Understanding the nuances of maintaining and rejuvenating your marker can greatly enhance your overall experience in the field. This section serves as a comprehensive guide, providing essential insights into the processes involved in keeping your equipment in optimal condition. Whether you’re facing minor hiccups or more significant challenges, the following information will equip you with the knowledge necessary for effective troubleshooting.

Through a detailed exploration of common issues, component functions, and best practices, you will gain valuable skills to ensure your device performs at its best. Emphasis will be placed on practical techniques and helpful tips that can be implemented easily, allowing you to tackle problems with confidence. Engaging with this content will empower you to take control of your maintenance tasks and extend the lifespan of your beloved equipment.

As you delve into the specifics, remember that each step you take contributes to a smoother operation and a more enjoyable experience on the field. Armed with the right information, you’ll be well-prepared to address any challenges that arise, ensuring that your equipment remains a reliable companion during your adventures.

Tippmann 98 Custom Overview

This section provides an insight into a popular marker in the world of paintball. Renowned for its reliability and user-friendly features, this model has become a favorite among both novice and experienced players. Its design prioritizes performance while ensuring ease of maintenance and customization.

Key Features

The marker is equipped with several standout attributes that enhance gameplay. Its robust construction ensures durability in various environments, while the versatile firing modes allow players to adapt to different styles of play. Additionally, compatibility with a range of accessories further enhances its functionality.

Specifications

| Feature | Details |

|---|---|

| Weight | Approx. 3 lbs |

| Length | 20 inches |

| Caliber | .68 caliber |

| Firing Modes | Semi-automatic, Response trigger |

| Feed System | Gravity-fed or electronic |

Common Issues with Tippmann Markers

When using paintball markers, players may encounter several recurring problems that can affect performance and gameplay. Understanding these issues can help users maintain their equipment effectively and ensure a smooth experience on the field.

Frequent Problems

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Air Leaks | Hissing sound, loss of pressure | Inspect O-rings, tighten fittings, replace damaged seals |

| Inconsistent Velocity | Fluctuating shot power, erratic range | Adjust regulator, clean barrel, check for blockages |

| Jams | Marker fails to fire, paintballs stuck | Clear obstruction, lubricate moving parts, check feed mechanism |

Maintenance Tips

Regular maintenance is crucial for preventing these issues. Keep the marker clean, perform routine inspections, and replace worn parts as necessary to ensure optimal performance during play.

Tools Needed for Repairs

When addressing issues with your equipment, having the right instruments at hand is crucial for effective troubleshooting and maintenance. This section outlines essential items that can facilitate the process, ensuring you are well-prepared for any task.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws of various sizes. |

| Wrench Set | For loosening and tightening bolts and nuts securely. |

| Pliers | For gripping and manipulating small parts and wires. |

| Hex Key Set | For accessing hex screws commonly found in assemblies. |

| Cleaning Supplies | To ensure all components are free of debris and dirt. |

| Lubricants | For maintaining moving parts and reducing friction. |

Step-by-Step Disassembly Guide

This section provides a detailed approach to taking apart your device safely and efficiently. Understanding the disassembly process is crucial for maintenance and troubleshooting, allowing you to identify issues and replace parts as necessary.

-

Gather necessary tools:

- Screwdriver set

- Wrench

- Pliers

- Soft cloth or mat

- Container for small parts

-

Prepare the workspace:

- Choose a clean, well-lit area.

- Lay out a soft cloth to prevent scratches.

- Organize tools within reach.

-

Remove external components:

- Detach any accessories attached to the device.

- Unscrew and remove the cover or casing.

-

Access internal parts:

- Carefully unscrew internal fasteners.

- Gently lift out internal assemblies, taking note of their arrangement.

-

Document the process:

- Take pictures or notes for reassembly.

- Keep small parts organized in the container.

-

Inspect components for wear or damage:

- Check seals, springs, and other critical parts.

- Replace any faulty components as needed.

Following these steps will help ensure a successful disassembly process. Always refer to specific guidelines for your model when needed.

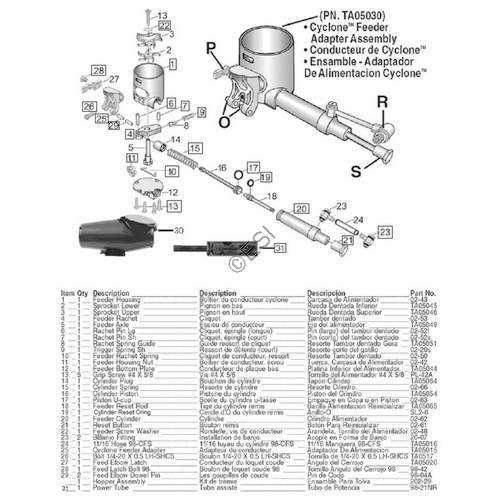

Identifying Parts and Components

Understanding the various elements and assemblies of a paintball marker is crucial for effective maintenance and functionality. This section will guide you through the essential parts that comprise the device, aiding in recognition and comprehension of their roles.

| Part Name | Description |

|---|---|

| Receiver | The main body that houses critical components and serves as the foundation of the marker. |

| Barrel | The tube through which paintballs are fired; its length and bore size can affect accuracy. |

| Trigger Assembly | Consists of the trigger and related components that control firing action. |

| Air Tank | Stores compressed gas used to propel paintballs; different sizes and types may be utilized. |

| Feed Neck | The attachment point for the hopper, which holds and feeds paintballs into the marker. |

| Detent | Prevents multiple paintballs from entering the chamber at once, ensuring proper firing. |

Maintenance Tips for Longevity

To ensure the extended lifespan of your equipment, consistent upkeep and attention to detail are essential. Regular maintenance not only enhances performance but also minimizes the likelihood of future issues, allowing you to enjoy a smooth operation.

1. Regular Cleaning: After each use, clean all parts thoroughly to remove debris and residue. Utilize a soft cloth and appropriate cleaning solutions to prevent buildup that could affect functionality.

2. Lubrication: Apply lubricant to moving parts regularly. This reduces friction and wear, promoting optimal performance and extending the life of critical components.

3. Inspection: Frequently inspect all components for signs of wear or damage. Identifying issues early can prevent more serious problems and costly repairs.

4. Proper Storage: Store your gear in a cool, dry place away from direct sunlight. This protects sensitive materials from degrading and helps maintain overall integrity.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and practices provided by the manufacturer. These guidelines are designed to maximize performance and durability.

By implementing these practices, you can significantly enhance the longevity and reliability of your equipment.

Replacing the O-Rings

O-rings play a crucial role in maintaining the integrity and functionality of various devices by preventing leaks and ensuring a tight seal. Over time, these components can wear out, leading to diminished performance. This section outlines the steps to effectively replace these essential parts.

Tools Needed

- Replacement O-rings

- O-ring pick or small flathead screwdriver

- Lubricant (silicone-based recommended)

- Clean cloth

Step-by-Step Instructions

- Ensure the device is unloaded and disassembled as necessary to access the O-rings.

- Carefully remove the old O-rings using the pick or screwdriver, taking care not to damage surrounding components.

- Clean the seating area with a cloth to remove any debris or residue.

- Apply a small amount of lubricant to the new O-rings to facilitate installation.

- Position the new O-rings into place, ensuring they are seated correctly.

- Reassemble the device, ensuring all components are secured properly.

Regular maintenance, including the replacement of these seals, is essential for optimal operation and longevity of your equipment.

Upgrading Internal Mechanisms

Enhancing the internal components of your marker can significantly improve its performance and reliability. Upgrades can lead to smoother operation, increased efficiency, and a more enjoyable experience on the field. This section will explore various options for upgrading these essential parts.

Consider the following upgrades to enhance functionality:

- Firing Assembly: Upgrading the firing mechanism can lead to better air efficiency and faster cycling rates.

- Bolt System: A high-quality bolt can reduce friction and increase durability, ensuring consistent performance.

- Valves: Installing upgraded valves can improve air flow and enhance the marker’s overall responsiveness.

- Spring Kits: Utilizing different spring configurations can fine-tune the firing pressure, allowing for better customization based on player preferences.

When selecting upgrades, it is crucial to ensure compatibility with existing components. Regular maintenance and careful installation can maximize the benefits of these enhancements, providing a competitive edge in gameplay.

Cleaning and Lubrication Techniques

Maintaining optimal performance of your equipment involves regular cleaning and proper lubrication. These practices not only enhance functionality but also extend the lifespan of the components. By eliminating dirt and applying the right substances, you can ensure smooth operation and prevent wear.

Cleaning should be approached methodically. Begin by disassembling the unit carefully, ensuring you keep track of all parts. Use a soft brush or cloth to remove debris from surfaces. For stubborn residues, a mild solvent may be utilized, but avoid harsh chemicals that could damage sensitive components. Pay special attention to areas prone to buildup, as neglect can lead to malfunctions.

Once the cleaning process is complete, lubrication is essential. Select a high-quality lubricant suitable for the specific parts being treated. Apply it sparingly, focusing on moving components to reduce friction. Over-lubricating can attract dirt, so a little goes a long way. Regular checks and maintenance will keep the mechanism functioning effectively and efficiently.

In summary, consistent cleaning and proper lubrication are crucial for maintaining the integrity and performance of your device. Implementing these techniques will result in a more reliable and enjoyable user experience.

Troubleshooting Firing Problems

When facing issues with the firing mechanism of a paintball marker, it’s essential to identify the underlying causes to restore optimal performance. Common challenges can arise from various components, affecting the overall functionality.

Check Air Source: Ensure that the air supply is fully charged and securely connected. A depleted or poorly connected tank can lead to inconsistent firing or complete failure to fire.

Inspect the Trigger Mechanism: A malfunctioning trigger assembly may hinder the firing process. Examine for any obstructions or wear that could impede movement. Cleaning and lubrication may enhance responsiveness.

Examine the Bolt: The bolt plays a crucial role in chambering paintballs. Inspect for debris or damage that could prevent it from moving freely. Proper alignment and cleanliness are key to ensuring reliable operation.

Review the Hopper: A clogged or malfunctioning hopper can disrupt the feed of paintballs. Ensure it is filled appropriately and check for jams that might be obstructing the flow.

Test the Battery: If your marker relies on electronic components, verify that the power source is functioning correctly. A weak or dead battery can lead to intermittent firing issues.

By systematically addressing these areas, users can effectively troubleshoot and resolve firing difficulties, enhancing the overall shooting experience.

Adjusting Velocity Settings

Fine-tuning the projectile speed is essential for optimal performance in any paintball marker. Proper adjustments not only enhance accuracy but also ensure safety during gameplay. This section will guide you through the necessary steps to achieve the desired velocity.

To begin, gather the following tools:

- Chronograph

- Adjustable wrench

- Lubricant

Follow these steps to adjust the velocity:

- Safety First: Always ensure that the marker is unloaded and pointed in a safe direction before making any adjustments.

- Locate the Adjustment Screw: Find the velocity adjustment screw, typically located near the back of the marker.

- Initial Settings: Use a chronograph to measure the current velocity. This will serve as your baseline.

- Make Adjustments: Turn the adjustment screw:

- Clockwise to increase velocity

- Counterclockwise to decrease velocity

- Test the Changes: After making adjustments, fire several shots and check the velocity readings again.

- Repeat as Necessary: Continue adjusting until the desired velocity is achieved.

Regular maintenance and periodic checks of the settings are recommended to maintain consistent performance during games.

Reassembly Process Explained

The reassembly of your marker requires careful attention to detail and a systematic approach. This section outlines the essential steps to ensure a smooth and efficient reassembly, helping you restore functionality while maintaining optimal performance.

Begin by organizing all components. Before you start putting everything back together, lay out all parts in a logical order. This practice will make it easier to identify each piece and understand where it fits within the assembly.

Follow a step-by-step method. Begin with the main body, carefully aligning any internal mechanisms. Ensure that all springs and detents are properly positioned before moving on to the next section. Taking your time at this stage is crucial, as any misalignment could lead to performance issues later.

Secure fasteners correctly. When attaching screws or bolts, use the appropriate tools and torque specifications. Over-tightening can cause damage, while under-tightening may result in loose parts that can affect operation.

Test functionality incrementally. After each major step, perform a quick test to ensure that all components work correctly. This approach allows you to identify and address potential issues before the final assembly.

By following these guidelines, you can effectively reassemble your equipment, ensuring it operates at its best for future use.

Resources for Further Assistance

When encountering challenges with your equipment, accessing the right support can make a significant difference. There are various resources available that can provide guidance, troubleshooting tips, and community insights to help you resolve issues effectively.

| Resource Type | Description | Link |

|---|---|---|

| Official Website | Access product specifications, FAQs, and customer service contact information. | Visit Site |

| Online Forums | Join discussions with fellow enthusiasts who share their experiences and solutions. | Join Forum |

| Video Tutorials | Watch step-by-step guides to understand assembly, maintenance, and troubleshooting processes. | Watch Tutorials |

| Community Groups | Participate in local or online groups to exchange tips and receive hands-on advice. | Join Group |