Understanding the intricacies of compact two-wheeled vehicles can enhance your experience and prolong the lifespan of your machine. This section delves into essential practices for troubleshooting, servicing, and ensuring optimal performance of lightweight personal transport. With the right knowledge, you can tackle common issues and keep your vehicle in prime condition.

Every enthusiast knows that regular upkeep is crucial for seamless operation. Whether you are facing challenges with the ignition system or addressing minor mechanical malfunctions, having a structured approach to maintenance is key. This guide will equip you with valuable insights and step-by-step instructions, empowering you to confidently address any situation.

By familiarizing yourself with the components and their functions, you will be better prepared to identify potential problems before they escalate. Equipped with the appropriate techniques and tips, even those new to the field can engage in effective upkeep. Let’s explore the vital areas that require attention and care for your beloved ride.

Understanding 50cc Scooter Mechanics

This section delves into the fundamental principles that govern the operation of small motorized two-wheelers. A clear comprehension of these mechanisms is essential for effective maintenance and troubleshooting, ensuring a smooth and reliable riding experience.

Key Components

- Engine: The heart of the vehicle, responsible for converting fuel into motion.

- Transmission: This system transfers power from the engine to the wheels, allowing for acceleration and deceleration.

- Brakes: Vital for safety, these components enable the rider to slow down or stop effectively.

- Suspension: Ensures a smooth ride by absorbing shocks from uneven surfaces.

- Electrical System: Powers lights, signals, and the ignition system, essential for visibility and safety.

Basic Operation Principles

- Fuel Combustion: The engine mixes fuel and air, igniting the mixture to create power.

- Power Transmission: The generated power is transmitted through the transmission system to the wheels.

- Stopping Mechanism: When brakes are applied, friction is created, slowing down the vehicle.

- Handling Control: Steering and balancing are critical for maneuvering effectively, especially at low speeds.

Understanding these elements allows for better insights into the operation and care of small motorized vehicles, paving the way for improved performance and longevity.

Common Issues in 50cc Scooters

Many small two-wheeled vehicles face a range of challenges that can affect their performance and reliability. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth ride. Below are some frequent issues encountered by riders of lightweight motorized transports.

Engine Performance Problems

One of the primary concerns with these vehicles is engine performance. Riders often experience difficulty starting the engine or notice a decrease in power while accelerating. This can be attributed to several factors, including:

- Fuel System Issues: Clogged fuel filters or dirty carburetors can hinder the flow of fuel, leading to poor engine performance.

- Ignition System Failures: Worn spark plugs or faulty ignition coils can prevent the engine from firing properly.

Tire and Brake Concerns

Another area that requires attention is the condition of tires and braking systems. Common complications include:

- Insufficient Tire Pressure: Low tire pressure can cause uneven wear and affect handling.

- Brake System Issues: Worn brake pads or malfunctioning calipers can lead to decreased stopping power, posing a safety risk.

Addressing these issues promptly can greatly enhance the overall performance and safety of your lightweight vehicle.

Essential Tools for Scooter Repairs

When it comes to maintaining and fixing two-wheeled vehicles, having the right equipment is crucial. A well-equipped toolkit ensures that enthusiasts can address a variety of issues effectively and efficiently. From basic maintenance to more intricate adjustments, the following tools will serve as a foundation for any DIY enthusiast looking to enhance their mechanical skills.

Basic Hand Tools

Every mechanic should start with a set of fundamental hand tools. Wrenches, screwdrivers, and pliers are essential for tackling everyday tasks. A good-quality socket set allows for easier access to bolts in tight spaces. Additionally, a torque wrench is vital for ensuring that components are tightened to the manufacturer’s specifications, preventing future complications.

Specialized Equipment

In addition to standard tools, some specialized equipment can greatly enhance the repair process. A multimeter is invaluable for diagnosing electrical issues, while a compression tester can help assess engine performance. Keeping a quality floor jack or lift on hand simplifies work on the undercarriage, making it safer and more convenient to inspect or replace parts.

Step-by-Step Maintenance Guide

This section aims to provide a comprehensive approach to ensuring optimal performance and longevity of your two-wheeled vehicle. Regular upkeep is essential not only for enhancing efficiency but also for promoting safety during rides. Following a systematic process can prevent common issues and contribute to a smoother experience.

1. Check the Oil Level

Start by inspecting the oil level regularly. Use the dipstick to assess whether it meets the required mark. If it’s low, add the appropriate type of lubricant recommended for your model. Regular oil changes are crucial for keeping the engine running smoothly.

2. Inspect the Tires

Maintaining proper tire pressure is vital. Use a pressure gauge to check if the tires are inflated to the recommended specifications. Look for any signs of wear or damage, such as cracks or bulges, and replace tires if necessary.

3. Clean the Air Filter

A clean air filter ensures optimal airflow to the engine. Remove the filter and inspect it for dirt and debris. If it’s clogged, clean it with compressed air or replace it to maintain performance.

4. Examine the Brakes

Brakes are crucial for safety. Inspect both the front and rear brakes for wear. Check the brake pads and fluid levels, and replace them if they are below the recommended thickness or if the fluid is contaminated.

5. Battery Maintenance

Regularly check the battery terminals for corrosion and ensure that connections are tight. Test the battery voltage and clean any dirt or grime to prevent poor electrical contact.

6. Clean and Lubricate the Chain

A well-lubricated chain improves performance and extends its life. Clean the chain thoroughly, then apply a suitable lubricant while rotating the wheel to ensure even coverage.

7. Final Checks

Before each ride, do a quick inspection. Ensure all lights function properly, mirrors are adjusted, and the overall condition is satisfactory. This final check can prevent potential issues on the road.

How to Troubleshoot Engine Problems

Tackling issues related to engine performance can seem daunting, but with a methodical approach, many common challenges can be diagnosed and resolved efficiently. This guide provides a structured way to identify and address potential malfunctions, ensuring optimal operation.

Initial Checks

- Ensure fuel levels are adequate and the fuel is fresh.

- Inspect the ignition system for signs of wear or damage.

- Examine the air filter for cleanliness and proper airflow.

- Check all electrical connections for corrosion or loose wires.

Common Symptoms and Solutions

- Engine Won’t Start:

- Verify that the kill switch is in the correct position.

- Test the battery voltage; recharge or replace if necessary.

- Unusual Noises:

- Identify the source of the noise; it could indicate loose components.

- Inspect for signs of internal damage if noises are persistent.

- Poor Performance:

- Examine the fuel system for blockages or leaks.

- Check the tuning and adjust as needed for optimal efficiency.

Replacing the Spark Plug Safely

Ensuring optimal performance of your vehicle requires occasional maintenance, and one crucial aspect is the replacement of the ignition component. This task, while straightforward, demands attention to safety and precision. Properly handling this element can significantly enhance engine efficiency and longevity.

Before beginning the process, gather the necessary tools, including a socket wrench and a new ignition component. Always prioritize safety by wearing gloves and goggles to protect against debris and potential hazards. Disconnect the battery to prevent any accidental electrical discharge during the replacement.

To start, locate the ignition component within the engine compartment. Carefully remove the old component using the socket wrench, turning it counterclockwise. Be mindful of any residual debris that may fall into the engine. Once removed, inspect the old component for wear and damage, as this can provide insight into engine performance issues.

Insert the new ignition component, ensuring it is properly aligned. Tighten it gently, being cautious not to overtighten, as this could cause damage to the threads. After securing the new component, reconnect the battery and start the engine to check for proper functionality. Listen for any unusual sounds and monitor the performance to ensure everything is working smoothly.

In conclusion, replacing the ignition component is a vital task that, when executed with care, contributes to the overall efficiency of your vehicle. Following these safety guidelines will help you complete the job successfully and confidently.

Brake System Inspection and Repair

Ensuring the functionality of the braking mechanism is essential for safe navigation. This section delves into the evaluation and maintenance procedures necessary to keep this critical system in optimal condition. Regular checks and timely interventions can prevent major issues and enhance overall performance.

Components to Examine

Key elements of the braking system should be scrutinized to identify wear or damage. Regular inspections can help in early detection of potential failures. Below are the primary components to assess:

| Component | Inspection Focus | Common Issues |

|---|---|---|

| Brake Pads | Thickness, wear patterns | Uneven wear, low thickness |

| Brake Discs | Surface condition, warping | Scoring, overheating |

| Brake Lines | Leaks, cracks | Fluid leaks, brittleness |

| Master Cylinder | Fluid level, function | Fluid contamination, malfunction |

Maintenance Steps

Routine upkeep is vital to ensure the braking system operates efficiently. Following these maintenance steps can prolong the lifespan of components:

1. Regularly check and replace worn brake pads.

2. Inspect brake discs for surface damage and replace if necessary.

3. Examine brake lines for integrity and replace any damaged sections.

4. Flush and replace brake fluid according to the manufacturer’s guidelines.

Battery Maintenance Tips for Scooters

Proper upkeep of the power source is essential for ensuring reliable performance and longevity. Following a few straightforward practices can significantly enhance the lifespan and efficiency of your energy provider. Here are some useful guidelines to keep in mind.

Regularly inspect connections to ensure they are clean and secure. Corrosion can hinder performance, so cleaning terminals with a mixture of baking soda and water can be beneficial. After cleaning, make sure to dry the terminals thoroughly.

Check the fluid levels if you have a maintenance-required type. Keeping the electrolyte levels at the recommended height helps prevent damage and ensures optimal functioning. Always use distilled water for topping up.

Avoid deep discharges whenever possible, as this can shorten the lifespan of the unit. It’s advisable to recharge before it drops below a certain percentage. Additionally, try to maintain a consistent charging routine, ideally using a smart charger that prevents overcharging.

Store the energy unit in a cool, dry place when not in use for extended periods. Extreme temperatures can negatively affect performance, so consider using a cover to protect against dust and moisture.

Finally, performing periodic load tests can help assess the condition of the power source. This proactive approach allows you to identify issues before they become significant problems, ensuring that your vehicle remains dependable.

Adjusting the Carburetor Settings

Proper tuning of the fuel-air mixture is crucial for optimal performance and efficiency of your vehicle. This process ensures smooth operation and can enhance acceleration and fuel economy. A well-adjusted unit minimizes emissions and prolongs engine life, making it a key aspect of maintenance.

Understanding the Components

Before diving into adjustments, it’s essential to familiarize yourself with the main parts involved:

- Idle Mixture Screw: Controls the air-fuel mixture at low speeds.

- Idle Speed Screw: Regulates the engine’s RPM when at rest.

- Main Jet: Influences fuel flow during higher speed operation.

Adjustment Steps

- Start the engine and let it warm up for a few minutes.

- Locate the idle mixture screw, usually found on the side of the carburetor.

- Turn the screw slowly clockwise until it lightly seats, then back it off about 1.5 turns.

- Adjust the idle speed screw to set the desired RPM, typically between 1,500 to 2,000.

- Perform a test ride and observe the engine’s response. If necessary, repeat the adjustments until the desired performance is achieved.

Regular checks and fine-tuning of these settings can lead to significant improvements in your vehicle’s operation.

Fluid Changes: Oil and Coolant

Maintaining optimal performance and longevity of your two-wheeled vehicle involves regular attention to its vital fluids. Ensuring that lubricants and cooling agents are fresh and at the correct levels is crucial for smooth operation and preventing overheating. This section will guide you through the process of replacing these essential liquids.

First, let’s focus on the lubricant. Over time, engine oil degrades due to heat and contaminants, leading to reduced efficiency and potential damage. Regularly checking and replacing the oil will help maintain engine integrity and performance. It’s advisable to follow the manufacturer’s recommendations for oil type and change intervals.

Next, coolant plays a vital role in regulating engine temperature. Like oil, coolant can become less effective over time and may need to be replaced to prevent overheating and corrosion. Regular inspection of coolant levels and condition will ensure that the cooling system functions properly, safeguarding against potential failures.

By prioritizing these fluid changes, you not only enhance the reliability of your vehicle but also contribute to a smoother riding experience. Adhering to a routine maintenance schedule will ultimately save you from costly repairs down the line.

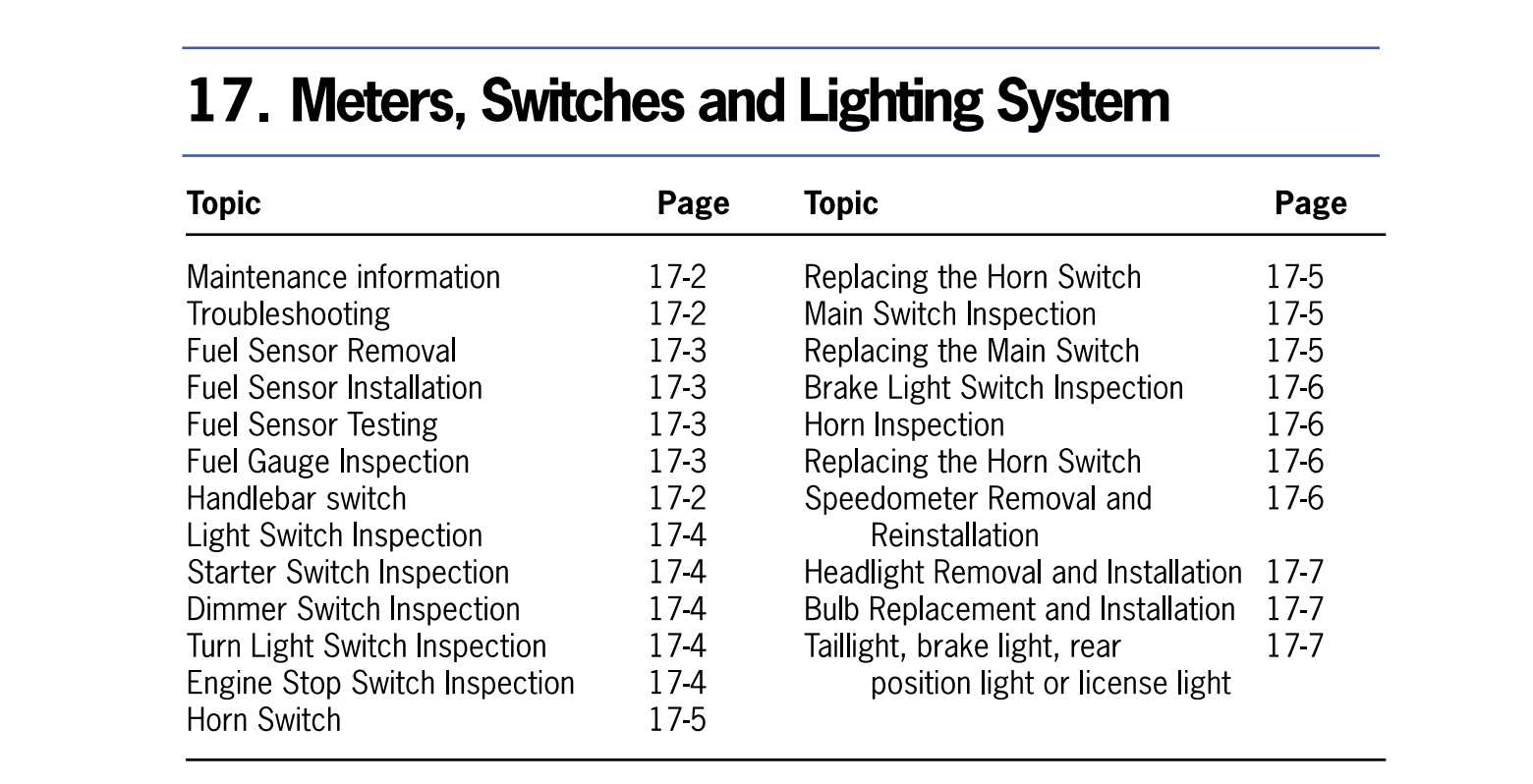

Electrical System Diagnostics Explained

Understanding the intricacies of an electrical system is crucial for maintaining optimal performance. This section delves into the essential methodologies and tools necessary for effectively diagnosing electrical issues, ensuring a smoother troubleshooting experience.

Common problems often stem from various components, requiring a structured approach to identify and resolve them. Here are key elements to consider:

- Power Source: Assessing the battery’s condition and connections is fundamental.

- Cables and Connections: Inspecting for wear, corrosion, or loose fittings can prevent potential failures.

- Grounding: Ensuring proper grounding is vital for electrical stability and safety.

- Fuses and Relays: Checking these components can reveal interruptions in electrical flow.

- Electrical Components: Evaluating switches, lights, and sensors for functionality helps pinpoint issues.

Utilizing a multimeter can provide valuable insights into voltage, resistance, and current flow. Here’s a suggested process for effective diagnostics:

- Start with a visual inspection of all wiring and connections.

- Test the battery voltage and condition.

- Use a multimeter to check individual components.

- Document any irregularities for further analysis.

- Replace or repair faulty parts as necessary.

By following these guidelines, one can systematically address and resolve electrical issues, leading to enhanced reliability and performance.

Upgrading Parts for Improved Performance

Enhancing the functionality of your two-wheeled vehicle can significantly elevate your riding experience. By substituting stock components with higher-quality alternatives, you can achieve better acceleration, increased speed, and improved overall efficiency. These upgrades not only contribute to enhanced performance but also help in prolonging the lifespan of your machine.

One of the first areas to consider for enhancement is the exhaust system. A performance exhaust can reduce back pressure, allowing for a more efficient flow of gases, which translates to better engine performance. Upgrading to a lighter, high-flow model can also contribute to weight reduction, aiding in agility.

Another crucial component is the carburetor. Installing a larger carburetor can provide a more optimal air-fuel mixture, resulting in improved combustion and power output. Ensure that any adjustments to the carburetor are matched with other upgrades to maintain balance in performance.

Furthermore, upgrading the transmission components, such as the variator and clutch, can enhance acceleration and responsiveness. High-performance variants are designed to engage more effectively, ensuring that the power is transferred smoothly to the wheels.

Lastly, don’t overlook the importance of tires. Investing in high-quality rubber can improve traction and handling, making your ride safer and more enjoyable. Performance tires are designed to provide better grip and stability, especially during cornering and high-speed maneuvers.

By strategically upgrading these parts, you can transform your vehicle into a more powerful and efficient machine, ensuring a thrilling and enjoyable ride every time.

Preventative Care for Longevity

Ensuring the extended lifespan of your two-wheeled vehicle requires consistent attention and proactive measures. By implementing a routine maintenance schedule and addressing minor issues before they escalate, you can significantly enhance performance and reliability. This section will outline key practices to maintain your ride in optimal condition.

Regular Maintenance Checks

Conducting periodic inspections is essential. Focus on the following areas:

- Fluid Levels: Regularly check and top off oil, brake fluid, and coolant to prevent overheating and ensure smooth operation.

- Tire Condition: Inspect tire pressure and tread depth to enhance traction and avoid blowouts.

- Brake System: Examine brake pads and discs for wear, replacing them as necessary to maintain stopping power.

- Battery Health: Keep the battery clean and ensure connections are secure to avoid electrical issues.

Seasonal Care Tips

Adjusting your maintenance routine with the changing seasons can further support longevity:

- Winter Preparation: Store your vehicle in a dry place and consider using a battery maintainer to prevent discharge.

- Spring Checkup: After months of inactivity, perform a thorough inspection and tune-up to address any potential issues.

- Summer Readiness: Monitor cooling systems closely during hot months to avoid overheating.

By following these preventative care practices, you can ensure your vehicle remains dependable and enjoyable for many journeys ahead.