In the realm of automotive engineering, the intricacies of power transfer systems play a pivotal role in vehicle performance. Understanding the functionality and maintenance of these systems can significantly enhance longevity and efficiency. This section delves into the essential aspects of managing and troubleshooting these vital components.

The operation of gear shifting systems is crucial for smooth driving experiences. These mechanisms not only influence acceleration and fuel efficiency but also contribute to overall driving pleasure. Regular oversight and timely interventions can prevent common issues, ensuring seamless operation for years to come.

By exploring various techniques and best practices, one can gain valuable insights into the nuances of upkeep and service. This guide aims to provide practical advice and in-depth knowledge, empowering enthusiasts and professionals alike to tackle challenges effectively and maintain optimal functionality.

This section provides a comprehensive understanding of a specific type of vehicle power delivery system that enhances fuel efficiency and smooth driving experience. This innovative approach uses a unique mechanism that allows for an infinite range of gear ratios, ensuring optimal performance under varying driving conditions.

Key Components of the System

The core elements of this system include various components that work harmoniously to facilitate seamless power transfer. These parts are essential for ensuring that the vehicle operates efficiently and reliably.

| Component | Function |

|---|---|

| Belt | Transfers power between the pulleys. |

| Pulleys | Adjust gear ratios dynamically. |

| Control Module | Regulates system performance. |

Benefits of the Technology

Utilizing this advanced system presents numerous advantages, including improved fuel economy, enhanced driving comfort, and reduced mechanical wear. These benefits make it a preferred choice for modern vehicles seeking to balance performance and efficiency.

Common Issues in CVT Systems

Continuously variable systems, known for their smooth acceleration and efficiency, can encounter various challenges over time. Understanding these common problems is essential for maintaining optimal performance and ensuring longevity.

Frequent Problems

- Unusual Noises: Drivers may notice grinding or whining sounds, often indicating internal wear or component malfunction.

- Slipping: A sensation of the vehicle losing power during acceleration can signal issues with the internal mechanism or fluid levels.

- Overheating: Excessive heat can cause performance drops and lead to further damage if not addressed promptly.

- Fluid Leaks: Discovering fluid beneath the vehicle can indicate a leak in the system, which should be inspected immediately.

- Warning Lights: The appearance of dashboard alerts often suggests that a malfunction is present, requiring further investigation.

Preventive Measures

- Regular Maintenance: Scheduled inspections can help identify and address potential issues before they escalate.

- Fluid Changes: Keeping the fluid at appropriate levels and replacing it according to guidelines can prevent many problems.

- Driving Habits: Smooth acceleration and braking can minimize stress on the system and prolong its life.

Tools Required for Repairs

When addressing issues in complex automotive systems, having the right instruments is crucial for achieving effective results. Each procedure demands specific tools to ensure precision and efficiency, which ultimately leads to successful outcomes in maintenance tasks.

First and foremost, a reliable set of wrenches and sockets is essential. These tools facilitate the loosening and tightening of fasteners, allowing for easy access to various components. Additionally, torque wrenches are necessary to ensure that connections are secured to the manufacturer’s specifications.

Moreover, specialized gauges and measurement devices help in assessing fluid levels and pressures, ensuring optimal performance. A quality hydraulic lift or jack is also indispensable, providing the necessary clearance for working underneath the vehicle safely.

Finally, a comprehensive toolkit that includes pliers, screwdrivers, and picks will aid in handling smaller parts effectively. By equipping oneself with these essential instruments, one can approach maintenance tasks with confidence and skill.

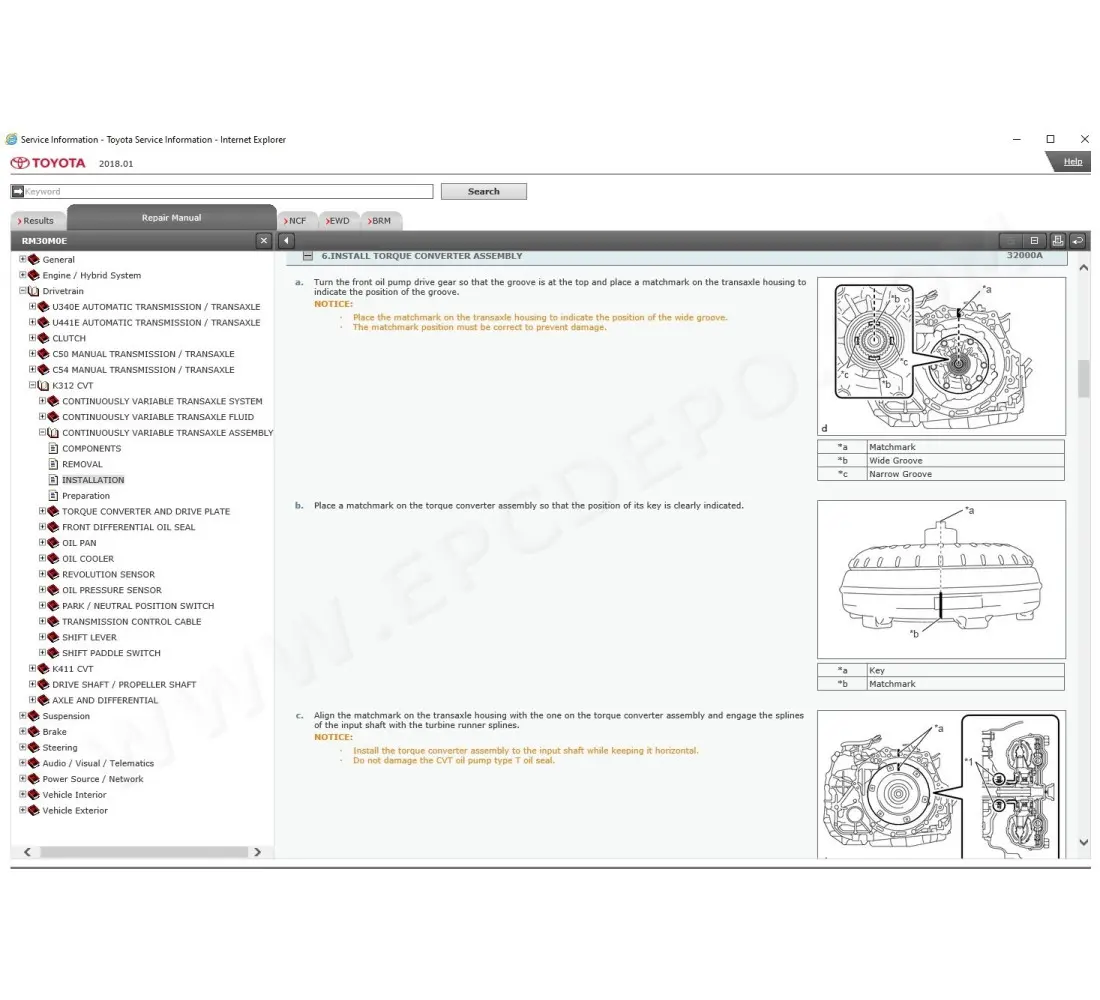

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with a specific type of vehicle power transfer system. Following a systematic method ensures that each aspect of the process is covered, leading to effective results.

Preparation Phase

- Gather necessary tools and equipment.

- Ensure a clean workspace to prevent contamination.

- Review safety protocols to mitigate risks during the procedure.

Disassembly and Inspection

- Carefully detach the components, noting their arrangement.

- Inspect each part for signs of wear or damage.

- Document any irregularities to guide future decisions.

Fluid Maintenance and Replacement

Proper upkeep of lubricating substances is crucial for ensuring optimal performance and longevity of a vehicle’s internal mechanisms. Regular monitoring and timely exchanges of these fluids help prevent wear and tear, ensuring that components function smoothly and efficiently. This section focuses on the importance of maintaining fluid integrity and offers guidelines for effective replacement practices.

Importance of Regular Checks

Routine inspections of fluid levels and conditions are essential for identifying potential issues early. Any signs of discoloration, contamination, or irregular levels should prompt immediate action. Keeping these fluids in good condition not only enhances operational efficiency but also contributes to overall vehicle reliability.

Replacement Procedures

When it comes time to replace the fluids, following manufacturer guidelines is paramount. Ensure that the appropriate type of lubricant is used and that all procedures are executed meticulously. This may involve draining old fluids, flushing systems, and filling with fresh substances. Regularly scheduled replacements will help maintain optimal function and prevent costly damages in the future.

Troubleshooting CVT Problems

Identifying issues with automatic gear systems can often feel overwhelming. However, understanding common signs of malfunction and systematic approaches can simplify the diagnosis process. Early detection and resolution of these problems can enhance performance and prolong the lifespan of the vehicle.

Common Symptoms of Issues

- Unusual noises during operation, such as grinding or whining

- Unexpected jerking or hesitation while accelerating

- Delayed response when shifting gears

- Fluctuations in engine RPMs

- Warning lights on the dashboard indicating potential faults

Diagnostic Steps to Take

- Check fluid levels: Ensure that the operational fluids are at the appropriate levels.

- Inspect for leaks: Look under the vehicle for any signs of fluid leakage.

- Examine connections: Ensure all cables and connections are secure and free from corrosion.

- Run a diagnostic test: Utilize specialized tools to read error codes from the vehicle’s computer.

- Consult a professional: If issues persist, seeking the expertise of a qualified technician is advisable.

Safety Precautions During Repairs

When performing maintenance on automotive systems, ensuring safety is paramount. Adopting appropriate measures can significantly reduce the risk of accidents and injuries. It is essential to follow guidelines that safeguard both the technician and the vehicle during the process.

Before commencing any work, ensure that the vehicle is parked on a flat surface and secured with wheel chocks. Disconnecting the battery is a crucial step to prevent electrical hazards. Additionally, utilizing personal protective equipment such as gloves and goggles can provide an extra layer of safety.

| Precaution | Description |

|---|---|

| Work Area | Maintain a clean and organized workspace to prevent tripping hazards. |

| Tools | Ensure all tools are in good condition and suitable for the task to avoid accidents. |

| Fluid Handling | Use proper containers for fluid disposal and avoid skin contact with hazardous materials. |

| Support | Use appropriate supports when working under the vehicle to prevent falls. |

By adhering to these essential safety practices, the likelihood of mishaps can be minimized, fostering a safer working environment for all involved.

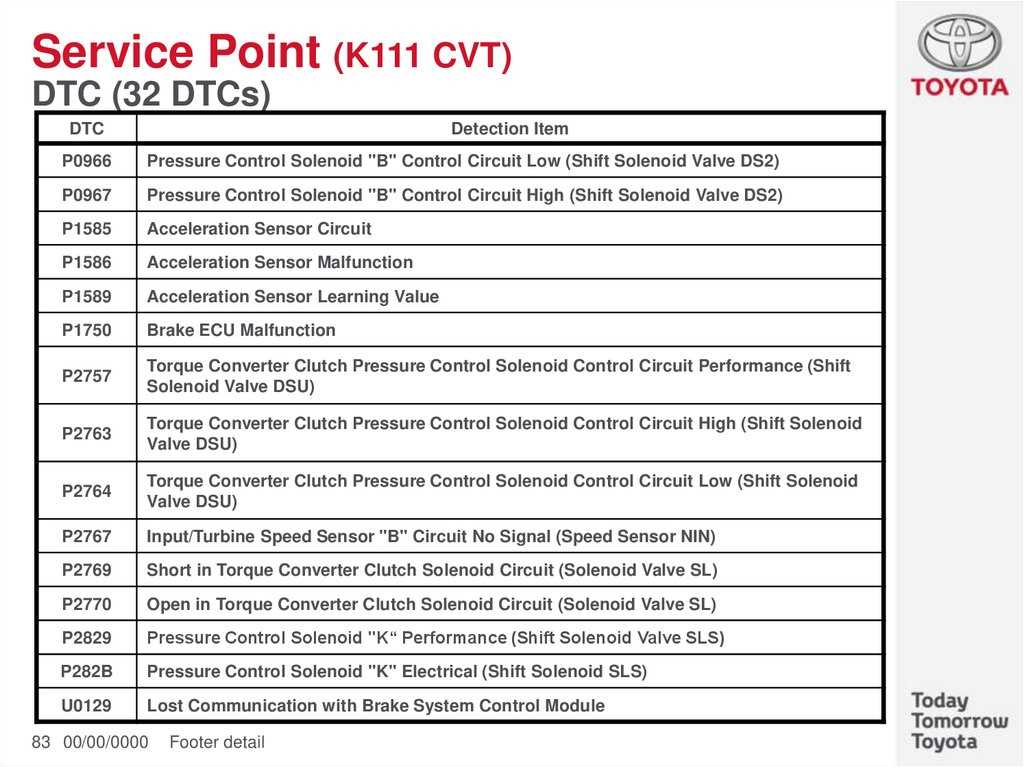

Understanding Diagnostic Codes

Diagnostic codes play a crucial role in the identification and troubleshooting of various system issues within vehicles. These codes, generated by onboard computers, provide insights into malfunctions and operational anomalies, helping technicians determine the underlying causes of performance problems.

How Diagnostic Codes Are Generated

When a vehicle’s systems detect irregularities, they trigger the onboard diagnostic system to record specific codes. These codes correspond to predefined issues, allowing technicians to quickly assess where attention is needed. The generation of these codes can be influenced by various factors, including sensor readings and system performance metrics.

Interpreting Diagnostic Codes

Once diagnostic codes are retrieved, they must be accurately interpreted to inform repair decisions. Each code corresponds to a specific issue, and understanding the associated meaning is essential for effective resolution. Below is a table that outlines common codes and their potential implications:

| Code | Description |

|---|---|

| P0101 | Mass or Volume Air Flow Circuit Range/Performance Problem |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) |

| P0300 | Random/Multiple Cylinder Misfire Detected |

| P0171 | System Too Lean (Bank 1) |

Performance Enhancements for CVTs

Improving the efficiency and responsiveness of automatic gear systems is a crucial goal for many vehicle enthusiasts. Various modifications can significantly enhance the performance of these systems, leading to smoother acceleration and improved overall driving experience.

Key Modifications

- Fluid Upgrades: Utilizing high-performance fluids can reduce friction and improve the heat dissipation of the system, enhancing responsiveness.

- Software Tuning: Adjusting the electronic control unit settings can optimize the shifting patterns and throttle response, resulting in a more engaging driving experience.

- Aftermarket Components: Installing upgraded pulleys and belts can lead to increased durability and efficiency, allowing for better power transfer.

Benefits of Enhancements

- Improved acceleration and deceleration response.

- Enhanced fuel efficiency through better energy management.

- Increased longevity of components due to reduced wear.

By implementing these enhancements, vehicle owners can achieve a more dynamic and enjoyable driving experience while ensuring the longevity of their automatic gear systems.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of advanced vehicle systems. Many users seek guidance on various aspects, from routine upkeep to specific issues that may arise during operation.

What should I do if I experience unusual noises?

It is essential to monitor any strange sounds while driving. Such noises can indicate underlying problems that may require immediate attention.

How often should I check fluid levels?

Regularly checking fluid levels is crucial for optimal performance. It is recommended to inspect these levels periodically, as specified in the vehicle’s guidelines.

What are the signs of malfunction?

Common indicators of a potential malfunction include warning lights on the dashboard, a decline in performance, or difficulty in acceleration. Addressing these symptoms promptly can help prevent further complications.

Can I perform maintenance tasks myself?

Many basic maintenance tasks can be completed by the owner with the right tools and knowledge. However, complex issues may require professional assistance for safe and effective resolution.