Maintaining a vehicle in optimal condition is essential for ensuring safety, performance, and longevity. An understanding of essential repair processes and routine check-ups can empower owners to tackle common issues confidently. This resource aims to provide comprehensive insights into the intricacies of automotive care, focusing on models from a specific era known for their reliability and efficiency.

Knowledge is power when it comes to addressing mechanical challenges. Familiarity with fundamental components, common malfunctions, and best practices can significantly enhance the ownership experience. This guide serves as a valuable tool for enthusiasts and everyday drivers alike, offering practical tips and procedures to navigate repairs and maintenance effectively.

By delving into detailed instructions and diagnostic approaches, readers can cultivate a deeper appreciation for their vehicle’s engineering. From minor adjustments to more complex tasks, this compilation is designed to assist individuals in becoming more self-sufficient while fostering a genuine connection with their automotive investment.

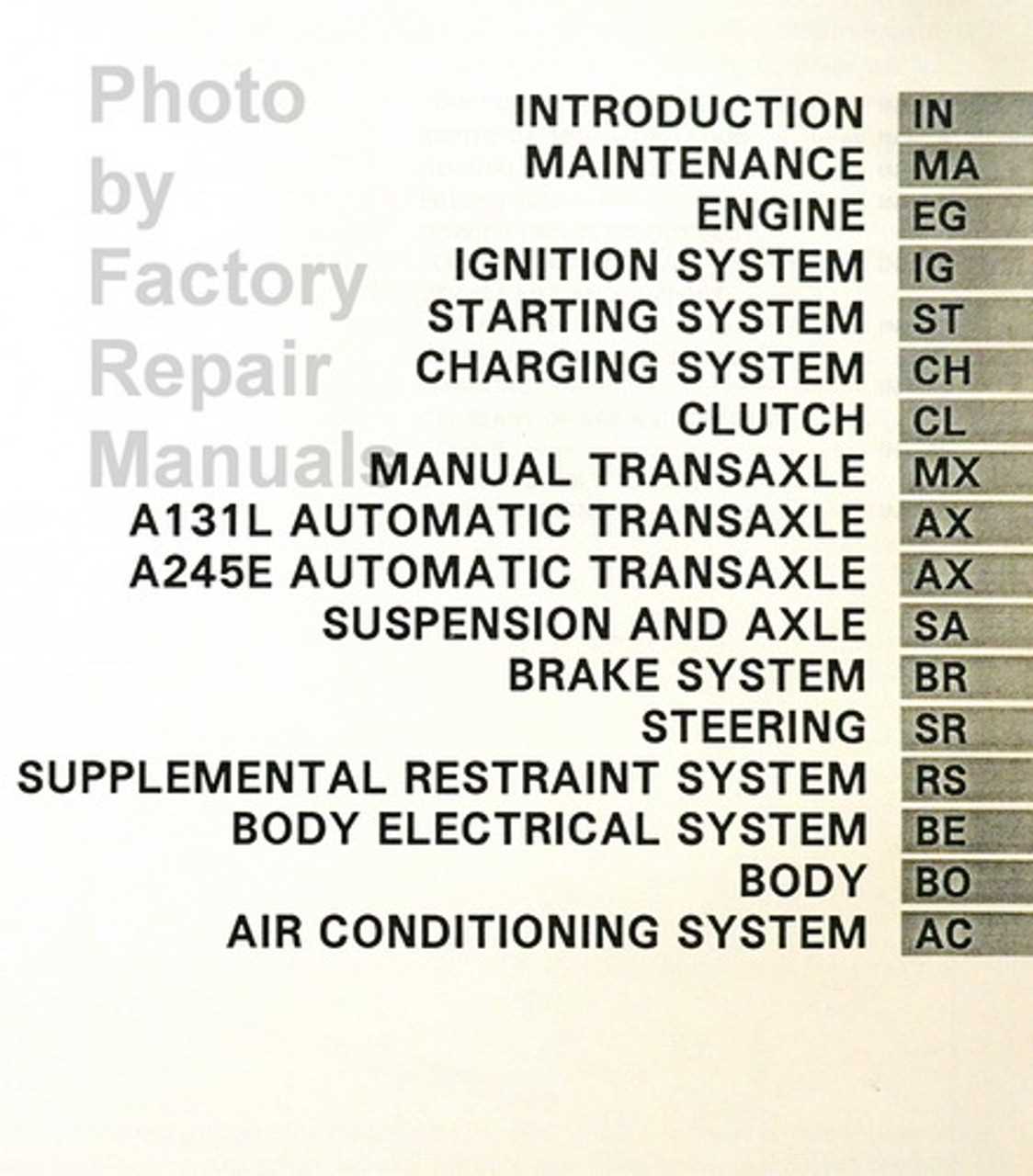

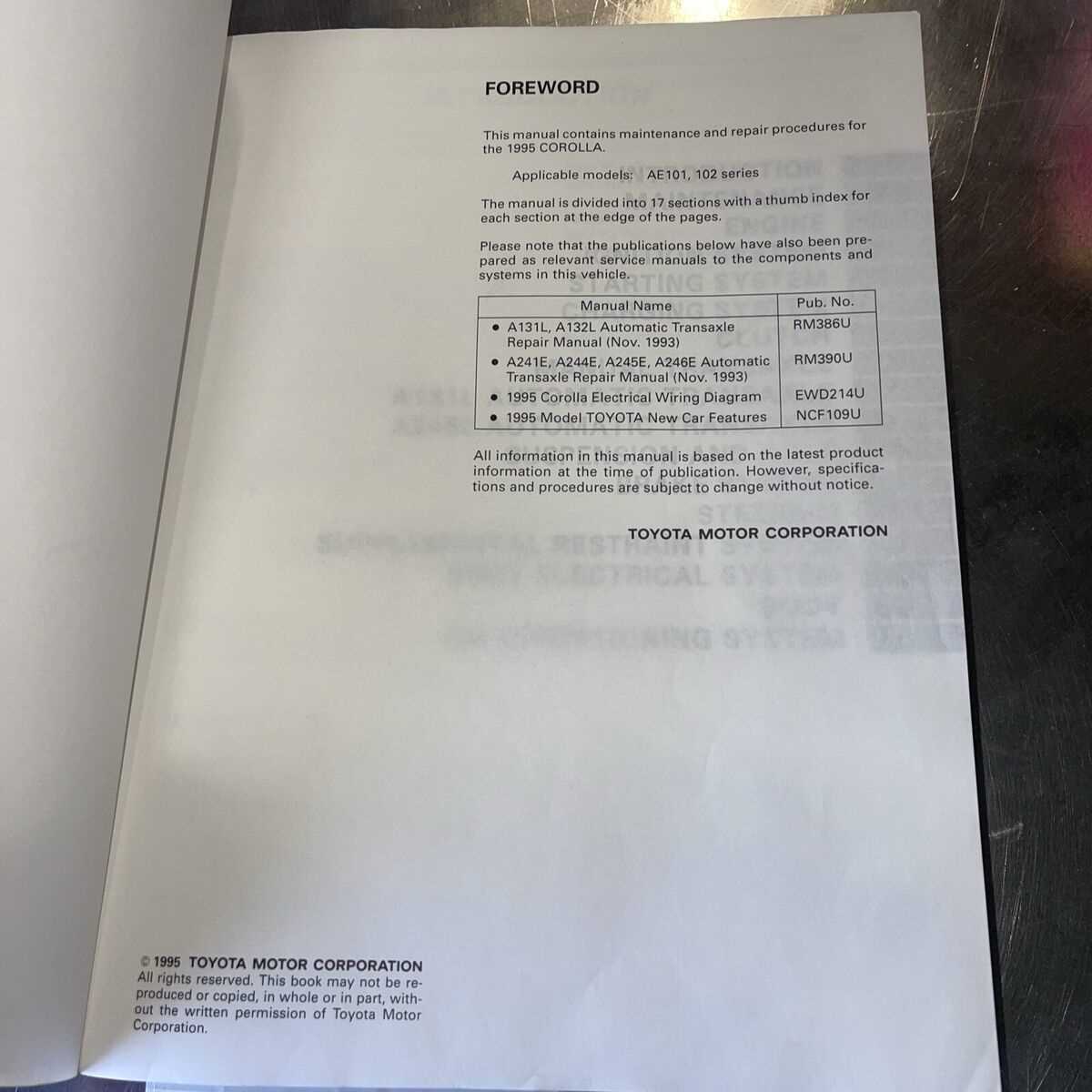

Toyota Corolla 1995 Overview

This section provides a comprehensive look at a compact vehicle renowned for its reliability and efficiency. Launched in the mid-1990s, this model has established itself as a favorite among drivers seeking a balance between performance and practicality. Its design and engineering focus on delivering a comfortable ride, making it a popular choice for daily commuting and long journeys alike.

Key Features

The vehicle is equipped with a range of features that enhance both safety and convenience. With an emphasis on user-friendly controls and a spacious interior, it caters to the needs of families and individual drivers. Fuel efficiency is a significant highlight, appealing to those mindful of their environmental impact and fuel costs.

Performance and Handling

Performance-wise, this model excels with a well-tuned suspension system that provides a smooth driving experience. The engine options available during this period offer a reliable blend of power and efficiency, ensuring that it remains agile in various driving conditions. Durability and longevity are hallmarks of this vehicle, making it a wise investment for owners seeking a long-lasting mode of transport.

Common Issues in 1995 Models

Vehicles from this era often exhibit a range of challenges that owners may encounter. Understanding these common problems can aid in maintenance and enhance longevity. Below are frequent issues reported by drivers of models produced in this year.

Electrical Problems: One prevalent issue relates to the electrical system, where components such as lights and window regulators may fail unexpectedly. Owners should check wiring connections and fuses regularly to prevent malfunctions.

Engine Performance: Some units may experience a decline in performance, often due to wear on parts like spark plugs or filters. Regular inspection and timely replacement of these components can improve efficiency and driveability.

Suspension Wear: The suspension system is another area that may show signs of wear over time. Drivers might notice unusual noises or handling issues, indicating the need for inspection and potential replacement of struts or bushings.

Transmission Issues: Gear shifting problems can arise, leading to rough transitions or slipping. It’s advisable to monitor fluid levels and seek immediate assistance if any irregularities are detected.

Being aware of these typical challenges can empower owners to address them proactively, ensuring a smoother driving experience for years to come.

Essential Tools for Repairs

When it comes to maintaining and fixing your vehicle, having the right equipment is crucial for achieving effective results. A well-equipped workspace not only enhances efficiency but also ensures safety during various tasks. This section highlights the must-have instruments that every automotive enthusiast should consider for successful upkeep.

Basic Hand Tools

To start, a selection of fundamental hand tools is essential. Wrenches, screwdrivers, and pliers form the backbone of any toolkit. These items allow you to tackle a wide range of tasks, from tightening loose components to replacing worn parts. Ensure you have both metric and standard sizes to cover all bases.

Specialized Equipment

In addition to basic tools, certain specialized equipment can significantly simplify complex tasks. Diagnostic scanners are invaluable for identifying issues, while jack stands provide safe elevation for undercarriage access. Investing in a good torque wrench ensures that fasteners are secured to the correct specifications, preventing damage and enhancing longevity.

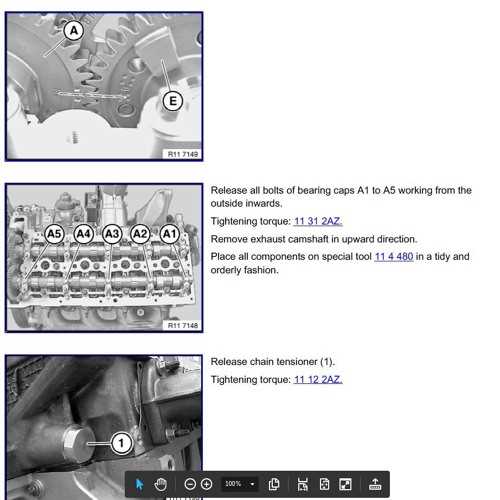

Engine Maintenance Procedures

Regular upkeep of the engine is essential for ensuring optimal performance and longevity. This section outlines the key practices that should be followed to maintain the engine effectively, thereby preventing potential issues and enhancing overall reliability.

- Oil Changes: Frequent oil changes are crucial for keeping the engine lubricated and free from contaminants. It is recommended to:

- Check oil levels monthly.

- Change the oil every 3,000 to 5,000 miles.

- Use the appropriate oil type as specified in the guidelines.

- Air Filter Inspection: The air filter plays a vital role in maintaining proper airflow to the engine. Steps include:

- Inspecting the air filter every 15,000 miles.

- Replacing a clogged filter to enhance performance.

- Cooling System Maintenance: The cooling system prevents overheating and maintains optimal engine temperature. Important tasks involve:

- Checking coolant levels regularly.

- Flushing the cooling system every two years.

- Inspecting hoses and connections for leaks or wear.

- Spark Plug Replacement: Spark plugs are vital for ignition and engine efficiency. Recommendations include:

- Replacing spark plugs every 30,000 miles.

- Inspecting the condition of the plugs during routine checks.

- Belt and Hose Inspection: Belts and hoses are critical for engine operation. Routine checks should cover:

- Examining belts for cracks or wear.

- Checking hoses for leaks and proper connections.

- Replacing any damaged components promptly.

lessCopy code

Following these maintenance procedures can greatly enhance engine performance and reliability, ultimately extending its service life. Regular inspections and timely replacements are key to avoiding costly repairs in the future.

Transmission Troubleshooting Tips

When facing issues with the gearbox, it’s essential to identify the symptoms and understand potential causes. This section provides practical advice for diagnosing common problems that may arise, helping to ensure smooth operation and longevity of the transmission system.

- Check Fluid Levels:

Ensure that the transmission fluid is at the correct level. Low fluid can lead to shifting problems and overheating.

- Inspect Fluid Condition:

Examine the fluid for discoloration or a burnt smell. Contaminated fluid can affect performance and may indicate internal damage.

- Listen for Unusual Noises:

Popping, grinding, or whining sounds can signal mechanical issues. Pay attention to noises during shifting or acceleration.

- Examine the Gear Shifter:

If the gear lever feels loose or sticks, it may need adjustment or inspection for wear.

- Check for Warning Lights:

Modern vehicles are equipped with warning systems. If a transmission warning light activates, consult the vehicle’s diagnostic system.

- Test Drive:

Conduct a test drive to identify when issues occur. Note any slipping, harsh shifting, or delay in response.

By systematically following these steps, you can narrow down potential issues and determine whether a professional evaluation is necessary. Addressing problems early can prevent further damage and costly repairs.

Brake System Repair Guide

The brake system is a critical component of vehicle safety, ensuring that the automobile can stop effectively and reliably. Proper maintenance and timely intervention can prevent accidents and extend the lifespan of the braking components. This section aims to provide a comprehensive overview of the essential practices for maintaining and fixing the braking system.

Understanding Components

Familiarity with the main parts of the braking mechanism is crucial. Key elements include brake pads, rotors, calipers, and the hydraulic system. Each part plays a significant role in the overall functionality, and recognizing signs of wear or damage is vital for timely action.

Inspection Procedures

Regular inspection is necessary to ensure optimal performance. Begin by visually examining the brake pads for thickness and signs of uneven wear. Check the rotors for any grooves or discoloration. Additionally, inspect the calipers for leaks and functionality. It is recommended to perform these checks periodically, especially before long trips.

Maintenance Tips

Routine maintenance can greatly enhance braking efficiency. Keep the braking system clean by removing dust and debris, and ensure that all components are lubricated appropriately. Bleeding the hydraulic system periodically will help eliminate air pockets, maintaining optimal brake fluid pressure.

Common Issues and Solutions

Some frequent problems include squeaking noises, reduced responsiveness, and vibrations during braking. Squeaking often indicates worn brake pads, while vibrations may suggest warped rotors. Address these issues promptly to avoid further damage. Replacement of affected components should be done following the manufacturer’s specifications to ensure compatibility and safety.

Conclusion

Maintaining a well-functioning brake system is essential for safe driving. Regular checks, proper upkeep, and timely repairs are fundamental practices that every vehicle owner should adopt. By following the guidelines outlined here, one can ensure that their braking system remains reliable and effective.

Suspension and Steering Adjustments

Ensuring optimal performance of a vehicle’s suspension and steering systems is crucial for a smooth and safe driving experience. Proper adjustments can enhance handling, improve comfort, and prolong the lifespan of components. This section outlines essential considerations for tuning these systems effectively.

Suspension Tuning involves several key factors, including ride height, alignment, and damping characteristics. The ride height should be adjusted to meet specific driving needs, whether for off-road capability or on-road stability. Regular checks of wheel alignment can prevent uneven tire wear and maintain directional stability, while appropriate damping settings can help absorb shocks and improve overall comfort.

Steering Adjustments play a vital role in vehicle control. Ensuring proper steering wheel alignment is essential for responsive handling. Adjustments may involve recalibrating the steering rack and inspecting the tie rods for wear. Regular maintenance of power steering fluid levels and checking for leaks will also contribute to smoother steering operation.

In summary, keeping the suspension and steering systems in optimal condition requires regular assessments and adjustments. By addressing these components proactively, drivers can enhance their vehicle’s performance and ensure a safer driving experience.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of a vehicle is essential for maintaining optimal performance. This process involves identifying faults that may affect various components, ensuring that everything operates smoothly. A systematic approach is necessary to pinpoint problems accurately and efficiently.

Common Electrical Problems

Several issues may arise within a vehicle’s electrical system, including:

- Dead battery or poor connections

- Faulty alternator

- Blown fuses

- Malfunctioning sensors

- Wiring damage or corrosion

Diagnostic Steps

- Check the battery voltage and connections.

- Inspect the alternator output.

- Examine fuses for continuity and integrity.

- Test sensors using a multimeter.

- Look for visible signs of wear or damage in wiring.

By following these steps, one can effectively identify and resolve issues within the electrical system, enhancing reliability and functionality.

Interior and Exterior Care

Maintaining the aesthetics and functionality of your vehicle is essential for its longevity and appeal. Proper attention to both the interior and exterior can enhance your driving experience and preserve value over time. This section provides insights into effective practices for keeping your automobile looking and performing its best.

| Aspect | Care Tips |

|---|---|

| Exterior Wash | Regularly wash with mild soap to remove dirt and contaminants. Use a soft sponge to avoid scratches. |

| Waxing | Apply wax every few months to protect the paint and enhance shine. Choose a high-quality product for best results. |

| Interior Cleaning | Vacuum seats and carpets regularly. Use appropriate cleaners for different materials, ensuring they are safe for upholstery. |

| Dashboard Care | Wipe down surfaces with a damp cloth and use protectants to prevent fading from UV rays. |

| Windows | Clean with a glass cleaner to ensure visibility. Regularly check for cracks and chips. |

By following these guidelines, you can ensure that your vehicle remains in excellent condition, both inside and out. Regular maintenance not only improves appearance but also contributes to a safer and more enjoyable driving experience.

Replacement Parts and Recommendations

When maintaining an older vehicle, sourcing the right components is essential for ensuring longevity and performance. This section outlines key suggestions for replacement elements that enhance reliability and safety. Selecting quality parts not only supports optimal functionality but also helps prevent future issues, making your maintenance tasks smoother.

Essential Components to Consider

Focus on critical areas such as the engine, transmission, and braking system. Parts like oil filters, brake pads, and belts are fundamental to your vehicle’s operation. Opt for reputable brands or OEM (Original Equipment Manufacturer) parts that guarantee compatibility and durability. It’s advisable to consult local auto parts suppliers or online retailers that specialize in vintage vehicle components.

Tips for Selecting Quality Parts

Always check reviews and ratings before making a purchase. Engaging with communities or forums dedicated to your vehicle model can provide valuable insights and recommendations. Additionally, keep an eye out for warranties and return policies, as they offer extra assurance in case the part doesn’t meet expectations. Investing time in research will ultimately lead to better performance and reduced maintenance costs.

DIY vs. Professional Repairs

When it comes to fixing your vehicle, the choice between tackling the task yourself or seeking the help of a skilled technician can be daunting. Each approach offers its own set of advantages and disadvantages, which can significantly influence both the outcome and the overall experience of the repair process.

Do-It-Yourself (DIY) repairs can be rewarding, providing a sense of accomplishment and saving money in the process. With the right tools and a bit of research, many enthusiasts find they can handle basic maintenance tasks and minor issues effectively. However, this path requires a solid understanding of the vehicle’s mechanics, as well as the potential for unexpected complications that could arise during the job.

On the other hand, opting for professional assistance guarantees expertise and experience. Trained technicians possess specialized knowledge and tools that can address complex problems efficiently. While this route may involve higher costs, the peace of mind that comes from knowing a qualified individual is handling the repairs can be invaluable, especially for more intricate tasks.

Ultimately, the decision hinges on factors such as your skill level, the severity of the issue, and your budget. Weighing the pros and cons of both DIY and professional options will help you determine the best approach for your specific situation.

Safety Considerations When Repairing

Ensuring safety during vehicle maintenance is crucial for both the technician and the vehicle’s integrity. Adhering to specific precautions can prevent accidents and injuries, making the process more efficient.

- Always wear appropriate personal protective equipment, including gloves and goggles.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the battery before starting any electrical work to prevent shocks.

Additionally, consider the following measures:

- Use jack stands when lifting the vehicle; never rely solely on a hydraulic jack.

- Keep tools organized to minimize the risk of accidents.

- Be aware of sharp edges and hot surfaces during maintenance.

Taking these precautions can significantly enhance safety and ensure a smoother workflow.