In the world of automotive engineering, the intricacies of power transfer mechanisms play a crucial role in ensuring optimal vehicle performance. This section delves into the essential aspects of these complex systems, providing insights into their functionality, maintenance, and troubleshooting. By understanding the underlying principles, enthusiasts and professionals alike can enhance their knowledge and skills in this vital area of vehicle mechanics.

Effective management of these intricate components not only improves efficiency but also prolongs the lifespan of vehicles. Proper diagnostic techniques and systematic approaches to resolving issues can significantly reduce downtime and repair costs. This guide aims to equip readers with the necessary information to navigate through various challenges associated with these systems.

Additionally, the importance of having reliable reference materials cannot be overstated. Accessible resources enable individuals to perform tasks with confidence and precision. Whether you’re a seasoned technician or a passionate hobbyist, understanding the technical nuances of these power transfer systems will empower you to tackle any project with assurance and expertise.

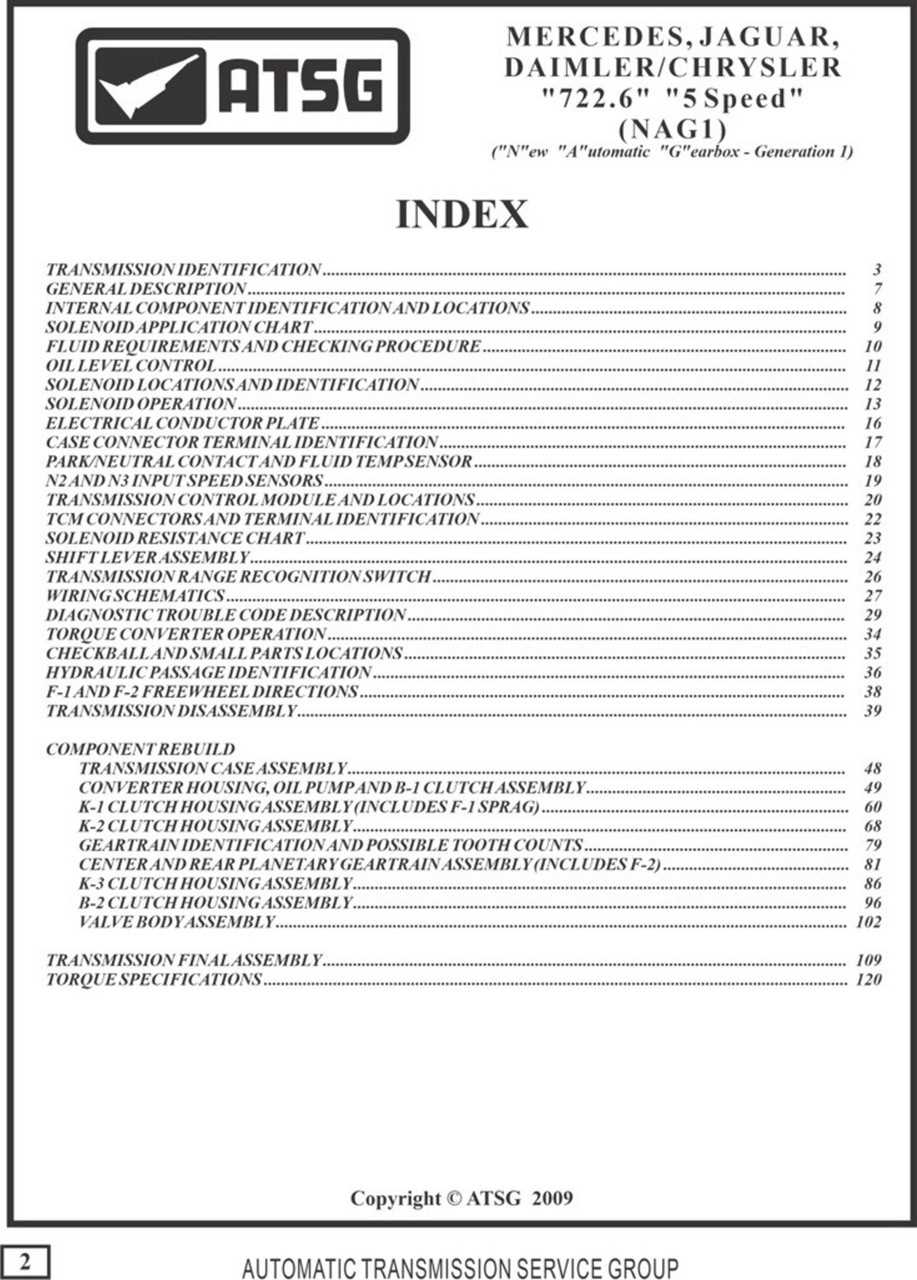

Understanding the 722.6 ATSG Manual

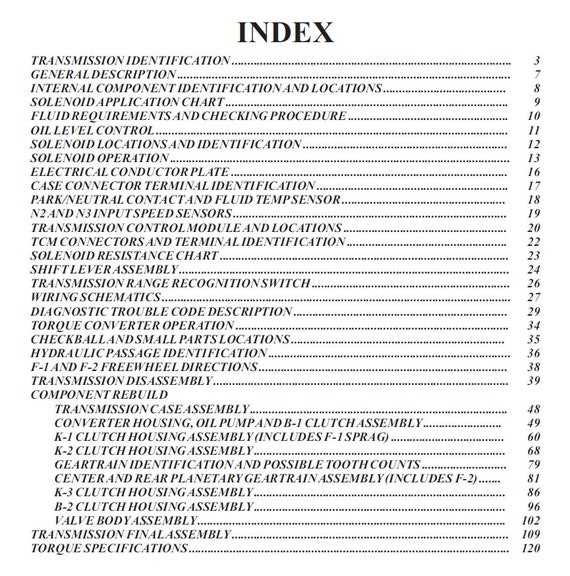

The resource serves as a comprehensive guide for those delving into the intricacies of automatic gear systems. It offers valuable insights into various components, their functions, and the principles behind their operation. This document is designed to enhance knowledge and facilitate effective troubleshooting and maintenance practices.

Structured to cater to both beginners and seasoned professionals, the guide breaks down complex concepts into manageable segments. Each section provides detailed descriptions and illustrative diagrams, making it easier to grasp essential information. Emphasizing clarity, it ensures users can confidently navigate through their tasks.

Moreover, this resource highlights common issues that may arise, alongside systematic approaches to diagnosing and resolving them. By fostering a deeper understanding of automatic systems, it empowers users to improve their skills and optimize performance.

In conclusion, this guide is not merely a reference; it is a valuable tool for anyone looking to enhance their expertise in the field. With its comprehensive coverage and user-friendly layout, it stands as an essential asset for effective maintenance and troubleshooting.

Overview of 722.6 Transmission System

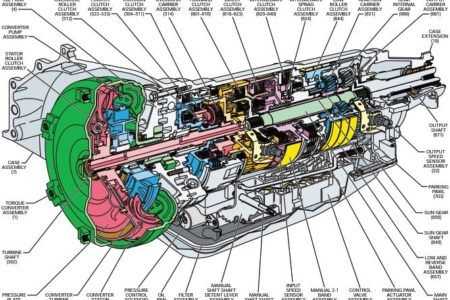

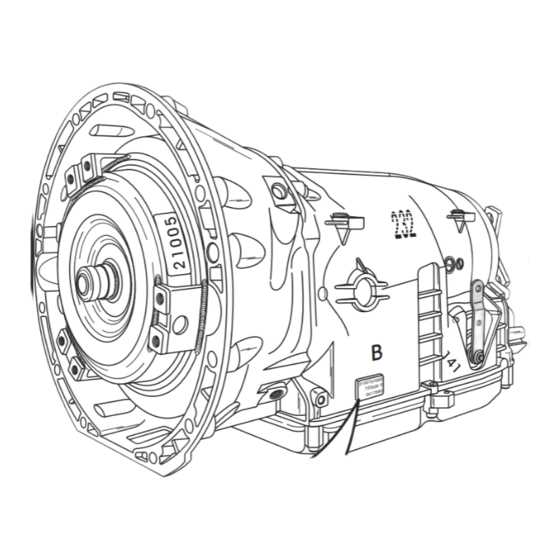

This section provides an insight into a sophisticated power delivery mechanism utilized in various automotive applications. The design emphasizes efficiency and smooth operation, contributing to the overall performance of the vehicle. Understanding its components and functionality is crucial for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Torque Converter | Facilitates the transfer of power from the engine to the drive system, allowing for smooth acceleration. |

| Clutch Packs | Engage and disengage gears to manage power flow, providing seamless gear shifts. |

| Valve Body | Acts as the control center, directing hydraulic fluid to various components based on driver inputs. |

| Gear Sets | Determine the gear ratios that allow the vehicle to operate efficiently at various speeds. |

| Electronic Control Unit | Monitors and adjusts system parameters for optimal performance and responsiveness. |

Comprehending the interplay among these elements is essential for diagnosing issues and ensuring reliable operation. A well-maintained system not only enhances vehicle performance but also extends its lifespan, making knowledge of this assembly invaluable for automotive enthusiasts and professionals alike.

Common Issues with 722.6 Transmissions

Many vehicle owners encounter a range of challenges with their automatic gear systems, leading to performance issues and decreased reliability. Understanding these common problems can aid in early detection and resolution, ultimately enhancing the lifespan of the vehicle.

- Slipping Gears: One frequent complaint is the sensation of gears slipping during acceleration, which can result in unexpected changes in power delivery.

- Delayed Engagement: Some drivers experience a noticeable lag when shifting from park to drive, indicating potential hydraulic or electronic issues.

- Fluid Leaks: Leaks can occur due to worn seals or gaskets, causing a drop in fluid levels and leading to overheating or failure.

- Unusual Noises: Grinding or whining sounds while shifting may suggest internal component wear or damage.

- Error Codes: Modern vehicles often display error codes related to the gearbox, which can help diagnose underlying issues.

Regular maintenance and attentive observation can prevent many of these common pitfalls. If problems arise, seeking professional assistance is advisable to ensure proper diagnosis and treatment.

Essential Tools for Transmission Repair

Working on vehicle power systems requires a specific set of instruments that ensure precision and efficiency. Whether you are a seasoned mechanic or a DIY enthusiast, having the right equipment can make all the difference in achieving successful outcomes. Below are some fundamental tools that are indispensable for any work involving gear systems.

Basic Hand Tools

- Socket set

- Wrenches (both standard and metric)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and standard)

- Torque wrench

Specialized Instruments

- Fluid transfer pump

- Measuring tools (calipers and gauges)

- Magnetic pickup tool

- Gear puller

- Seal installer

Investing in these essential tools not only enhances the quality of your work but also contributes to a smoother process, ultimately leading to more reliable performance from the components you service.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing essential fixes on specific automotive components. Following a structured approach ensures efficiency and accuracy, allowing you to tackle issues systematically. Each step is designed to simplify the process and enhance your understanding of the underlying mechanisms involved.

Preparation and Tools

Before beginning the work, gather the necessary tools and materials. Proper preparation is key to a successful outcome. Below is a list of items you’ll need:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners |

| Screwdriver Set | For removing and securing screws |

| Torque Wrench | To ensure bolts are tightened to specifications |

| Pliers | For gripping and manipulating components |

| Diagnostic Tool | To check for error codes and system functionality |

Step-by-Step Process

Follow these steps to ensure a thorough and effective procedure:

- Disconnect the battery to ensure safety while working.

- Remove any necessary panels or covers to access the target component.

- Carefully detach the component, taking note of its orientation and connection points.

- Inspect all related parts for wear or damage, replacing as necessary.

- Reassemble the component in the reverse order of disassembly, ensuring all connections are secure.

- Reconnect the battery and perform a systems check to confirm proper operation.

By adhering to these outlined procedures, you can effectively manage component issues, ensuring reliability and longevity in performance.

Diagnostic Techniques for Transmission Problems

Identifying issues within the power transfer system is crucial for ensuring optimal vehicle performance. Various methods exist to diagnose faults, allowing technicians to pinpoint malfunctions accurately. Employing these techniques can lead to effective resolutions, minimizing downtime and improving vehicle reliability.

Visual Inspection

A thorough visual examination is the first step in troubleshooting. Checking for leaks, worn components, and signs of overheating can provide immediate clues about underlying issues. Look for any physical damage or abnormal wear patterns that might indicate a need for further investigation.

Diagnostic Tools and Equipment

Utilizing advanced diagnostic tools can significantly enhance the detection process. Scanners that interface with the vehicle’s onboard computer systems can reveal error codes that point to specific faults. Additionally, pressure gauges and fluid analyzers can help assess the condition of hydraulic fluids and systems, ensuring they meet manufacturer specifications.

Understanding Symptoms is essential for accurate diagnosis. Common indicators such as slipping, delayed engagement, or unusual noises can guide technicians toward the root cause. By combining these approaches, professionals can develop a comprehensive understanding of the issues at hand, ultimately leading to effective solutions.

Preventive Maintenance Tips for Longevity

Ensuring the extended lifespan of complex machinery requires a proactive approach to upkeep and care. By implementing consistent preventive measures, one can significantly reduce the likelihood of unexpected failures and costly repairs. Regular attention to critical components not only enhances performance but also promotes efficiency and reliability.

Firstly, it is essential to adhere to a scheduled inspection routine. Regular checks can help identify wear and tear before it escalates into a major issue. This includes monitoring fluid levels and ensuring they are clean and at appropriate levels to facilitate optimal function.

Secondly, cleaning and servicing key parts is crucial. Dirt and debris can accumulate over time, leading to increased friction and potential damage. Utilizing appropriate cleaning techniques and products will help maintain the integrity of vital elements.

Additionally, pay attention to operational habits. Gentle driving practices can lessen strain on components, thereby extending their lifespan. Avoiding aggressive acceleration and sudden stops can make a significant difference in wear rates.

Finally, maintaining proper temperature ranges is vital. Overheating can lead to serious damage, so ensuring that cooling systems are functioning correctly and that there are no blockages is imperative. Regular maintenance of cooling systems will help keep temperatures in check, promoting longevity.

Transmission Fluid Specifications and Recommendations

Proper lubrication is essential for the efficient functioning of any vehicle’s drivetrain system. Selecting the right fluid can significantly enhance performance, extend service life, and ensure smooth operation. This section outlines key specifications and recommendations for optimal fluid use.

When choosing the appropriate lubricant, consider the following factors:

- Viscosity: The thickness of the fluid at different temperatures affects its performance. Check the manufacturer’s recommendations for the ideal viscosity grade.

- Additive Package: Different formulations include various additives that enhance characteristics like oxidation resistance, anti-wear properties, and foam control.

- Compatibility: Ensure the fluid is compatible with existing materials in the system, such as seals and gaskets, to prevent leaks or degradation.

- Specifications: Look for fluids that meet or exceed industry standards or specific OEM requirements.

It’s crucial to follow manufacturer guidelines regarding fluid change intervals and the type of product to use. Regular maintenance can prevent premature wear and costly repairs.

To ensure longevity and optimal performance, always consult a trusted source for fluid selection and maintenance recommendations. Following these guidelines will help maintain the efficiency and reliability of your vehicle’s system.

Identifying Symptoms of Transmission Failure

Recognizing the signs of malfunction in your vehicle’s drivetrain is crucial for maintaining optimal performance. Early detection can prevent more extensive damage and costly repairs. Understanding the common indicators of issues can help you address problems before they escalate.

Common Symptoms

- Unusual Noises: Grinding, clunking, or whining sounds can indicate internal damage.

- Delayed Engagement: Hesitation when shifting gears may suggest a problem with the shifting mechanism.

- Fluid Leaks: Puddles of reddish fluid under the vehicle can point to leaks that require immediate attention.

- Warning Lights: Dashboard alerts specifically related to drivetrain issues should never be ignored.

- Burning Smell: A burnt odor can signal overheating or fluid breakdown.

Behavioral Changes

- Inconsistent Shifting: Sudden changes in gear or failure to shift smoothly can indicate a fault.

- Loss of Power: Difficulty accelerating or maintaining speed may be a sign of underlying problems.

- Rough Handling: Jerking or stuttering during gear transitions can point to system failures.

Addressing these symptoms promptly can save time and money, ensuring that your vehicle remains in good working order. Regular inspections and maintenance can also help prevent these issues from arising in the first place.

Rebuilding vs. Replacing the Transmission

When faced with issues related to a vehicle’s power delivery system, owners often grapple with the decision of whether to restore the existing unit or to install a new one. Each option has its advantages and drawbacks, and understanding these can help in making an informed choice that aligns with both budget and performance needs.

Advantages of Rebuilding

- Cost-Effective: Restoring the current unit can be less expensive than purchasing a new assembly.

- Familiarity: Mechanics can often identify and fix specific problems based on their knowledge of the original system.

- Customization: Owners may have the option to enhance performance during the rebuild process.

- Environmental Impact: Rebuilding contributes to reducing waste by reusing components.

Benefits of Replacement

- Reliability: New units typically come with warranties, providing peace of mind.

- Advanced Technology: Modern units may offer improved efficiency and performance features.

- Time-Saving: Installation of a new assembly can often be quicker than a comprehensive rebuild.

- Elimination of Unknowns: New parts reduce the risk of unexpected failures due to hidden damage.

Ultimately, the decision between restoring or replacing hinges on individual circumstances, including the vehicle’s age, overall condition, and the owner’s financial considerations. Each route has its merits, making it essential to evaluate all factors before proceeding.

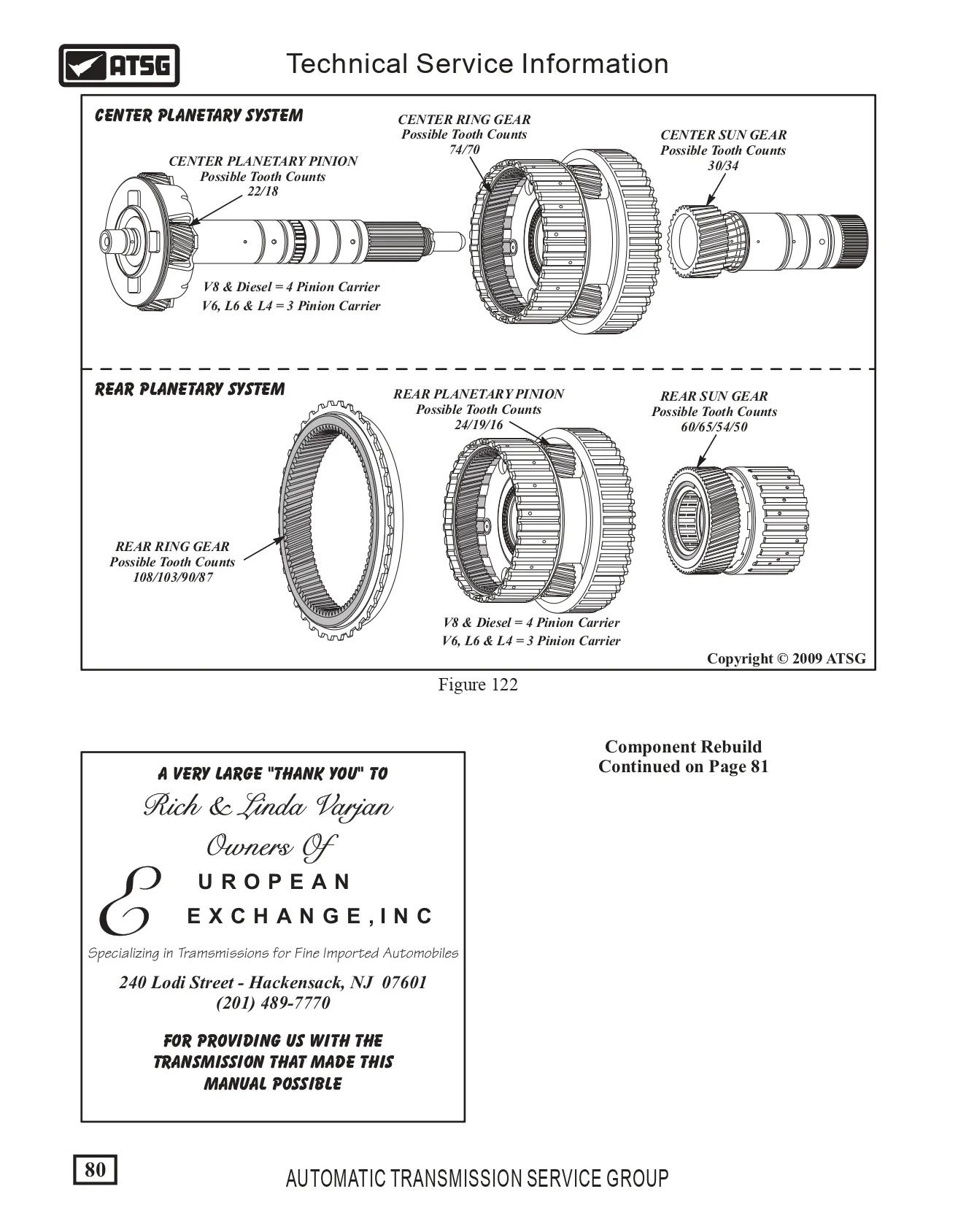

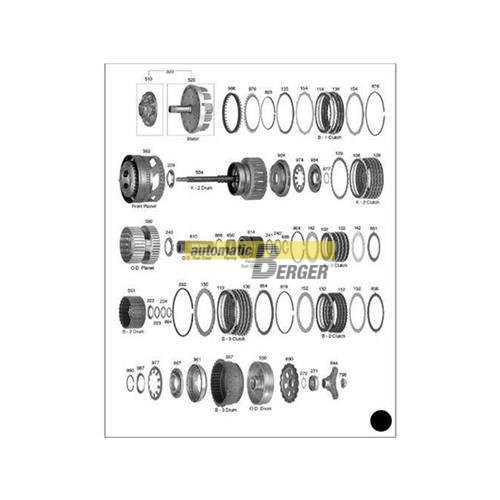

Key Components in the 722.6 System

The functioning of any complex machinery relies heavily on its essential elements. In this context, understanding the critical components involved can provide insights into how the system operates effectively. Each part plays a vital role in ensuring smooth performance and reliability.

Valve Body is a fundamental element that directs fluid flow to various clutches and bands. Its intricate design facilitates the precise engagement and disengagement of components, which is crucial for optimal functionality.

Clutch Packs serve as the power transfer mechanism, enabling the system to shift gears seamlessly. These packs consist of multiple friction discs that engage and disengage under hydraulic pressure, allowing for smooth transitions during operation.

Torque Converter plays an important role in enhancing efficiency by multiplying engine torque. This component allows for a smoother start and aids in the transition between stationary and moving states, providing a seamless driving experience.

Electronic Control Unit (ECU) is responsible for managing the overall operation of the system. By processing various inputs from sensors, it adjusts shifting patterns and optimizes performance, ensuring the machinery responds effectively to driving conditions.

Each of these components is designed to work in harmony, contributing to the overall reliability and performance of the assembly. Understanding their functions is essential for anyone looking to delve deeper into the mechanics of this sophisticated system.

Cost Analysis of Repairing Transmissions

Evaluating the financial aspects of restoring vehicle gear systems is crucial for both professionals and vehicle owners. Understanding the various expenses involved can aid in making informed decisions. This section will explore the key factors influencing the overall costs associated with these services, including labor, parts, and diagnostics.

Components of Expense

The primary components that contribute to the total expense include the price of replacement parts, which can vary significantly based on the vehicle model and the extent of wear. Labor costs are another critical factor; skilled technicians often charge a premium for their expertise. Additionally, diagnostic fees can add to the initial costs, especially if specialized equipment is required to identify the issues accurately.

Long-Term Considerations

Investing in the restoration of gear systems can lead to substantial long-term savings. A well-maintained system can improve fuel efficiency and enhance vehicle performance, potentially lowering overall operating costs. Furthermore, timely service may prevent more severe issues, which could result in more extensive and expensive repairs in the future.

Resources for Further Learning and Support

Expanding your knowledge and skills in automotive systems is crucial for anyone looking to enhance their expertise. Various resources are available to provide guidance, whether you are a beginner or an experienced professional. This section outlines valuable tools, communities, and literature to assist in your journey.

Online Communities and Forums

Engaging with fellow enthusiasts and professionals can significantly enhance your understanding. Online forums offer platforms for discussion, troubleshooting, and sharing experiences. Participating in these communities allows you to ask questions and receive insights from individuals with diverse backgrounds.

Recommended Literature

Books and manuals written by industry experts can serve as excellent references. These resources often cover fundamental principles, advanced techniques, and practical applications, making them indispensable for ongoing education.

| Resource Type | Recommended Resources |

|---|---|

| Online Forums | AutomotiveForums.com, GearHead-Forums.com |

| Books | The Complete Guide to Automotive Systems, Advanced Automotive Technology |

| Video Tutorials | YouTube channels like “ChrisFix” and “Scotty Kilmer” |

| Workshops | Local community colleges and technical schools |