In the realm of outdoor tools, proper upkeep is essential for optimal performance and longevity. This section delves into the various aspects of maintaining high-pressure cleaning devices, ensuring they function effectively when needed. Understanding how to troubleshoot common issues can save time and resources, making the cleaning process more efficient.

Preventive measures are crucial to avoiding potential breakdowns. Regular inspections and timely interventions can enhance the lifespan of these valuable machines. Users will benefit from a thorough understanding of the components involved and how they interact during operation.

Additionally, this guide offers insights into common problems that may arise, along with practical solutions. By following the outlined procedures, individuals can confidently address issues and restore their equipment to peak condition, ultimately improving their cleaning efficiency.

Understanding Common Pressure Washer Issues

Many users encounter various challenges when operating cleaning devices, leading to frustration and inefficiency. Recognizing typical problems is essential for effective troubleshooting and maintenance. By understanding the common faults, users can ensure optimal performance and longevity of their equipment.

Reduced Water Flow: A frequent concern is the diminished flow of liquid from the nozzle. This issue can stem from clogged filters or hoses. Regular cleaning of these components can help maintain a steady stream and enhance overall efficiency.

Inconsistent Pressure: Fluctuating force during operation often indicates issues within the system. Potential causes include air leaks in hoses or malfunctioning valves. Inspecting and sealing connections can alleviate this problem and restore consistent output.

Engine Starting Difficulties: Struggles to initiate the motor can be attributed to fuel or ignition system failures. Ensuring proper fuel levels and checking spark plugs are vital steps in resolving this issue.

Excessive Vibration: Unusual movement during operation may signal internal imbalances or worn components. Examining the device for loose parts and ensuring everything is securely fastened can help mitigate this concern.

By familiarizing oneself with these common challenges, users can take proactive measures to address issues promptly and maintain the efficiency of their cleaning equipment.

Essential Tools for Repairing Equipment

When tackling maintenance and restoration tasks on various types of machinery, having the right instruments at hand can make all the difference. A well-equipped toolkit not only facilitates the process but also enhances efficiency and accuracy. Below is a guide to the fundamental implements that every technician should consider including in their arsenal.

1. Wrenches are crucial for loosening and tightening bolts and nuts. A set that includes both standard and adjustable varieties ensures versatility for different tasks.

2. Screwdrivers come in various types, such as flat-head and Phillips, enabling access to different screw types. Having multiple sizes on hand is essential for effective assembly and disassembly.

3. Pliers provide a firm grip on components, aiding in manipulation and extraction. Needle-nose pliers are particularly useful for reaching tight spaces.

4. Multimeters are invaluable for diagnosing electrical issues. They help measure voltage, current, and resistance, allowing for accurate troubleshooting.

5. Cleaning supplies, including brushes and cloths, are necessary for maintaining cleanliness during and after the work. Keeping surfaces free of debris is vital for optimal performance.

Equipped with these essential tools, anyone can confidently approach the challenge of restoring and maintaining their equipment, ensuring longevity and reliability in operation.

Identifying Signs of Malfunction

Recognizing issues in equipment performance is crucial for maintaining efficiency and extending lifespan. Various indicators can suggest that something is not functioning as intended. Observing these signs promptly can prevent further complications and ensure effective operation.

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Loose components or mechanical wear |

| Inconsistent output | Clogged nozzle or inadequate pressure |

| Leaking fluid | Damaged seals or connections |

| Excessive vibrations | Imbalanced parts or misalignment |

| Failure to start | Electrical issues or empty fuel tank |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing and resolving common issues encountered with cleaning equipment. Following these steps will help identify the root cause of malfunctioning components and facilitate effective solutions.

Begin by checking the power source. Ensure that the unit is connected properly and that there is no interruption in the electrical supply. Inspect the power cord for any visible damage.

If the device fails to start, examine the safety features. Many units are equipped with automatic shut-off mechanisms that activate during certain conditions. Refer to the user guidelines to understand how these functions operate.

Next, assess the fluid supply. Verify that there is an adequate amount of liquid and that all hoses are free from blockages. Any obstruction can hinder performance and lead to reduced effectiveness.

After confirming the fluid system, look at the operational settings. Ensure that the correct modes and adjustments are selected for the intended task. Incorrect settings can significantly impact the functionality.

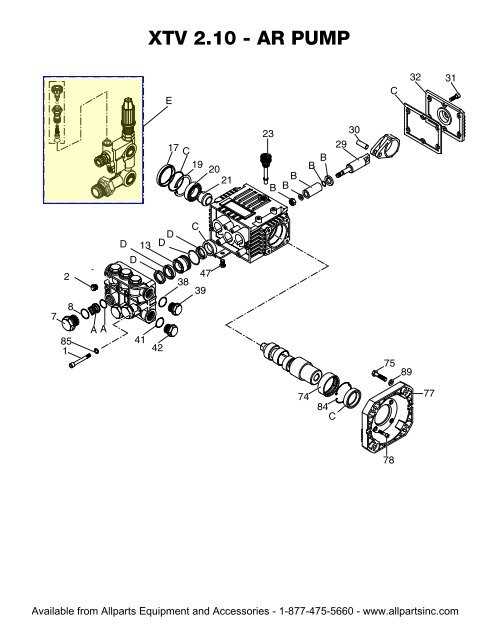

If the problem persists, inspect the internal components. Remove any covers as per the instructions and look for signs of wear or damage in critical parts. Address any visible issues accordingly.

Finally, consult the troubleshooting charts provided in the documentation for further guidance. These charts can offer specific insights based on symptoms and can assist in pinpointing more complex problems.

How to Replace Worn Components

Over time, various parts of cleaning equipment can experience wear and tear, leading to decreased performance. Regularly assessing these components is crucial for maintaining efficiency and prolonging the lifespan of the device. This section outlines the steps to effectively replace outdated or damaged parts, ensuring optimal functionality.

Before starting, gather the necessary tools and replacement components. It’s advisable to consult the specifications of your equipment to ensure compatibility. Below is a general guideline for identifying and replacing common components:

| Component | Signs of Wear | Replacement Steps |

|---|---|---|

| Seals and O-rings | Leaking fluid, reduced pressure | 1. Disconnect the unit. 2. Remove the old seals carefully. 3. Install new seals, ensuring a snug fit. |

| Hoses | Cracks, bulges, kinks | 1. Detach the damaged hose. 2. Measure and cut a new hose to the required length. 3. Attach the new hose securely. |

| Nozzle | Clogs, inconsistent spray pattern | 1. Remove the nozzle from the lance. 2. Clean or replace with a compatible new nozzle. 3. Reattach and test the spray. |

Following these steps will help ensure that your equipment functions effectively, reducing the risk of further damage and enhancing overall cleaning performance.

Cleaning the Nozzle and Spray Tips

Maintaining optimal performance of your cleaning equipment requires regular attention to the nozzle and spray tips. These components are crucial for effective operation and can become clogged or damaged over time. Proper care ensures that the equipment functions efficiently and extends its lifespan.

To clean these parts effectively, follow these steps:

- Gather Supplies: Ensure you have the following items on hand:

- Warm water

- Mild detergent

- Soft brush or cloth

- Narrow wire or toothpick

- Remove the Nozzle: Carefully detach the nozzle from the spray gun, taking care not to damage any threads or connectors.

- Soak in Soapy Water: Submerge the nozzle and spray tips in a mixture of warm water and mild detergent. Allow them to soak for several minutes to loosen any debris.

- Scrub Gently: Use a soft brush or cloth to scrub the exterior of the nozzle and spray tips. For stubborn residue, use a narrow wire or toothpick to dislodge any blockages from the tip openings.

- Rinse Thoroughly: Rinse the components under clean running water to remove any soap and loosened debris.

- Dry Completely: Use a clean cloth to dry the nozzle and spray tips thoroughly before reassembling. This prevents moisture from causing damage or corrosion.

- Reattach the Nozzle: Once everything is dry, carefully reattach the nozzle to the spray gun, ensuring a secure fit.

By following these steps regularly, you can maintain the effectiveness of your cleaning device and ensure consistent performance during use.

Maintaining Engine Performance

Ensuring optimal functionality of the power unit is essential for achieving peak efficiency and longevity. Regular attention to various components and systems contributes significantly to overall performance and reliability.

Regular Oil Changes: Routine replacement of lubrication fluid is crucial for minimizing wear and tear on internal components. Check the manufacturer’s recommendations for frequency and type of oil suitable for your unit.

Air Filter Maintenance: A clean air intake is vital for the combustion process. Inspect and replace the air filtration element as needed to prevent dirt and debris from entering the engine, which can hinder performance.

Fuel System Care: Utilizing fresh, high-quality fuel can prevent deposits and corrosion within the system. Consider adding fuel stabilizers if the equipment will be stored for extended periods.

Spark Plug Inspection: Regularly examining and replacing spark plugs ensures smooth ignition and efficient fuel consumption. Look for signs of wear, such as corrosion or excessive carbon buildup.

Cooling System Check: Maintaining the proper operating temperature is critical. Ensure that cooling pathways are unobstructed and that coolant levels are adequate to prevent overheating.

By following these guidelines, users can enhance the performance and durability of the power unit, ultimately leading to a more efficient operation and reduced likelihood of unexpected failures.

Fixing Leaks in the System

Addressing fluid leaks in equipment is crucial for maintaining efficiency and prolonging its lifespan. Identifying the source of these leaks and implementing effective solutions can prevent further damage and ensure optimal performance.

Begin by inspecting all connections and seals for signs of wear or damage. Common areas to check include:

| Component | Signs of Leaks | Recommended Action |

|---|---|---|

| Hoses | Cracks or splits | Replace damaged hoses |

| Fittings | Loose connections | Tighten or replace fittings |

| Seals | Visible wear | Replace seals as necessary |

| Gaskets | Oil or fluid pooling | Inspect and replace gaskets |

After addressing the visible issues, perform a thorough test to ensure all components are functioning correctly and that no leaks persist. Regular maintenance checks will help in early detection and prevention of potential issues.

Proper Storage Techniques for Longevity

Ensuring the durability of your cleaning equipment involves implementing effective storage strategies. Properly maintaining the environment and conditions in which the unit is kept can significantly extend its lifespan and functionality.

Here are some essential techniques to consider:

- Clean Thoroughly: Before storing, remove any residual dirt or debris to prevent buildup and corrosion.

- Drain Fluids: Empty all liquids, including water and cleaning solutions, to avoid contamination and freezing damage during colder months.

- Protect from Elements: Store in a dry, sheltered location, away from direct sunlight and extreme temperatures.

In addition, consider the following recommendations:

- Use a Cover: Employ a protective cover to shield the equipment from dust and moisture.

- Avoid Ground Contact: Place the unit on a shelf or pallet to prevent exposure to moisture from the ground.

- Check Regularly: Periodically inspect the equipment during storage for any signs of wear or damage.

Implementing these practices will help maintain the efficiency and reliability of your cleaning equipment for years to come.

Safety Precautions During Repairs

Ensuring personal safety and minimizing risks while conducting maintenance tasks is paramount. Adhering to specific guidelines helps protect both the individual and the equipment from potential hazards.

Proper Gear and Environment

Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and closed-toe footwear. Ensure that the workspace is well-ventilated and free of clutter to reduce the likelihood of accidents. Additionally, keep flammable materials away from the work area.

Electrical and Mechanical Safety

Before starting any maintenance, disconnect the power source to avoid accidental activation. Be mindful of moving parts and potential pinch points. If necessary, consult the manufacturer’s documentation for specific safety instructions related to the device.

Recognizing When to Seek Help

Understanding when to consult a professional can be crucial for effective maintenance and troubleshooting. Certain signs indicate that the issue at hand may be beyond simple fixes, requiring the expertise of a skilled technician. Recognizing these indicators can save time and prevent further complications.

Common situations that suggest seeking external assistance include persistent leaks, unusual noises during operation, and inconsistent performance. These symptoms may point to underlying problems that necessitate specialized knowledge or tools for proper resolution.

| Indicator | Possible Cause | Recommended Action |

|---|---|---|

| Persistent leaks | Damaged seals or components | Consult a technician for assessment |

| Unusual noises | Mechanical issues or misalignment | Seek professional diagnosis |

| Inconsistent performance | Clogged filters or failing parts | Request help for thorough examination |

By being aware of these signs, users can make informed decisions about when to reach out for assistance, ensuring their equipment remains in optimal condition.

Cost-Effective Repair Solutions

When it comes to fixing outdoor cleaning equipment, exploring budget-friendly options can make a significant difference. Many users overlook simple strategies that not only reduce expenses but also enhance the longevity of their devices. By focusing on common issues and DIY approaches, owners can effectively manage costs while ensuring optimal performance.

Identifying Common Issues

Understanding frequent malfunctions can help users address problems before they escalate. Here are some typical concerns to keep in mind:

- Clogs in hoses and nozzles

- Motor overheating

- Leakage from connections

- Faulty power supply or wiring

DIY Solutions to Consider

Many repairs can be tackled without professional assistance. Here are some cost-effective methods to consider:

- Regularly clean all components to prevent buildup.

- Inspect and replace worn-out seals or gaskets to stop leaks.

- Utilize online tutorials for guidance on specific fixes.

- Purchase generic parts instead of brand-name items when possible.

By taking these steps, users can effectively address issues and prolong the life of their equipment without breaking the bank.