This section provides essential information for maintaining and troubleshooting advanced cleaning equipment designed for efficient surface cleansing. Understanding the intricacies of these devices can greatly enhance their longevity and performance, ensuring optimal results with every use.

Regular upkeep is vital for preventing common issues that can arise during operation. Users will find step-by-step guidance on identifying and resolving various complications that may impede functionality. By following these procedures, one can keep their cleaning apparatus in peak condition, ready to tackle any task.

Additionally, this guide emphasizes the importance of safety measures when handling these sophisticated tools. Proper precautions not only protect the user but also contribute to the effective maintenance of the equipment, minimizing the risk of damage or accidents.

With a focus on practical advice and straightforward solutions, this resource aims to empower users to take charge of their cleaning devices. Whether addressing minor concerns or conducting comprehensive inspections, this guide serves as a valuable companion for every owner.

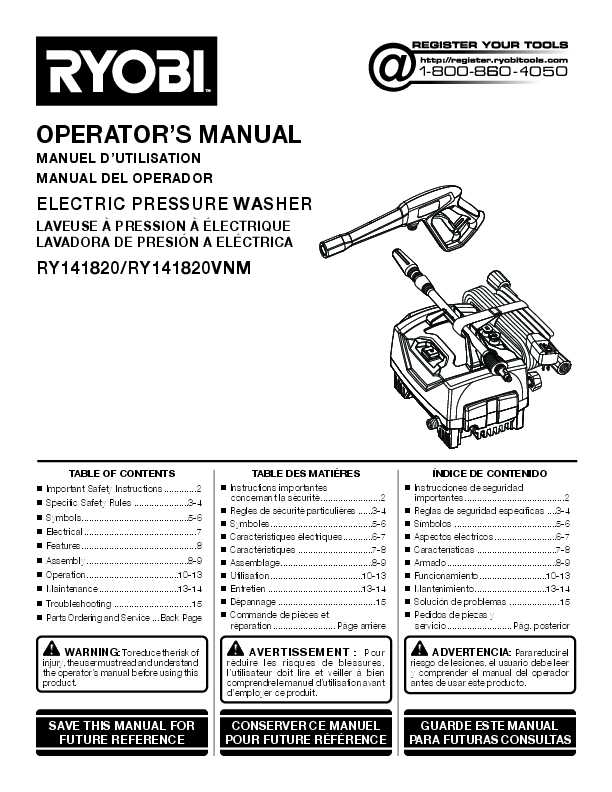

Understanding Electric Pressure Washers

This section delves into the functioning and advantages of high-powered cleaning devices designed for efficient surface maintenance. These tools are essential for various tasks, ranging from light cleaning to tackling tough stains.

Key features include:

- Varied pressure settings to adapt to different surfaces

- Energy-efficient operation for eco-conscious users

- Interchangeable attachments for specialized tasks

When considering the selection of such a device, it’s important to evaluate:

- Cleaning power measured in terms of effective output

- Weight and portability for ease of use

- Durability of materials used in construction

- Accessibility of components for maintenance

Understanding these aspects can greatly enhance the user experience and extend the lifespan of the equipment.

Common Issues with Electric Models

When dealing with these cleaning devices, users often encounter various challenges that can hinder their effectiveness. Understanding these frequent problems can help in diagnosing issues and restoring functionality.

One common concern is the failure to start, which may result from an electrical fault or a disconnected power source. Regular inspections of cords and connections can mitigate this issue.

Another prevalent complication is inadequate water flow. This can be attributed to blockages within the hose or nozzle, as well as issues with the internal pump mechanism. Regular maintenance is crucial to ensure smooth operation.

Furthermore, unusual noises during operation may indicate mechanical wear or loose components. Addressing these sounds promptly can prevent further damage and extend the lifespan of the device.

Lastly, overheating can occur if the unit is used for extended periods without adequate breaks. Users should adhere to recommended usage guidelines to avoid overheating and potential shutdowns.

Safety Precautions for Repairs

When addressing maintenance tasks on high-powered cleaning equipment, it is crucial to prioritize safety. Proper precautions can help prevent accidents and ensure a smooth working process. Understanding the risks involved and following safety guidelines will create a secure environment for effective servicing.

Personal Protective Equipment

Always wear appropriate personal protective gear. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from chemicals and sharp edges, and sturdy footwear to prevent slips or injuries. Taking these steps minimizes potential hazards during maintenance activities.

Electrical Safety Considerations

Before beginning any work, ensure that the device is disconnected from its power source. This reduces the risk of electric shock and allows for safe handling of internal components. Additionally, inspect all cords and connections for damage prior to use to avoid short circuits or fires.

Essential Tools for Maintenance

Proper upkeep of your cleaning device requires a selection of vital instruments to ensure efficiency and longevity. These tools facilitate routine checks, part replacements, and overall service, helping maintain optimal functionality.

Among the most important items is a wrench set, which allows for easy adjustments and securing of components. A screwdriver kit is equally essential, as it aids in accessing various sections of the equipment.

Cleaning brushes play a significant role in removing debris and buildup, while gauges help monitor performance levels. Additionally, having a multimeter is beneficial for diagnosing electrical issues.

By equipping yourself with these essential tools, you can ensure that your cleaning equipment remains in excellent working order, ready to tackle any task.

Troubleshooting Power Problems

When faced with issues related to energy supply, it is crucial to systematically identify and address potential faults. Understanding the core components involved in the operation can significantly aid in diagnosing the problem efficiently.

Begin by examining the power source. Ensure that the outlet is functioning properly and providing the correct voltage. A multimeter can be an invaluable tool for checking this. If the outlet appears fine, inspect the connection to the device itself for any signs of wear or damage.

Next, consider the internal components. Fuses or circuit breakers may have tripped, interrupting the flow of energy. Replacing a blown fuse or resetting a tripped breaker can often resolve the issue. Always check for any visible signs of damage or corrosion that may indicate deeper electrical issues.

If the problem persists, further investigate the motor and associated wiring. Faulty wiring or a malfunctioning motor can prevent the unit from operating as intended. Look for frayed wires or loose connections that could disrupt performance.

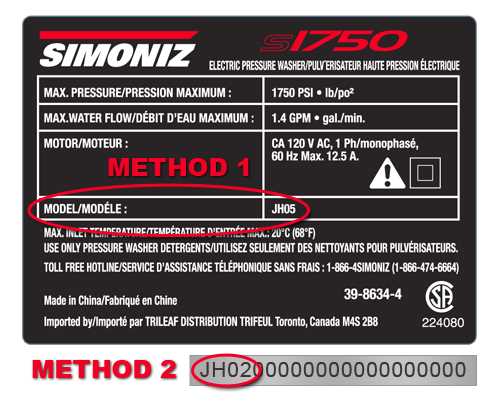

Lastly, consult the specifications and troubleshooting guide specific to the model in question. This can provide additional insights and solutions tailored to the equipment being used.

Cleaning and Replacing Nozzles

Proper maintenance of the spray tips is essential for optimal performance and longevity of your cleaning device. Ensuring that these components are clean and in good condition will enhance effectiveness and efficiency.

Follow these steps to maintain and replace your spray tips:

- Inspection: Regularly check the nozzles for clogs or damage.

- Cleaning:

- Remove the nozzle from the wand.

- Soak it in warm, soapy water to loosen debris.

- Use a soft brush to scrub any remaining particles.

- Rinse thoroughly with clean water and allow to dry.

- Replacement: If cleaning does not restore function, consider replacing the nozzle.

- Select the appropriate replacement based on your device’s specifications.

- Install the new nozzle securely on the wand.

Regular care of these components will ensure your cleaning tool operates at its best, providing the ultimate performance for your tasks.

Repairing Water Leaks Effectively

Addressing water leaks is crucial for maintaining the functionality of your cleaning device. Identifying and fixing these issues promptly can prevent further damage and ensure optimal performance.

Follow these steps to tackle leaks efficiently:

- Inspect the Hose: Look for cracks or wear. Replace any damaged sections to prevent loss of fluid.

- Check Connections: Ensure all fittings are tightly secured. Loose connections can lead to leaks.

- Examine Seals and Gaskets: Look for deterioration. Replace worn or damaged seals to maintain a tight fit.

- Test for Leaks: After making adjustments, run a brief test. Observe all joints and connections for any signs of escaping liquid.

- Consult the Manual: If issues persist, refer to the provided guidelines for specific troubleshooting steps.

By following these recommendations, you can effectively manage water loss and enhance the longevity of your cleaning equipment.

Motor and Pump Inspection Guide

In this section, we will explore essential steps for assessing the functionality of the main components responsible for generating and delivering fluid under pressure. Proper examination of these elements is crucial for ensuring optimal performance and longevity.

Initial Assessment: Begin by visually inspecting both the motor and the fluid-moving device for any signs of damage or wear. Look for cracks, leaks, or corrosion that may affect their operation. Ensure all connections are secure and free from debris.

Operational Checks: Activate the system and listen for unusual noises that might indicate underlying issues. A smooth and steady operation is a sign of health, while rattling or grinding sounds could signal the need for further investigation.

Performance Evaluation: Monitor the output flow and pressure. If the flow rate is lower than expected, or if there are fluctuations in pressure, it may suggest blockages or malfunctioning parts that require attention.

Maintenance Recommendations: Regular cleaning and lubrication of moving parts can prevent future problems. Follow the manufacturer’s guidelines for any specific maintenance practices to enhance the longevity of these critical components.

Replacing Worn Hoses and Fittings

Maintaining optimal functionality requires periodic assessment and replacement of deteriorated tubes and connectors. Ensuring that these components are in good condition is crucial for performance and safety, as any leaks or weaknesses can lead to inefficiency and potential hazards.

Identifying Worn Components

Examine the hoses and fittings for signs of wear such as cracks, bulges, or fraying. Any visible damage can affect the overall operation, so prompt action is necessary to prevent further issues.

Replacement Process

To replace damaged hoses and fittings, follow these steps:

| Step | Action |

|---|---|

| 1 | Disconnect the unit from its power source. |

| 2 | Carefully detach the old hoses and fittings. |

| 3 | Install new components, ensuring secure connections. |

| 4 | Reconnect to the power source and perform a test. |

Electrical System Diagnostics

Assessing the functionality of a power-driven unit’s circuitry is crucial for identifying issues that may hinder performance. This section outlines essential diagnostic procedures to ensure optimal operation and longevity of the device.

Key Components to Examine

- Power Source: Verify voltage levels and connections.

- Control Unit: Check for signs of wear or malfunction.

- Wiring: Inspect for frays, breaks, or corrosion.

- Switches and Sensors: Ensure they are functioning correctly.

Diagnostic Procedures

- Begin by disconnecting the unit from the power supply.

- Use a multimeter to measure voltage across key components.

- Inspect all connections for security and cleanliness.

- Replace any damaged or faulty parts as needed.

- Reconnect and test the system to confirm resolution of issues.

Reassembling After Repairs

When restoring a device after maintenance, it is essential to approach the process methodically to ensure optimal functionality. Each component must be positioned correctly to avoid issues during operation. This section outlines key steps to effectively bring the unit back together.

Step-by-Step Assembly

Begin by gathering all parts and tools needed for the task. Review any documentation or notes made during disassembly to guide the process. Start with the main housing, ensuring that all seals and gaskets are intact. Carefully place internal components in their designated locations, securing them as specified.

Final Checks

Once reassembly is complete, conduct thorough inspections to confirm that everything is aligned and tightly fitted. Check for any loose screws or fittings that may affect performance. After ensuring all parts are correctly installed, power on the device to test its functionality. Make any necessary adjustments if issues arise.

Testing the Pressure Output

This section focuses on assessing the performance of the cleaning unit’s output force. Ensuring that the device functions effectively is crucial for optimal cleaning results. The evaluation process involves several steps that will help identify any discrepancies in performance.

Required Tools

- Pressure gauge

- Water source

- Hose connectors

- Wrench

Procedure

- Connect the pressure gauge to the outlet of the device.

- Ensure that all connections are secure to prevent leaks.

- Turn on the water supply to the unit.

- Start the machine and allow it to reach operating conditions.

- Observe the reading on the gauge to determine the output force.

- Compare the measured value with the manufacturer’s specifications.

- If the output is below the recommended level, further investigation may be needed.

Preventative Maintenance Practices

Regular upkeep is essential for ensuring longevity and optimal performance of your equipment. Implementing a series of routine actions can help prevent unexpected failures and maintain efficiency over time.

Key Maintenance Activities

Engaging in specific tasks can significantly extend the lifespan of your device. Below are fundamental practices that should be part of your maintenance routine:

| Activity | Frequency | Description |

|---|---|---|

| Inspect Hoses | Monthly | Check for cracks, leaks, or wear to ensure proper water flow. |

| Clean Filters | Every Use | Remove debris and dirt from filters to prevent clogs and improve performance. |

| Check Connections | Monthly | Ensure all connections are secure and free from corrosion. |

| Lubricate Moving Parts | Every 6 Months | Apply suitable lubricant to moving components to reduce friction and wear. |

Benefits of Regular Upkeep

Consistent maintenance not only enhances functionality but also promotes safety and reliability. By investing time in these practices, you can avoid costly repairs and ensure that your equipment operates at its best.