Understanding the intricacies of maintaining a marine propulsion system is crucial for any enthusiast or professional. Regular upkeep not only enhances performance but also extends the lifespan of the engine, ensuring reliability on the water. This guide provides insights into the essential procedures and tips needed to keep your outboard motor in optimal condition.

Every engine type has its unique characteristics and requirements. Familiarizing yourself with specific components and their functions will empower you to troubleshoot issues effectively. A thorough comprehension of operational mechanisms and common problems is invaluable for both novice and seasoned users.

By following a structured approach to maintenance, including periodic inspections and necessary adjustments, you can prevent minor issues from escalating into major repairs. Emphasizing proactive care helps maintain efficiency and ensures a safe and enjoyable experience while navigating the waters.

Overview and Features

This section provides an insightful look into a high-performance outboard motor designed for reliability and efficiency on the water. Engineered for various marine applications, this engine combines advanced technology with user-friendly features, making it a popular choice among boating enthusiasts.

Key attributes of this powerful unit include:

- Lightweight Design: Optimized for easy handling and installation, enhancing overall performance.

- Fuel Efficiency: Engineered to minimize fuel consumption while maximizing power output, leading to cost savings on longer journeys.

- Robust Performance: Capable of delivering strong thrust and acceleration, suitable for various water conditions.

- Advanced Cooling System: Features a reliable cooling mechanism to prevent overheating during extended use.

- Quiet Operation: Designed to operate with minimal noise, enhancing the boating experience.

Additional benefits include:

- Durability: Built with high-quality materials that withstand harsh marine environments.

- Ease of Maintenance: Simple access to critical components for routine checks and servicing.

- Versatile Applications: Ideal for both recreational and commercial use, catering to a wide range of boating needs.

- Intuitive Controls: User-friendly interface for effortless operation, suitable for both novice and experienced users.

Overall, this outboard motor stands out for its blend of performance, efficiency, and convenience, making it a top choice for those seeking adventure on the water.

Common Issues with Suzuki DF70

When operating a marine outboard engine, various challenges may arise that can impact performance and reliability. Understanding these frequent problems is essential for effective maintenance and troubleshooting. Below are some of the most commonly encountered issues that users might face.

Electrical Problems

- Battery Failure: Regularly check the battery condition and connections to prevent starting issues.

- Ignition System Malfunctions: Look for faulty spark plugs or ignition coils that can lead to misfires.

- Wiring Corrosion: Inspect electrical connections for signs of rust or corrosion, which can disrupt power flow.

Fuel System Issues

- Clogged Fuel Filters: Regular replacement is necessary to ensure optimal fuel flow and engine performance.

- Fuel Leaks: Inspect hoses and connections for any signs of leakage that could lead to safety hazards.

- Carburetor Problems: Sticking float valves or dirty jets can affect fuel delivery, causing performance issues.

By being aware of these potential challenges, users can take proactive steps to maintain their equipment and ensure a smooth experience on the water.

Essential Tools for Repair

Having the right equipment is crucial for maintaining and fixing any machinery. Proper tools not only facilitate the process but also ensure that the work is done efficiently and safely. Below are some fundamental items that should be part of any toolkit for effective maintenance tasks.

- Wrenches: A variety of sizes, including adjustable wrenches, are essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for various types of screws.

- Pliers: Needle-nose and regular pliers are useful for gripping and bending materials.

- Socket Set: A comprehensive socket set allows for easy access to nuts and bolts in tight spaces.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

In addition to the basics, other specialized tools can enhance your capability:

- Multimeter: Essential for diagnosing electrical issues.

- Fuel Line Wrench: Useful for working with fuel systems.

- Diagnostic Scanner: Helps in reading error codes and troubleshooting electronic components.

- Cleaning Supplies: Brushes and solvents are important for maintaining cleanliness and ensuring longevity.

Equipping yourself with these tools will provide a strong foundation for any maintenance project, ensuring a smoother and more effective process.

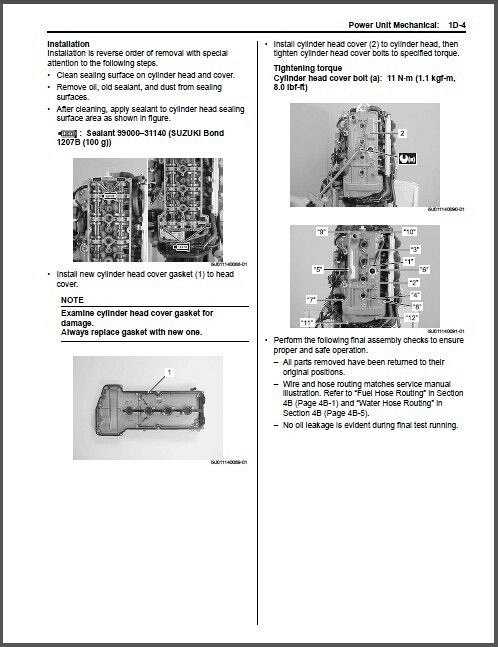

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your outboard engine. Following systematic maintenance tasks not only enhances efficiency but also helps identify potential issues before they escalate. This section outlines a series of straightforward procedures to keep your marine equipment in top shape.

1. Inspection of Fluid Levels

Begin by checking the engine oil, coolant, and fuel levels. Ensure all fluids are at appropriate levels and free from contamination. Replace any fluids that appear dirty or are below the recommended levels.

2. Cleaning the Fuel System

Regularly inspect and clean the fuel filter and lines to prevent blockages. Replace the fuel filter as recommended to maintain a clean fuel supply, which is crucial for efficient operation.

3. Spark Plug Maintenance

Remove and inspect the spark plugs for wear or buildup. Clean or replace them as necessary. Properly functioning spark plugs are vital for smooth ignition and optimal engine performance.

4. Checking the Propeller

Inspect the propeller for damage, such as dents or bends. Ensure it is securely attached and free from debris. A well-maintained propeller maximizes thrust and minimizes fuel consumption.

5. Battery Care

Check the battery terminals for corrosion and ensure all connections are tight. Clean the terminals and inspect the battery for any signs of leakage or damage. Maintaining a reliable power source is crucial for starting and running the engine efficiently.

6. Regular Lubrication

Apply lubricant to moving parts, including throttle and gear mechanisms. This reduces friction and wear, contributing to smoother operation. Always use the manufacturer-recommended lubricants for best results.

7. Visual Inspections

Conduct visual inspections of hoses, belts, and connections for signs of wear or deterioration. Promptly replace any components that appear damaged to prevent future failures.

By following these maintenance procedures diligently, you can ensure reliable performance and extend the life of your outboard engine, making your time on the water more enjoyable and worry-free.

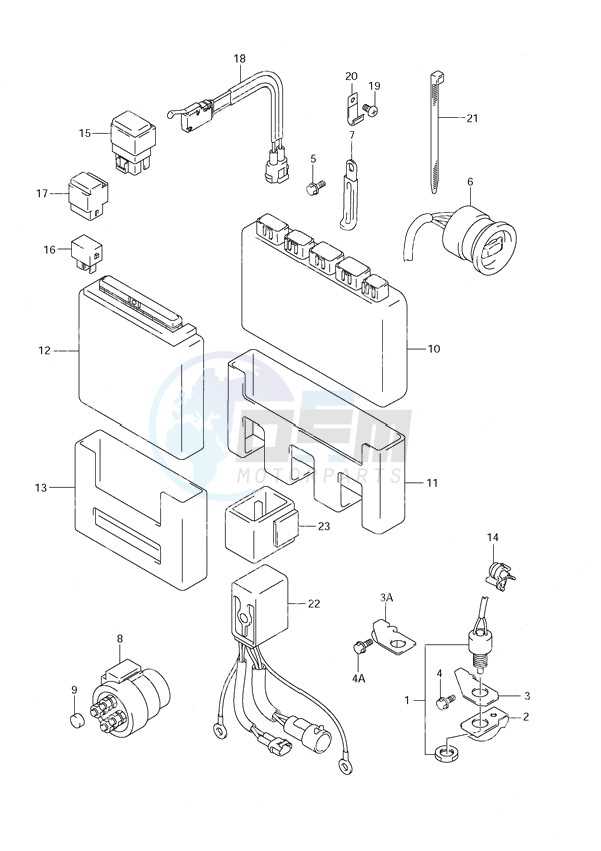

Understanding the Engine Components

The inner workings of an outboard motor are complex yet fascinating. Each component plays a critical role in ensuring the engine operates efficiently. A thorough understanding of these parts can significantly enhance maintenance and troubleshooting skills, allowing for a smoother experience on the water.

Key Components

- Powerhead: The heart of the engine, housing the cylinders, pistons, and crankshaft. It converts fuel into mechanical energy.

- Lower Unit: This section contains the gears and driveshaft, facilitating propulsion through the water.

- Cooling System: Ensures the engine remains at an optimal temperature, preventing overheating during operation.

- Fuel System: Responsible for delivering the right mixture of fuel and air to the engine for combustion.

- Electrical System: Powers the ignition and other electrical components, ensuring reliable starting and operation.

Importance of Each Component

Understanding how each part functions contributes to effective maintenance:

- Regular checks on the powerhead can prevent performance issues.

- Inspecting the lower unit ensures proper gear function and reduces wear.

- Monitoring the cooling system is vital to avoid engine damage.

- Keeping the fuel system clean prevents clogs and maintains efficiency.

- Maintaining the electrical system ensures reliable ignition and operation.

Safety Precautions During Repairs

When engaging in maintenance activities, ensuring personal safety and protecting the equipment are of utmost importance. Proper precautions not only minimize the risk of injury but also enhance the effectiveness of the work being carried out. Adhering to specific guidelines can lead to a smoother and more efficient process.

Essential Gear and Equipment

Before starting any tasks, it is crucial to equip yourself with the right protective gear. This includes gloves, safety goggles, and sturdy footwear. Always ensure that your work area is well-lit and organized to prevent accidents. Furthermore, using the appropriate tools for each job not only facilitates the work but also helps avoid damaging components.

Workspace Safety

Maintaining a clean and clutter-free workspace is vital. Remove any unnecessary items that could pose tripping hazards. Additionally, be mindful of the environmental conditions; avoid working in wet or damp areas to reduce the risk of electrical hazards. Finally, it is wise to have a first aid kit readily available, should any minor accidents occur.

Diagnosing Engine Problems Effectively

Identifying issues within an engine can be a complex task, but with the right approach, it becomes manageable. A systematic method allows for the pinpointing of faults, ensuring that repairs are both accurate and efficient. By focusing on symptoms and employing a series of diagnostic steps, you can streamline the troubleshooting process and enhance the performance of the engine.

Begin by observing any unusual signs. This includes strange noises, changes in performance, or warning indicators on the dashboard. Noting these symptoms is crucial as they guide the subsequent investigation. Documenting the conditions under which these symptoms occur can provide valuable context, helping to narrow down potential causes.

Next, check the basics. Ensure that the fuel supply, oil levels, and electrical connections are all in good condition. Often, simple issues like a clogged fuel filter or low oil can manifest as more serious problems. Performing a thorough inspection of these components can save time and resources in the long run.

Utilize diagnostic tools. Whether it’s a multimeter for electrical issues or a compression tester for internal engine health, having the right instruments at hand is essential. These tools can provide data that will clarify whether the problem lies within the ignition system, fuel delivery, or other critical areas. Interpreting this data accurately is key to effective troubleshooting.

Lastly, consult technical resources. Technical documents and online forums can offer insights into common problems and solutions. Engaging with experienced individuals can also provide perspectives that may not be immediately apparent. Combining personal observations with expert advice often leads to a more comprehensive understanding of the issue at hand.

Fuel System Troubleshooting Guide

Proper function of the fuel delivery system is essential for optimal engine performance. Issues can arise that may hinder operation, causing frustration for users. This guide will help identify common problems and suggest potential solutions, enabling effective maintenance and restoration of performance.

Common Symptoms

- Engine fails to start

- Inefficient acceleration

- Unusual engine noises

- Inconsistent idle speed

- Excessive fuel consumption

Troubleshooting Steps

- Check Fuel Supply: Ensure that there is an adequate amount of fuel in the tank. Inspect the fuel lines for any signs of leaks or blockages.

- Inspect Fuel Filter: A clogged filter can restrict fuel flow. Replace it if it appears dirty or contaminated.

- Examine Fuel Pump: Listen for any unusual noises from the pump. Ensure it is functioning correctly and providing sufficient pressure.

- Verify Fuel Quality: Contaminated fuel can lead to various issues. Consider draining the tank and refilling with fresh fuel.

- Assess Carburetor or Injectors: For carbureted systems, ensure the carburetor is clean and adjusted properly. For fuel-injected systems, check the injectors for clogs.

Electrical System Insights

The electrical system of any marine vessel plays a crucial role in its overall performance and safety. Understanding the components and their functions is essential for maintaining optimal operation and preventing potential issues. This section delves into the intricacies of the electrical network, emphasizing key elements that ensure reliability and efficiency on the water.

Key Components

The primary components of a marine electrical system include the battery, alternator, wiring, and circuit breakers. Each part has a specific function: the battery stores energy, the alternator generates power, and the wiring distributes electricity throughout the vessel. Regular inspections of these components are vital to identify wear or damage that could lead to failures.

Troubleshooting Common Issues

Electrical failures can manifest in various ways, such as flickering lights or unresponsive equipment. Identifying the root cause involves checking connections, testing voltage, and ensuring that fuses are intact. By systematically evaluating each part of the electrical system, one can quickly diagnose and resolve issues, enhancing the overall reliability of the vessel.

Recommended Replacement Parts

Ensuring optimal performance of your outboard motor often involves the timely substitution of certain components. By selecting high-quality replacement items, you can enhance the longevity and efficiency of your engine. Below is a list of essential parts that should be considered for routine updates and replacements.

1. Oil Filter: Regularly replacing the oil filter is crucial for maintaining clean engine oil, which in turn supports smooth operation and reduces wear on internal parts.

2. Spark Plugs: New spark plugs can significantly improve ignition efficiency, resulting in better fuel combustion and overall engine performance.

3. Fuel Filter: A clean fuel filter is vital for preventing contaminants from entering the fuel system, ensuring a steady flow of clean fuel to the engine.

4. Water Pump Kit: The water pump is essential for cooling the engine. Replacing the pump kit periodically will help avoid overheating and related damage.

5. Anodes: Sacrificial anodes protect metal parts from corrosion. Regular inspection and replacement are necessary to extend the life of your motor.

6. Gaskets and Seals: Over time, gaskets and seals can deteriorate, leading to leaks. Replacing them helps maintain the integrity of the engine.

Incorporating these components into your maintenance routine can help prevent unforeseen issues and ensure that your motor runs efficiently for years to come.

Performing Regular Maintenance Tasks

Regular upkeep is essential for ensuring optimal performance and longevity of any marine engine. By adhering to a structured maintenance routine, users can prevent unexpected breakdowns and enhance the overall efficiency of their vessel. This section outlines key tasks that should be performed consistently to maintain peak operating conditions.

Essential Maintenance Checks

Routine inspections play a vital role in identifying potential issues before they escalate. Key areas to focus on include checking fluid levels, inspecting the fuel system, and ensuring all connections are secure. Additionally, examining the electrical components for any signs of wear or corrosion can prevent future complications.

Lubrication and Component Care

Proper lubrication of moving parts is crucial for minimizing friction and wear. Regularly applying the appropriate lubricants not only protects components but also enhances overall functionality. Furthermore, keeping the cooling system clean and clear of debris ensures efficient temperature regulation, thereby prolonging the life of the engine.

Helpful Tips for Efficient Repairs

When it comes to maintaining marine engines, efficiency is key. Proper techniques not only save time but also ensure that the work is done correctly. Understanding common practices can lead to smoother operations and better outcomes.

1. Prepare Your Workspace

Having a clean and organized area is crucial. Gather all necessary tools and parts before starting. This minimizes interruptions and allows for a more focused approach.

2. Follow a Systematic Approach

Start with a thorough inspection. Document any issues and create a checklist. This methodical process helps in identifying all areas that require attention, preventing oversights.

3. Use Quality Parts

Investing in high-quality components can significantly enhance performance and longevity. Subpar parts often lead to repeated issues, resulting in wasted time and resources.

4. Refer to Resources

Utilizing available documentation can provide valuable insights and troubleshooting steps. Familiarizing yourself with operational guidelines enhances your understanding and efficiency.

5. Keep Learning

Stay updated on the latest techniques and technologies in marine maintenance. Attending workshops or reading relevant literature can broaden your skill set and improve your proficiency.

6. Practice Safety First

Always prioritize safety by using appropriate protective gear and adhering to safety protocols. This not only protects you but also ensures a smooth workflow without interruptions due to accidents.