This section offers a detailed overview of essential procedures and techniques for maintaining a popular family vehicle. Covering various aspects of upkeep, it aims to empower owners with the knowledge needed to ensure optimal performance and longevity of their automobile.

In the following segments, readers will find systematic instructions, troubleshooting tips, and crucial insights designed to facilitate a smoother experience in handling common issues. With a focus on practicality, this guide serves as a valuable resource for both novice and seasoned car enthusiasts.

Whether you are seeking to perform routine checks or address specific concerns, the information provided here is tailored to enhance your understanding of the vehicle’s systems. Through careful attention to detail, owners can navigate challenges confidently and efficiently.

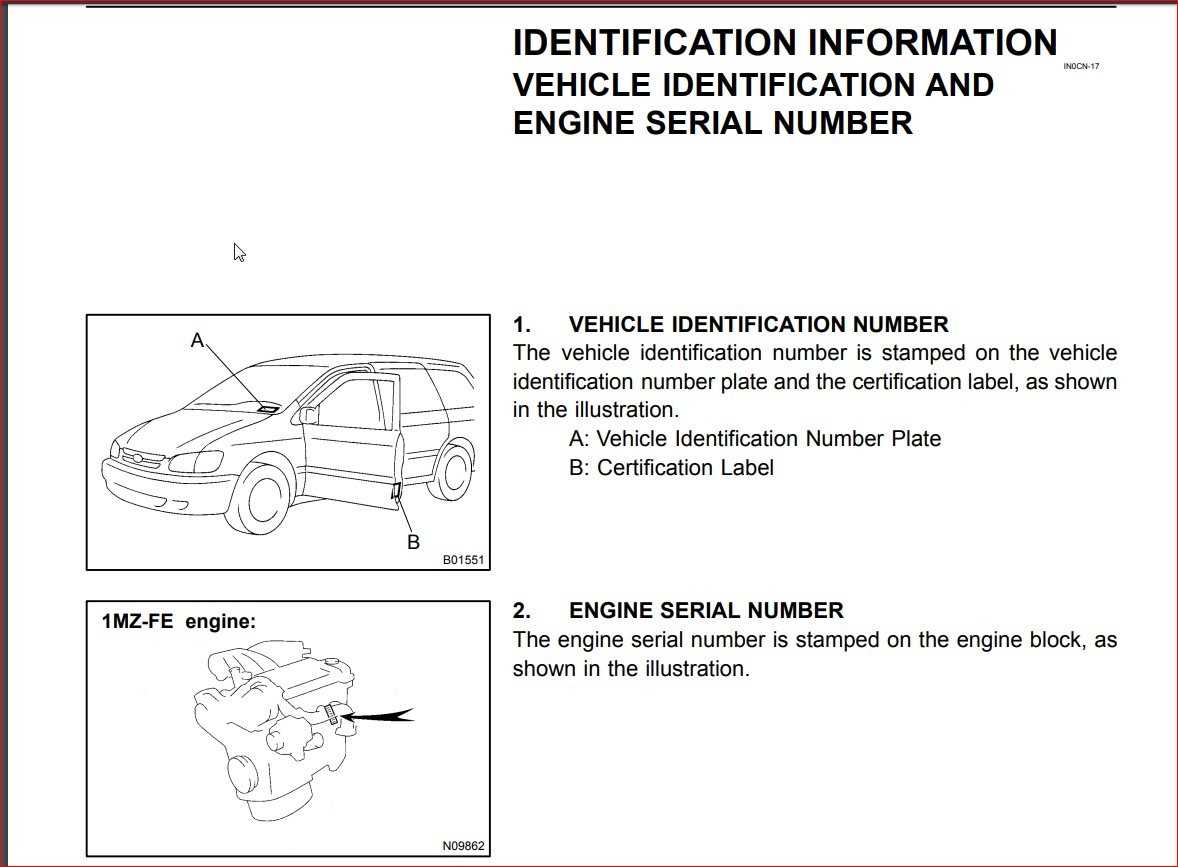

Toyota Sienna 2003 Overview

This section provides a comprehensive look at a versatile family vehicle known for its reliability and comfort. It is designed to meet the needs of both daily commutes and longer journeys, making it a popular choice among various drivers.

Performance is a key aspect, with a robust engine and smooth handling that enhance driving experience. The spacious interior accommodates multiple passengers, ensuring everyone travels in comfort.

Safety features are paramount, offering peace of mind for families. Advanced technologies and solid construction contribute to the overall protection of occupants, making it suitable for both city and highway driving.

Moreover, the vehicle boasts efficient fuel economy, allowing for longer trips without frequent refueling. Its design reflects a balance of functionality and style, appealing to a wide range of consumers.

Essential Tools for Repairs

Having the right equipment is crucial for efficient maintenance and troubleshooting. This section outlines the fundamental instruments needed to ensure smooth and effective work on your vehicle, enabling you to tackle various tasks with confidence.

Basic hand tools, such as wrenches and screwdrivers, are indispensable for any task, providing the versatility required for different components. Additionally, specialized instruments like torque wrenches help ensure that fasteners are tightened to the correct specifications, preventing damage and ensuring safety.

Diagnostic tools play a vital role in identifying issues, allowing you to analyze the vehicle’s systems effectively. A multimeter is essential for electrical troubleshooting, while an OBD-II scanner aids in reading error codes, streamlining the diagnostic process.

Safety equipment should never be overlooked. Items such as gloves, goggles, and a first aid kit protect you during maintenance tasks, ensuring a safe working environment. Having a sturdy creeper or mat can also enhance comfort while working underneath the vehicle.

Lastly, storage solutions for organizing tools and parts are important. A well-organized workspace minimizes time spent searching for items and enhances productivity. Investing in quality tools not only makes the job easier but also improves the longevity of the equipment and your vehicle.

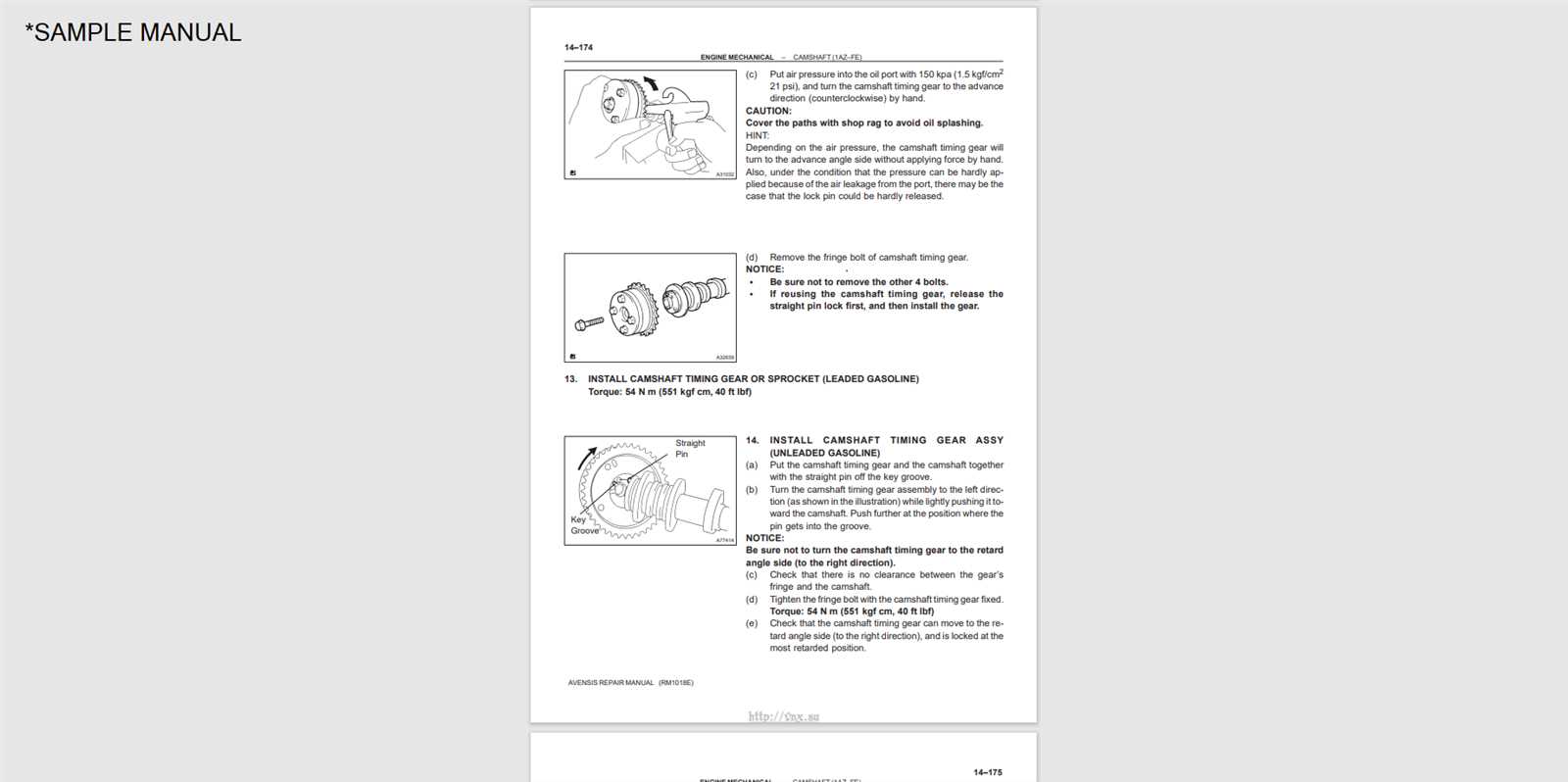

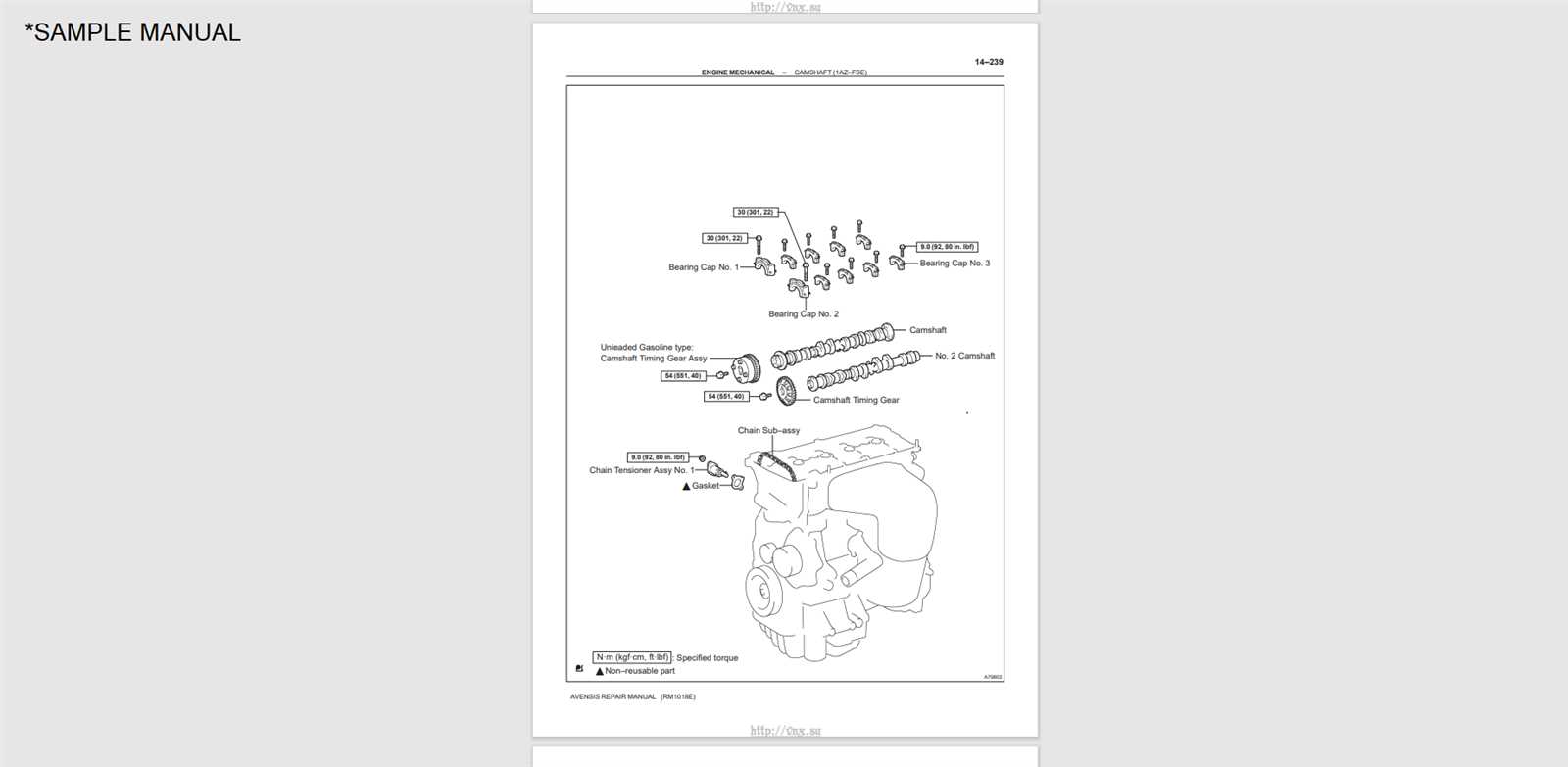

Engine Maintenance Guidelines

Ensuring optimal performance and longevity of the engine requires regular attention and proper care. Following specific recommendations can help in maintaining the mechanical heart of the vehicle, thus enhancing efficiency and reducing the likelihood of unforeseen issues.

Regular checks and timely service are essential to keep the engine running smoothly. Key components such as oil, filters, and belts should be monitored and replaced as needed to prevent deterioration and maintain functionality.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 miles | Use manufacturer-recommended oil type. |

| Air Filter Inspection | Every 15,000 miles | Replace if dirty or clogged. |

| Coolant Level Check | Monthly | Maintain proper fluid levels to prevent overheating. |

| Belt Inspection | Every 30,000 miles | Look for signs of wear or damage. |

| Spark Plug Replacement | Every 100,000 miles | Replace as per manufacturer’s specifications. |

Adhering to these guidelines can significantly enhance engine reliability and performance, ensuring a smooth driving experience over time.

Transmission Troubleshooting Techniques

Identifying issues within a vehicle’s shifting mechanism requires a systematic approach. By recognizing symptoms and applying effective diagnostic methods, one can often pinpoint the underlying causes of operational failures.

Common Symptoms of Malfunction

- Unusual noises during shifting

- Slipping gears or unexpected changes in speed

- Warning lights on the dashboard

- Fluid leaks under the vehicle

Diagnostic Steps

- Check fluid levels and condition: Low or contaminated fluid can lead to performance issues.

- Inspect for leaks: Examine hoses and seals for any signs of wear or damage.

- Perform a visual inspection: Look for signs of physical damage to the transmission components.

- Utilize diagnostic tools: Scan for error codes that may indicate specific problems.

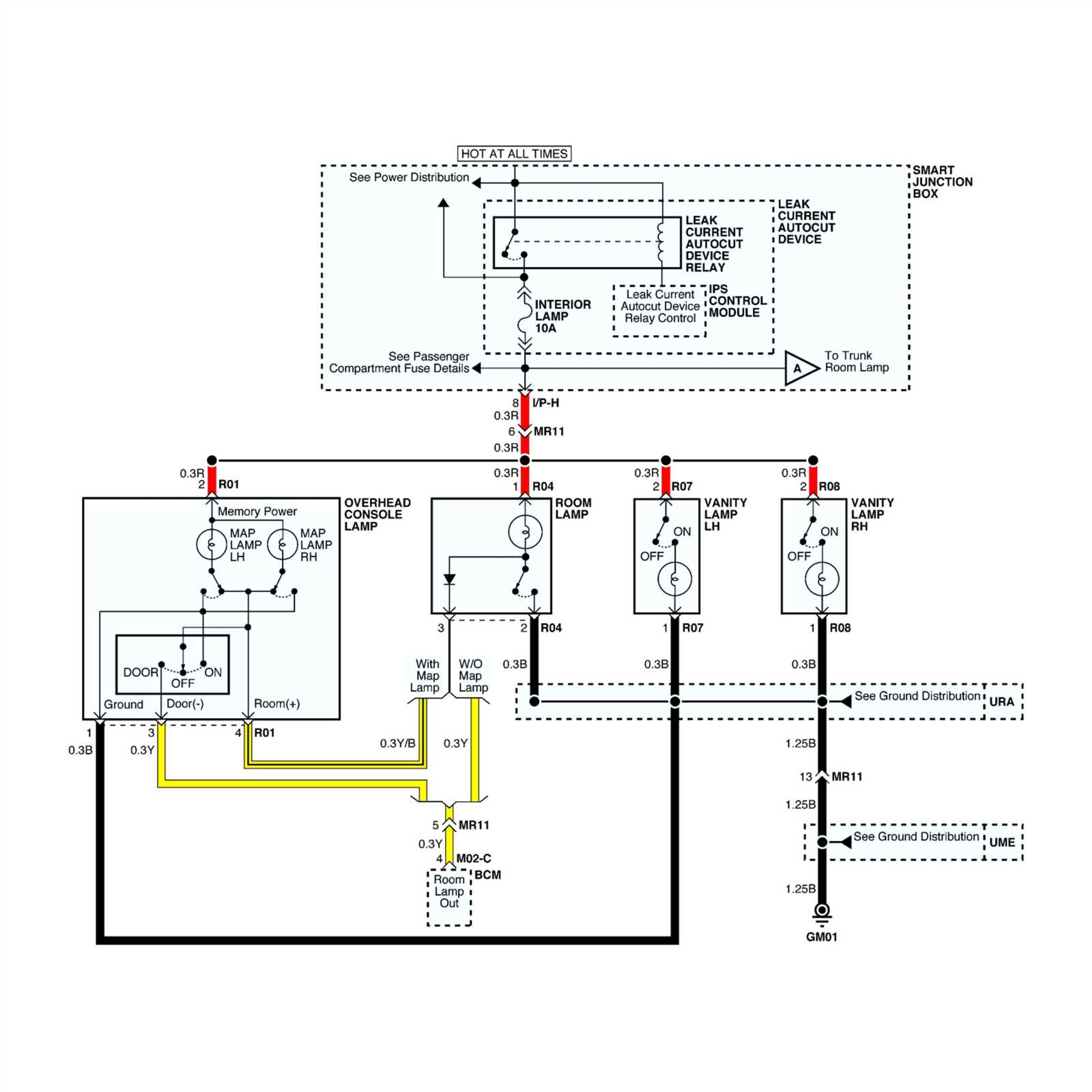

Electrical System Diagnostics

This section addresses the methodologies and procedures for evaluating the functionality of the vehicle’s electrical components. Proper diagnostics are essential for identifying issues within the system, ensuring optimal performance and reliability.

Common Issues and Symptoms

Identifying problems early can prevent more significant failures. Symptoms such as dimming lights, irregular instrument readings, or failure of electronic accessories may indicate underlying issues. A thorough inspection and understanding of these signs are crucial for effective troubleshooting.

Diagnostic Tools and Techniques

Utilizing specialized equipment such as multimeters and scan tools is vital in assessing the health of electrical systems. Voltage measurements, continuity tests, and scanning for error codes provide valuable insights into the condition of wiring, connections, and components. Regular maintenance and checks can significantly enhance the lifespan of the vehicle’s electrical system.

Brake System Inspection Steps

Regular examination of the braking mechanism is crucial for ensuring optimal performance and safety. This section outlines the essential procedures to assess the functionality and integrity of the braking components effectively.

Begin by checking the brake fluid level in the reservoir, ensuring it meets the manufacturer’s specified range. Inspect the fluid for any signs of contamination or discoloration, which could indicate the need for replacement.

Next, visually examine the brake pads and shoes for wear. Look for uneven surfaces or excessive thinning, which can affect stopping power. If necessary, measure the remaining thickness using a caliper to determine if they need replacement.

Assess the rotors and drums for any irregularities such as grooves, cracks, or warping. These imperfections can lead to reduced braking efficiency. If damage is detected, consider resurfacing or replacing the affected components.

Finally, check the brake lines for leaks or deterioration. Ensure all connections are secure and that there are no visible signs of wear. Any issues found during this inspection should be addressed promptly to maintain safety and performance.

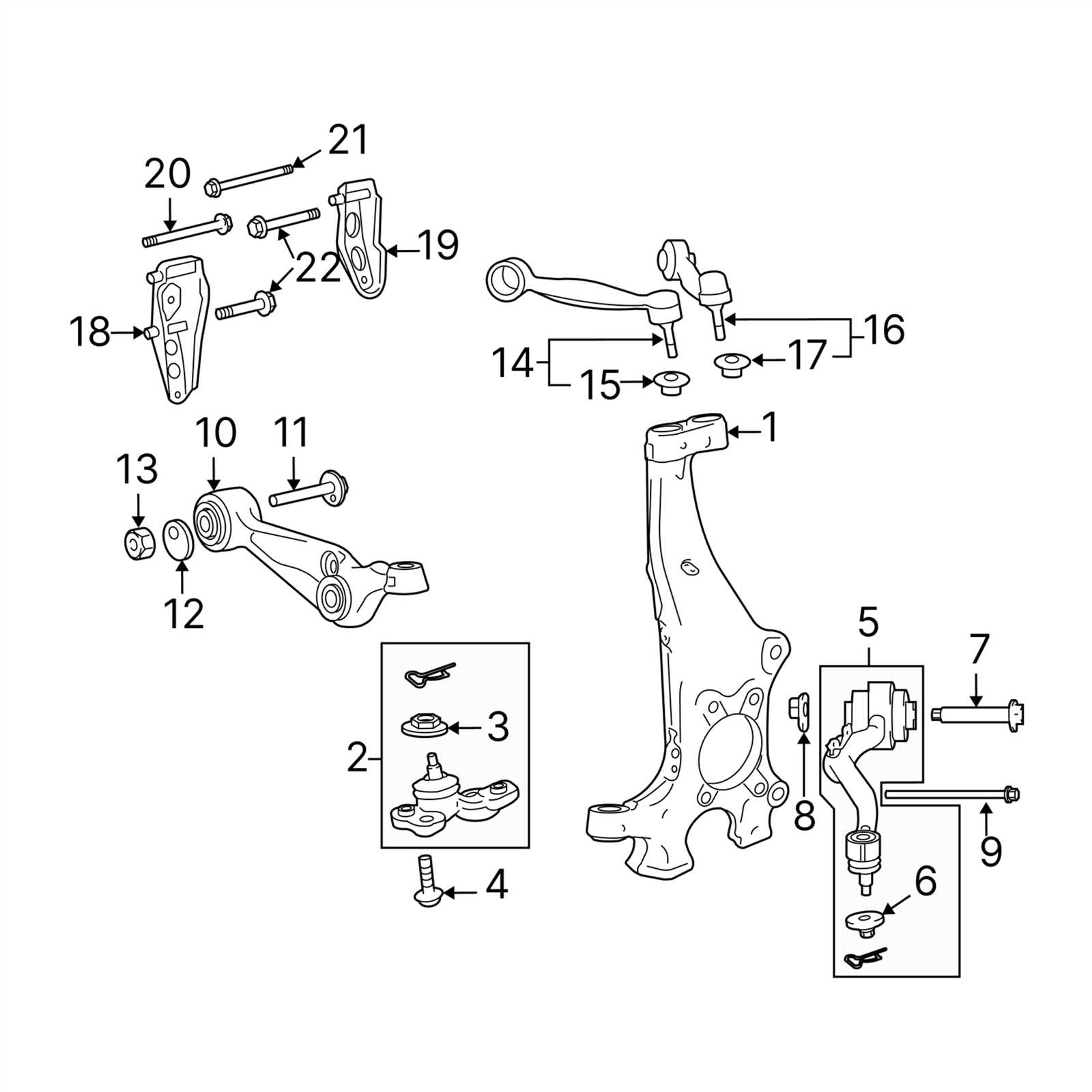

Suspension and Steering Repairs

This section provides essential guidance on addressing issues related to the vehicle’s suspension and steering systems. Proper maintenance of these components ensures enhanced handling and safety while driving.

Common Symptoms

Identifying early signs of trouble can prevent more significant problems down the line. Look out for the following indicators:

| Symptoms | Possible Causes |

|---|---|

| Excessive bouncing | Worn shocks or struts |

| Pulling to one side | Misaligned wheels |

| Steering wheel vibration | Unbalanced tires or worn components |

| Clunking noises | Loose or damaged mounts |

Maintenance Tips

Regular inspections and timely replacements are crucial for optimal performance. Consider these maintenance practices:

- Check fluid levels and replace as necessary.

- Inspect components for wear and tear.

- Rotate tires regularly to ensure even wear.

- Seek professional assessments for alignment and balancing.

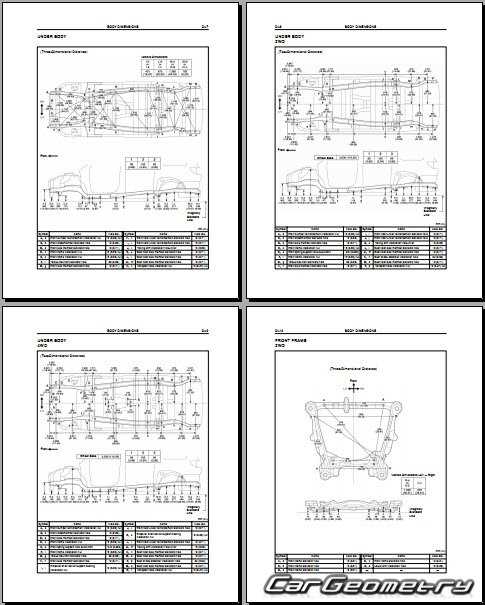

Bodywork and Interior Restoration

Restoring the exterior and interior of a vehicle involves a meticulous approach to bring back its original allure and functionality. This process not only enhances aesthetic appeal but also contributes to overall value and longevity. It encompasses a range of tasks, from addressing surface imperfections to renewing the cabin space for comfort and style.

Exterior Restoration Steps

- Assessment: Evaluate the condition of the bodywork, identifying dents, scratches, and rust spots.

- Preparation: Clean the surface thoroughly to ensure proper adhesion of paints and sealants.

- Repair: Fill in dents and scratches with appropriate materials, followed by sanding to achieve a smooth finish.

- Painting: Apply a high-quality paint that matches the original color, ensuring multiple layers for durability.

- Finishing: Polish the surface to restore shine and protect against environmental elements.

Interior Restoration Steps

- Cleaning: Remove dirt and grime from upholstery and surfaces using suitable cleaning agents.

- Repairing Upholstery: Patch or replace worn-out fabric, ensuring it matches the original texture and color.

- Replacing Components: Install new elements such as dashboard parts, knobs, and trim for a refreshed look.

- Detailing: Pay attention to all nooks and crannies, ensuring a comprehensive clean and restoration.

Through careful execution of these steps, both the exterior and interior can be transformed, providing a pleasing experience for owners and passengers alike.

Regular Maintenance Schedule

Establishing a consistent upkeep timetable is essential for ensuring optimal performance and longevity of your vehicle. Adhering to a well-structured plan can help identify potential issues before they escalate, keeping your transportation reliable and safe.

Interval Recommendations

It is advisable to conduct routine checks at specific intervals. Regular assessments should include oil changes, fluid top-ups, and inspections of critical components such as brakes, tires, and belts. A good practice is to follow a schedule based on mileage or time, whichever comes first, to maintain efficiency.

Key Services

Engine Oil: Change the engine lubricant every 5,000 to 7,500 miles or as per the manufacturer’s guidelines to ensure smooth operation.

Filters: Replace the air and cabin filters regularly, typically every 15,000 to 30,000 miles, to maintain air quality and engine performance.

Tires: Rotate tires every 5,000 to 7,500 miles to promote even wear and enhance safety.

By following these guidelines, you can help ensure that your vehicle operates efficiently and remains in excellent condition throughout its lifespan.

Common Problems and Solutions

This section addresses frequent issues encountered in a specific vehicle model and offers practical solutions to resolve them. Understanding these challenges can enhance maintenance and improve overall functionality.

-

Engine Performance Issues:

Many users experience a decrease in power or unusual noises. Regularly checking the air filter and fuel system can help alleviate these problems.

-

Electrical System Failures:

Malfunctions in lights or dashboard indicators are common. Inspecting fuses and wiring connections can often restore functionality.

-

Transmission Problems:

Shifting difficulties may arise. Ensuring proper fluid levels and conducting a thorough inspection of the transmission system are crucial steps.

-

Suspension Concerns:

Noises or vibrations while driving can indicate suspension wear. Regular checks of struts and shock absorbers can prevent further complications.

-

Brake System Issues:

Squeaking or grinding sounds may signal worn brake pads. Regular inspection and timely replacement of brake components are essential for safety.

Addressing these common challenges promptly can lead to better vehicle performance and longevity. It is advisable to keep a checklist for routine inspections to preemptively tackle potential issues.

Parts Replacement Instructions

This section provides detailed guidance for the process of swapping out components in your vehicle. Following the proper steps ensures functionality and longevity, making it essential for maintaining peak performance.

Before commencing any replacements, gather all necessary tools and parts to facilitate a smooth operation. It is advisable to review the specific requirements for each component, including torque specifications and any special procedures that may be necessary.

Begin by disconnecting the battery to prevent any electrical mishaps. Carefully remove the old component, taking note of how it is connected to ensure correct installation of the new part. Be mindful of any clips, screws, or connectors that may need to be detached.

Once the old part is removed, position the new component in place, ensuring that it aligns correctly with the existing fittings. Secure it properly, following any recommended torque settings. Finally, reconnect the battery and test the system to verify that everything is functioning as intended.