Understanding the intricacies of vehicle maintenance is essential for ensuring longevity and optimal performance. This section provides insights into the fundamental aspects of maintaining a specific type of automotive power unit, focusing on various components and procedures that contribute to its efficiency. Proper knowledge of these elements can lead to enhanced driving experiences and increased reliability.

From identifying common issues to performing routine checks, having a structured approach to upkeep can significantly impact the lifespan of the machinery. This resource aims to empower enthusiasts and professionals alike with the necessary tools and techniques to address challenges effectively. Investing time in learning about the mechanisms involved can ultimately lead to better outcomes and a deeper appreciation for the craftsmanship behind these mechanical systems.

Whether you are a novice or an experienced individual, familiarity with the workings of this type of power unit will prove invaluable. Through careful attention to detail and systematic practices, you can ensure that the vehicle remains in top condition for years to come. Embracing the journey of maintenance not only fosters a sense of accomplishment but also contributes to safer and more efficient driving.

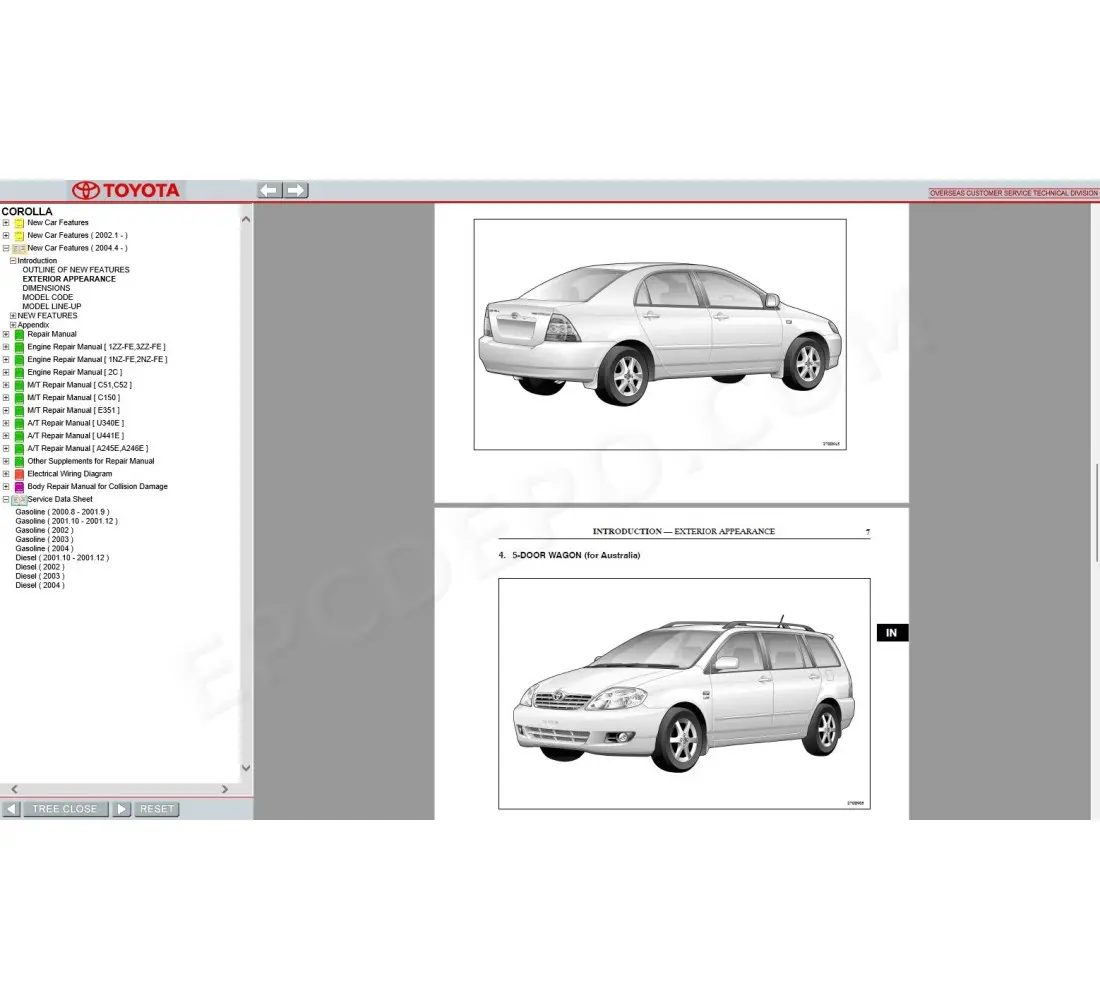

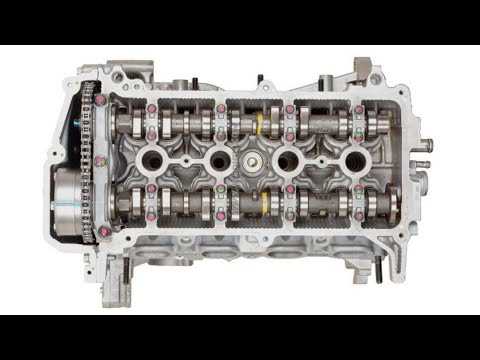

This section will provide an insightful exploration of a specific power unit, focusing on its fundamental characteristics and functionality. Understanding these elements is essential for effective maintenance and performance enhancement.

- Basic Structure: An outline of the primary components and their roles.

- Specifications: Key details such as displacement, configuration, and output.

- Operating Principles: Explanation of how the system generates power.

- Common Applications: Examples of vehicles that utilize this particular unit.

By grasping the overview, readers will be better equipped to delve into more specific topics related to its upkeep and enhancements.

Common Issues and Troubleshooting

This section addresses frequent complications encountered with a specific automotive power unit, along with effective strategies for resolving them. Understanding these common challenges can enhance the longevity and performance of the system.

Overheating Problems: One of the prevalent issues is excessive heat generation, which can lead to significant damage if not addressed promptly. Regularly checking the cooling system, including the radiator and coolant levels, is crucial to prevent overheating.

Fuel System Malfunctions: Inadequate fuel delivery can result in poor performance and decreased efficiency. Inspecting the fuel pump, filter, and injectors for blockages or wear can help maintain optimal function.

Electrical Failures: Electrical components may fail, leading to starting difficulties or intermittent operation. Ensuring that connections are secure and testing the battery and alternator can mitigate these issues.

Oil Leaks: Oil leaks are a common concern that can lead to decreased lubrication and potential damage. Regular inspections for signs of leakage around seals and gaskets are recommended to maintain proper function.

By staying vigilant and addressing these common complications, you can ensure the continued reliability of your automotive system.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance and servicing of any mechanical system. Proper tools not only enhance the efficiency of tasks but also ensure safety and precision during the process. Familiarity with these implements is essential for anyone looking to undertake this type of work.

Basic Hand Tools

Starting with basic hand tools, a good selection is necessary for various tasks. Common items include wrenches, screwdrivers, and pliers. Each tool serves a specific function and contributes to the overall effectiveness of the work. Ensuring that these tools are of high quality can significantly reduce the risk of damage to components.

Specialized Instruments

In addition to hand tools, specialized instruments may be required for more complex tasks. Tools such as torque wrenches and compression testers provide the precision needed for delicate adjustments and diagnostics. Investing in these specialized tools can facilitate accurate work, ultimately leading to better performance and longevity of the system.

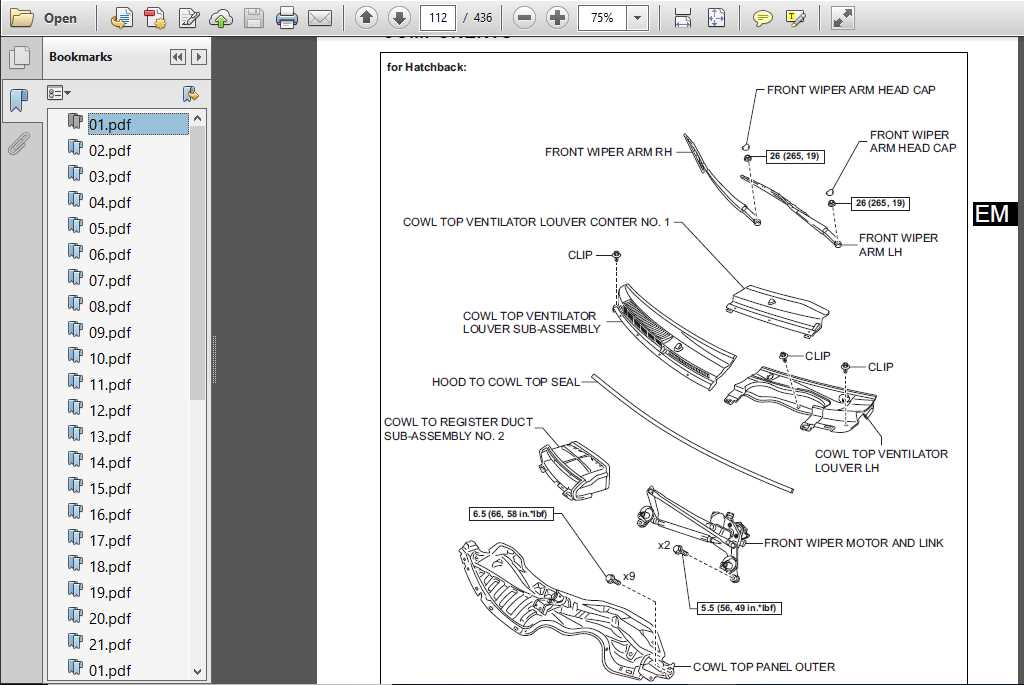

Step-by-Step Repair Procedures

Maintaining the functionality of your vehicle’s power source is essential for optimal performance. This section outlines a structured approach to addressing common issues, ensuring that each stage is clearly defined for effective execution.

Initial Assessment: Begin by examining the components thoroughly. Identify any visible signs of wear or damage that may require attention.

Disassembly Process: Carefully remove the outer casing and relevant parts to access the internal mechanisms. Keep track of all screws and components for easy reassembly.

Inspection and Cleaning: Once disassembled, inspect each part for corrosion or residue. Use appropriate cleaning agents to ensure all surfaces are free from dirt and contaminants.

Replacement of Worn Parts: If any components are found to be defective, replace them with new, high-quality alternatives. Ensure compatibility with existing parts for seamless operation.

Reassembly: Reverse the disassembly process. Ensure that each part is securely fastened and in its correct position to prevent future issues.

Final Testing: Once reassembled, conduct a thorough test to ensure everything is functioning correctly. Monitor performance closely to identify any lingering problems.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle’s power source involves consistent care and attention. By following a few fundamental practices, you can enhance performance and prevent potential issues that may arise over time.

Regularly checking fluid levels is crucial. Keep an eye on oil, coolant, and transmission fluid to ensure they are within recommended ranges. Changing these fluids at suggested intervals helps maintain optimal functionality.

Additionally, monitoring the condition of belts and hoses can prevent unexpected failures. Replacing worn components promptly can save you from more significant repairs down the line.

Pay attention to air filters as well; a clean filter promotes better airflow, which can improve efficiency. Regular inspections and timely replacements will help your system operate smoothly.

Finally, adhering to a schedule for routine inspections will allow you to catch potential problems early, ensuring that your machinery remains reliable for years to come.

Parts Replacement Guide

When it comes to maintaining optimal performance in your vehicle, understanding how to effectively replace components is essential. This section provides a comprehensive overview of the steps and considerations involved in swapping out parts to ensure longevity and reliability.

Before beginning any replacement process, it’s crucial to gather the necessary tools and familiarize yourself with the specific components involved. Here are the key elements to consider:

- Identification: Ensure you know the exact part number and specifications for the component you intend to replace.

- Tools: Prepare the appropriate tools for the job, which may include wrenches, screwdrivers, and pliers.

- Safety Precautions: Always wear safety gear and follow guidelines to protect yourself from potential hazards.

Follow these general steps for effective part replacement:

- Remove the Old Component: Carefully detach the faulty part, making sure not to damage surrounding areas.

- Inspect for Damage: Check the surrounding components for any signs of wear or damage that may need attention.

- Install the New Part: Position the new component in place, ensuring a secure fit.

- Test Functionality: Once installed, conduct a test to verify that everything operates as expected.

By adhering to these guidelines, you can successfully replace parts and contribute to the overall health of your vehicle. Regular maintenance and prompt replacement of worn components will enhance performance and extend the lifespan of your transportation.

Performance Upgrades to Consider

Enhancing the capabilities of your vehicle can significantly improve its overall performance and driving experience. There are several modifications that can be implemented to achieve better power output, efficiency, and handling characteristics. Each upgrade not only boosts performance but can also contribute to a more enjoyable driving experience.

Common Modifications for Enhanced Performance

When considering enhancements, the following upgrades are often recommended:

- Intake System Improvements: Upgrading the air intake can facilitate better airflow, resulting in improved combustion efficiency.

- Exhaust System Upgrades: A high-performance exhaust system can reduce back pressure and enhance engine output.

- ECU Remapping: Tuning the electronic control unit can optimize fuel delivery and ignition timing for increased horsepower and torque.

- Suspension Enhancements: Upgrading the suspension components can improve handling and stability, providing better cornering capabilities.

- Brake System Enhancements: High-performance brake pads and rotors can significantly improve stopping power, ensuring safety during spirited driving.

Considerations Before Upgrading

Before proceeding with any modifications, it is essential to consider the following:

- Ensure compatibility with existing components to avoid any performance issues.

- Consult with professionals to understand the impact of upgrades on warranty and reliability.

- Assess your driving style and goals to choose the most suitable enhancements.

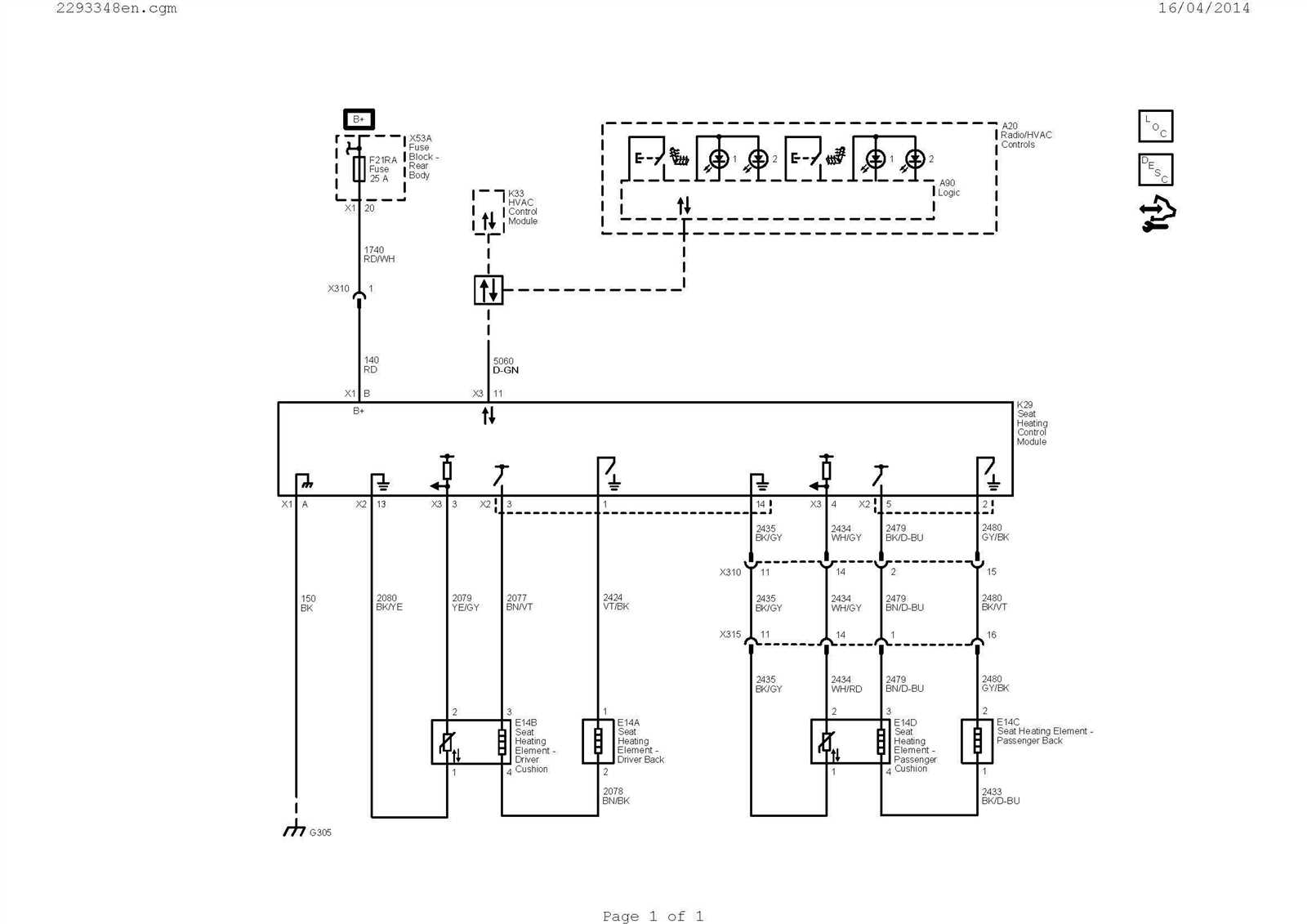

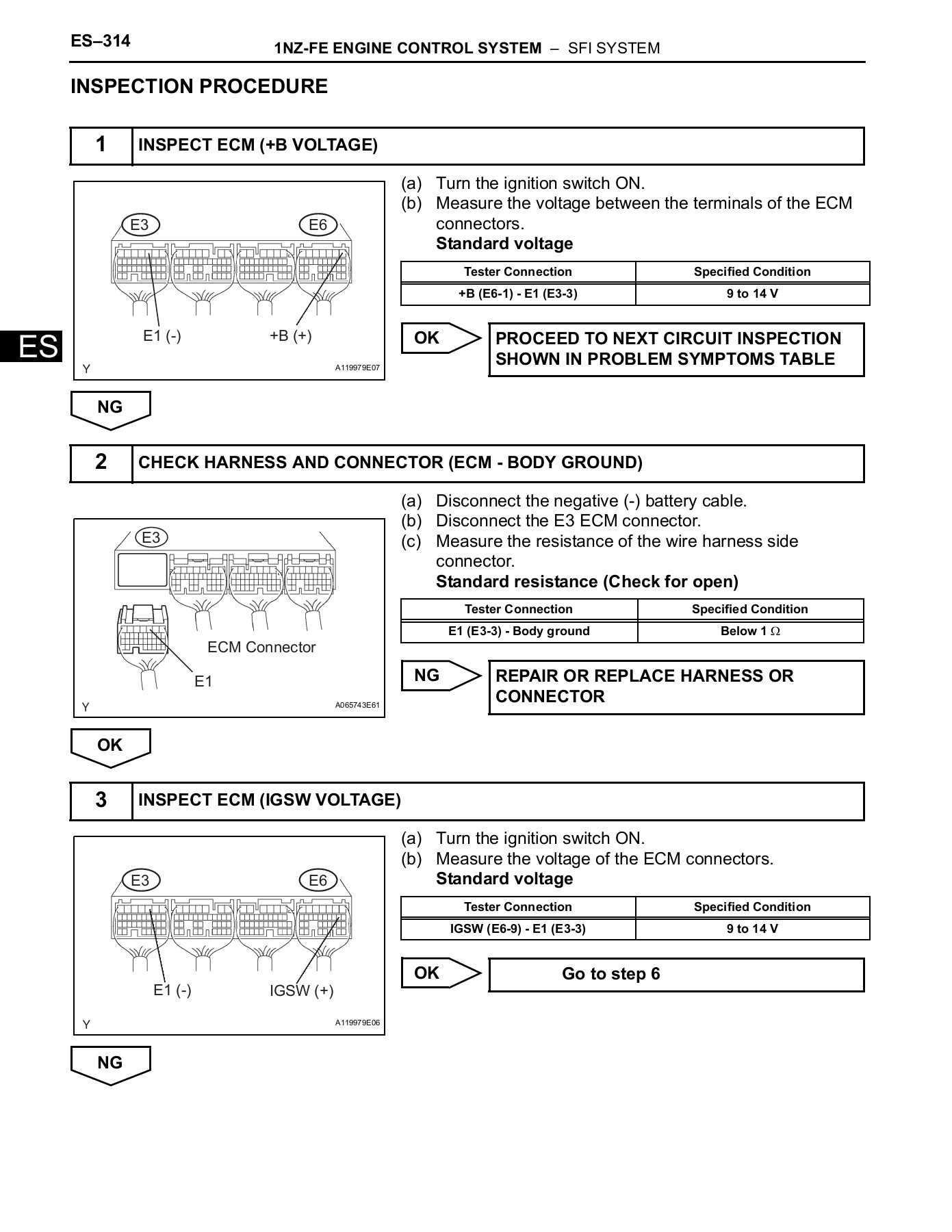

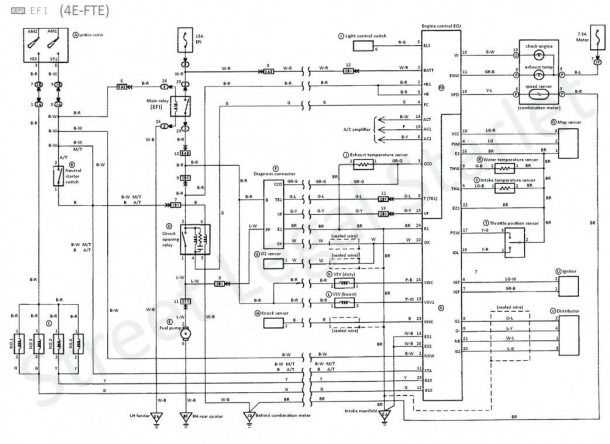

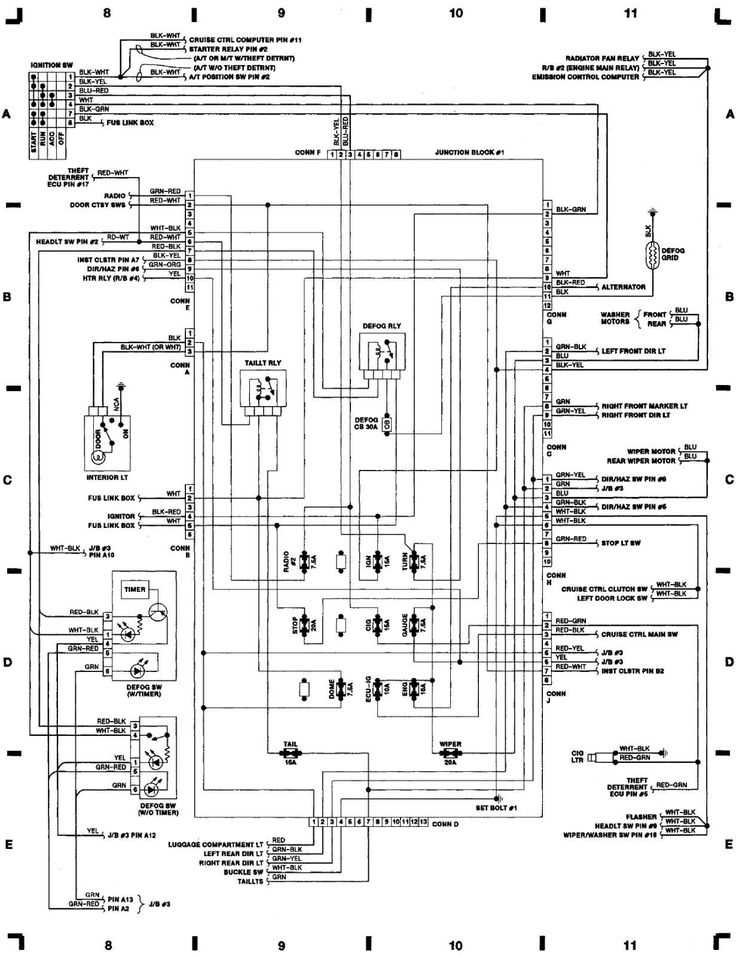

Electrical System Diagnostics

Understanding the intricacies of the electrical framework within a vehicle is crucial for ensuring optimal performance and reliability. This segment delves into the methods and tools used to assess the various components of the electrical system, identifying issues that may lead to malfunctions or inefficiencies.

Key Components to Inspect

Regular examination of the following elements can help pinpoint electrical issues:

- Batteries: Check for charge levels and corrosion.

- Wiring: Look for frayed or damaged cables.

- Fuses: Ensure all fuses are intact and functioning.

- Connectors: Inspect for loose or corroded connections.

Diagnostic Tools and Techniques

Utilizing appropriate diagnostic equipment can streamline the process of identifying electrical problems. Consider the following tools:

- Multimeter: Measures voltage, current, and resistance.

- Oscilloscope: Analyzes waveform patterns in the electrical signals.

- Scan tool: Reads error codes from the vehicle’s onboard computer.

- Battery tester: Evaluates the health of the battery.

Employing these techniques and tools will facilitate a thorough understanding of the electrical system’s health and enable timely interventions.

Cooling System Maintenance

Regular upkeep of the cooling system is crucial for the optimal functioning of a vehicle’s components. This system plays a vital role in regulating temperature, preventing overheating, and ensuring efficient performance. By adhering to maintenance protocols, owners can extend the lifespan of their vehicles and enhance reliability.

Key Maintenance Tasks

To maintain the cooling system effectively, consider the following essential tasks:

- Coolant Level Check: Regularly inspect the coolant level in the reservoir and top it off as necessary.

- Coolant Replacement: Change the coolant according to the manufacturer’s recommendations, usually every 30,000 to 50,000 miles.

- Inspect Hoses: Check for any signs of wear, cracks, or leaks in the hoses connected to the radiator and engine.

- Radiator Cleaning: Clean the radiator fins to remove debris that may obstruct airflow and reduce cooling efficiency.

- Thermostat Functionality: Ensure that the thermostat opens and closes properly to regulate coolant flow.

Signs of Cooling System Issues

Be alert for the following indicators that may signal problems within the cooling system:

- Overheating temperature gauge.

- Coolant leaks under the vehicle.

- Unusual engine noises, such as hissing or bubbling.

- Cloudy or contaminated coolant.

Addressing these signs promptly can prevent further damage and maintain the vehicle’s performance. Regular attention to the cooling system will lead to better efficiency and longevity.

Fuel System Components Explained

The fuel delivery system plays a crucial role in the performance and efficiency of a vehicle. Understanding its various elements can enhance maintenance and troubleshooting efforts. Each component serves a distinct purpose, ensuring that the combustion process occurs smoothly and effectively.

Key components of this system include:

- Fuel Tank: The storage unit for fuel, designed to withstand pressure and prevent leaks.

- Fuel Pump: A device that moves fuel from the tank to the engine, often electric or mechanical.

- Fuel Filter: This component removes impurities and contaminants from the fuel before it reaches the engine.

- Fuel Injectors: Precision devices that atomize fuel for efficient combustion, delivering it directly into the combustion chamber.

- Fuel Pressure Regulator: Maintains consistent fuel pressure within the system to optimize engine performance.

Each of these parts contributes to the overall functionality of the fuel system, making it essential for smooth operation and optimal performance.

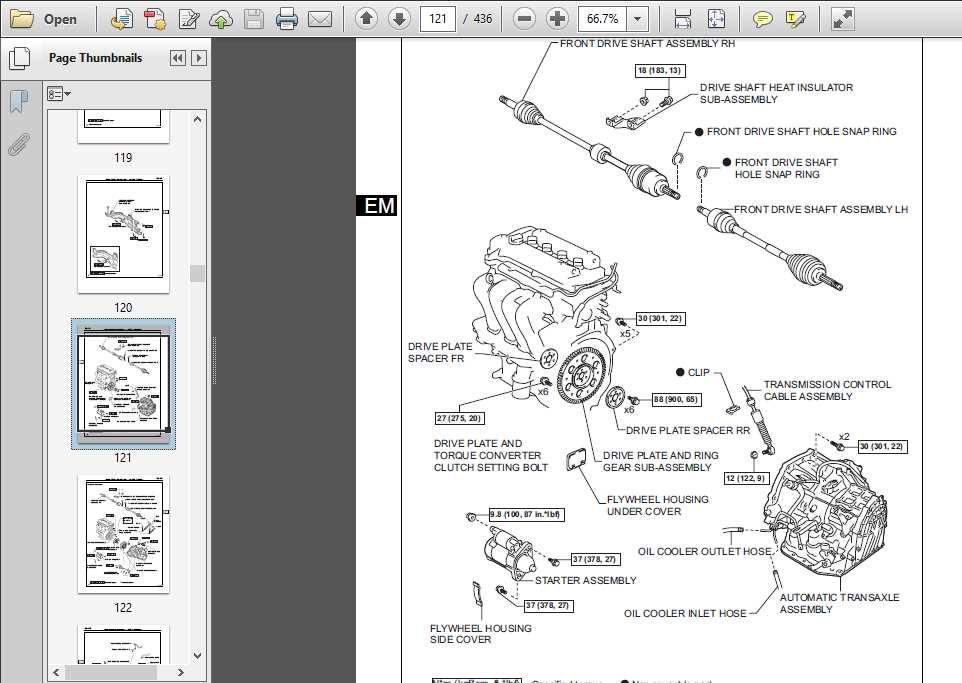

Engine Assembly and Disassembly Tips

When working on the intricate task of reassembling or taking apart a power unit, certain strategies can enhance the process and ensure successful outcomes. Adopting a systematic approach is crucial for maintaining order and preventing component damage.

Here are some essential tips to consider:

- Organize Your Workspace: Keep your area tidy and free from clutter. Use trays or containers to sort components by type or sequence.

- Document the Process: Take photographs or make notes during disassembly. This can serve as a helpful reference during reassembly.

- Use the Right Tools: Ensure you have the necessary tools on hand to avoid improvisation that could lead to mistakes.

- Follow Specifications: Adhere to the manufacturer’s guidelines for torque settings and assembly sequences to ensure proper functioning.

- Clean Components: Remove dirt and old lubricant from parts before reassembly to ensure optimal performance and prevent wear.

By following these tips, you can facilitate a smoother and more efficient process, ultimately leading to a successful project.