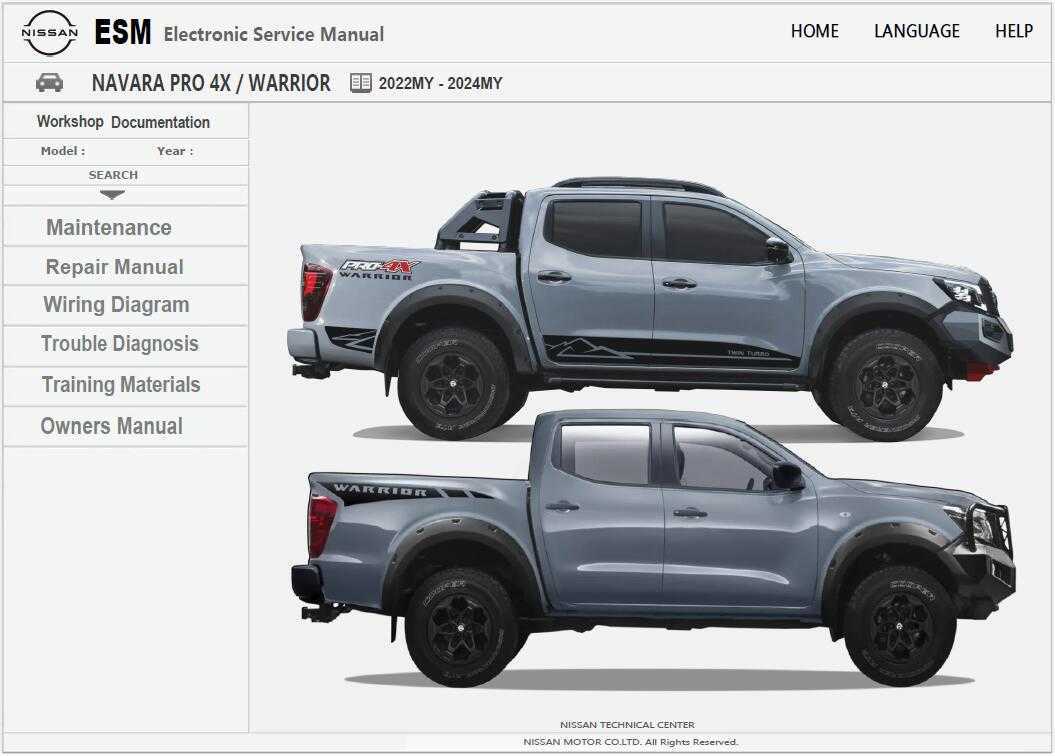

When it comes to ensuring the longevity and optimal performance of your automobile, having access to a thorough guide can be invaluable. This section aims to provide insights into the essential processes and techniques required for keeping your vehicle in top condition. With the right knowledge, car enthusiasts and everyday drivers alike can navigate the complexities of automotive care with confidence.

Understanding the intricate systems of your vehicle is crucial for effective upkeep. From the engine to the transmission, each component plays a vital role in the overall functionality. Familiarizing yourself with these systems not only helps in identifying potential issues early on but also empowers you to make informed decisions about necessary actions.

Furthermore, this resource serves as a helpful companion for those seeking to enhance their mechanical skills. By learning various troubleshooting methods and maintenance tasks, individuals can save time and money while gaining a deeper appreciation for their automobiles. Whether you’re a seasoned mechanic or a curious beginner, this guide offers valuable knowledge to aid you in your automotive journey.

Nissan Maintenance Guidelines Overview

Maintaining optimal performance and longevity of your vehicle requires adherence to specific recommendations. These protocols are designed to ensure reliability and efficiency throughout its lifespan. Understanding the essentials of upkeep can greatly enhance driving experience and safety.

Regular Inspections: Routine evaluations are crucial. Components such as brakes, tires, and fluid levels should be checked periodically to identify wear and tear early on.

Fluid Changes: Keeping fluids fresh is vital for operational integrity. Regularly replacing engine oil, coolant, and transmission fluid helps in preventing overheating and excessive wear.

Scheduled Servicing: Following a predetermined schedule for maintenance tasks, as outlined in the guidelines, assists in prolonging the vehicle’s life and performance. This includes aspects like filter replacements and timing belt checks.

By following these foundational principles, you ensure that your vehicle remains in prime condition, ready for any journey ahead.

Common Issues and Troubleshooting Steps

This section aims to highlight frequent problems encountered during vehicle operation and provide practical solutions. By identifying these challenges early, vehicle owners can avoid more significant issues and ensure their vehicles remain in optimal condition.

Frequent Problems

Vehicles may experience a range of issues, from electrical failures to mechanical complications. Understanding these common concerns allows for prompt intervention and minimizes potential disruptions. Below is a table summarizing typical problems and their possible solutions:

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Engine Won’t Start | Dead Battery | Check battery connections; jump-start the battery if necessary. |

| Overheating | Low Coolant Level | Inspect coolant reservoir; refill as needed; check for leaks. |

| Strange Noises | Worn Belts or Bearings | Examine belts for wear; replace if frayed or cracked. |

| Poor Fuel Economy | Dirty Air Filter | Inspect and clean or replace the air filter as required. |

Diagnostic Techniques

To effectively address issues, it is crucial to utilize diagnostic techniques. Observing warning lights, conducting visual inspections, and utilizing specialized tools can provide valuable insights into the underlying causes of vehicle problems. Regular maintenance checks can also prevent many issues from arising.

Tools Required for Nissan Repairs

When it comes to maintaining and fixing vehicles, having the right set of tools is essential. A well-equipped toolkit not only ensures efficiency but also enhances the overall quality of work. Understanding the various instruments needed can make any task simpler and more effective.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners. |

| Wrenches | For gripping, turning, and pulling nuts and bolts. |

| Screwdrivers | For driving screws and accessing tight spaces. |

| Torque Wrench | For applying precise torque to fasteners. |

| Pliers | For gripping, twisting, and cutting wires. |

| Multimeter | For testing electrical systems and components. |

| Jack and Stands | For lifting the vehicle safely during maintenance. |

| Diagnostic Scanner | For identifying issues within the vehicle’s systems. |

Having these essential tools at your disposal can significantly streamline the maintenance process, allowing for quicker and more accurate work. Being prepared with the right equipment is a vital aspect of any successful automotive task.

Understanding Nissan Diagnostic Codes

Diagnostic codes serve as essential tools for identifying issues within a vehicle’s systems. These alphanumeric sequences provide insight into potential malfunctions, guiding technicians in troubleshooting processes. By interpreting these codes, one can effectively narrow down the underlying problems, leading to efficient repairs and enhanced vehicle performance.

Types of Diagnostic Codes

Diagnostic codes can be categorized into two main types: generic and manufacturer-specific. Generic codes apply across various makes and models, while manufacturer-specific codes are tailored to individual brands. Understanding these distinctions is crucial for accurate diagnostics.

Common Diagnostic Codes and Their Meanings

| Code | Description |

|---|---|

| P0300 | Random/multiple cylinder misfire detected |

| P0420 | Catalyst system efficiency below threshold |

| P0442 | Evaporative emission control system leak detected (small leak) |

| P0455 | Evaporative emission control system leak detected (gross leak) |

| P0171 | System too lean (Bank 1) |

Familiarity with these codes empowers vehicle owners and technicians alike to make informed decisions regarding maintenance and repairs, ultimately contributing to the longevity of the vehicle.

Routine Checks for Optimal Performance

Regular assessments are essential for ensuring that vehicles operate efficiently and reliably. These systematic evaluations help identify potential issues before they escalate, contributing to smoother performance and prolonged lifespan. Adopting a proactive approach can significantly enhance the overall driving experience.

One key aspect involves inspecting fluid levels, including engine oil, coolant, and brake fluid. Maintaining appropriate levels not only supports optimal functionality but also prevents damage to critical components. Additionally, monitoring tire pressure and tread depth is crucial for safety and fuel efficiency.

Another vital check includes examining the battery condition. Corrosion on terminals or weak connections can lead to starting difficulties and electrical system failures. Ensuring that the battery is secure and adequately charged is paramount.

Lastly, evaluating the braking system, including pads and rotors, plays a significant role in maintaining safety. Regular inspection of these components helps ensure effective stopping power and reduces the risk of accidents.

Safety Procedures During Repairs

Ensuring a safe environment while performing maintenance tasks is paramount. Adhering to specific protocols not only protects individuals involved but also contributes to the longevity and reliability of the machinery being serviced. These guidelines serve as a foundation for a secure and effective workflow.

Personal Protective Equipment (PPE) is essential in minimizing hazards. This includes items such as gloves, goggles, and helmets that safeguard against potential injuries. Always inspect PPE for wear and tear before use, ensuring maximum protection during any task.

Work Area Organization plays a critical role in maintaining safety. Keeping tools and materials organized reduces the risk of accidents and promotes efficiency. Ensure that all pathways are clear, and hazardous materials are stored properly to prevent spills and injuries.

Emergency Preparedness is vital for any work environment. Familiarize yourself with the location of first aid kits, fire extinguishers, and emergency exits. Conduct regular safety drills to ensure everyone knows how to respond effectively in case of an emergency.

By following these essential practices, individuals can create a safe working atmosphere that promotes both productivity and well-being. Prioritizing safety not only benefits the individual but also enhances the overall performance of the equipment being maintained.

Parts Replacement and Compatibility

When it comes to maintaining a vehicle, understanding the intricacies of component substitution and their compatibility is essential. Properly selecting replacement parts ensures optimal performance and longevity, while also safeguarding against potential issues that may arise from incorrect fittings.

Importance of Compatibility

Choosing components that are designed to work harmoniously with each other is crucial. Mismatched parts can lead to inefficiencies and may even compromise safety. Ensuring compatibility involves considering factors such as dimensions, specifications, and the overall design of the vehicle.

Sources for Replacement Parts

There are various sources to obtain quality replacement items. Original equipment manufacturers (OEM) provide parts specifically engineered for the vehicle, while aftermarket options offer alternatives that may be more cost-effective. It’s important to research and evaluate these sources to make informed decisions that align with your vehicle’s needs.

Fluid Types and Maintenance Tips

Maintaining optimal performance in your vehicle requires an understanding of various liquid substances essential for its operation. Each type plays a crucial role in ensuring that different systems function smoothly, while regular upkeep can significantly extend the lifespan of your automobile.

Here are some common types of fluids used in vehicles and tips for their maintenance:

| Fluid Type | Function | Maintenance Tips |

|---|---|---|

| Engine Oil | Lubricates engine components and reduces friction. | Check levels regularly and change every 5,000 to 7,500 miles. |

| Transmission Fluid | Facilitates smooth shifting of gears. | Inspect for color change; replace as per manufacturer guidelines. |

| Coolant | Regulates engine temperature and prevents overheating. | Flush system every 30,000 miles and monitor levels frequently. |

| Brake Fluid | Transmits force from the pedal to the brakes. | Check for moisture and replace every two years. |

| Power Steering Fluid | Assists in steering operation. | Keep at recommended levels; top off as needed. |

Understanding and managing these vital fluids will enhance your vehicle’s reliability and performance, making regular checks a beneficial habit for every vehicle owner.

Electrical System Diagnostics Explained

The process of identifying issues within the electrical framework of vehicles is crucial for ensuring optimal performance and reliability. Understanding the intricacies of this system can significantly enhance troubleshooting efficiency.

Key components involved in diagnostics include:

- Battery and Charging System

- Wiring Harness and Connectors

- Sensors and Actuators

- Control Modules

Diagnostic tools play an essential role in this process. Commonly utilized instruments are:

- Multimeter for voltage and resistance measurements

- Scan tool for retrieving fault codes

- Oscilloscope for analyzing waveforms

By systematically testing each component, technicians can pinpoint failures and implement effective solutions. Regular checks and maintenance can prevent potential electrical problems, contributing to the longevity of the vehicle’s performance.

Engine Components and Functions

The internal combustion engine is a complex assembly of various parts that work together to convert fuel into mechanical energy. Understanding these components is essential for diagnosing performance issues and ensuring optimal operation. Each element plays a crucial role in the overall functionality, contributing to efficiency, power output, and emissions control.

Major Engine Parts

The primary elements include the cylinder block, pistons, crankshaft, and cylinder head. The cylinder block houses the cylinders where combustion occurs. Pistons move within these cylinders, driven by the force of expanding gases. The crankshaft converts this linear motion into rotational energy, powering the vehicle. The cylinder head contains the valves and other vital components that regulate airflow and combustion processes.

Supporting Systems

Transmission Care and Maintenance

Proper upkeep of the transmission system is essential for the smooth operation and longevity of your vehicle. Regular attention to this component can prevent costly issues and ensure optimal performance. By following best practices for maintenance, you can enhance driving experience and reliability.

Regular Fluid Checks

Monitoring and changing the transmission fluid at recommended intervals is crucial. Fluid levels should be checked routinely, and any signs of contamination or degradation warrant immediate attention. Clean fluid helps maintain hydraulic pressure and prevents wear on internal parts.

Inspection and Adjustment

Routine inspections of the transmission for leaks, unusual noises, or shifting issues are vital. Addressing these problems promptly can mitigate further damage. Additionally, ensuring that linkage adjustments are accurate promotes efficient operation, contributing to a seamless driving experience.

Wheel Alignment and Suspension Work

Ensuring proper wheel orientation and suspension integrity is crucial for optimal vehicle performance and safety. This process involves adjusting the angles of the wheels to align them with each other and the road. Proper alignment not only enhances handling but also prolongs the lifespan of tires and other components.

Importance of Accurate Alignment

Accurate alignment minimizes tire wear and improves fuel efficiency. When wheels are misaligned, it can lead to uneven tire wear, steering issues, and reduced traction. Regular checks and adjustments can prevent these problems, ensuring a smoother driving experience.

Suspension Components and Maintenance

The suspension system plays a vital role in providing stability and comfort. Key components include shock absorbers, springs, and control arms. Regular inspection and maintenance of these elements are essential to maintain proper vehicle handling. Any worn or damaged parts should be replaced promptly to avoid compromising safety.