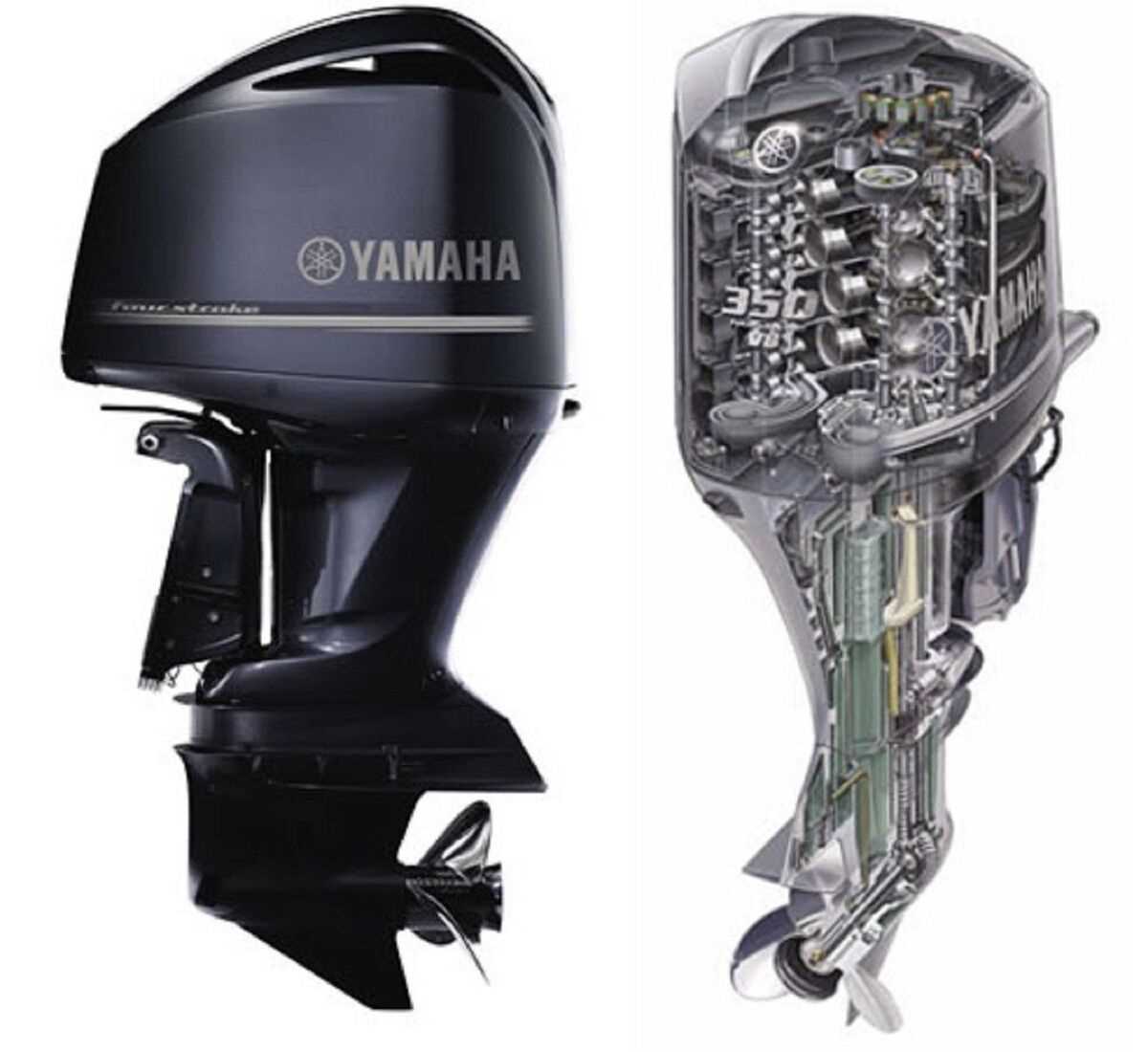

Ensuring the longevity and optimal performance of your marine propulsion unit is essential for a seamless boating experience. This section will delve into various essential procedures aimed at keeping your engine running efficiently. By adhering to these guidelines, you can avoid potential issues and enhance the reliability of your vessel.

From routine checks to troubleshooting common problems, this guide covers everything you need to know to maintain peak functionality. Understanding the intricacies of your engine and implementing preventive measures will help you navigate the waters with confidence. Regular upkeep not only extends the lifespan of your equipment but also contributes to safer and more enjoyable outings.

Equipped with the right knowledge and tools, you can tackle various tasks with ease. This resource is designed to empower you with the necessary insights to address any challenges that may arise. With a focus on practical advice and clear instructions, you will be well-prepared to care for your marine engine effectively.

Understanding the typical problems that can arise with marine propulsion systems is essential for maintaining optimal performance. This section aims to highlight prevalent challenges and provide practical solutions to enhance reliability and efficiency.

Frequent Problems

- Engine Won’t Start

- Overheating Issues

- Unusual Noises During Operation

- Fuel Leaks

- Power Loss or Poor Acceleration

Troubleshooting Strategies

- Engine Won’t Start:

- Check the battery connections and charge status.

- Inspect the ignition system for faults.

- Verify fuel supply and quality.

- Overheating:

- Examine the cooling system for blockages.

- Ensure the water intake is unobstructed.

- Check the thermostat and pump operation.

- Unusual Noises:

- Listen for grinding sounds which may indicate bearing wear.

- Look for loose components or damaged parts.

- Fuel Leaks:

- Inspect fuel lines and connectors for wear or damage.

- Ensure all fittings are secure and check for corrosion.

- Power Loss:

- Examine the fuel filter and replace if necessary.

- Check the propeller for damage or obstruction.

- Inspect the throttle system for responsiveness.

By systematically addressing these common issues, users can significantly improve the longevity and performance of their marine equipment.

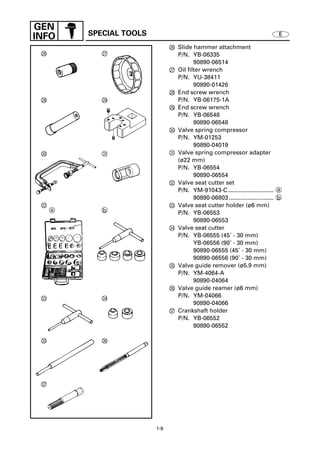

Tools Needed for Repairs

When it comes to maintaining and fixing your marine engine, having the right equipment is essential for a smooth process. A well-equipped workspace not only saves time but also enhances safety and efficiency. Below is a comprehensive list of tools that are beneficial for various tasks associated with engine upkeep.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and standard)

- Socket set

- Torque wrench

- Wire cutters and strippers

Specialized Equipment

- Multimeter for electrical diagnostics

- Oil filter wrench

- Propeller puller

- Fuel pressure gauge

- Diagnostic software (if applicable)

Having these tools at your disposal will facilitate effective maintenance and troubleshooting, ensuring that your engine operates optimally for years to come.

Step-by-Step Service Procedures

This section outlines a systematic approach to maintaining and troubleshooting your marine engine, ensuring optimal performance and longevity. By following these structured steps, you can effectively address common issues and enhance the reliability of your vessel.

1. Preparation: Begin by gathering all necessary tools and materials. A clean workspace is essential for efficiency. Ensure you have access to safety gear, as well as the appropriate lubricants and replacement parts.

2. Inspection: Conduct a thorough examination of the engine components. Look for any signs of wear, corrosion, or damage. Pay particular attention to the fuel system, electrical connections, and cooling mechanisms. Document any irregularities.

3. Cleaning: Remove debris and contaminants from the engine surfaces. Use suitable cleaning agents and tools to maintain the integrity of the components. A clean engine promotes better performance and can help identify potential issues.

4. Maintenance Tasks: Proceed with routine maintenance tasks such as changing the oil, replacing filters, and inspecting the propeller. Follow the specified intervals for each task to ensure peak functionality.

5. Testing: After completing the necessary procedures, perform a series of tests to verify that the engine operates smoothly. Check for unusual noises, vibrations, or leaks during operation. Adjust as needed.

6. Final Inspection: Conduct a final assessment to ensure all components are reassembled correctly. Verify that all tools and materials are removed from the workspace, and that safety protocols are followed before launching the vessel.

By adhering to these detailed procedures, you can maintain the performance and reliability of your engine, ensuring safe and enjoyable experiences on the water.

Electrical System Diagnostics

The electrical system is crucial for optimal performance, as it powers essential components and ensures proper operation. Diagnosing issues within this system requires a systematic approach to identify faults and verify functionality. A thorough understanding of the electrical components, including wiring, connections, and devices, is essential for effective troubleshooting.

Key Steps in Diagnosis: Begin by inspecting the wiring harness for any signs of damage, corrosion, or loose connections. Utilize a multimeter to measure voltage, continuity, and resistance across various components. This helps in pinpointing any irregularities that may indicate a malfunction.

Common Issues: Battery problems, such as insufficient charge or poor connections, can lead to performance issues. Additionally, faulty sensors or switches may disrupt the electrical flow, affecting the entire system’s efficiency. Regular checks of fuses and relays can also prevent unexpected failures.

Documenting findings and observations during the diagnostic process is vital. This allows for tracking patterns over time and facilitates a more comprehensive understanding of the electrical system’s health.

Cooling System Maintenance Techniques

Maintaining the cooling system is essential for optimal engine performance and longevity. A well-functioning cooling mechanism prevents overheating and ensures that the engine operates within the desired temperature range. Regular maintenance not only enhances efficiency but also minimizes the risk of costly repairs down the line.

Regular Inspection

Frequent checks of the cooling system components can help identify potential issues before they escalate. Focus on the following areas:

- Hoses: Examine for cracks, leaks, or signs of wear.

- Water Pump: Ensure it is functioning properly and that impellers are in good condition.

- Cooling Passages: Clear any debris or obstructions that may hinder flow.

Flushing the System

Flushing the cooling system is crucial for removing sediments and buildup that can impair performance. Follow these steps:

- Turn off the engine and allow it to cool.

- Disconnect the intake hose from the water pump.

- Use fresh water to flush the system, ensuring a thorough cleanse.

- Reconnect the hoses and run the engine briefly to clear any remaining debris.

By adhering to these maintenance techniques, one can ensure the cooling system operates efficiently, safeguarding the engine’s health and performance.

Fuel System Inspection and Repair

The fuel system is a critical component that ensures optimal performance and efficiency. Regular examination and maintenance of this system can prevent malfunctions and extend the lifespan of the engine. This section focuses on essential practices for assessing and rectifying any issues within the fuel delivery mechanism.

Common Issues and Symptoms

Several signs may indicate a problem within the fuel system. Recognizing these symptoms early can facilitate timely intervention. Below is a list of common issues and their corresponding indicators:

| Issue | Symptoms |

|---|---|

| Clogged fuel filter | Engine stalling, reduced power |

| Leaking fuel lines | Visible fuel odor, damp spots |

| Defective fuel pump | Hard starting, sputtering |

| Contaminated fuel | Misfiring, poor acceleration |

Inspection Steps

To maintain the fuel system effectively, follow these inspection steps:

- Visually check for leaks in fuel lines and connections.

- Examine the fuel filter for clogs and replace it if necessary.

- Test the fuel pump for proper operation.

- Assess the quality of the fuel and consider draining contaminated fuel.

By adhering to these guidelines, you can ensure the fuel system operates smoothly, contributing to the overall efficiency and reliability of the engine.

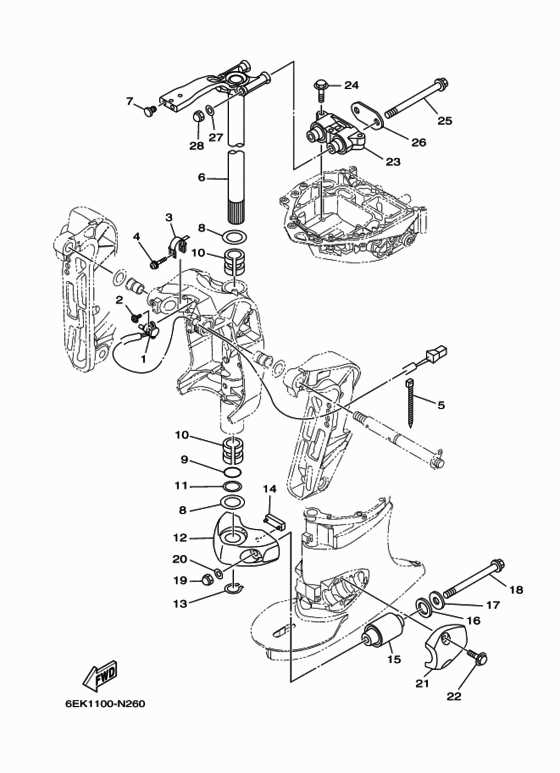

Propeller and Gearcase Adjustments

Ensuring optimal performance of your marine propulsion system requires careful attention to propeller and gearcase settings. Proper adjustments can enhance efficiency, improve handling, and extend the lifespan of crucial components. This section outlines the importance of aligning these elements to achieve peak operational capabilities.

To begin, it is essential to verify the pitch and diameter of the propeller, as these factors significantly influence thrust and fuel consumption. An incorrect pitch can lead to either underperformance or excessive engine strain. Regular checks and modifications help maintain the ideal balance for various operating conditions.

Next, the gearcase alignment plays a critical role in the overall function of the system. Ensuring that the gearcase is correctly positioned can prevent unnecessary wear and tear, while also enhancing the transmission of power. Adjustments may involve checking for any misalignments and making necessary corrections to guarantee smooth operation.

Lastly, periodic inspection of both the propeller and gearcase is advisable. This includes looking for signs of damage or wear that may hinder performance. Maintaining these components in peak condition is vital for safe and efficient navigation on the water.

Regular Lubrication Practices

Maintaining optimal performance of marine engines requires consistent attention to lubrication. Proper lubrication ensures that moving parts operate smoothly, reducing friction and wear. Establishing a routine for applying suitable lubricants can extend the lifespan of critical components and enhance overall efficiency.

It is essential to identify key areas that require regular lubrication. These include bearings, joints, and other mechanical interfaces where metal surfaces come into contact. Using the appropriate type of lubricant and adhering to recommended intervals can prevent potential issues and promote reliable operation.

| Component | Recommended Lubricant | Lubrication Interval |

|---|---|---|

| Gearcase | High-performance marine grease | Every 100 hours or annually |

| Steering System | Marine-grade lubricant | Every 50 hours or semi-annually |

| Throttle and Shift Linkage | Light oil or grease | Every 50 hours |

| Trim Tabs | Marine lubricant | Every 100 hours or annually |

By adhering to these lubrication practices, operators can ensure smoother operation and mitigate the risks of mechanical failures. Consistent checks and timely applications of the right lubricants will ultimately contribute to the longevity and reliability of marine engines.

Winterization and Storage Advice

Preparing your marine engine for the colder months is essential for maintaining its performance and longevity. Proper winterization not only protects vital components from freezing temperatures but also ensures that the engine is ready for smooth operation when the season changes. This guide outlines important steps to effectively winterize and store your vessel.

Essential Winterization Steps

- Flush the Cooling System: Run fresh water through the cooling system to remove salt, dirt, and debris.

- Change the Oil: Replace old oil and filter to prevent contaminants from causing damage during storage.

- Stabilize the Fuel: Add fuel stabilizer to the tank and run the engine briefly to circulate it throughout the system.

- Inspect and Replace Filters: Check and replace any worn or clogged filters to ensure optimal performance.

Storage Recommendations

- Choose a Suitable Location: Store the engine in a dry, well-ventilated area, away from direct exposure to moisture.

- Cover the Engine: Use a protective cover to shield the engine from dust and debris.

- Check Battery Maintenance: Remove the battery and store it in a cool, dry place, ensuring it is fully charged.

- Regular Inspections: Periodically check on the engine throughout the winter to address any potential issues.

Following these guidelines will help safeguard your marine engine during the winter months, ensuring it is ready for action when the weather warms up again.

Recommended Replacement Parts List

This section provides a comprehensive overview of essential components that may require replacement over time to ensure optimal performance and longevity of your marine engine. Regular maintenance and timely replacement of worn parts are crucial for the reliability and efficiency of your vessel.

1. Fuel Filter – This component is vital for keeping impurities out of the fuel system, ensuring smooth operation.

2. Oil Filter – Regularly changing the oil filter helps maintain engine health by preventing contaminants from circulating.

3. Spark Plugs – These should be replaced periodically to ensure proper ignition and efficient combustion.

4. Water Pump Impeller – A critical part for cooling, replacing the impeller regularly helps prevent overheating.

5. Thermostat – This component regulates engine temperature, and replacement is necessary if overheating issues arise.

6. Batteries – Ensuring reliable power supply is essential, so check and replace batteries as needed.

7. Belts and Hoses – Inspecting and replacing these components can prevent leaks and drive failures.

8. Propeller – Damaged or worn propellers can affect performance; regular inspection and replacement are advised.

9. Zinc Anodes – These protect against corrosion; they should be replaced when they are significantly eroded.

10. Fuel Lines – Check for wear and replace to avoid leaks and ensure fuel delivery is consistent.

Expert Tips for Long-lasting Performance

Ensuring the longevity and efficiency of your marine engine requires diligent care and attention. By implementing a few essential practices, you can significantly enhance its performance and durability, ultimately leading to a more enjoyable experience on the water.

Regular inspections are crucial. Check for signs of wear and tear, including hoses, filters, and electrical connections. Addressing minor issues promptly can prevent costly repairs in the future.

Routine maintenance is key to optimal functioning. Change the oil and replace the fuel filters according to the manufacturer’s recommendations. Clean the propeller and check for any debris that may hinder performance.

Use quality fuel and lubricants to ensure your engine runs smoothly. Contaminated fuel can lead to performance issues and damage components, so always opt for reputable sources.

Proper storage is equally important. When not in use, ensure your engine is winterized and protected from the elements. This will help prevent corrosion and other damage during off-seasons.

Lastly, consult with a professional for periodic comprehensive evaluations. Their expertise can provide insights that enhance your engine’s performance and extend its lifespan.