Maintaining a vehicle in top condition requires knowledge and attention to detail. This guide provides essential information to help enthusiasts and mechanics keep their cars running smoothly. Whether you’re addressing routine upkeep or diagnosing issues, having access to a detailed resource is invaluable.

In this section, you’ll find practical instructions for performing various tasks, from basic inspections to complex diagnostics. These steps are designed to enhance your understanding of vehicle systems, ensuring safe and efficient operation. With this knowledge, you’ll be well-equipped to handle potential challenges.

By following the guidelines provided, you can extend the lifespan of your car and avoid costly repairs. Learn the best practices for maintaining critical components and find solutions to common problems. This resource is tailored to meet the needs of both experienced mechanics and those new to car care.

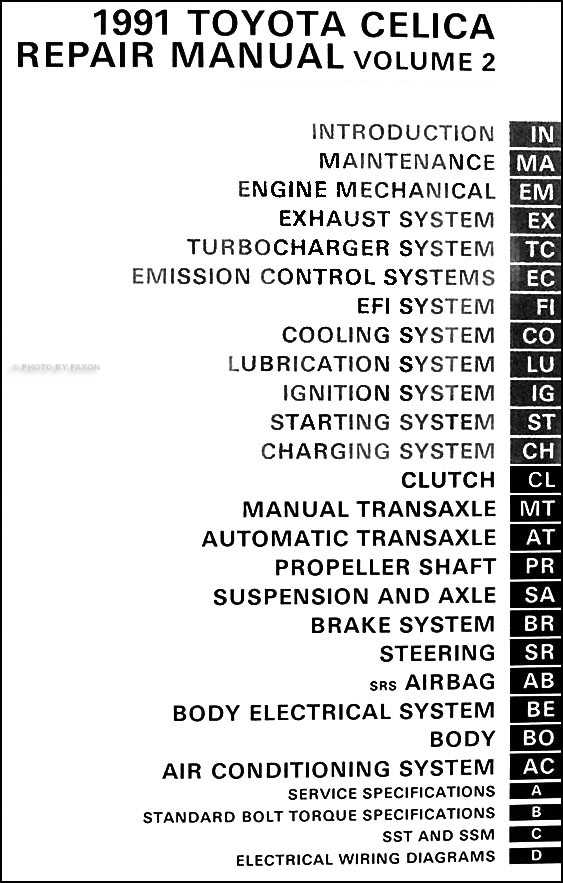

Comprehensive Overview of 1991 Toyota Celica Maintenance

Maintaining a vehicle ensures its longevity and reliable performance. Proper care and attention to key systems can prevent unexpected breakdowns and extend the life of crucial components. Regular inspections and following recommended service intervals are essential to keep everything running smoothly.

Key Maintenance Areas

Regular upkeep focuses on several key areas that are critical for optimal vehicle performance. These include the engine, transmission, braking system, and suspension. Consistent servicing helps to address wear and tear before it becomes a larger problem, ensuring that the vehicle remains safe and efficient.

| Maintenance Task | Recommended Interval |

|---|---|

| Oil Change | Every 5,000 miles |

| Brake Inspection | Every 10,000 miles |

| Transmission Fluid Check | Every 30,000 miles |

| Suspension Check | Every 20,000 miles |

Preventive Measures

In addition to regular inspections, adopting preventive maintenance practices can greatly enhance vehicle reliability. Checking fluid levels, replacing worn-out components, and maintaining proper tire pressure are simple steps that can prevent more costly repairs in the future. Staying ahead of potential issues ensures smooth operation and long-term dependability.

Understanding Common Engine Issues and Fixes

Engine problems can arise unexpectedly, often leading to reduced performance and efficiency. By identifying common issues early on, drivers can prevent further damage and maintain the reliability of their vehicle. Understanding these problems and knowing how to address them is essential for ensuring the engine remains in optimal condition.

Overheating: One of the most frequent engine issues, overheating, can be caused by a malfunctioning cooling system. Components like the radiator, water pump, or thermostat may fail, leading to excessive engine heat. Regularly checking coolant levels and inspecting for leaks can prevent this problem. If the issue persists, replacing faulty parts is often necessary.

Oil Leaks: Oil leakage can significantly affect engine performance. Leaks may occur due to worn gaskets, seals, or cracked oil pans. Identifying the source of the leak and addressing it promptly by replacing damaged parts or tightening loose components can prevent long-term damage.

Misfiring: Engine misfiring can result from a range of issues, including faulty spark plugs, ignition coils, or fuel injectors. Regular maintenance of these components and timely replacement when wear is detected can restore smooth engine operation.

Fuel System Problems: Clogged fuel injectors, faulty fuel pumps, or contaminated fuel can lead to poor engine performance. Cleaning the fuel system and ensuring that only clean, high-quality fuel is used can prevent such issues. In more severe cases, replacing damaged components may be required.

Timing Belt Failure: A worn or broken timing belt can cause significant engine damage. Regular inspection of the belt and replacing it at recommended intervals can prevent engine failure and costly repairs.

By staying vigilant and performing regular maintenance, many of these engine issues can be avoided. When problems do arise, addressing them quickly will help ens

Essential Tools for Toyota Celica Repairs

To ensure efficient maintenance and upkeep of your vehicle, it’s important to be equipped with the right set of tools. Whether performing routine checks or addressing more complex mechanical issues, having the appropriate equipment on hand will help simplify tasks and ensure precision.

Basic Hand Tools

- Socket Set: A comprehensive socket set with a range of sizes is crucial for handling various bolts and fasteners found throughout the engine, suspension, and other systems.

- Wrenches: Adjustable and combination wrenches are essential for tasks involving nuts and bolts in tight spaces.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for interior components, electrical connections, and smaller adjustments.

Advanced Diagnostic Tools

For more in-depth diagnostics and repairs, advanced tools are necessary to identify and resolve issues that may not be immediately visible.

- OBD-II Scanner: This tool helps read fault codes from the vehicle’s electronic control unit, making it easier to diagnose potential problems.

- Multimeter: Useful for checking electrical circuits, measuring voltage, and troubleshooting sensor-related issues.

- Torque Wrench: Ensures that bolts and nuts are tightened to the correct specification, preventing over-tightening or under-tightening.

- Ensure all tools are maintained in good working condition for accurate and safe repairs.

- Invest in quality tools to enhance the longevity and performance of your vehicle maintenance efforts.

How to Troubleshoot Electrical Problems

Dealing with electrical issues in vehicles can be challenging, but following a systematic approach can help identify the root cause. A well-organized troubleshooting process ensures that potential problems are isolated and resolved without unnecessary component replacements. Below are essential steps and techniques to effectively diagnose electrical issues in cars.

Step-by-Step Troubleshooting Process

- Check the Battery: Always start by inspecting the battery. Ensure that it has enough charge and that the terminals are clean and properly connected.

- Inspect Fuses: Examine the fuse box for any blown fuses. Replace any damaged ones and verify if they fix the issue.

- Test Wiring and Connections: Loose or corroded connections can cause many electrical problems. Inspect all wiring, particularly in areas that are prone to moisture or heat exposure.

- Use a Multimeter: A multimeter is an essential tool for measuring voltage, current, and resistance. Use it to test components like relays, sensors, and switches to determine if they are functioning properly.

- Check Ground Connections: Faulty ground connections can cause erratic behavior in electrical systems. Make sure all grounding points are secure and free of rust or debris.

Common Signs of Electrical Issues

- Dim or Flickering Lights: This could indicate a weak battery, failing alternator

Brake System Repair Tips for Toyota Celica

Maintaining the braking system is essential for safe driving and vehicle longevity. By regularly inspecting and servicing key components, you can ensure optimal performance and prevent potential issues before they escalate. Below are some practical guidelines to help you keep the braking mechanism in top shape.

Start by checking the brake pads for wear. Thin or uneven pads can significantly reduce stopping power and cause damage to the rotors. It’s important to replace them before they are completely worn out. Additionally, inspect the brake discs for warping or deep grooves, as these can lead to inefficient braking and vibration when applying the brakes.

Fluid levels in the brake master cylinder should be monitored consistently. Low fluid may indicate a leak in the system or excessive pad wear, both of which require immediate attention. Ensure that the brake fluid is clean and within the recommended level to avoid hydraulic issues.

Another critical aspect is the brake lines. Inspect for any cracks, corrosion, or leaks in the rubber or metal components. Replacing damaged lines promptly helps prevent fluid leaks and maintains proper hydraulic pressure.

Component Inspection Frequency Action Brake Pads Every 10,000 miles DIY Guide to Suspension System Maintenance

Maintaining the suspension system is essential to ensure a smooth and safe ride. Over time, various components can wear out, leading to reduced stability and handling. Regular inspections and basic upkeep can prevent costly repairs and prolong the lifespan of your vehicle’s suspension. This guide will provide a step-by-step approach to keeping your suspension in optimal condition.

Begin by checking the visible parts for any signs of wear, such as cracked bushings or leaking shocks. Pay special attention to the shock absorbers and springs, as they play a crucial role in cushioning and stability. Ensure that all mounting points are secure and free from corrosion or damage.

Next, test the alignment of the wheels. Misaligned wheels can lead to uneven tire wear and poor handling. Use a jack to lift the vehicle and inspect the tires for abnormal wear patterns. If you notice uneven wear, consider checking or adjusting the alignment to restore balance and improve driving performance.

It is also important to examine the control arms and ball joints for excessive movement or damage. Worn ball joints can lead to clunking noises or erratic steering. If any of these parts appear loose or worn, they should be replaced to maintain proper suspension function.

Finally, don’t forget to lubricate any moving parts as needed and replace any damaged or worn components promptly. Proper care and attention to your vehicle’s suspension system will enhance safety and ensure a more comfortable driving experience.

Transmission Troubleshooting and Repair Methods

Transmission issues can lead to poor vehicle performance, making it essential to diagnose problems early and apply the correct fixes. Understanding the signs of malfunction and the steps to address them ensures smooth and reliable driving. This section covers key methods for identifying common problems and outlines practical solutions for effective repair.

One of the first steps in troubleshooting is to recognize the symptoms, such as slipping gears, delayed shifting, or unusual noises during operation. These issues often point to problems within the transmission system and require a thorough inspection. Start by checking the fluid levels and condition. Low or dirty transmission fluid can cause a range of issues and may be resolved with a simple fluid change or flush.

For more complex problems, such as gear shifting failures or complete loss of power, a deeper inspection is necessary. This may involve testing the solenoids, sensors, and other electronic components, as they can impact the transmission’s ability to function properly. If these parts are faulty, replacing them is typically the best course of action.

In some cases, mechanical damage to components like the clutch, gears, or torque converter might be the root cause. Repairing or replacing these parts will require disassembly of the transmission system, which is a more advanced procedure. For those without experience, seeking professional assistance is advised.

Regular maintenance, including checking for leaks and ensuring the transmission operates at optimal temperatures, can prevent many common issues. By staying proactive and addressing minor problems early, you can extend the life of your vehicle’s transmission and avoid costly repairs.

Replacing and Adjusting the Celica Timing Belt

The timing belt is a critical component in ensuring that the engine runs smoothly and efficiently. It synchronizes the movement of key engine parts, and regular maintenance or replacement can prevent costly damage. Knowing how to replace and adjust it correctly is essential for keeping the vehicle in optimal condition.

Preparation and Tools: Before starting, ensure you have the proper tools such as a wrench set, socket set, and torque wrench. Always disconnect the battery to avoid accidental electrical issues during the process. It’s also helpful to have a service guide for reference.

Removing the Old Belt: Begin by removing any components that block access to the timing cover. Once removed, carefully detach the cover and inspect the old belt. Loosen the tensioner to relieve pressure from the belt, allowing it to slide off easily. Pay attention to the alignment of the pulleys as this will be important during reassembly.

Installing the New Belt: Align the new belt with the pulleys, ensuring the markings on the belt match the timing marks on the engine. Tighten the tensioner to the specified torque, ensuring the belt has the proper tension. It’s important that the belt is not too tight or too loose, as this can affect engine performance.

Final Adjustment: After the new belt is in place, manually rotate the engine using a wrench to ensure everything is properly aligned and functioning smoothly. If there is any unusual resistance, recheck the alignment. Finally, reassemble the components and reconnect the battery.

Regular inspection and timely replacement of the timing belt can significantly prolong the lifespan of the engine, ensuring reliable performance.

Fixing Fuel System Issues in Older Toyota Models

Older vehicle models often experience fuel delivery problems that can affect performance and efficiency. Addressing these issues promptly can enhance reliability and prolong the life of the vehicle. This section provides guidance on identifying and resolving common fuel system challenges in vintage cars.

Understanding the components of the fuel system is crucial for effective troubleshooting. Key parts include:

- Fuel tank

- Fuel pump

- Fuel filter

- Fuel injectors

- Carburetor (in some older models)

- Fuel lines

Here are common problems and suggested solutions:

- Fuel Leaks: Inspect fuel lines and connections for signs of leakage. Replace any damaged hoses or fittings to prevent fuel loss and ensure safety.

- Clogged Fuel Filter: Regularly check and replace the fuel filter. A clogged filter can restrict fuel flow, leading to poor engine performance.

- Faulty Fuel Pump: Listen for unusual noises from the fuel pump, which may indicate failure. Testing the pump’s pressure can help determine if it needs replacement.

- Dirty Injectors or Carburetor: Clean fuel injectors or carburetors to improve fuel atomization and combustion efficiency. Consider using a professional cleaning service if necessary.

- Contaminated Fuel: Ensure the fuel used is clean and free from contaminants. Drain and replace the fuel if contamination is suspected.

Regular maintenance is vital for optimal function. Implementing a preventive approach can minimize future issues and enhance overall vehicle performance.

Tips for Maintaining the Exhaust System

Proper care of the exhaust system is crucial for ensuring optimal performance and longevity of your vehicle. A well-maintained exhaust not only helps to reduce harmful emissions but also improves fuel efficiency and enhances overall engine performance. Here are some effective strategies to keep the exhaust system in top condition.

Regular Inspections

Frequent checks can help identify potential issues before they escalate. Look for signs of rust, corrosion, or any visible damage. Listening for unusual noises can also indicate problems within the system. Catching these issues early can save time and money on repairs.

Keep it Clean

Accumulation of dirt and debris can affect the exhaust system’s functionality. Regularly clean the exterior parts to prevent buildup, which can lead to rust and other complications. Consider using a high-quality exhaust cleaner for thorough maintenance.

Maintenance Tip Frequency Benefit Visual Inspection Every 6 months Early detection of damage Cleaning Every 3 months Prevents rust and buildup Professional Check-up Annually Comprehensive assessment of the system Step-by-Step Guide to Clutch Replacement

Replacing a vehicle’s clutch is a critical task that ensures smooth gear shifting and overall performance. This procedure requires careful attention and a systematic approach to effectively remove the old clutch assembly and install a new one. Below is a comprehensive guide to assist you through this intricate process.

1. Gather the Necessary Tools and Materials: Before beginning, ensure you have all required tools, including a jack, jack stands, wrenches, and a clutch replacement kit. Proper preparation will make the job smoother.

2. Safety First: Always prioritize safety by wearing protective gear and working in a well-ventilated area. Secure the vehicle on a flat surface and use jack stands to elevate it safely.

3. Remove the Transmission: Start by disconnecting the battery and removing the components obstructing access to the transmission, such as the exhaust system and drive shafts. Carefully detach the transmission by unscrewing the bolts securing it to the engine.

4. Take Out the Old Clutch: With the transmission removed, you will have access to the clutch assembly. Mark the orientation of the clutch for reference and unbolt it from the flywheel. Remove any additional components, such as the pressure plate and throw-out bearing.

5. Inspect and Clean: Inspect the flywheel for wear or damage. Clean the surface thoroughly to ensure proper contact with the new clutch. If necessary, resurfacing the flywheel can provide a better fit.

6. Install the New Clutch: Align the new clutch disc according to the marks made earlier. Secure the pressure plate by tightening the bolts in a crisscross pattern to ensure even pressure distribution.

7. Reassemble the Transmission: Carefully reattach the transmission, ensuring that it aligns properly with the engine. Reconnect all previously removed components, including the exhaust and drive shafts.

8. Final Checks: Once everything is reassembled, reconnect the battery and check the clutch pedal for proper operation. Test drive the vehicle to ensure everything functions smoothly.

By following these detailed steps, you can effectively replace the clutch in your vehicle, restoring its performance and reliability.

Cooling System Repair for Improved Engine Performance

The efficiency of an engine is significantly influenced by the cooling system, which plays a vital role in regulating temperature and preventing overheating. A well-functioning cooling mechanism not only enhances performance but also extends the lifespan of the engine components. Proper maintenance and timely repairs of the cooling system are essential for achieving optimal operation.

Key components that require attention include:

- Radiator: Ensure the radiator is free from debris and blockages to facilitate proper airflow and coolant circulation.

- Hoses: Inspect hoses for leaks, cracks, or wear. Replace any damaged hoses to prevent coolant loss.

- Thermostat: Test the thermostat for proper functioning. A faulty thermostat can cause overheating or inadequate engine temperature.

- Water Pump: Verify that the water pump is operating efficiently. A malfunctioning pump can lead to poor coolant flow.

- Coolant Fluid: Regularly check coolant levels and condition. Replace old or contaminated coolant to ensure effective heat transfer.

Regular inspection and maintenance of these elements will contribute to enhanced engine performance, allowing for smoother operation and greater fuel efficiency. Taking proactive measures in maintaining the cooling system not only prevents costly repairs but also ensures a reliable driving experience.