In the realm of automotive excellence, understanding the intricacies of power units is essential for enthusiasts and professionals alike. This section delves into the vital aspects of maintaining and enhancing performance, offering invaluable insights for those keen on optimizing their vehicles.

Whether you are a seasoned mechanic or a novice, navigating the complexities of mechanical systems can seem daunting. However, with the right information at your fingertips, you can confidently tackle challenges, ensuring longevity and efficiency in your driving experience.

Throughout this guide, we will explore various techniques, troubleshooting tips, and maintenance practices designed to empower you. Emphasizing hands-on knowledge and practical advice, this resource aims to equip you with the skills necessary to achieve optimal results.

Toyota 1DZ II Engine Overview

This section provides a comprehensive insight into a particular type of power unit known for its durability and efficiency. Designed to meet various performance standards, this system plays a crucial role in powering numerous vehicles, offering reliability in diverse conditions. Understanding its components and functionality can significantly aid in maintenance and troubleshooting tasks.

Key Specifications

| Specification | Details |

|---|---|

| Cylinders | 4 |

| Displacement | 2.4L |

| Power Output | 80-100 HP |

| Torque | 150-200 Nm |

| Fuel Type | Diesel |

Component Overview

The unit consists of several critical parts, each contributing to its overall performance. These include the combustion chamber, fuel injection system, and cooling mechanisms. A thorough understanding of these components enhances the ability to diagnose issues and optimize functionality, ensuring longevity and peak efficiency during operation.

Common Issues with 1DZ II Engines

Many enthusiasts and mechanics encounter several prevalent challenges associated with this particular power unit. Understanding these common problems can aid in effective troubleshooting and maintenance, ensuring longevity and optimal performance.

Overheating Problems

One of the frequent concerns involves excessive heat generation. This issue can stem from various sources, including coolant leaks, faulty thermostats, or malfunctioning water pumps. Regular monitoring of temperature levels and cooling systems is crucial to prevent severe damage.

Fuel System Failures

Another notable issue pertains to the fuel delivery mechanism. Clogs in injectors or filters may lead to poor performance and reduced efficiency. Ensuring proper fuel quality and timely replacement of filters can mitigate these complications.

Regular maintenance and awareness of these potential issues can significantly enhance the reliability of this power unit.

Essential Tools for Engine Repair

When tackling the intricate task of overhauling mechanical units, having the right equipment at your disposal is crucial. This selection of instruments not only streamlines the process but also enhances accuracy and safety. Here’s a guide to the fundamental implements you’ll need for effective maintenance and restoration.

- Socket Set: A comprehensive socket set allows for the efficient loosening and tightening of various fasteners.

- Torque Wrench: Essential for applying the correct amount of force to bolts and nuts, ensuring optimal performance.

- Wrenches: A variety of adjustable and fixed wrenches will help navigate different sizes and types of fittings.

- Screwdrivers: Both flathead and Phillips types are necessary for accessing screws in various locations.

- Pliers: These are vital for gripping, twisting, and cutting wires and other materials.

In addition to the basic tools, consider adding specialized equipment to your toolkit:

- Multimeter: For diagnosing electrical issues, this device is invaluable.

- Oil Filter Wrench: Designed specifically for removing and installing oil filters.

- Fuel Line Disconnect Tool: Facilitates safe and easy separation of fuel lines.

Lastly, ensure you have adequate safety gear to protect yourself during the process:

- Safety Glasses: Protects your eyes from debris and harmful substances.

- Gloves: Prevents skin contact with oils and chemicals, ensuring safety and cleanliness.

- Face Mask: Useful for protecting against dust and harmful fumes.

By equipping yourself with these essential tools, you will be well-prepared to tackle any challenges that arise during mechanical maintenance and enhancements.

Step-by-Step Disassembly Process

This section outlines a systematic approach to carefully dismantling a complex mechanical assembly. Following these guidelines will help ensure that each component is removed safely and efficiently, minimizing the risk of damage or loss.

Preparation Steps

- Gather all necessary tools and equipment.

- Ensure the workspace is clean and organized.

- Review any relevant documentation or diagrams for guidance.

- Wear appropriate safety gear to protect against hazards.

Disassembly Procedure

- Start by disconnecting any electrical connections to prevent shorts.

- Remove exterior covers or shields to gain access to internal components.

- Take off the primary housing by unscrewing the fasteners in a sequential manner.

- Carefully detach each sub-assembly, making note of the order and orientation of parts.

- Use a labeling system for small components to facilitate reassembly.

- Inspect each part for wear or damage during the disassembly process.

- Store disassembled parts in a designated area, organized for easy retrieval.

Following these steps will help maintain an orderly process and ensure that all components are accounted for during reassembly.

Reassembly Tips for Toyota Engines

Reassembling a power unit requires precision and attention to detail. A methodical approach can significantly enhance performance and longevity. Here are some essential suggestions to keep in mind during the process.

- Cleanliness is Crucial: Ensure that all components are thoroughly cleaned before reassembly. This prevents contamination and potential damage.

- Organize Components: Keep parts organized using labeled containers. This simplifies the process and reduces the risk of losing essential pieces.

- Consult Specifications: Always refer to the manufacturer’s specifications for torque settings and assembly sequences to maintain integrity.

- Use Quality Gaskets: Replace old gaskets with new ones to ensure a proper seal and avoid leaks.

- Lubrication: Apply appropriate lubricants to moving parts during reassembly to reduce friction and wear.

- Follow a Systematic Order: Reassemble in a logical sequence, typically starting from the bottom and working upwards, to ensure no steps are missed.

By adhering to these guidelines, you can facilitate a smoother assembly process, ultimately leading to better performance and reliability.

Diagnosing Engine Performance Problems

Identifying issues related to power and efficiency is crucial for maintaining optimal functionality in any mechanical system. Proper diagnosis can prevent minor complications from escalating into significant failures, ensuring longevity and reliability. Understanding the symptoms and underlying causes is essential for effective troubleshooting.

Start by observing any unusual behavior, such as decreased power, irregular sounds, or changes in responsiveness. These signs can indicate various underlying issues, from fuel supply problems to ignition system failures. Gathering data from performance metrics, such as acceleration rates and fuel consumption, can provide valuable insights into potential malfunctions.

Next, conduct a thorough inspection of critical components. Look for visible wear, leaks, or blockages that may hinder performance. It is also advisable to check electrical connections and sensors, as these play a vital role in regulating operations. Utilizing diagnostic tools can help in pinpointing faults with precision, streamlining the troubleshooting process.

Once potential issues are identified, perform tests to confirm the source of the problem. This may include examining compression levels, fuel pressure, and ignition timing. Analyzing the results will allow for informed decisions on necessary adjustments or replacements to restore optimal performance.

In conclusion, a systematic approach to diagnosing performance issues can greatly enhance the efficiency and reliability of the system. By remaining vigilant and proactive, one can ensure that any complications are addressed promptly, maintaining smooth operation over time.

Maintenance Best Practices for Longevity

Ensuring the long-lasting performance of your vehicle requires a consistent and thoughtful approach to upkeep. By following a set of best practices, you can significantly extend the lifespan of key components, enhance efficiency, and reduce the likelihood of costly repairs. Regular attention to maintenance not only preserves functionality but also contributes to a safer driving experience.

First and foremost, adhering to a routine schedule for inspections and services is crucial. This includes regular checks on fluid levels, filters, and belts. Keeping everything well-lubricated and in proper working order minimizes wear and tear. Additionally, addressing minor issues promptly can prevent them from escalating into major problems.

Equally important is maintaining clean air intake and exhaust systems. Regularly replacing air filters ensures optimal airflow, which enhances performance and efficiency. Likewise, periodic checks of exhaust components can help prevent blockages and improve emissions control.

Another key aspect is tire care. Ensuring correct tire pressure and performing regular rotations not only improves handling but also extends the life of your tires. Monitoring tread depth is essential for maintaining traction and safety on the road.

Finally, keeping your vehicle clean, both inside and out, protects surfaces from corrosion and wear. Regular washing, waxing, and interior cleaning contribute to a healthier environment for all components and enhance the overall aesthetics.

Engine Replacement vs. Repair Considerations

When faced with mechanical issues, one must weigh the benefits of full unit substitution against the option of localized fixes. Each choice carries its own implications for cost, longevity, and overall performance. Understanding these factors is crucial for making an informed decision that aligns with both budgetary constraints and operational needs.

In many cases, opting for a complete unit swap may seem advantageous, particularly if the existing assembly has sustained extensive damage. However, it is essential to consider the age, condition, and history of the original components. Conversely, targeted interventions can be more economical and environmentally friendly, provided that the root causes of the failures are accurately diagnosed.

| Criteria | Replacement | Repair |

|---|---|---|

| Cost | Higher initial expenditure | Potentially lower upfront cost |

| Time | Longer downtime | Quicker turnaround |

| Reliability | New component reliability | Dependent on quality of work |

| Longevity | Longer lifespan expected | May require future interventions |

| Environmental Impact | Potential waste from old unit | More sustainable if done correctly |

Ultimately, the decision hinges on specific circumstances, including budget, time constraints, and the anticipated lifespan of the vehicle. Engaging with a qualified technician can provide valuable insights, ensuring that the choice made is both practical and beneficial in the long run.

Fuel System Troubleshooting Guide

This section focuses on diagnosing issues related to the fuel delivery system. Proper functioning of this system is crucial for optimal performance and efficiency. Identifying symptoms and understanding potential causes will help in addressing any irregularities effectively.

Common Symptoms

Several indicators can signal problems within the fuel delivery mechanism. These may include:

- Engine Misfire: Unstable operation often leads to decreased power output.

- Hard Starting: Difficulty initiating the combustion process may point to insufficient fuel flow.

- Excessive Fuel Consumption: A sudden increase in fuel usage can indicate leaks or malfunctions.

Troubleshooting Steps

To effectively troubleshoot the system, consider the following steps:

- Inspect Fuel Lines: Check for cracks, leaks, or blockages that may hinder fuel flow.

- Test Fuel Pump: Ensure the pump operates within the specified pressure range.

- Examine Filters: Clogged filters can restrict fuel supply and should be replaced regularly.

By systematically addressing these areas, issues can be identified and resolved, ensuring the vehicle operates smoothly and efficiently.

Cooling System Maintenance Essentials

The cooling system is a crucial component that ensures optimal performance and longevity of the vehicle. Regular upkeep is necessary to prevent overheating and maintain the overall health of the mechanical parts. Proper management of this system not only enhances efficiency but also minimizes the risk of costly repairs in the future.

Routine Checks

Coolant Replacement

Periodic replacement of the coolant is essential for effective temperature regulation. Over time, coolant can degrade and lose its protective properties, leading to corrosion within the system. Follow the manufacturer’s guidelines for replacement intervals to ensure optimal functionality and protection against engine wear.

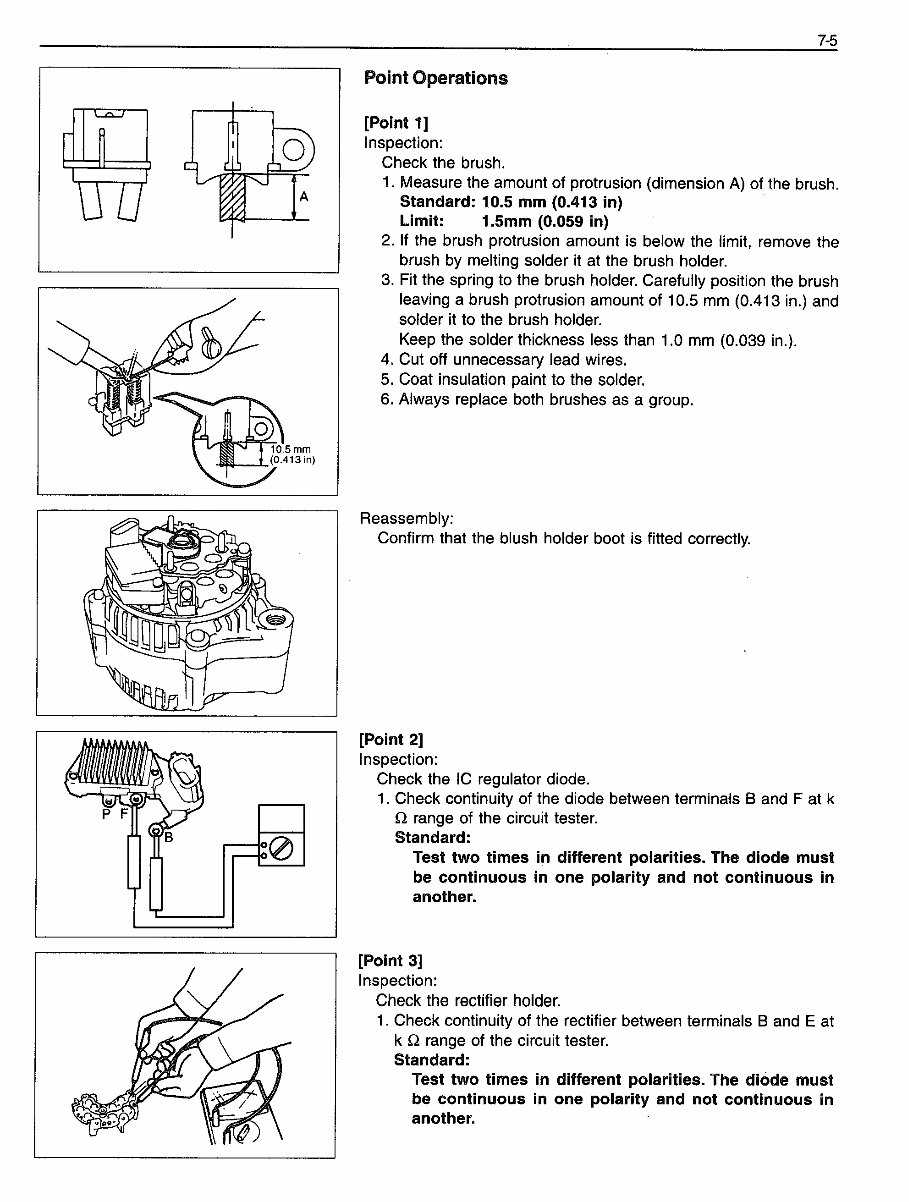

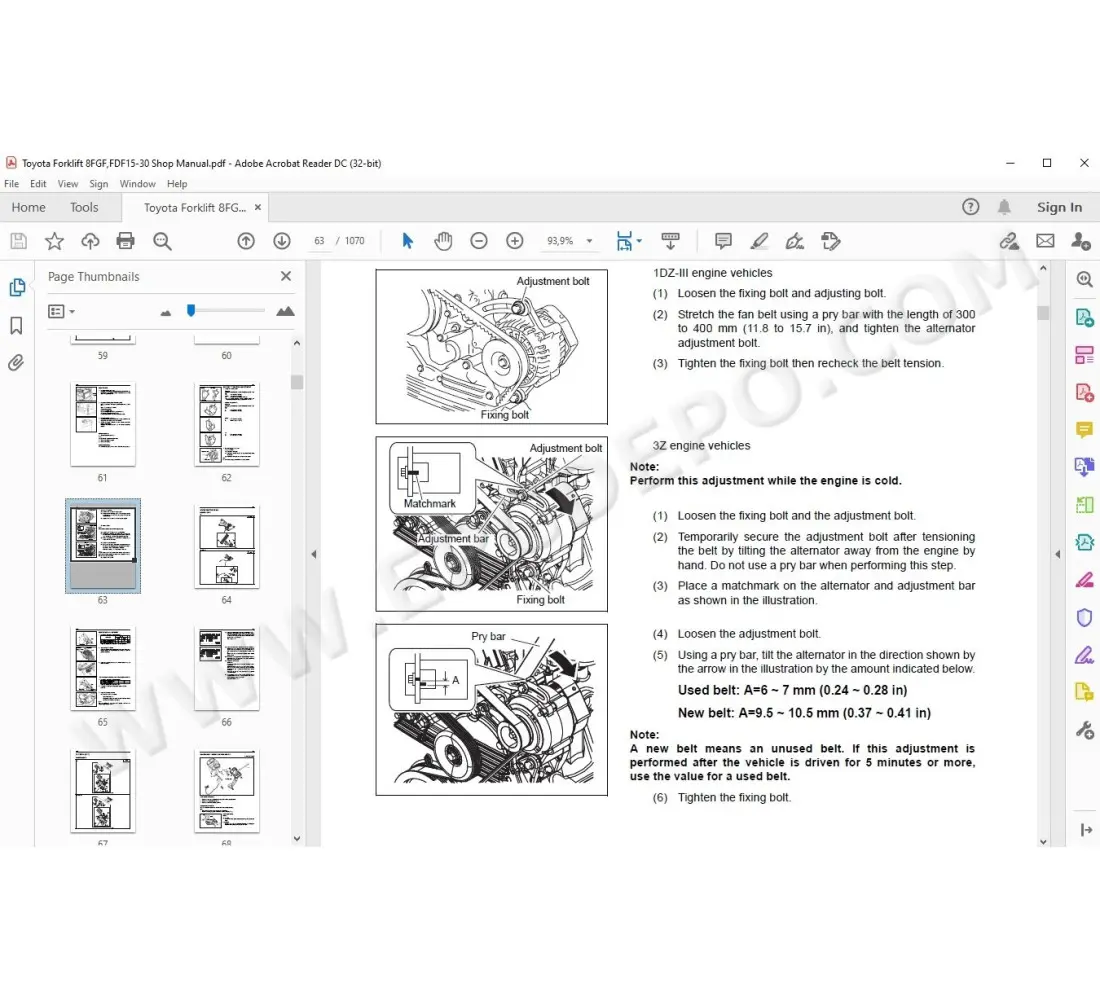

Electrical Components Inspection Techniques

Inspecting electrical elements is crucial for ensuring optimal functionality and longevity of various mechanical systems. This process involves systematic evaluation and testing of individual parts to identify potential issues. Employing appropriate techniques can help maintain performance and prevent unexpected failures.

Common Inspection Methods

Different methods can be utilized to assess electrical components effectively. Here are some prevalent approaches:

| Method | Description |

|---|---|

| Visual Inspection | Check for obvious signs of damage, wear, or corrosion on terminals and wires. |

| Continuity Testing | Use a multimeter to ensure there is a complete electrical path through the circuit. |

| Voltage Testing | Measure voltage levels at various points to ensure they meet specified standards. |

| Resistance Testing | Assess the resistance of components to identify shorts or opens in the circuit. |

Best Practices

Adhering to best practices during inspections enhances reliability. Always ensure that the system is powered down before beginning any evaluations. Utilize appropriate tools and follow manufacturer guidelines to minimize the risk of accidents or damage. Regular inspections not only improve safety but also extend the lifespan of electrical components.

Understanding Engine Specifications and Ratings

Grasping the nuances of performance metrics and technical characteristics is crucial for anyone interested in optimizing vehicle functionality. These specifications provide insight into the power output, efficiency, and overall capabilities of a mechanical unit. Understanding these details enables enthusiasts and professionals alike to make informed decisions regarding maintenance and upgrades.

Key ratings include horsepower, torque, displacement, and fuel efficiency. Each of these elements contributes to the overall performance and reliability of the system. Familiarizing oneself with these terms allows for better comprehension of how different components interact and affect the driving experience.

| Specification | Description |

|---|---|

| Horsepower | A measure of the engine’s power output, influencing acceleration and top speed. |

| Torque | The rotational force produced, crucial for towing capacity and off-the-line acceleration. |

| Displacement | The total volume of all cylinders, affecting power and fuel consumption. |

| Fuel Efficiency | The distance traveled per unit of fuel, impacting operational costs and environmental footprint. |

By analyzing these specifications, one can not only evaluate the current state of a unit but also anticipate its performance under various conditions. This knowledge is invaluable for enhancing longevity and ensuring optimal operation.

Resources for Further Learning

Enhancing your knowledge in the realm of mechanical systems can significantly improve your ability to maintain and troubleshoot various machinery. There are numerous avenues available to deepen your understanding, ranging from online courses to dedicated literature and forums where enthusiasts share their experiences.

Books on automotive technology often provide in-depth insights into fundamental principles and specific components. Look for publications that cover practical techniques and industry standards. Additionally, instructional videos on platforms such as YouTube can offer visual guidance, making complex tasks more approachable.

Engaging with online communities can be incredibly beneficial. Forums and social media groups are excellent for asking questions and receiving advice from seasoned professionals and fellow hobbyists. Consider participating in workshops or local meetups to gain hands-on experience and connect with others who share your interests.

Finally, exploring manufacturer websites can yield valuable resources, including technical bulletins and updates on best practices. Emphasizing continuous learning through diverse sources will empower you to tackle any challenges you may face in your projects.