Maintaining and troubleshooting garden machinery is essential for optimal performance and longevity. This guide provides a detailed overview of essential procedures and insights necessary for keeping your equipment in top condition. From routine upkeep to complex diagnostics, understanding the nuances of maintenance can significantly enhance the user experience.

With the right knowledge and tools, any operator can confidently approach various tasks. This resource is designed to empower users with practical advice and step-by-step instructions, ensuring that every aspect of their machinery is addressed. Emphasizing clarity and accessibility, it serves as a valuable reference for both novices and experienced users alike.

Familiarity with the operational aspects can prevent common issues and reduce the need for extensive interventions. By utilizing the techniques outlined in this guide, individuals can not only enhance efficiency but also extend the lifespan of their equipment. A proactive approach to maintenance is the key to achieving lasting performance and reliability.

Proper upkeep of your equipment is crucial for ensuring its longevity and optimal performance. Utilizing the right implements not only simplifies tasks but also enhances efficiency, making it easier to keep your machinery in excellent condition. Here is a comprehensive overview of the fundamental tools necessary for effective maintenance.

Basic Hand Tools

Having a set of essential hand tools is vital for any maintenance routine. These implements can handle various tasks, from tightening bolts to performing minor adjustments.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening or tightening nuts and bolts. |

| Screwdriver Set | For driving screws and making adjustments to components. |

| Pliers | Helpful for gripping, twisting, and cutting wire. |

| Socket Set | Ideal for reaching fasteners in tight spaces. |

Power Tools

In addition to hand tools, power tools can greatly expedite maintenance processes. These tools offer increased efficiency and precision, especially for more demanding tasks.

| Tool | Purpose |

|---|---|

| Electric Drill | Useful for drilling holes and driving screws quickly. |

| Impact Wrench | Provides high torque for loosening stubborn fasteners. |

| Angle Grinder | Effective for cutting and grinding materials. |

| Pressure Washer | For cleaning surfaces and removing debris efficiently. |

Step-by-Step Repair Procedures

This section outlines the systematic approach to addressing common issues encountered with the equipment. Following a structured method not only enhances efficiency but also ensures that each component is thoroughly evaluated for optimal functionality.

Initial Assessment

Before embarking on any corrective actions, it is essential to conduct a comprehensive assessment. Identify the symptoms and document any unusual noises or behaviors. This preliminary step aids in pinpointing the root cause of the malfunction, facilitating targeted interventions.

Disassembly and Inspection

Once the problem has been identified, carefully proceed with the disassembly of the relevant sections. Ensure to follow a logical order, keeping track of all components. Inspect each part for signs of wear or damage. Replace any defective components before reassembling to maintain the integrity of the equipment.

Safety Precautions During Repairs

When conducting maintenance on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines ensures a secure environment for both the individual performing the tasks and any bystanders. Proper preparation and awareness of potential hazards play a significant role in achieving a successful and safe working experience.

Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear, to minimize risks during maintenance activities. Additionally, ensure that the work area is well-lit and free from clutter to avoid tripping hazards. Before beginning any procedure, disconnect the power source to prevent unintentional starts that could lead to serious injuries.

Familiarize yourself with the equipment’s components and functionality to effectively manage any risks. Always follow the manufacturer’s recommendations and guidelines to ensure compliance with safety protocols. If using tools, inspect them for any defects before use, as damaged tools can contribute to accidents. Lastly, maintain a clear understanding of emergency procedures in case of accidents, ensuring that assistance is readily available if needed.

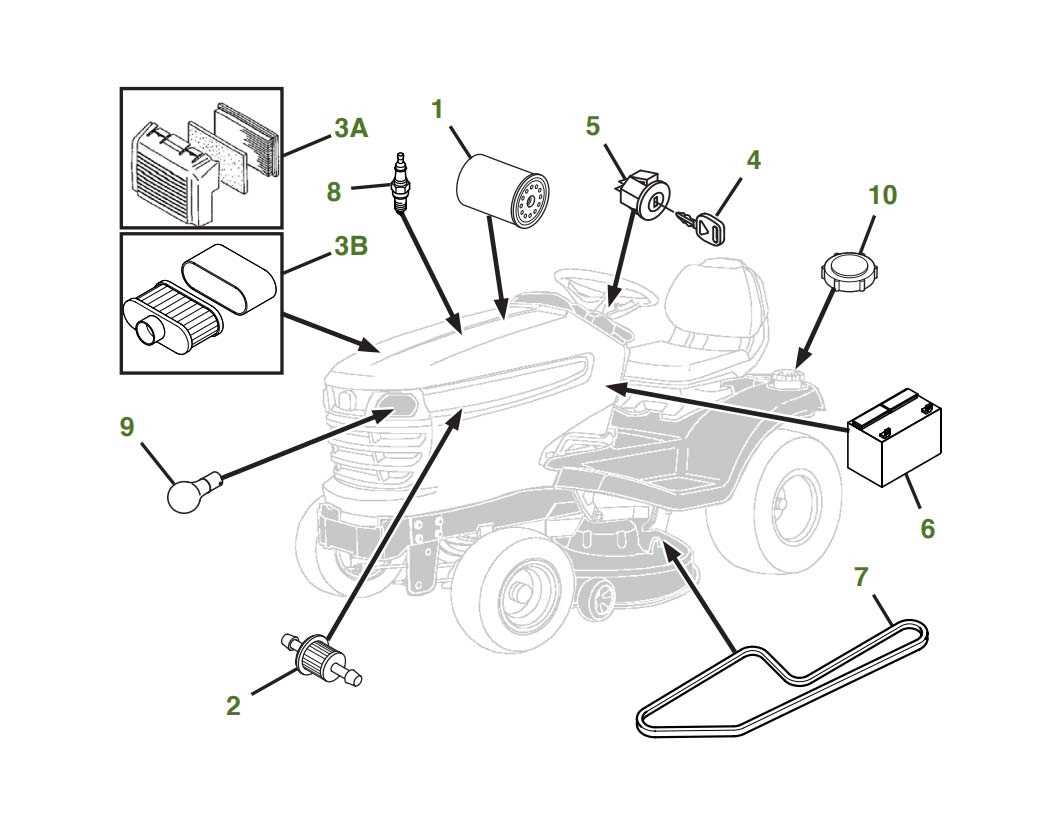

Identifying Parts and Components

Understanding the various elements of a machine is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, and recognizing these parts can significantly enhance operational efficiency. Familiarity with individual elements allows for timely intervention and minimizes the risk of mechanical failures.

Common Elements include the engine, transmission, and cutting deck. These parts are vital for performance and often require routine checks. Engines provide the necessary power, while the transmission transfers that power to the wheels, enabling movement. The cutting deck is responsible for the actual mowing, and keeping it in optimal condition is key for achieving a neat finish.

Additional Components such as belts, pulleys, and filters also warrant attention. Belts facilitate the movement of various parts, while pulleys help in the distribution of power. Regular inspection of filters ensures that the engine operates efficiently by keeping out contaminants. A thorough understanding of these components can greatly contribute to the longevity and reliability of the equipment.

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Adhering to a seasonal maintenance schedule can prevent potential issues and enhance efficiency. Below is a comprehensive checklist designed to guide you through the necessary tasks to keep your machine in top condition throughout the year.

Spring Maintenance Tasks

As the growing season begins, it is vital to prepare your equipment for the demands ahead. Focus on the following tasks:

| Task | Description |

|---|---|

| Inspect and Replace Air Filter | Check the air filter for dirt and debris; replace if necessary to ensure proper airflow. |

| Change Engine Oil | Replace old oil with fresh oil to maintain engine health and performance. |

| Sharpen Blades | Ensure cutting blades are sharp for efficient grass cutting. |

Fall Maintenance Tasks

As the season transitions, it’s crucial to prepare your equipment for winter storage. Consider the following tasks:

| Task | Description |

|---|---|

| Clean the Equipment | Remove grass clippings, dirt, and debris from the exterior and underside. |

| Store Properly | Find a dry, sheltered location for storage to protect from harsh weather conditions. |

| Check Fuel System | Add fuel stabilizer to the gas tank and run the engine for a few minutes to circulate it. |

Troubleshooting Electrical Problems

Electrical issues can significantly hinder the performance of outdoor machinery. Identifying and resolving these problems promptly is essential for ensuring optimal functionality. This section outlines key strategies for diagnosing common electrical faults, allowing users to restore equipment to working order efficiently.

Begin by examining the following areas:

- Battery Condition: Check for corrosion on terminals and ensure the battery is fully charged.

- Wiring Inspection: Look for frayed or damaged wires that may cause shorts or disruptions.

- Fuses: Inspect all fuses for signs of damage or failure, replacing any that are blown.

- Switches: Test all electrical switches to ensure they are functioning correctly.

When encountering persistent issues, consider these steps:

- Verify the voltage supply using a multimeter.

- Consult the equipment’s documentation for wiring diagrams and specifications.

- Engage a qualified technician if the problem persists after performing basic checks.

By systematically addressing these areas, users can effectively troubleshoot and resolve electrical complications, enhancing the reliability and performance of their machinery.

Engine Care and Servicing Tips

Proper maintenance of your power unit is essential for optimal performance and longevity. Regular attention to various components ensures that the machine operates efficiently, reducing the likelihood of breakdowns and costly repairs. Below are some crucial care strategies to keep your engine running smoothly.

Regular Oil Changes

Changing the lubricant at recommended intervals is vital for engine health. Fresh oil helps minimize friction and wear, ensuring all parts function effectively.

- Check oil levels frequently.

- Use the appropriate type of lubricant as specified in the guidelines.

- Replace oil filters with every oil change to maintain cleanliness.

Air Filter Maintenance

A clean air intake is crucial for proper combustion and overall efficiency. Neglecting the air filter can lead to decreased performance and fuel efficiency.

- Inspect the air filter regularly for dirt and debris.

- Clean or replace the filter as needed, depending on the operating environment.

- Ensure that the filter is seated properly to prevent unfiltered air from entering the engine.

By following these recommendations, you can enhance the reliability of your equipment, ensuring it remains in top-notch condition throughout its lifespan.

Upgrading Your Lawn Tractor Performance

Enhancing the efficiency and capabilities of your gardening equipment can significantly improve its functionality and lifespan. By making thoughtful modifications, you can achieve better performance, increased power, and improved handling, ensuring that your outdoor tasks are completed more effectively.

One effective approach is to upgrade the engine components, such as the air filter and exhaust system. A high-flow air filter allows for better airflow, resulting in improved combustion and power output. Similarly, an upgraded exhaust system can reduce back pressure and enhance engine efficiency.

Additionally, consider adjusting the cutting deck height and sharpness of the blades. Maintaining well-sharpened blades ensures cleaner cuts and can reduce stress on the motor. Fine-tuning the height can also optimize grass collection and reduce clumping, making your mowing experience more efficient.

Another aspect to explore is tire upgrades. Opting for high-traction tires can enhance maneuverability and stability on various terrains, providing better grip and reducing slippage. This can be particularly beneficial when navigating uneven ground or wet conditions.

Lastly, regular maintenance practices, such as oil changes and belt inspections, are essential for sustaining performance improvements. Keeping your equipment in top condition will not only prolong its life but also ensure that any enhancements made are fully realized.