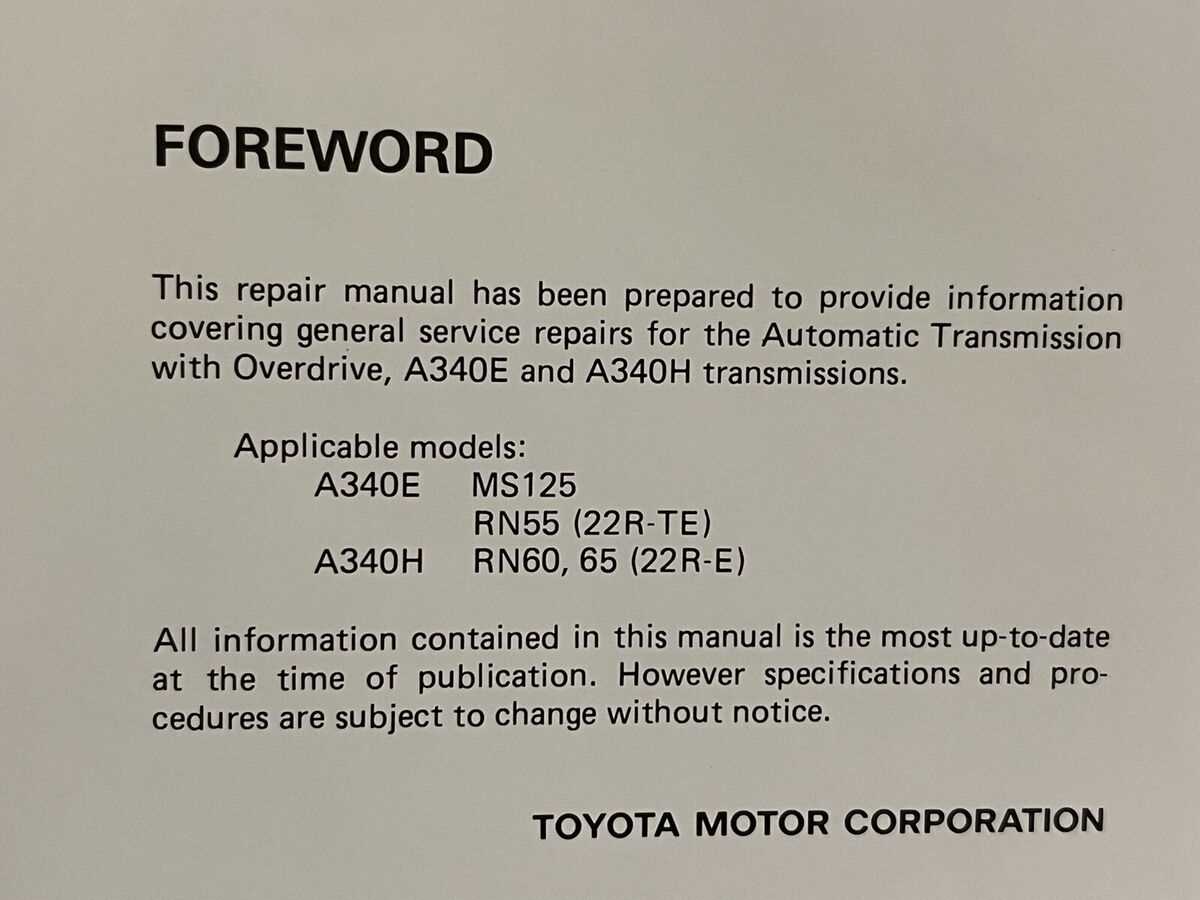

Understanding the intricacies of automotive systems is essential for both enthusiasts and professionals. This guide delves into the essential aspects of maintaining and restoring critical components responsible for power transmission in vehicles. With an emphasis on practical insights, it aims to equip readers with the knowledge needed to tackle challenges effectively.

For those keen on enhancing their technical skills, this resource serves as a valuable tool. It encompasses detailed procedures and best practices, ensuring that users can confidently approach their projects. By exploring various techniques and methodologies, individuals will gain a deeper appreciation for the mechanics involved.

Moreover, this compilation highlights common pitfalls and troubleshooting strategies, making it easier to navigate complex issues. With a focus on clarity and accessibility, the content is tailored to accommodate various skill levels, from novices to seasoned mechanics. Embrace the journey of understanding and perfecting the art of vehicle maintenance.

A340 Transmission Overview

This section provides a comprehensive understanding of a specific type of gearbox utilized in various automotive applications. Designed for reliability and efficiency, this system plays a crucial role in enhancing vehicle performance by facilitating smooth power delivery from the engine to the wheels.

Key Features

One of the standout characteristics of this gearbox is its ability to handle a wide range of operating conditions. Advanced engineering allows for improved responsiveness and adaptability, making it suitable for both everyday driving and demanding scenarios. Durability is another significant aspect, ensuring that it can withstand rigorous use while maintaining optimal function.

Functionality and Benefits

The mechanism is designed to optimize fuel efficiency, allowing for a seamless driving experience. It incorporates innovative technologies that enhance shifting precision, contributing to overall vehicle stability. Moreover, the integration of modern features ensures compatibility with contemporary automotive advancements, making it a preferred choice for many manufacturers.

Common Transmission Issues

In the realm of automotive mechanics, certain challenges frequently arise that can hinder vehicle performance and efficiency. Understanding these prevalent concerns can aid in early detection and preventive measures, ultimately enhancing the longevity and reliability of the system in question.

Shifting Difficulties

One of the most common problems is related to shifting gears smoothly. Drivers may experience hesitation or difficulty in engaging the desired gear. This can be attributed to several factors, including worn components or insufficient fluid levels. Regular inspections and maintenance can often mitigate these issues.

Fluid Leaks

Another significant issue involves the presence of leaks, which can lead to inadequate lubrication and overheating. Identifying the source of a leak is crucial, as it could stem from damaged seals or hoses. Prompt attention to fluid levels and leak repairs is essential for maintaining optimal function.

In summary, recognizing these typical challenges enables vehicle owners to address problems before they escalate, ensuring a smoother and more efficient driving experience. Vigilance and proactive maintenance are key.

Signs of Transmission Failure

Recognizing the early indicators of a malfunction in the drivetrain system is crucial for maintaining vehicle performance. Awareness of these symptoms can help prevent more severe issues and costly repairs down the line. Below are common signs that may suggest an underlying problem.

Common Symptoms

Drivers may experience a variety of warning signs that indicate a potential breakdown in the drivetrain. Being attentive to these signals is essential for timely intervention.

| Symptom | Description |

|---|---|

| Unusual Noises | Grinding, whining, or clunking sounds may indicate internal damage. |

| Fluid Leaks | Spots of liquid under the vehicle may point to fluid loss, affecting functionality. |

| Slipping | The vehicle may unexpectedly change gears or fail to respond to acceleration. |

| Warning Lights | Dashboard indicators may illuminate, signaling a potential issue with the system. |

Conclusion

Being aware of these signs can empower vehicle owners to act quickly, minimizing the risk of severe damage. Regular maintenance checks and vigilance in observing unusual behaviors are key to ensuring longevity and reliability.

Essential Tools for Repairs

When undertaking any mechanical work, having the right instruments at your disposal is crucial for achieving optimal results. A well-equipped workspace not only enhances efficiency but also ensures safety throughout the process. Familiarity with essential equipment can make a significant difference in both the ease of the task and the quality of the outcome.

Commonly Used Instruments

Understanding the variety of tools needed can simplify the workflow. Here’s a list of some basic equipment that is often required for successful tasks:

| Tool Name | Purpose |

|---|---|

| Socket Set | For fastening and loosening various fasteners. |

| Torque Wrench | Ensures that bolts are tightened to the correct specifications. |

| Diagnostic Scanner | Helps identify issues by reading error codes. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

| Oil Filter Wrench | Facilitates the removal of oil filters with ease. |

Safety Gear

Equipping yourself with protective gear is just as important as having the right tools. Essential safety items should include gloves, goggles, and a face mask to shield against debris and harmful substances. Prioritizing safety not only protects the individual but also contributes to a more efficient working environment.

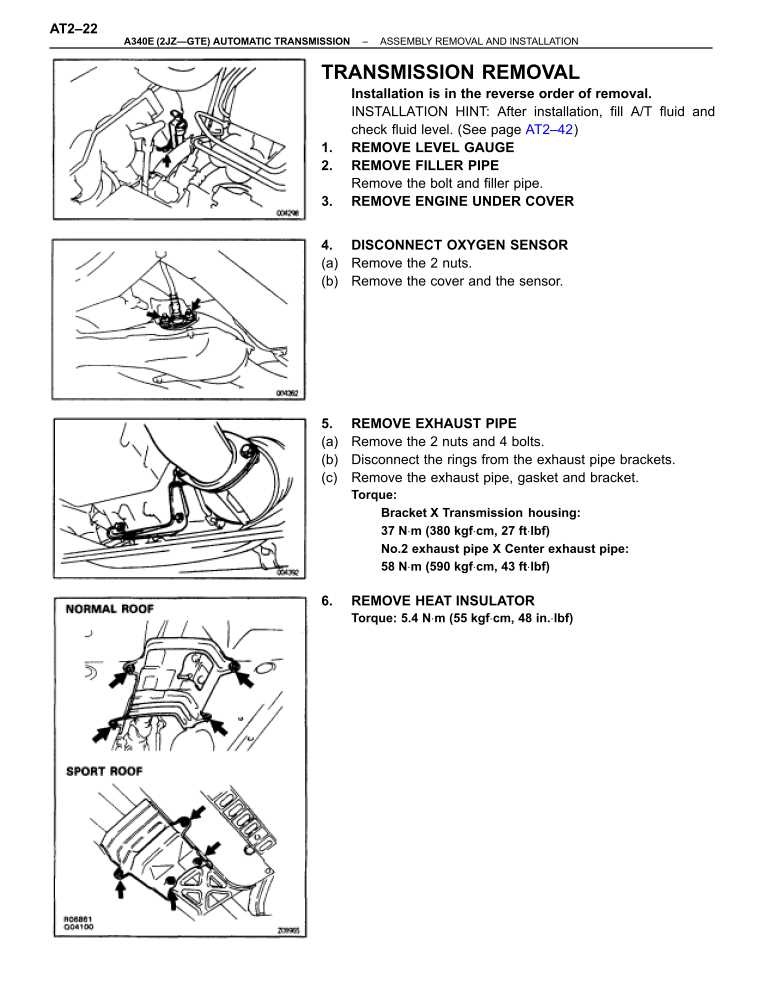

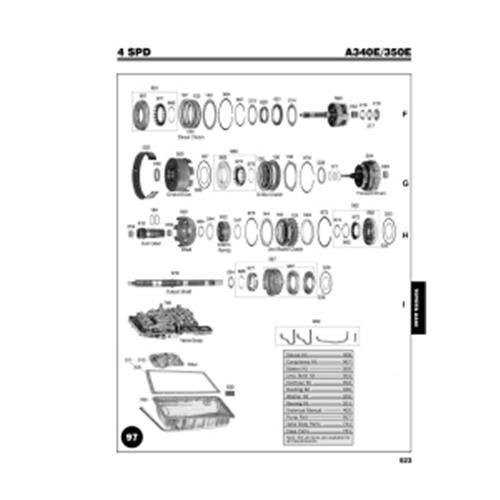

Step-by-Step Repair Process

This section provides a comprehensive guide to effectively addressing issues in the system, ensuring a systematic approach to restoration. By following these outlined steps, you can achieve optimal results and enhance the longevity of the components.

Preparation Phase

Before beginning the intervention, it is crucial to gather all necessary tools and materials. This ensures a smooth workflow and minimizes disruptions.

- Gather essential tools: wrenches, sockets, screwdrivers, etc.

- Collect replacement parts based on diagnostic findings.

- Ensure a clean and organized workspace to facilitate efficiency.

Execution Steps

Follow these detailed stages to systematically address the issues at hand:

- Disconnect the power source to prevent any accidents.

- Carefully remove the outer casing or housing, taking note of the screws and fasteners.

- Inspect internal components for wear or damage, documenting any findings.

- Replace or repair damaged parts as necessary, following manufacturer specifications.

- Reassemble the unit, ensuring all connections are secure and properly aligned.

- Reconnect the power source and conduct a thorough functionality test.

- Perform final checks to confirm everything operates smoothly.

Adhering to this structured process will significantly improve the chances of a successful intervention, restoring functionality and reliability to the system.

Fluid Types and Maintenance

Proper selection and management of lubricants are crucial for the optimal functioning of any mechanical system. The right fluid not only ensures efficient operation but also prolongs the lifespan of components by reducing wear and tear. Understanding the types of fluids available and their specific applications is essential for maintaining peak performance.

Types of Fluids

There are several categories of lubricants designed for various systems. Each type offers distinct properties that cater to specific operational needs. Mineral oils are commonly used due to their affordability and good performance in general applications. Synthetic fluids, on the other hand, provide enhanced stability and resistance to breakdown under extreme conditions. Biodegradable options are becoming increasingly popular for environmentally conscious practices.

Maintenance Practices

Regular checks and timely replacements of lubricants are essential maintenance practices. Establishing a fluid change interval based on manufacturer recommendations can prevent potential failures. It’s also important to monitor fluid levels and quality regularly, ensuring that contaminants do not compromise efficiency. Adopting these practices will lead to better reliability and performance of the entire system.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when performing maintenance tasks. Adhering to established safety protocols minimizes risks and enhances the effectiveness of the job. Proper precautions not only protect the technician but also safeguard the equipment involved.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes items such as gloves, goggles, and steel-toed boots, which provide vital protection against potential hazards. By utilizing these safety measures, individuals can significantly reduce the likelihood of injuries during the process.

Work Area Safety

Maintaining a tidy and organized workspace is equally important. A clutter-free environment minimizes the risk of accidents. Additionally, ensuring proper ventilation and having fire extinguishing equipment readily available are critical components of a safe atmosphere. Always be aware of your surroundings and follow standard operational procedures to enhance safety during any maintenance activities.

Diagnosing Electrical Problems

Identifying issues related to electrical systems requires a systematic approach to isolate faults and determine their root causes. The complexity of these systems often leads to various symptoms that can complicate troubleshooting. By following a methodical process, technicians can effectively pinpoint the source of malfunctions and implement appropriate solutions.

Begin by observing the symptoms exhibited by the system. This may include erratic behavior, intermittent failures, or complete inoperability. Gathering this information is crucial as it guides the diagnostic efforts. Utilize a multimeter to measure voltage, current, and resistance in key components, ensuring that all readings are within specified limits.

Next, check for loose connections or damaged wiring, as these are common culprits in electrical faults. Visual inspections can reveal signs of wear or corrosion that may impact performance. If necessary, refer to wiring diagrams to trace circuits and identify potential areas of concern.

It is also advisable to consider environmental factors that might affect the system, such as temperature fluctuations or moisture ingress. These elements can contribute to electrical failures, so assessing the operating conditions is essential. Finally, consult any relevant documentation for specifications and troubleshooting procedures, as this can provide valuable insights into resolving the issues encountered.

Replacement Parts and Costs

When addressing the needs of complex automotive systems, understanding the necessary components and their associated expenses is crucial. This section delves into the various elements that may require replacement during the maintenance process and provides an overview of the financial implications involved.

Essential Components often include gears, seals, and electronic sensors. Each part plays a vital role in ensuring the smooth operation of the overall mechanism. When planning for maintenance, it’s important to consider both the quality and the compatibility of these components to avoid future complications.

The cost of parts can vary significantly based on the manufacturer, quality, and source. OEM (Original Equipment Manufacturer) components typically come at a premium but offer reliability, while aftermarket alternatives can provide cost savings, albeit with potential trade-offs in quality and lifespan. Budgeting for these components should take into account not only the purchase price but also potential installation costs.

Furthermore, it’s advisable to conduct regular assessments of these elements to identify wear and tear early. By doing so, one can mitigate larger expenses that may arise from unexpected failures and ensure a smoother, more efficient operation over time.

Testing and Calibration Techniques

Ensuring optimal functionality of complex machinery requires precise assessment and adjustment of various components. This section delves into effective methodologies for evaluating and fine-tuning mechanisms, highlighting the importance of accuracy in enhancing performance and longevity.

Evaluation Procedures are essential for identifying discrepancies within the system. Utilizing diagnostic tools allows for the systematic analysis of performance metrics, ensuring that each part operates within specified parameters. Regular evaluations help in early detection of potential issues, minimizing the risk of more significant failures.

Calibration is a critical process that aligns the operational characteristics of the system with established standards. This involves adjusting the settings of specific components to achieve optimal performance. Implementing a regular calibration schedule can significantly enhance efficiency and reliability, ensuring that all elements function harmoniously.

Additionally, employing simulation techniques can provide valuable insights into the behavior of the system under various conditions. By modeling potential scenarios, technicians can anticipate challenges and make informed adjustments, leading to improved operational stability.

In conclusion, effective assessment and adjustment techniques are vital for maintaining the integrity and performance of intricate systems. Regular evaluations and calibrations not only extend the lifespan of components but also enhance overall functionality, paving the way for smoother operations.

Tips for Preventing Future Issues

Maintaining optimal performance of your vehicle’s drivetrain system is essential for ensuring longevity and efficiency. Proactive measures can significantly reduce the likelihood of encountering complications down the road. Below are some practical strategies to help you keep your system in excellent condition.

Regular Maintenance Checks: Schedule routine inspections to identify potential problems before they escalate. Regular fluid changes and component evaluations can help maintain peak functionality.

Quality Fluids: Always use high-quality lubricants that meet or exceed manufacturer specifications. Proper fluid levels and cleanliness are crucial for smooth operation.

Driving Habits: Adopt mindful driving practices. Avoid sudden starts and stops, and refrain from overloading the vehicle. Gentle acceleration and deceleration contribute to the longevity of various components.

Monitoring Performance: Pay attention to any changes in performance, such as unusual noises or shifting patterns. Early detection of abnormalities can lead to timely intervention.

Educate Yourself: Stay informed about your vehicle’s specific requirements and common issues. Knowledge empowers you to recognize problems early and take appropriate action.

Resources for Further Learning

Expanding your knowledge on automotive systems and their intricacies is essential for both enthusiasts and professionals alike. This section offers a curated selection of materials to deepen your understanding and enhance your skills in the field.

Books and online courses provide foundational knowledge, covering everything from basic mechanics to advanced techniques. Websites and forums dedicated to automotive discussions are valuable for practical insights and community support. Additionally, instructional videos can visually demonstrate complex processes, making them easier to comprehend.

Industry certifications and workshops present opportunities for hands-on experience, further solidifying theoretical concepts. By leveraging these diverse resources, you can cultivate a well-rounded expertise that will serve you throughout your automotive journey.