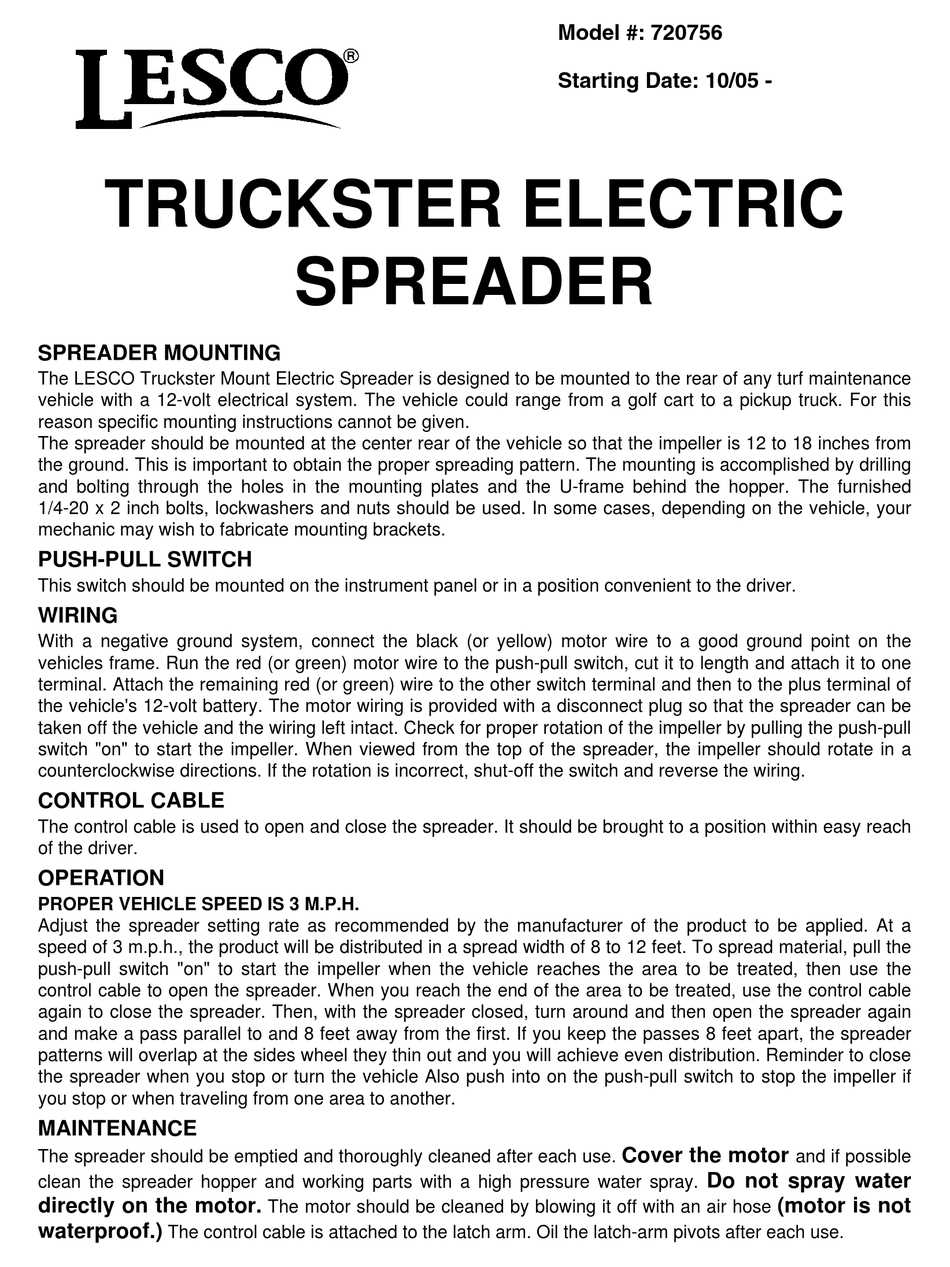

Ensuring the longevity and functionality of your turf application equipment is essential for achieving optimal results in lawn care. Regular maintenance not only enhances performance but also prevents potential issues that can arise from neglect. Understanding the components and functions of this machinery will empower you to keep it in peak condition.

In this section, we will explore various aspects of servicing and troubleshooting, providing you with insights and practical steps to address common challenges. By familiarizing yourself with the inner workings of your equipment, you can make informed decisions and carry out effective interventions as needed.

Proper upkeep is crucial to maintaining efficiency and productivity. Adopting a proactive approach to care will ensure that your equipment continues to perform at its best, allowing you to focus on achieving a lush, healthy landscape.

Understanding the frequent problems that arise with distribution devices can enhance their efficiency and longevity. Identifying these concerns early can prevent costly repairs and ensure optimal performance during use.

Here are some typical challenges encountered:

- Uneven Distribution: Inconsistent flow can result from blockages or worn components, leading to irregular application.

- Mechanical Failures: Components may become damaged due to wear and tear, impacting functionality.

- Calibration Issues: Incorrect settings can lead to excessive or insufficient material being dispensed.

- Corrosion: Exposure to moisture and chemicals can cause parts to degrade, affecting overall performance.

- Handling Difficulties: User errors in operation can result in inefficient use, such as incorrect speed or angle adjustments.

Regular maintenance and prompt attention to these issues can significantly enhance the effectiveness of your equipment.

Tools Needed for Repairs

When it comes to maintaining and restoring your equipment, having the right tools on hand is essential for efficiency and effectiveness. This section outlines the key instruments that can facilitate the process and ensure a successful outcome.

Basic Hand Tools: A set of reliable hand tools is fundamental for any maintenance task. This includes screwdrivers, wrenches, and pliers to handle various fasteners and components. Quality tools provide the necessary leverage and grip to work effectively.

Power Tools: Depending on the extent of the work required, power tools such as drills and saws may be advantageous. These instruments can expedite tasks that would be labor-intensive with hand tools, saving both time and effort.

Specialized Equipment: Certain repairs might necessitate specialized instruments, like calipers or gauge tools, for precise measurements. These tools ensure that every component fits perfectly, maintaining the integrity of the machine.

Safety Gear: Don’t forget to prioritize safety by utilizing gloves, goggles, and other protective equipment. Working with machinery can pose risks, and appropriate safety measures can help prevent accidents.

Step-by-Step Repair Guide

This section offers a comprehensive approach to restoring your equipment, ensuring optimal functionality and longevity. By following a structured process, you can effectively address common issues and maintain peak performance.

Begin by gathering all necessary tools and replacement components. A well-organized workspace will facilitate a smoother workflow and enhance your efficiency.

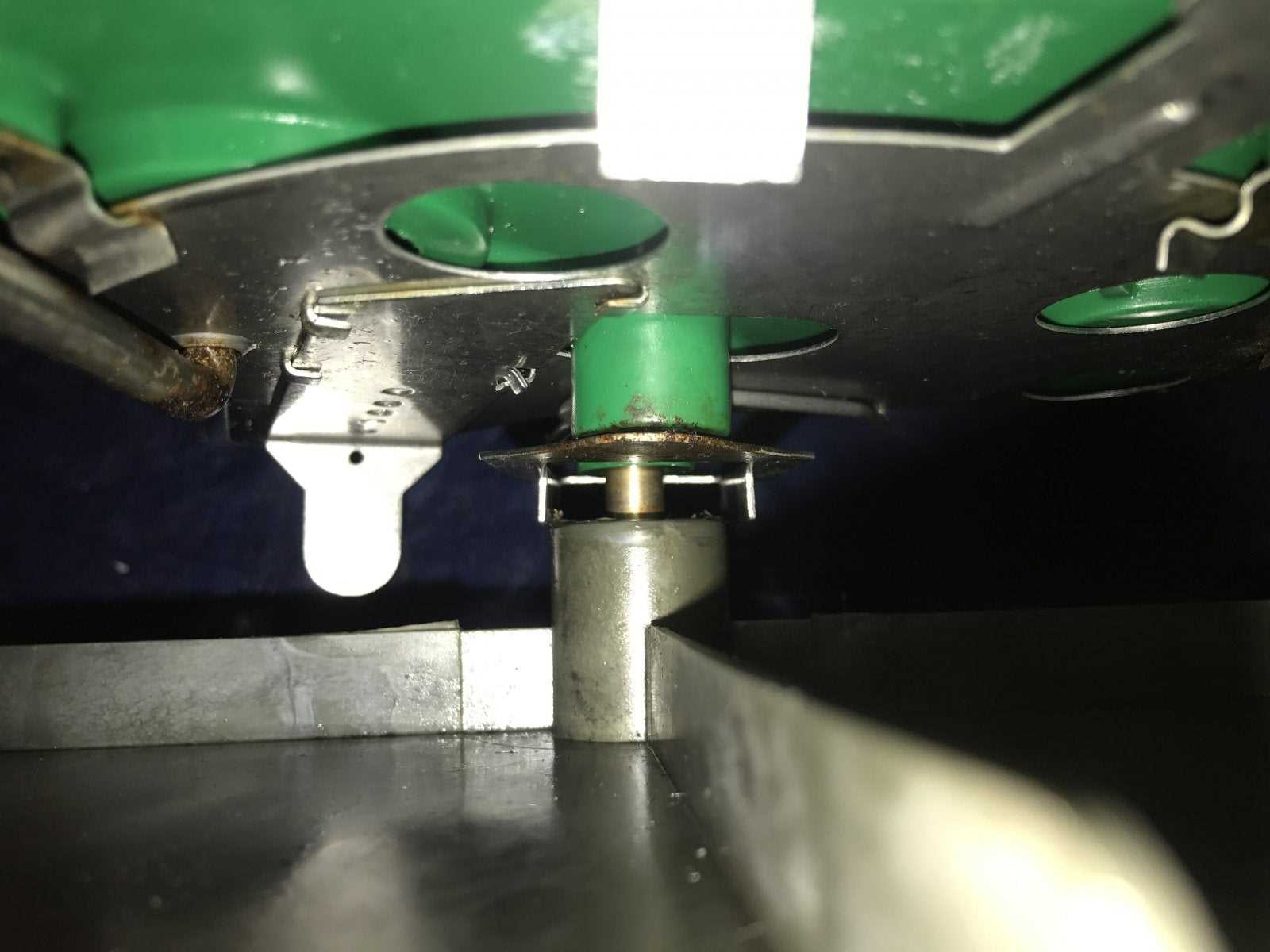

Next, disassemble the unit carefully, taking note of each component’s placement. Use labeled containers to store screws and small parts to avoid misplacement during reassembly.

Inspect each element for wear or damage, focusing on areas that may require attention. Cleaning any debris or buildup is essential, as it contributes to improved performance.

Replace any defective parts with high-quality alternatives to ensure durability. Follow the manufacturer’s specifications to guarantee compatibility.

After completing the repairs, reassemble the unit meticulously, ensuring all components fit snugly and securely. Once reassembled, conduct a thorough test to verify that the equipment operates smoothly and meets performance expectations.

Regular maintenance will prolong the life of your device, so develop a routine to check for issues and perform necessary upkeep.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular care and attention. Implementing a few essential practices can significantly extend its lifespan and enhance functionality. This section outlines key strategies for maintaining your device effectively.

Regular Cleaning

Routine cleaning is vital to prevent the buildup of debris and corrosive materials. After each use, remove any residual substance from the device’s components. Utilizing a soft brush or cloth can help preserve its surfaces and functionality.

Routine Inspections

Conducting periodic inspections allows you to identify any potential issues early on. Check for signs of wear or damage, focusing on moving parts and connections. Addressing minor concerns promptly can prevent major problems in the future.

Replacing Key Components

Maintaining the efficiency and functionality of your equipment often requires the replacement of essential parts. Understanding how to properly exchange these components ensures optimal performance and prolongs the lifespan of your machinery. This section outlines the critical elements that may need attention and provides guidance on how to proceed with their substitution.

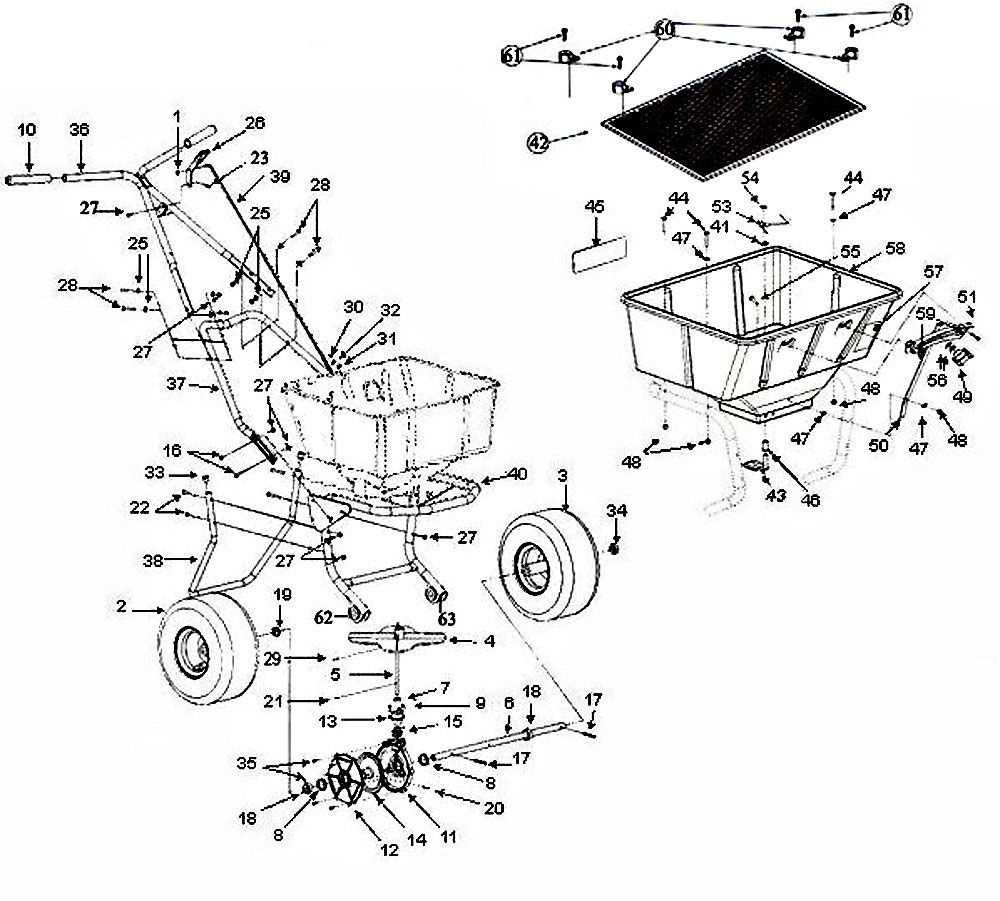

Identifying Components for Replacement

Before initiating the replacement process, it is crucial to identify which elements are underperforming or damaged. Commonly affected parts include gears, motors, and control mechanisms. Conducting a thorough inspection will help pinpoint issues and facilitate a smooth transition during the exchange.

Step-by-Step Replacement Process

Once the components requiring replacement have been identified, follow a systematic approach for their removal and installation. Start by ensuring the machinery is powered down and disconnected from any power source. Carefully remove the faulty part, taking note of any screws or fasteners that need to be retained. Install the new component by reversing the removal steps, ensuring all connections are secure and functional before testing the equipment.

Troubleshooting Common Problems

When operating a fertilizer distribution device, various issues may arise that can hinder its performance. Identifying and addressing these common complications promptly is essential for maintaining efficiency and prolonging the lifespan of the equipment. Below are some typical challenges encountered and their potential solutions.

Frequent Clogs and Blockages

Clogs can occur due to debris or material buildup, affecting the consistent flow of the contents. Regular cleaning and inspection are crucial to prevent this issue.

Uneven Distribution Patterns

Inconsistent spread patterns can lead to over-fertilization in some areas and under-fertilization in others. This problem may stem from improper calibration or mechanical faults.

| Issue | Possible Cause | Solution |

|---|---|---|

| Clogs | Debris accumulation | Regularly clean the hopper and the distribution mechanism |

| Uneven distribution | Improper calibration | Check and adjust the calibration settings |

| Low flow rate | Incorrect settings or blockage | Inspect for blockages and verify the settings |

| Excessive wear | Poor maintenance | Perform routine maintenance and replace worn parts |

Adjusting Spreader Settings

Fine-tuning the distribution apparatus is crucial for achieving optimal results when applying materials to your landscape. Proper adjustments can enhance efficiency and ensure uniform coverage, reducing waste and improving the health of your lawn or garden.

To start, it is essential to identify the specific requirements of the materials you intend to distribute. Different substances may necessitate varying settings for effective application. For instance, granular fertilizers and seeds often have distinct optimal openings and rates of flow.

Follow these steps to adjust your equipment:

- Consult the product specifications to determine the recommended settings for the materials you are using.

- Locate the adjustment mechanism, which may be a dial or lever on the device.

- Make incremental changes to the settings, testing the output in a small area to assess coverage.

- Monitor the results and adjust as needed, ensuring an even distribution across the intended area.

Regular maintenance and periodic adjustments to the settings will prolong the life of your equipment while ensuring effective performance. By investing time in this process, you can achieve a beautifully maintained landscape with minimal effort.

Safety Precautions During Repairs

When undertaking maintenance on any equipment, it is crucial to prioritize safety to prevent accidents and ensure a smooth process. Adhering to proper guidelines minimizes risks associated with mechanical failures or mishandling of tools. By implementing effective safety measures, one can protect not only themselves but also the equipment involved.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential during maintenance tasks. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges or chemicals, and sturdy footwear to provide stability and protection against heavy objects. Ensuring all team members are equipped with the right PPE enhances overall safety.

Work Area Safety

Maintaining a clean and organized workspace is vital for safe operations. Clear away any unnecessary tools or materials that may create hazards. Ensure proper lighting to enhance visibility and prevent mishaps. Additionally, using the correct tools for the job reduces the likelihood of injury and improves efficiency.

Finding Replacement Parts

Locating suitable components for your equipment is crucial for maintaining its efficiency and performance. Understanding where to source these elements can save time and enhance your operational success.

Here are some effective strategies for finding the necessary replacements:

- Authorized Dealers: Check with official distributors who specialize in parts for your type of equipment. They often carry genuine items that meet manufacturer specifications.

- Online Retailers: Numerous e-commerce platforms provide a wide array of components. Look for trusted websites that offer detailed descriptions and customer reviews.

- Local Hardware Stores: Sometimes, neighborhood shops may stock compatible parts or can order them for you. Building relationships with these retailers can be beneficial.

- Manufacturer Websites: Explore the manufacturer’s site for a catalog of available parts. Many companies also have a support section to assist with finding the right components.

- Second-Hand Markets: Consider checking classified ads or auction sites. Pre-owned parts can be cost-effective, but ensure they are in good condition.

Once you identify potential sources, compare prices and availability to make informed purchasing decisions. Ensuring you have the right components is essential for keeping your equipment running smoothly.

When to Seek Professional Help

Understanding the right moments to call in experts can save time and prevent further issues. While some maintenance tasks can be handled independently, there are certain situations where professional assistance is essential.

Here are some scenarios that warrant seeking help from trained technicians:

- Complex Mechanical Issues: If you encounter intricate problems that require specialized knowledge or tools.

- Electrical Malfunctions: When there are signs of wiring issues or electrical failures, which can pose safety risks.

- Frequent Breakdowns: If you notice recurring malfunctions despite regular upkeep, indicating underlying problems.

- Time Constraints: When you lack the time or resources to troubleshoot and resolve issues effectively.

- Uncertainty with Repairs: If you’re unsure about how to proceed with a specific task and fear making the situation worse.

In these cases, enlisting the help of professionals ensures that your equipment is handled safely and efficiently, extending its lifespan and optimizing performance.