This section provides essential information and guidance for individuals looking to enhance their understanding of two-wheeled vehicles. It emphasizes the importance of proper upkeep and attention to detail, which are crucial for ensuring optimal performance and longevity of the machine.

In this guide, readers will find various insights into troubleshooting, part replacement, and regular service tasks. Each aspect of vehicle care is discussed in detail, allowing enthusiasts and riders alike to engage in effective maintenance practices. This resource aims to empower users with the knowledge needed to keep their vehicles in excellent condition.

Moreover, understanding the intricacies of the vehicle’s components and systems plays a vital role in enhancing overall riding experience. By following the suggested practices and recommendations, one can develop a greater appreciation for the mechanics behind their machine, ultimately leading to safer and more enjoyable journeys.

Proper upkeep of a motorcycle necessitates specific instruments that facilitate various tasks. Having the right equipment ensures efficiency and effectiveness while working on your vehicle, contributing to its longevity and performance. Below is a list of essential tools to have on hand for routine servicing and repairs.

Basic Hand Tools

- Socket set

- Wrench set

- Phillips and flathead screwdrivers

- Torque wrench

- Adjustable pliers

Specialized Tools

- Chain breaker tool

- Oil filter wrench

- Gap gauge

- Brake bleeder kit

- Tire lever set

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing various mechanical issues. Following a systematic methodology ensures efficiency and enhances the overall performance of the vehicle. Each step is designed to guide users through essential tasks, promoting a thorough understanding of the processes involved.

The procedures can be divided into several key phases, allowing for a structured progression through the necessary tasks.

| Phase | Description |

|---|---|

| Inspection | Begin by examining the components to identify any visible wear, leaks, or damages that require attention. |

| Dismantling | Carefully disassemble the relevant parts while keeping track of fasteners and components for easy reassembly. |

| Cleaning | Utilize appropriate cleaning agents to remove dirt and grease from components, ensuring all parts are in optimal condition. |

| Replacement | Replace any worn or damaged parts with new components that meet the manufacturer’s specifications. |

| Reassembly | Reassemble the parts in reverse order of disassembly, ensuring all fasteners are tightened to the specified torque. |

| Testing | Conduct a thorough test to verify that all systems are functioning correctly and there are no leaks or issues. |

Engine Troubleshooting Guide

This section provides essential insights for diagnosing common issues that may arise in the power unit of your vehicle. Recognizing symptoms early can help in efficiently addressing any complications, ensuring optimal performance and longevity.

Here are some common problems and their potential causes:

- Engine Won’t Start:

- Defective battery or electrical connections

- Faulty starter motor

- Empty fuel tank

- Clogged fuel lines or filter

- Overheating:

- Low coolant level

- Blocked radiator

- Faulty thermostat

- Worn-out water pump

- Unusual Noises:

- Loose or damaged components

- Insufficient lubrication

- Worn bearings or belts

- Poor Fuel Efficiency:

- Improper tire pressure

- Dirty air filter

- Incorrect fuel type

- Faulty fuel injectors

To systematically troubleshoot, follow these steps:

- Identify the symptoms being experienced.

- Consult the vehicle’s specifications for any relevant parameters.

- Inspect components associated with the issue.

- Test suspected faulty parts, replacing as necessary.

- Conduct a final check to ensure everything is functioning correctly.

By adhering to these guidelines, you can effectively diagnose and resolve issues, keeping your engine in prime condition.

Electrical System Diagnostics

The evaluation of the electrical framework is crucial for ensuring optimal performance and reliability of your motorcycle. This segment covers essential procedures for identifying issues within the electrical components, which can lead to improved functionality and longevity.

Begin by examining the battery condition, as it serves as the primary energy source. A weak or discharged battery can cause various problems, including poor starting and erratic electrical behavior. Use a multimeter to measure the voltage; a healthy battery should read around 12.6 volts when fully charged.

Next, assess the wiring harness for any signs of wear, fraying, or corrosion. Damaged wiring can lead to short circuits or power loss. Pay special attention to connectors and terminals, ensuring they are clean and secure. Good connections are essential for optimal conductivity.

Furthermore, inspect the fuses to ensure they are intact. A blown fuse may indicate an overload or a short circuit within the system. Replacing any faulty fuses is a straightforward task that can resolve many electrical issues.

Lastly, evaluate the various electrical components such as the starter motor, alternator, and relays. Testing these parts individually can help pinpoint the source of any malfunction. Regular diagnostics of the electrical system can prevent potential failures and enhance the overall riding experience.

Suspension and Chassis Adjustments

Proper tuning of the suspension and frame components is crucial for optimal performance and handling of any two-wheeled vehicle. These adjustments can significantly enhance ride comfort, stability, and control, allowing riders to adapt their machine to various conditions and personal preferences.

Understanding Suspension Settings

Adjusting the suspension involves modifying elements such as preload, compression, and rebound settings. Each of these factors influences how the bike responds to road irregularities and impacts, ultimately affecting overall ride quality. Riders should familiarize themselves with the specific characteristics of their vehicle’s suspension system to achieve the desired balance between comfort and performance.

Chassis Alignment and Maintenance

Maintaining proper alignment of the frame is essential for safe operation. Regular checks for any misalignments or wear can prevent handling issues and prolong the lifespan of the machine. Proper torque settings on various components, along with periodic inspections, ensure that the chassis remains stable and secure, enhancing both safety and performance.

Brake System Maintenance Tips

Proper upkeep of the braking mechanism is essential for ensuring safe operation and longevity. Regular inspections and timely interventions can prevent costly repairs and enhance performance.

- Regular Inspection: Check brake pads, discs, and fluid levels frequently to identify wear and tear early.

- Fluid Replacement: Change brake fluid every two years to maintain optimal hydraulic performance and prevent moisture contamination.

- Pad Replacement: Replace brake pads when they reach a thickness of 3mm to ensure effective stopping power.

- Brake Disc Maintenance: Inspect brake discs for warping or scoring; replace if necessary to maintain consistent braking performance.

- Bleeding the Brakes: Regularly bleed the brake lines to remove air bubbles, ensuring responsive braking action.

- Cleaning Components: Clean the calipers and brake pads to remove debris and dust that can cause noise or reduce efficiency.

Implementing these maintenance practices can significantly enhance the reliability of the braking system and contribute to a safer riding experience.

Transmission and Clutch Insights

The transmission and clutch system plays a crucial role in the overall performance and efficiency of a motorcycle. Understanding how these components work together can significantly enhance the riding experience. This section delves into essential aspects of these systems, providing valuable information for maintenance and troubleshooting.

Functionality of the Transmission

The primary purpose of the transmission is to facilitate the transfer of power from the engine to the wheels. This process involves several key elements:

- Gear Ratios: Different gears provide varying levels of torque and speed, allowing for smooth acceleration.

- Shifting Mechanism: A well-functioning shifting system enables seamless transitions between gears, improving responsiveness.

- Lubrication: Proper lubrication is essential to reduce friction and wear within the transmission.

Clutch Operation and Maintenance

The clutch is integral for controlling the power flow from the engine. Its proper function is vital for smooth starts and gear changes. Consider the following maintenance tips:

- Regularly check the clutch cable for tension and wear.

- Inspect the clutch plates for signs of damage or excessive wear.

- Ensure proper adjustment of the clutch lever to avoid engagement issues.

By maintaining both the transmission and clutch systems, riders can ensure optimal performance and longevity of their motorcycle.

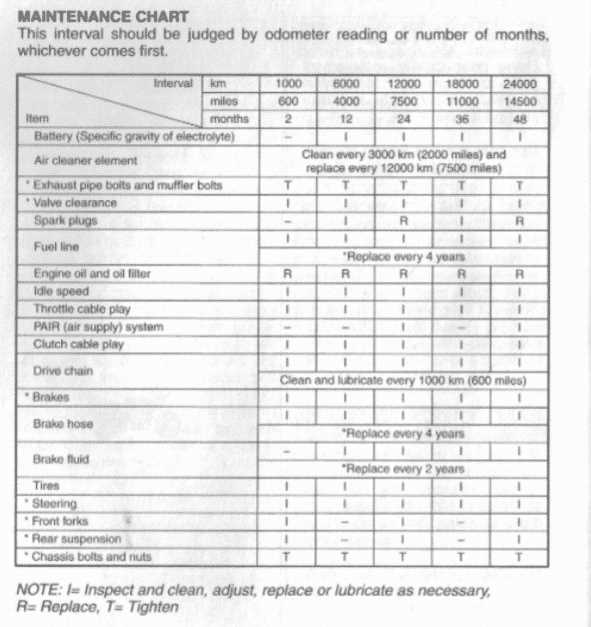

Regular Maintenance Schedule

Establishing a consistent upkeep routine is vital for ensuring optimal performance and longevity of your vehicle. Adhering to a well-structured plan can prevent unexpected issues and enhance the overall riding experience. This section outlines essential tasks and their recommended intervals for effective management.

Essential Maintenance Tasks

- Inspect and replace the engine oil every 3,000 to 5,000 miles.

- Check the coolant level and top off as necessary.

- Examine the air filter and clean or replace it as needed.

- Inspect the brake system, including pads and fluid levels, every 6,000 miles.

- Monitor tire pressure and tread depth regularly.

- Check the battery condition and terminals periodically.

Seasonal Considerations

- Before winter storage, perform a comprehensive check-up and clean the vehicle.

- In spring, inspect all systems and make necessary adjustments before regular use.

- Throughout the riding season, maintain tire pressure and perform routine checks after long trips.

Following these guidelines will help maintain efficiency and safety, providing a smooth and enjoyable riding experience.

Upgrading and Modifying Components

Enhancing and altering various elements of a motorcycle can significantly improve its performance and aesthetics. These modifications not only allow riders to tailor their machines to personal preferences but also can lead to enhanced handling, increased power, and improved efficiency. This section will explore some common upgrades that enthusiasts often consider.

Performance Enhancements

To achieve better acceleration and responsiveness, several components can be upgraded:

- Exhaust System: A high-performance exhaust can reduce back pressure and increase horsepower.

- Air Filter: An aftermarket air filter can improve airflow, resulting in better combustion and power output.

- Fuel Management System: Adjusting or replacing the fuel system can optimize fuel delivery for enhanced performance.

Aesthetic Modifications

Riders may also wish to personalize the appearance of their machine. Consider the following:

- Custom Paint Jobs: A unique color scheme can make a bike stand out on the road.

- Seat Upgrades: Aftermarket seats can enhance comfort and style.

- Lighting Kits: Upgrading to LED lights not only improves visibility but also adds a modern touch.

By carefully selecting which parts to enhance or modify, riders can create a machine that reflects their style and meets their performance needs.

Safety Precautions During Repairs

When undertaking maintenance tasks on your vehicle, ensuring a safe working environment is essential. Adhering to proper guidelines can prevent accidents and injuries while enhancing the efficiency of your work. This section outlines crucial safety measures that should be observed throughout the process.

General Safety Guidelines

- Always wear appropriate personal protective equipment, such as gloves and safety goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep your workspace organized to minimize the risk of accidents.

- Be cautious when handling tools and equipment, ensuring they are in good condition.

Electrical Safety

- Disconnect the battery before beginning any electrical work.

- Avoid working on wet surfaces or with wet hands to prevent electric shocks.

- Use insulated tools when dealing with electrical components.

Finding Replacement Parts

Locating suitable components for your motorcycle can be a straightforward process when you know where to look. The market offers a wide range of options for sourcing essential parts, ensuring that you can maintain your vehicle’s performance and longevity. Whether you prefer new or used items, various resources are available to meet your needs.

One effective method for acquiring parts is to explore local dealerships and specialized stores that focus on motorcycles. These establishments often carry a selection of components specifically designed for various models. Additionally, they can provide expert advice on compatibility and installation.

Online platforms have also become increasingly popular for purchasing parts. Websites dedicated to motorcycle enthusiasts frequently feature listings of both new and pre-owned items. These sites may include reviews and ratings, which can help you assess the reliability of the components before making a purchase.

Another valuable option is to connect with fellow riders through forums and social media groups. Engaging with a community of enthusiasts can lead to recommendations for trustworthy suppliers and may even result in opportunities to purchase parts from other riders who have upgraded or no longer need specific components.