Maintaining and troubleshooting your vehicle’s complex powertrain components is essential for optimal performance and longevity. This section delves into the intricacies of automatic gear systems, providing crucial insights for both novice and experienced enthusiasts alike.

As technology advances, the mechanisms that govern the shifting of gears become increasingly sophisticated. Familiarity with these systems can empower owners to address issues proactively, ensuring smoother operation and reducing the risk of costly repairs.

Whether you’re experiencing unusual noises, erratic shifting patterns, or simply seeking to enhance your knowledge, this guide will equip you with the essential information. Through clear instructions and detailed illustrations, you will learn how to navigate the challenges associated with these intricate assemblies.

Understanding the 6R140 Transmission

The engineering behind modern automatic gear systems reflects a remarkable blend of technology and design aimed at enhancing vehicle performance. This sophisticated assembly plays a crucial role in ensuring smooth shifts and optimal power delivery, making it essential for efficient driving experiences.

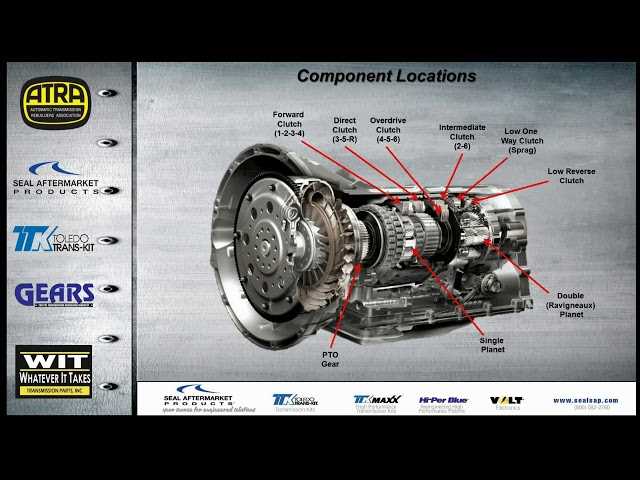

Components of this system include various intricate parts that work in unison to facilitate gear changes. Each element, from hydraulic circuits to electronic controls, contributes to the overall functionality, providing seamless transitions and improved fuel efficiency.

One of the standout features is its adaptive learning capability, which allows the system to adjust its behavior based on driving patterns. This intelligent design not only improves responsiveness but also enhances overall drivability, adapting to different conditions and preferences.

Understanding the mechanics and features of this advanced gear assembly is vital for any automotive enthusiast or technician. Knowledge of its operation and potential issues can lead to better maintenance practices, ensuring longevity and reliability in performance.

Common Issues with 6R140 Units

When dealing with high-performance gear systems, several recurring problems can arise that may affect overall functionality and reliability. Understanding these issues is crucial for anyone looking to maintain or troubleshoot these units effectively.

Frequent Problems Encountered

- Delayed Shifting: Many users report experiencing delays when shifting between gears, which can lead to a sluggish driving experience.

- Overheating: Excessive heat generation can cause components to wear out prematurely, affecting performance and longevity.

- Fluid Leaks: Leaking fluids are a common concern, often indicating seal or gasket failures that require immediate attention.

- Noisy Operation: Unusual sounds during operation may suggest issues with internal components, necessitating further investigation.

Potential Causes

- Poor Maintenance: Neglecting regular service can lead to the accumulation of debris and fluid degradation.

- Improper Installation: Incorrect assembly or alignment of parts can result in operational inefficiencies.

- Quality of Parts: Using substandard components may contribute to early failures and overall system instability.

Essential Tools for Transmission Repair

When tackling complex mechanical systems, having the right equipment is crucial for success. A well-equipped workshop not only enhances efficiency but also ensures precision in every task. Understanding the fundamental instruments needed for such intricate work is the first step toward achieving optimal results.

1. Socket Set: A versatile socket set is indispensable for loosening and tightening various fasteners. Opt for both standard and deep sockets to accommodate different sizes and depths.

2. Torque Wrench: Accuracy is paramount in assembly and disassembly. A torque wrench helps achieve the correct tightness, preventing damage due to over-tightening.

3. Pliers and Wrenches: A variety of pliers and adjustable wrenches will aid in gripping, twisting, and turning components, making tasks easier and more effective.

4. Screwdrivers: A complete set of screwdrivers, including both flathead and Phillips types, allows for the removal of numerous screws and fasteners found in various systems.

5. Diagnostic Tools: Utilizing electronic diagnostic equipment can provide valuable insights into system performance, helping identify issues that may not be immediately visible.

6. Gasket Scraper: When working on assembly, a gasket scraper is vital for removing old seals and ensuring a clean surface for new gaskets.

7. Cleaning Supplies: Maintaining cleanliness is essential. Keep solvents and rags handy to clean parts and tools, promoting a safe working environment.

Investing in these essential tools not only simplifies the process but also contributes to a smoother workflow, ultimately leading to a successful outcome in any mechanical endeavor.

Step-by-Step Repair Process

This section outlines a systematic approach to fixing common issues in automatic gear systems. By following these detailed steps, you can ensure a thorough examination and resolution of any faults present. Adhering to safety measures and using the right tools is essential for success.

- Preparation

- Gather necessary tools and equipment.

- Ensure a clean workspace to avoid contamination.

- Review any technical bulletins or previous service history.

- Initial Inspection

- Check for visible leaks and damage.

- Examine fluid condition; look for discoloration or metal shavings.

- Connect a diagnostic scanner to read error codes.

- Disassembly

- Remove the assembly from the vehicle carefully.

- Document each step to ensure correct reassembly.

- Keep track of all components and fasteners.

- Component Assessment

- Inspect gears and clutches for wear or damage.

- Check seals and gaskets for signs of deterioration.

- Test electronic components and sensors for functionality.

- Replacement and Repair

- Replace any worn or damaged parts with high-quality components.

- Utilize proper torque specifications when reassembling.

- Apply fresh fluid to ensure optimal performance.

- Reassembly

- Carefully reassemble all components according to your documentation.

- Double-check that all connections are secure.

- Ensure that all new seals and gaskets are properly seated.

- Testing

- Reconnect the assembly to the vehicle.

- Fill with fluid and check for leaks.

- Conduct a test drive to verify functionality and performance.

By meticulously following each phase, you can effectively address issues and enhance the reliability of the gear system. Regular maintenance checks can prevent future complications, ensuring long-lasting performance.

Diagnostic Techniques for 6R140 Problems

Identifying issues within complex machinery can be challenging yet essential for maintaining optimal performance. Effective diagnostic techniques enable technicians to pinpoint malfunctions and implement appropriate solutions. This section outlines various methods to troubleshoot common problems associated with this particular vehicle system.

1. Visual Inspection: Begin with a thorough visual examination. Check for fluid leaks, damaged wiring, or unusual wear on components. Signs of overheating or corrosion may indicate underlying issues that need addressing.

2. Fluid Analysis: Assess the quality and condition of the hydraulic fluid. Discoloration, burning smell, or metal shavings can signal significant problems. Proper fluid maintenance can often prevent larger failures.

3. Diagnostic Tools: Utilize electronic diagnostic equipment to read error codes. These tools can provide valuable insights into performance anomalies and sensor malfunctions, guiding further investigation.

4. Road Test: Conduct a comprehensive road test to observe the behavior under various conditions. Pay attention to shifting patterns, unusual noises, or hesitation during acceleration. Documenting these observations helps in correlating symptoms with potential faults.

5. Pressure Testing: Measure hydraulic pressure at various points to ensure proper functioning. Deviations from manufacturer specifications can highlight issues with pump performance or internal leaks.

6. Component Testing: Isolate and test individual components, such as solenoids and clutches. This can confirm their operational status and help identify specific failures that may be affecting overall functionality.

Employing these techniques systematically can significantly enhance the diagnosis process, leading to effective interventions and restoring vehicle efficiency.

Replacing Components: A How-To Guide

Maintaining the efficiency of your vehicle often requires the replacement of various internal parts. This guide outlines the essential steps for successfully swapping out components, ensuring optimal performance and longevity. By following these instructions, you can tackle the task confidently and effectively.

Before beginning, gather the necessary tools and parts. A well-organized workspace will enhance your efficiency and minimize the risk of losing small components. Here’s a simple checklist of what you’ll need:

| Item | Description |

|---|---|

| Socket Set | For loosening and tightening bolts. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Sealant | To prevent leaks between joined surfaces. |

| Replacement Parts | Specific components that need to be replaced. |

Once you have all your materials ready, start by disconnecting the battery to avoid any electrical issues. Next, remove the necessary covers or shields to access the components you need to replace. It’s crucial to keep track of all screws and fasteners during this process; using a magnetic tray can be helpful.

Carefully detach the old parts, paying attention to any connections that may need to be unplugged. Inspect surrounding areas for wear or damage, as this may necessitate further action. Once the old parts are removed, install the new components by reversing the removal steps. Ensure all connections are secure and properly aligned.

After installation, reattach any shields or covers that were removed. Finally, reconnect the battery and test the system to confirm everything is functioning correctly. Regularly monitoring performance after component replacement can help identify any potential issues early.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your vehicle’s key components, regular upkeep is essential. By following a few simple practices, you can prevent premature wear and maintain efficiency.

- Regular Fluid Checks: Periodically inspect and replace fluids as necessary to ensure smooth operation.

- Monitor Temperature: Keep an eye on temperature readings to prevent overheating, which can lead to significant damage.

- Routine Inspections: Conduct thorough checks on all connections and parts for signs of wear or damage.

- Keep it Clean: Maintain cleanliness in the surrounding area to avoid debris buildup that can cause issues.

Additionally, consider the following recommendations:

- Drive Smoothly: Avoid harsh acceleration and abrupt stops to reduce strain on mechanical components.

- Follow Manufacturer Guidelines: Adhere to the specified maintenance schedule for optimal results.

- Use Quality Parts: When replacements are necessary, opt for high-quality components to ensure reliability.

- Seek Professional Help: Don’t hesitate to consult a qualified technician for complex issues or concerns.

By implementing these strategies, you can enhance the durability and functionality of your vehicle, ultimately leading to a more enjoyable driving experience.

Identifying Fluid Leaks and Solutions

Detecting fluid leaks in a vehicle’s system is crucial for maintaining optimal performance and avoiding further damage. Leaks can manifest in various forms, and recognizing their source is the first step toward effective resolution. This section will guide you through common indicators of fluid leaks and practical solutions to address them.

Common signs of fluid leaks include:

- Unusual spots or puddles under the vehicle

- Visible drips or streams during operation

- Fluid stains on the ground, which may vary in color and consistency

- Unpleasant odors, indicating potential fluid types

To identify the type of fluid, consider the following:

- Oil: Typically brown or black, with a slippery texture.

- Coolant: Often green, orange, or pink, with a sweet smell.

- Brake fluid: Clear to yellowish, with a somewhat oily feel.

- Transmission fluid: Red or brown, with a distinctive smell similar to burnt oil.

Once the leak is identified, follow these steps to address the issue:

- Locate the Source: Inspect hoses, seals, and connections for signs of wear or damage.

- Repair or Replace: Depending on the severity, you may need to tighten fittings, replace gaskets, or install new components.

- Monitor Levels: Regularly check fluid levels after repairs to ensure no further leaks occur.

- Seek Professional Help: If leaks persist or if you are unsure about the repairs, consult a qualified technician.

Timely identification and resolution of fluid leaks can prevent more serious issues and prolong the lifespan of your vehicle’s systems. Stay vigilant and proactive to keep everything running smoothly.

Upgrading Your 6R140 Transmission

Enhancing the performance of your vehicle’s gear system can significantly improve driving experience and reliability. This section will explore various strategies for upgrading components, optimizing functionality, and ensuring a smoother operation.

Key Areas for Improvement

- Clutch Kits: Consider installing high-performance clutch kits that offer better grip and durability, providing a firmer connection between moving parts.

- Fluid Upgrades: Utilizing synthetic fluids can enhance heat resistance and reduce friction, leading to improved efficiency and lifespan.

- Torque Converters: Upgrading to a performance torque converter can improve throttle response and overall power delivery.

Installation Tips

- Always ensure the vehicle is on a stable surface and properly secured before beginning any modifications.

- Follow manufacturer guidelines for all components, paying close attention to torque specifications during installation.

- Consider consulting with a professional if you are unfamiliar with mechanical work to avoid potential issues.

By focusing on these key areas and adhering to best practices, you can significantly enhance your vehicle’s performance and reliability.

Resources for Further Learning

Expanding your knowledge in the field of automotive mechanics can greatly enhance your skills and understanding. Various resources are available that cover essential techniques, troubleshooting strategies, and detailed insights into complex systems. Engaging with these materials will not only deepen your comprehension but also improve your practical capabilities.

Books and online courses are excellent starting points for gaining theoretical knowledge. Many publications focus on specific components, providing in-depth analysis and illustrations. Additionally, interactive courses offer hands-on experience and expert guidance, which can be invaluable for both novices and seasoned professionals.

Forums and community groups are also beneficial for exchanging ideas and solutions. Joining discussions with fellow enthusiasts can lead to new perspectives and troubleshooting tips. Many experienced mechanics share their insights online, making these platforms a rich source of information.

Lastly, instructional videos on platforms like YouTube can provide visual demonstrations of complex procedures. Watching skilled technicians at work can clarify difficult concepts and techniques, allowing for better retention of information. Utilizing these diverse resources will empower you to tackle automotive challenges with confidence.