Maintaining outdoor machinery is essential for ensuring their longevity and optimal performance. A comprehensive guide can provide valuable insights into the common issues faced by users and the necessary steps to address them effectively. By following a structured approach, individuals can enhance the functionality and efficiency of their devices, leading to a more enjoyable experience in outdoor maintenance tasks.

Understanding the intricacies of mechanical systems can significantly simplify troubleshooting. Regular inspections and routine care can prevent minor problems from escalating into major failures. Embracing a proactive mindset towards upkeep allows users to identify potential challenges before they hinder productivity.

Equipping oneself with the right knowledge is crucial. Whether it’s basic maintenance tasks or more complex procedures, having a detailed resource at hand ensures that users can navigate through various scenarios with confidence. This guide aims to empower users by providing practical information and step-by-step instructions tailored for their specific needs.

Common Issues and Troubleshooting Techniques

When operating outdoor equipment, encountering various challenges is common. Recognizing these issues promptly and applying effective solutions can enhance performance and extend the lifespan of the machinery. This section explores frequent problems users face and provides practical troubleshooting methods.

Typical Problems

Several issues may arise, ranging from mechanical failures to operational inconsistencies. Understanding these common faults allows for quicker resolutions. Below is a list of prevalent complications:

| Issue | Description | Possible Solution |

|---|---|---|

| Engine Not Starting | Power issues or fuel shortages may prevent ignition. | Check the fuel levels and battery condition; replace if necessary. |

| Uneven Cutting | Blades may be dull or improperly aligned, leading to inconsistent results. | Sharpen or replace blades; ensure correct leveling of the cutting deck. |

| Overheating | Overuse or inadequate maintenance can cause temperature spikes. | Allow the engine to cool; check for blockages in cooling systems. |

| Strange Noises | Unusual sounds may indicate loose parts or wear and tear. | Inspect and tighten components; replace worn parts as needed. |

Maintenance Tips

Regular upkeep is essential to minimize problems and ensure reliable performance. Users should consider the following maintenance practices:

- Inspect and clean air filters regularly to maintain airflow.

- Change oil according to the manufacturer’s recommendations.

- Keep blades sharp for efficient cutting.

- Store equipment in a dry place to prevent rust and corrosion.

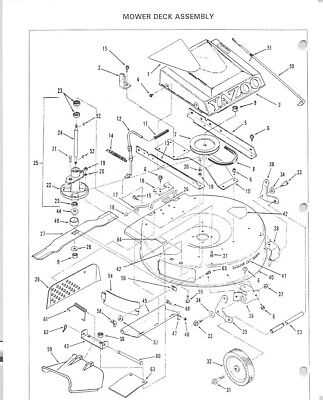

Step-by-Step Repair Procedures

This section provides detailed guidelines for addressing common issues that may arise with lawn care equipment. Following these systematic instructions will ensure effective troubleshooting and restoration, allowing for optimal performance.

Before beginning any work, ensure you have the necessary tools and safety equipment on hand. Here’s a general outline of the procedures to follow:

-

Preparation:

- Gather essential tools such as wrenches, screwdrivers, and safety goggles.

- Read through the guidelines thoroughly to familiarize yourself with the process.

-

Inspection:

- Examine the equipment for visible signs of wear or damage.

- Check all connections and components for secure fitment.

-

Disassembly:

- Carefully remove covers or panels using appropriate tools.

- Document the location and orientation of components for reassembly.

-

Diagnosis:

- Identify the source of the issue based on observations made during inspection.

- Consult reference materials for potential fixes relevant to the identified problem.

-

Replacement or Repair:

- Replace any faulty parts with high-quality components.

- If repair is possible, ensure that it is performed according to best practices.

-

Reassembly:

- Reattach all components securely, following the documentation from disassembly.

- Ensure that all screws and bolts are tightened appropriately.

-

Testing:

- Power on the equipment to verify that it functions correctly.

- Monitor for any unusual sounds or behaviors during operation.

By adhering to these outlined steps, individuals can effectively restore their equipment to full functionality, enhancing their overall experience and efficiency in lawn maintenance tasks.

Engine Care and Replacement Guidelines

Maintaining optimal performance and longevity of any engine requires a systematic approach to care and, when necessary, replacement. Proper attention to various components ensures smooth operation and minimizes the risk of malfunction. This section provides essential practices to uphold engine integrity and guidelines for replacement when needed.

To keep the engine running efficiently, consider the following maintenance tips:

- Regularly check and change the oil according to the manufacturer’s recommendations.

- Inspect air filters frequently and replace them as needed to ensure proper airflow.

- Examine spark plugs for wear and replace them if they show signs of corrosion or damage.

- Keep cooling systems free from debris and check coolant levels periodically.

- Monitor fuel quality and storage conditions to prevent contamination.

When it comes to replacing an engine, follow these steps for a smooth transition:

- Gather all necessary tools and a suitable replacement engine that matches specifications.

- Disconnect the battery and remove any components obstructing access to the engine.

- Carefully detach the old engine, noting the connections for reinstallation.

- Install the new engine, ensuring all connections are secure and follow the specified torque settings.

- Reconnect the battery and perform initial tests to verify proper operation.

Adhering to these guidelines will help maintain engine functionality and ensure a successful replacement process when necessary.

Blade Sharpening and Replacement Tips

Maintaining cutting implements is crucial for achieving optimal performance in various tasks. Proper care not only enhances the efficiency of the tools but also extends their lifespan. This section provides essential guidelines for keeping cutting edges in prime condition through effective sharpening techniques and timely replacement.

Here are some key tips for sharpening and replacing blades:

- Regular Inspection: Frequently check the edges for signs of wear or damage. Look for chips, dullness, or irregularities that could affect performance.

- Sharpening Frequency: Establish a routine based on usage. Frequent use may necessitate sharpening every few hours, while occasional tasks might allow for longer intervals.

- Sharpening Tools: Use appropriate tools such as whetstones, sharpening jigs, or electric sharpeners. Ensure the angle of sharpening matches the original edge for optimal results.

- Technique: When sharpening, maintain consistent pressure and angle. Move the blade in a controlled manner to achieve a uniform edge.

- Cleaning: After sharpening, clean the blade thoroughly to remove metal filings and debris that can cause corrosion.

When it’s time to replace a blade, follow these guidelines:

- Selection: Choose a blade that matches the specifications required for your specific tasks. Pay attention to size, type, and material for best performance.

- Safe Removal: Always ensure the tool is powered off and disconnected from any power source before attempting to replace the cutting implement.

- Installation: Follow manufacturer instructions for proper installation. Securely attach the new blade to prevent it from loosening during use.

- Post-Installation Check: After replacement, double-check the alignment and tightness of the blade. A loose or misaligned blade can lead to poor performance or accidents.

By adhering to these tips, you can enhance the performance and longevity of your cutting tools, ensuring they remain efficient and effective for years to come.

Understanding the Electrical System

The electrical framework in any machinery plays a critical role in ensuring smooth operation and efficient performance. This system encompasses various components that work together to provide power and control necessary functions. A solid grasp of this network can significantly aid in diagnosing issues and maintaining optimal functionality.

Key Components of the Electrical System

- Batteries: These serve as the primary power source, supplying energy to start the engine and operate various electrical devices.

- Wiring Harness: This assembly of wires connects different electrical parts, facilitating communication and power distribution.

- Ignition System: Responsible for initiating combustion in the engine, this system relies on various sensors and modules.

- Switches and Relays: These components control the flow of electricity, allowing for the operation of lights, fans, and other features.

Troubleshooting Electrical Issues

Identifying electrical problems requires a methodical approach. Here are some steps to consider:

- Check the battery voltage using a multimeter to ensure it is within the recommended range.

- Inspect the wiring for any signs of wear, damage, or loose connections.

- Test switches and relays for functionality, replacing any faulty components.

- Review the ignition system, ensuring all sensors are functioning correctly.

By understanding the intricacies of the electrical system, individuals can enhance the longevity and reliability of their machinery.

Transmission and Drive System Insights

The effectiveness of any outdoor equipment largely depends on the functionality of its transmission and propulsion mechanisms. Understanding these components is crucial for optimal performance and longevity. Proper maintenance and occasional troubleshooting can significantly enhance the efficiency of these systems, ensuring that they operate smoothly and reliably.

At the heart of the drive system is the mechanism that transfers power from the engine to the wheels, facilitating movement. Various types of transmissions can be found in outdoor equipment, each with its unique advantages and operational characteristics. Familiarity with these elements can aid in identifying issues and implementing solutions.

| Component | Description | Common Issues |

|---|---|---|

| Transmission | Controls the speed and torque by regulating power transfer. | Slipping, noisy operation, or complete failure. |

| Drive Belts | Transfer power from the engine to the wheels; often made of rubber or composite materials. | Wear and tear, cracks, or misalignment. |

| Gearbox | Contains gears that alter speed and torque as required for different tasks. | Overheating, leaks, or gear grinding. |

| Axles | Connect the wheels to the drive system and transmit power to them. | Rust, bending, or breakage. |

Regular inspection and maintenance of these components can prevent breakdowns and ensure smooth operation. It is advisable to follow manufacturer guidelines regarding service intervals and procedures to keep these systems in peak condition.

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of outdoor equipment. By adhering to a seasonal maintenance schedule, operators can address potential issues before they escalate, enhancing efficiency and reliability throughout the year.

Spring Maintenance

- Inspect and clean air filters to ensure proper airflow.

- Sharpen blades for effective cutting and reduced strain on the engine.

- Change the oil and replace the oil filter to promote smooth operation.

- Check fuel lines and connections for any signs of wear or leaks.

- Examine belts for signs of cracking or fraying and replace if necessary.

Fall Maintenance

- Flush and clean the fuel system to prevent buildup during storage.

- Check battery condition and clean terminals to ensure reliable starting.

- Inspect tires for proper inflation and tread wear.

- Cover or store equipment in a dry, sheltered area to protect it from harsh weather.

- Perform a general inspection to identify any additional repairs needed before the off-season.

Safety Protocols During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both personal safety and the integrity of the equipment. Proper precautions can significantly reduce the risk of accidents and injuries.

Before starting any work, it is essential to wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear to shield against potential hazards. Additionally, make sure to work in a well-ventilated area to avoid inhaling harmful fumes.

Disconnecting the power source is a fundamental step before initiating any task. This action prevents accidental starts that could lead to injuries. Furthermore, always double-check that the equipment is securely positioned and will not move during the process.

Utilizing the right tools is vital for safe and effective handling. Using tools that are specifically designed for the task at hand helps avoid unnecessary strain and ensures efficient operation. Keeping tools in good condition also plays a key role in maintaining safety standards.

Following proper procedures for disassembly and reassembly is essential. Always refer to relevant guidelines and ensure that components are replaced correctly to avoid malfunction. After completing the work, conduct a thorough inspection to confirm everything is secure before re-engaging the power source.

By adhering to these safety protocols, individuals can enhance their protection and ensure a smoother workflow while undertaking maintenance tasks.

Frequently Asked Repair Questions

This section addresses common inquiries related to maintenance and troubleshooting issues encountered by users. Understanding these frequent concerns can help enhance your experience and ensure smooth operation of your equipment.

What are the common signs of malfunction?

Users often report various indicators that suggest a need for attention. These may include unusual noises, difficulty starting, or a lack of power during operation. Recognizing these symptoms early can prevent further complications.

How can I perform basic maintenance?

Regular upkeep is crucial for optimal functionality. Tasks such as checking fluid levels, inspecting blades, and cleaning air filters can significantly extend the lifespan of your equipment. Following these simple procedures can help maintain peak performance.