The intricate systems within a vehicle play a crucial role in its overall performance and efficiency. This section delves into the various components responsible for power transfer, providing insights that can enhance your understanding of how these elements work together. Familiarity with these systems can lead to better maintenance practices and improved vehicle longevity.

By exploring common issues and solutions related to these mechanisms, readers can equip themselves with valuable knowledge that may prevent costly setbacks. Detailed guidance and explanations will illuminate the processes involved, making it easier to navigate any challenges that may arise.

Whether you are a seasoned enthusiast or a novice looking to learn more, grasping the essentials of these vital systems will empower you to take informed actions. Understanding the underlying principles will foster confidence in addressing potential problems, ultimately contributing to a smoother driving experience.

Understanding 4eat Transmission Basics

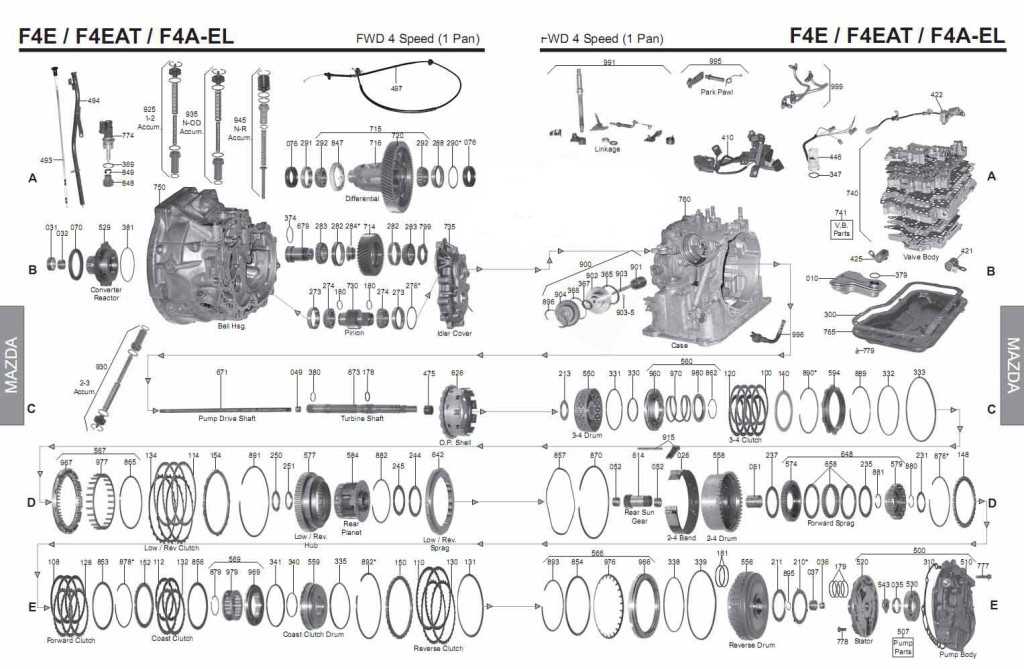

Grasping the fundamentals of automatic gear systems is essential for vehicle enthusiasts and owners. This section delves into the key components and operations of a particular type of automatic gear mechanism, helping you to appreciate its functionality and importance in vehicle performance.

These systems utilize a complex network of parts working harmoniously to facilitate smooth shifting and efficient power transfer. Understanding the essential elements can enhance your knowledge and support better maintenance practices.

- Components:

- Hydraulic System: Responsible for fluid management, enabling gear shifts.

- Control Module: An electronic unit that governs shifting patterns based on various parameters.

- Gear Sets: A series of gears that determine the vehicle’s speed and torque.

- Functionality:

- Fluid Dynamics: The movement of hydraulic fluid is crucial for engaging and disengaging gears.

- Shifting Mechanisms: These can be either electronic or mechanical, affecting how the vehicle accelerates.

- Feedback Systems: Sensors provide real-time data to optimize performance and efficiency.

By familiarizing yourself with these basic principles, you can gain insights into how to maintain the system effectively and recognize potential issues early on. This foundational knowledge empowers you to make informed decisions regarding maintenance and performance enhancements.

Common Symptoms of Transmission Issues

Identifying problems with your vehicle’s gear-shifting system can be crucial for maintaining performance and safety. Various signs may indicate underlying issues that require attention. Recognizing these symptoms early can help prevent further complications and costly repairs.

Unusual Noises

One of the most noticeable indicators of potential issues is the presence of strange sounds while driving. This may include grinding, whining, or clunking noises that were not previously experienced. These sounds can suggest problems with internal components, which may need immediate investigation.

Difficulty Shifting Gears

If you encounter resistance or find it challenging to change gears, this may point to a malfunction. Smooth transitions are essential for optimal vehicle operation; thus, any difficulty could indicate a need for inspection. Delayed or rough shifting can also signal that something is amiss within the system.

Step-by-Step Repair Process Overview

This section provides a comprehensive outline of the procedures involved in addressing mechanical issues within a specific automotive component. Each phase of the process is crucial for ensuring effective diagnosis and resolution of any faults that may arise, ultimately enhancing performance and longevity.

1. Initial Assessment: Begin by conducting a thorough examination of the system. Identify symptoms and gather relevant data to understand the underlying problems. This stage is vital for determining the appropriate course of action.

2. Disassembly: Carefully dismantle the affected unit while keeping track of all components and their respective positions. Utilize proper tools and techniques to avoid damage during this critical phase.

3. Inspection: Evaluate each part for wear, damage, or failure. This step requires keen attention to detail and may involve measuring tolerances to ensure all elements meet operational standards.

4. Component Replacement: Substitute any defective parts with new or refurbished items. Ensure that all replacements conform to the specifications required for optimal functionality.

5. Reassembly: Once all necessary modifications are completed, reassemble the unit methodically. Refer back to the initial disassembly notes to ensure that every component is restored to its correct position.

6. Testing: After reassembly, conduct thorough testing to verify that the component operates correctly. Monitor for any irregularities and make adjustments as needed to achieve desired performance levels.

7. Final Inspection: Perform a conclusive review of the system to confirm that all procedures have been completed effectively. Document any findings and ensure that everything adheres to safety and operational standards.

This structured approach not only facilitates efficient problem-solving but also aids in the maintenance of quality throughout the entire process.

Essential Tools for Transmission Repair

When tackling complex mechanical systems, having the right equipment is crucial for successful maintenance and troubleshooting. Various instruments facilitate effective disassembly, inspection, and reassembly, ensuring that every component functions optimally. Understanding the necessary tools can streamline the process and lead to more efficient outcomes.

Basic Hand Tools

Basic hand tools are indispensable for any mechanical task. They provide the foundation for most procedures, enabling technicians to manipulate components with precision. A comprehensive toolkit includes:

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Wrenches | Essential for gripping and turning fasteners. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Screwdrivers | Required for removing and securing screws of various types. |

Specialized Equipment

In addition to basic tools, specialized equipment enhances the ability to perform intricate tasks effectively. This equipment is designed to handle specific challenges associated with mechanical systems:

| Tool | Purpose |

|---|---|

| Fluid Transfer Pump | Facilitates the efficient movement of fluids during maintenance. |

| Inspection Camera | Allows for visual inspection of hard-to-reach areas. |

| Pressure Tester | Evaluates the integrity of seals and hoses. |

| Lift or Jack Stands | Enables safe access to the underside of the system. |

Safety Precautions When Repairing

Ensuring safety during mechanical maintenance is crucial for both the technician and the equipment. Proper precautions minimize the risk of accidents and injuries while working on complex systems. It is essential to follow established guidelines and utilize appropriate protective gear to create a secure working environment.

Personal Protective Equipment

Wearing suitable protective gear is fundamental when engaging in mechanical work. This includes gloves, goggles, and durable footwear. Such equipment safeguards against potential hazards, such as sharp edges and hazardous substances, ensuring that the technician remains safe throughout the process.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Clear any unnecessary tools or materials from the area to reduce the risk of tripping or injury. Additionally, ensuring proper ventilation when working with chemicals or fluids is essential for avoiding inhalation of harmful vapors. Always have a first aid kit readily available in case of emergencies.

Fluid Types and Maintenance Tips

Understanding the various fluid types and their maintenance is essential for ensuring optimal performance and longevity of your vehicle’s system. Proper care can prevent costly issues and enhance efficiency, making it crucial to follow recommended guidelines.

Different fluids serve specific purposes, and using the correct type is vital. Below is a summary of common fluid types and essential maintenance tips:

| Fluid Type | Description | Maintenance Tips |

|---|---|---|

| Hydraulic Fluid | Used for powering hydraulic systems, ensuring smooth operation. | Check levels regularly; replace if contaminated or low. |

| Gear Oil | Lubricates gears, reducing friction and wear. | Change based on manufacturer’s recommendations; monitor for leaks. |

| Cooling Fluid | Regulates temperature, preventing overheating. | Inspect periodically; flush and replace every few years. |

Maintaining these fluids will contribute to the overall health of your vehicle’s system, enhancing performance and reliability. Always refer to your manufacturer’s specifications for the best practices.

Diagnosing Electrical Problems in Transmissions

Identifying issues related to the electronic systems within vehicle drivetrains is crucial for optimal performance. These problems often manifest as unusual behaviors, affecting the vehicle’s efficiency and driving experience. A systematic approach to troubleshooting can help isolate the root causes of electrical malfunctions.

Common Symptoms: Drivers may notice erratic shifting, slipping gears, or warning lights illuminating on the dashboard. These signs often indicate an underlying electrical concern that requires thorough investigation.

Initial Checks: Start by inspecting the wiring and connectors for any signs of wear, corrosion, or loose connections. These components are vital for proper functionality, and even minor issues can lead to significant performance problems.

Using Diagnostic Tools: Employ diagnostic equipment to read error codes from the vehicle’s onboard computer. This information can provide valuable insights into specific electrical faults and guide the troubleshooting process.

Continuity Testing: Conduct continuity tests on wiring harnesses to ensure there are no breaks or shorts in the circuits. This step is essential for confirming the integrity of the electrical pathways.

Component Inspection: Evaluate the various electronic components, such as sensors and actuators, for proper operation. Faulty parts can cause a cascade of issues, impacting overall functionality.

Professional Assistance: If the problem persists despite thorough checks and repairs, consulting a professional technician may be necessary. Their expertise can provide a deeper understanding of complex electrical systems and aid in resolving persistent issues.

Common Repairs and Replacement Parts

This section covers frequently encountered issues and the necessary components that may require attention during maintenance. Understanding these common challenges can aid in maintaining optimal performance and longevity.

One of the most prevalent concerns involves fluid leaks, which can stem from worn seals or gaskets. Addressing these leaks promptly can prevent more extensive damage and costly interventions. Replacement of these components is essential for ensuring a tight seal and preventing further fluid loss.

Another common issue relates to shifting difficulties, often linked to worn-out gears or linkage problems. Replacing these parts can significantly enhance the efficiency and responsiveness of the entire system. Regular inspections can help identify these problems early, allowing for timely replacements.

Additionally, over time, filters can become clogged with debris, impacting overall functionality. Replacing filters is a straightforward task that can lead to improved performance and reliability. Regular maintenance of these components is crucial to avoid more serious complications down the line.

In summary, staying vigilant about these typical issues and their associated parts can greatly contribute to the longevity and reliability of the system, ensuring smooth operation for years to come.

Testing the Transmission After Repairs

Once the necessary adjustments have been made, it is crucial to evaluate the overall functionality of the system to ensure optimal performance. This process involves a series of assessments designed to verify that all components are working harmoniously and efficiently.

Begin by performing a thorough visual inspection to identify any potential leaks or irregularities. Next, engage the system in a controlled environment, gradually increasing the load to observe its response. Pay close attention to any unusual noises or vibrations that may indicate underlying issues.

It is also advisable to monitor the fluid levels and check for any signs of contamination. After running the system through various speeds and conditions, note how it reacts during shifting and acceleration. Documenting these observations will provide valuable insights into its overall condition.

Finally, consider conducting a diagnostic scan using appropriate equipment to gather additional data. This comprehensive approach will help ensure that everything is functioning as intended, providing confidence in the reliability of the system.

Upgrades for Improved Transmission Performance

Enhancing the functionality and efficiency of a vehicle’s shifting mechanism can significantly impact overall performance. Various modifications can be implemented to achieve better responsiveness, durability, and power handling capabilities. These enhancements can lead to a more exhilarating driving experience and increased reliability.

One of the most effective upgrades is the installation of high-performance components. Aftermarket clutches, for instance, can provide a more robust connection, ensuring smoother gear transitions and reducing slippage. Additionally, upgrading to heavy-duty torque converters can enhance the power transfer from the engine, allowing for quicker acceleration and improved throttle response.

Another vital aspect to consider is the quality of lubricants used in the system. Utilizing advanced fluids specifically designed for enhanced protection and performance can greatly reduce wear and improve operational efficiency. Heat exchangers may also be beneficial, as they help maintain optimal temperatures, preventing overheating and extending the lifespan of critical components.

Finally, proper tuning and calibration of the electronic control systems can further optimize shifting patterns, making them more adaptive to driving conditions. By investing in these upgrades, vehicle owners can ensure their systems operate at peak efficiency, resulting in a more enjoyable and powerful driving experience.

Recognizing When to Seek Help

Understanding the signs that indicate the need for professional assistance is crucial for maintaining the health of your vehicle’s components. Many drivers may overlook minor issues, assuming they will resolve on their own. However, neglecting these early warning signs can lead to more significant problems down the line. Being proactive and informed is essential in ensuring longevity and performance.

Common Indicators of Trouble

Unusual sounds, such as grinding or whining, often signal a deeper issue. Additionally, any changes in responsiveness, like slipping gears or delayed engagement, should raise a red flag. It’s essential to remain attentive to fluid leaks, as they can indicate a lack of necessary lubricants affecting the system’s efficiency. Ignoring these symptoms can result in further complications, making timely intervention critical.

When to Consult a Specialist

If you notice persistent issues or experience a sudden change in vehicle behavior, it’s wise to consult a professional. Specialized technicians possess the expertise to diagnose underlying problems accurately and recommend appropriate solutions. Relying on their knowledge can save both time and money, as early detection often prevents extensive damage.

Cost Estimates for Common Repairs

Understanding the financial implications of various maintenance tasks is essential for any vehicle owner. By having a clear idea of the potential expenses associated with routine issues, one can budget effectively and make informed decisions when faced with mechanical challenges.

Below are common maintenance tasks and their estimated costs:

-

Fluid Replacement:

- Fluid change for lubrication systems: $80 – $150

- Coolant replacement: $100 – $200

-

Seal and Gasket Installation:

- Output shaft seal replacement: $150 – $250

- Pan gasket installation: $120 – $220

-

Component Replacement:

- Replacement of internal gears: $400 – $800

- Clutch kit installation: $300 – $600

Prices may vary depending on the service provider, location, and specific vehicle models. Always consult with professionals for precise estimates tailored to your situation.

Frequently Asked Questions on 4eat Repairs

This section addresses common inquiries regarding the maintenance and troubleshooting of certain vehicle systems. Understanding these topics can help owners enhance their knowledge and facilitate smoother experiences during servicing.

Common Issues

- What symptoms indicate a need for attention?

- How can I identify abnormal sounds during operation?

- What signs suggest that fluid levels may be low?

Maintenance Tips

- Regularly check fluid conditions and levels.

- Ensure that connections and components are securely fastened.

- Schedule routine inspections with qualified professionals.

By familiarizing yourself with these frequently asked questions, you can better understand the care and attention needed for your vehicle’s components.