucial for maintaining optimal performance. By recognizing symptoms early and applying the right solutions, you can prevent further complications and extend the lifespan of the engine.

- Difficulty Starting: If the engine struggles to start, check the fuel supply first. Ensure there is enough fuel in the tank and inspect the fuel lines for any blockages. Next, examine the spark plugs; if they appear dirty or worn, replacing them can improve ignition. Finally, consider checking the battery’s condition to rule out electrical problems.

- Rough Idling: An engine that idles roughly may indicate an issue with the air-fuel mixture. Cleaning or replacing the air filter can help restore smooth operation. It is also beneficial to inspect the throttle body for carbon buildup, which can interfere with airflow.

- Overheating: Consistent overheating usually points to problems with the cooling system. Start by ensuring the coolant level is adequate. If the coolant appears fine, inspect the radiator for any signs of clogging or damage, and check the thermostat for proper operation. Replacing a faulty thermostat or flushing the radiator can often resolve temperat

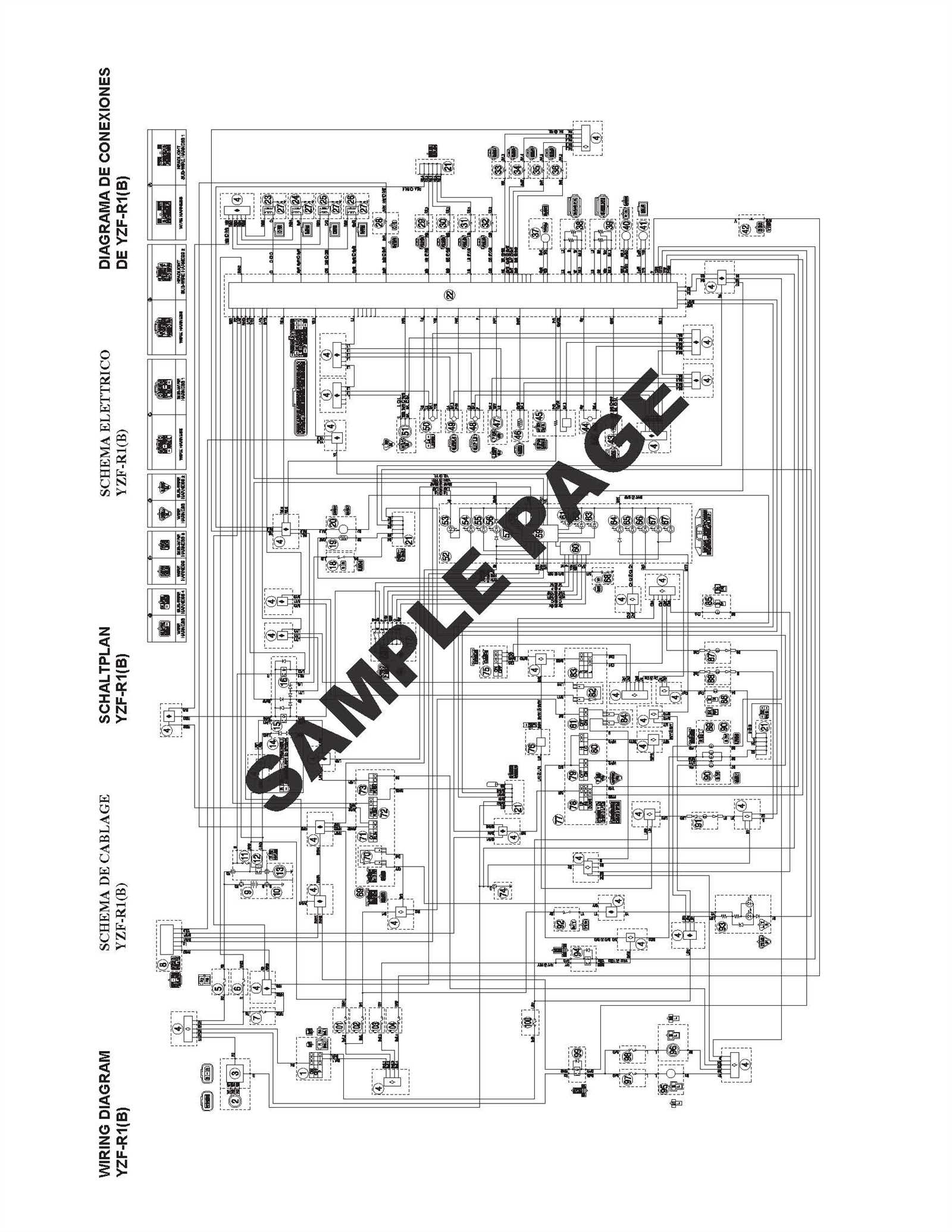

How to Diagnose Electrical Problems

Identifying issues with a vehicle’s electrical system requires a systematic approach to ensure accurate troubleshooting. By methodically checking various components and connections, you can pinpoint the source of electrical malfunctions and address them effectively.

- Check the Battery: Begin by inspecting the battery for proper voltage and signs of corrosion on the terminals. A weak or dead battery is often the root cause of electrical faults.

- Inspect Fuses and Relays: Examine the fuse box for blown fuses and test the relays. Replacing damaged fuses or faulty relays can restore normal electrical functions.

- Examine Wiring Connections: Look for loose, damaged, or corroded wires, as they can disrupt the electrical flow. Repair or replace any compromised wiring to maintain connectivity.

- Test Switches and Controls: Ensure that switches and controls are functioning correctly. If a switch appears unresponsive, it may be due to a wiring problem or an internal fault within the component.

- Use a Multimeter: A multimeter can measure voltage, resistance, and continuity. Use it to test different parts of the electrical system and identify where the circuit is broken.

Following these steps will help you syste

Brake System Repair Techniques

Maintaining optimal braking performance is crucial for safety and control. Addressing common issues and performing routine upkeep can significantly enhance braking efficiency. The process involves not only addressing wear but also ensuring that all components work harmoniously for smooth and reliable stopping power.

Inspecting Brake Pads and Discs

Regularly check the pads for signs of wear, such as thinning or uneven surfaces. If the pads are worn down to their minimum thickness, replacement is necessary. Disc inspection is equally important; look for grooves, warping, or discoloration, which may indicate the need for resurfacing or replacement. Clean both pads and discs thoroughly to remove any debris that can affect braking performance.

Bleeding the Brake Lines

Over time, air can become trapped within the hydraulic lines, reducing braking effectiveness. Bleeding the system involves releasing trapped air by opening the bleed valves while applying pressure to the brake lever. This process should be repeated until the fluid flows consistently w

Suspension Tuning for Better Handling

Optimizing the suspension system of a motorcycle plays a crucial role in enhancing overall performance and ride quality. Proper tuning not only improves stability during cornering but also contributes to rider comfort, allowing for a more enjoyable experience on varied terrains. Adjustments to suspension settings can significantly affect how a bike responds to different riding conditions, making it essential for enthusiasts to understand the principles of suspension dynamics.

To achieve optimal handling, riders should begin by assessing their current setup. This includes evaluating the preload, compression, and rebound settings of both front and rear suspension components. Preload adjustments affect ride height and weight distribution, while compression and rebound settings control how quickly the suspension absorbs impacts and returns to its original position. Balancing these elements can lead to improved traction and responsiveness.

Additionally, it is important to consider the type of riding and the conditions in which the motorcycle will be used. For instance, track riding may require stiffer settings to handle high-speed maneuvers, whereas touring may benefit from a softer setup for comfort over long distances. Experimenting with different configurations and taking note of performance changes will help in fine-tuning the suspension to suit personal preferences and riding styles.

Finally, regular maintenance of suspension components is vital. Ensuring that the fork oil and shock absorber fluids are fresh, along with checking for any wear or damage, will keep the suspension functioning optimally. A well-maintained suspension not only enhances handling but also extends the lifespan of the components, contributing to a safer and more thrilling ride.

Replacing the Exhaust System

Replacing the exhaust system is an essential maintenance task that can enhance performance and reduce noise levels. Over time, components may become corroded or damaged, leading to decreased efficiency. This section will guide you through the necessary steps to effectively replace the exhaust system, ensuring optimal functionality and compliance with emission regulations.

Preparation for Replacement

Before beginning the replacement process, ensure you have the right tools and materials on hand. Common tools required include a socket set, wrenches, and a torque wrench. Additionally, a new exhaust system and necessary gaskets or clamps should be gathered. It’s crucial to work in a well-ventilated area to avoid inhaling any fumes during the procedure.

Removal of the Old System

Start by safely lifting the vehicle using a jack and securing it with jack stands. This provides better access to the exhaust components. Locate the mounting bolts connecting the exhaust system to the engine and the exhaust pipe. Carefully remove these bolts, ensuring to keep them for reuse if they are in good condition. Once detached, gently pull the old system away, taking care not to damage any surrounding parts.

After the old system is removed, inspect the mounting areas for any signs of rust or debris. Cleaning these surfaces will ensure a proper seal and fit for the new exhaust system. With everything prepared, you can proceed to install the new components.

Installation of the New System

Position the new exhaust system in place, aligning it with the mounting points. Use the original bolts to secure the system, tightening them to the manufacturer’s specifications. Ensure all gaskets are properly seated to prevent leaks. Once everything is in place, start the engine and check for any unusual sounds or leaks, making adjustments as necessary.

Completing this task not only improves performance but also contributes to a smoother and more enjoyable ride. Regular maintenance of the exhaust system is vital for ensuring longevity and efficiency.

Chain and Sprocket Maintenance Guide

Proper upkeep of the chain and sprocket assembly is vital for ensuring smooth operation and extending the lifespan of your two-wheeled vehicle. Regular inspections and maintenance practices can prevent excessive wear and enhance performance, providing a safer riding experience.

This guide will cover essential maintenance tasks, including lubrication, tension adjustments, and wear checks. Adhering to these procedures can help you avoid potential issues that may arise from neglecting this critical component.

- Inspection: Routinely check the chain and sprockets for signs of wear or damage. Look for irregularities such as stiff links, excessive rust, or worn teeth.

- Cleaning: Remove dirt and debris from the chain and sprockets using a suitable cleaner. A brush can help reach into tight spaces and effectively clean the components.

- Lubrication: Apply appropriate chain lubricant to ensure smooth movement. It’s essential to use a product designed for motorcycle chains to provide the best protection.

- Tension Adjustment: Check the chain tension regularly. An improperly tensioned chain can lead to premature wear or even failure. Refer to the manufacturer’s specifications for the correct tension settings.

- Alignment Check: Ensure the rear wheel is aligned with the front wheel. Misalignment can cause uneven wear and affect handling.

By following these maintenance steps, you can enhance the longevity and performance of the chain and sprocket assembly. Always consult your vehicle’s specifications for detailed instructions and recommended intervals for maintenance tasks.

Cooling System Repair Procedures

This section outlines the essential processes for maintaining and restoring the cooling system of a high-performance motorcycle. Proper function of the cooling system is crucial to prevent overheating and ensure optimal engine performance. Below are key steps and considerations to follow during maintenance.

Regular inspection of the cooling system components is vital. The following list highlights the main elements to check:

- Radiator for blockages and leaks

- Hoses for wear and deterioration

- Thermostat functionality

- Water pump performance

- Coolant condition and level

When performing service tasks, adhere to these procedures:

- Drain the Coolant: Begin by positioning a container beneath the radiator. Remove the drain plug and allow the coolant to completely exit the system.

- Inspect Components: Examine the radiator, hoses, and water pump for any signs of damage or wear. Replace any parts that show significant deterioration.

- Flush the System: Use a flushing agent and clean water to remove debris and buildup. Follow up by draining the system again.

- Replace the Coolant: Fill the system with a high-quality coolant suitable for your motorcycle model. Ensure to follow the manufacturer’s recommendations for the coolant mixture.

- Check for Leaks: After refilling, start the engine and let it reach operating temperature. Inspect all connections and components for any signs of leakage.

By following these guidelines, the cooling system can function effectively, contributing to the overall reliability and longevity of the motorcycle.

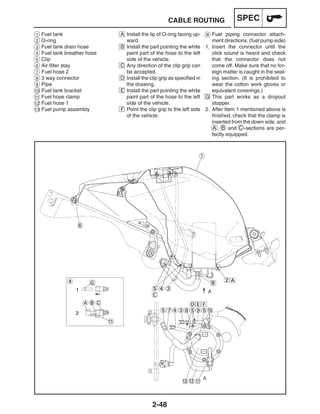

Understanding Fuel System Components

The fuel system in a motorcycle plays a crucial role in ensuring the engine operates efficiently and effectively. This system is responsible for delivering the right amount of fuel to the engine, where it mixes with air for combustion. A thorough understanding of its various components helps in diagnosing issues and maintaining optimal performance.

Key Components

The fuel system comprises several essential parts, each contributing to the overall functionality. Below is a brief overview of these components:

Component Function Fuel Tank Stores the fuel before it is delivered to the engine. Fuel Pump Transfers fuel from the tank to the engine, maintaining the required pressure. Fuel Filter Removes impurities from the fuel to prevent clogging of injectors. Fuel Injector Sprays a fine mist of fuel into the intake air stream for efficient combustion. Throttle Body Controls the amount of air-fuel mixture entering the engine. Importance of Maintenance

Regular maintenance of these components is vital for the longevity and performance of the motorcycle. Neglecting the fuel system can lead to reduced efficiency, poor fuel economy, and even engine failure. Understanding the role of each part enables owners to address issues promptly and keep their machines running smoothly.