| Brake Noise |

Essential Tools for Tiguan Repairs

To efficiently address various maintenance tasks, having the right set of tools is crucial. These tools not only simplify procedures but also help ensure safe and effective handling of components. Proper equipment can transform what might be a complex job into a manageable one, saving both time and effort.

Basic Equipment for Everyday Needs

For routine maintenance, a basic toolkit with high-quality wrenches, screwdrivers, and pliers is indispensable. These essentials cover many adjustments and part replacements. Additionally, a torque wrench is highly recommended to tighten bolts to precise specifications, protecting against over-tightening or under-tightening.

Advanced Tools for Specific Tasks

For more complex procedures, having specialized tools like diagnostic scanners

Engine Troubleshooting and Fixes

Identifying and resolving issues related to engine performance requires an understanding of potential causes and a systematic approach. The following guide highlights common problems and solutions, aiming to restore optimal functionality and reliability in the vehicle’s operation.

Common Causes of Engine Malfunctions

Engine issues can stem from a range of factors, including fuel system inefficiencies, ignition malfunctions, and sensor errors

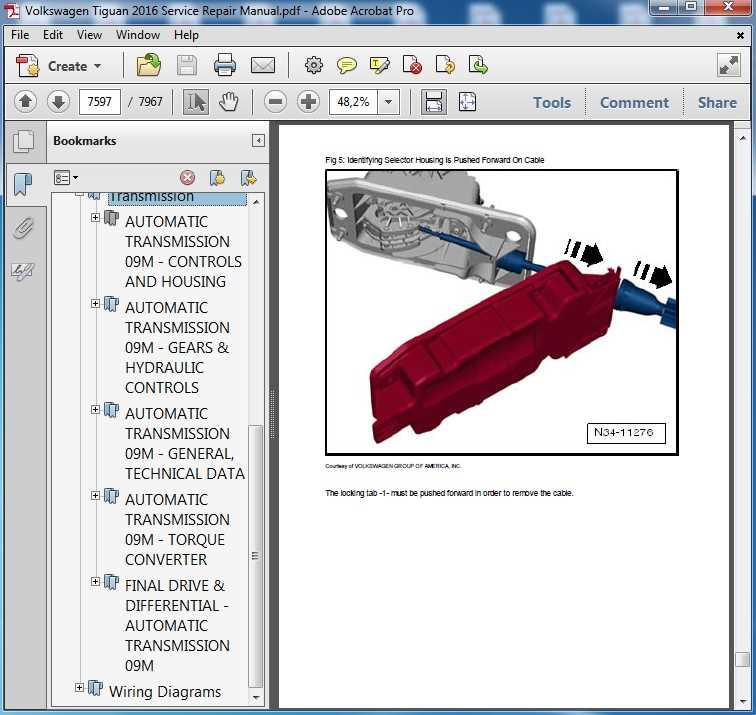

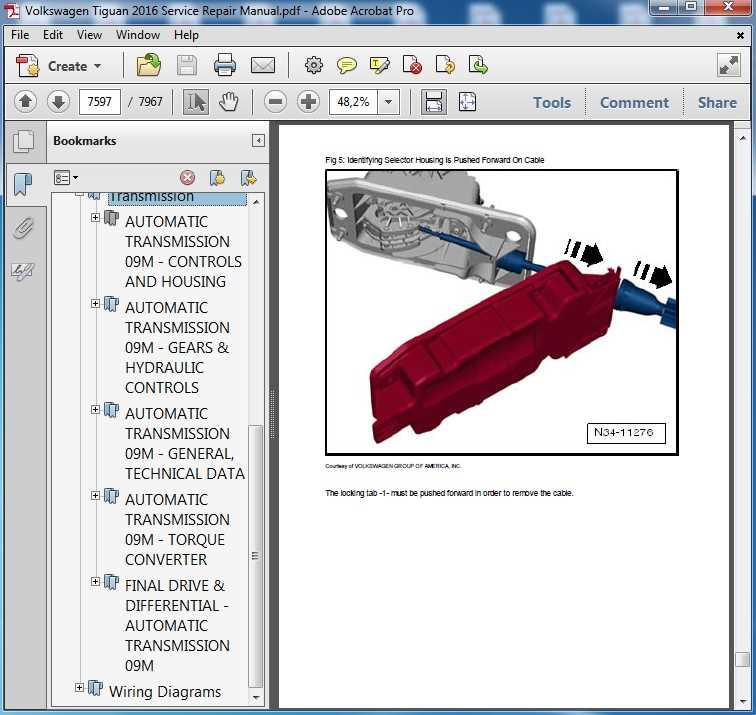

Transmission Maintenance Tips

Proper upkeep of the transmission system is essential to ensure smooth vehicle operation and to prolong the lifespan of key components. By following certain maintenance guidelines, drivers can reduce the risk of common transmission issues and enhance the overall performance of their car.

Check and Replace Fluid Regularly

Transmission fluid plays a vital role in cooling and lubricating the transmission’s moving parts. Regularly inspecting the fluid level and quality helps prevent overheating and excessive wear. Use only the recommended type of fluid and schedule changes as

Suspension System Repair Guide

The suspension system plays a critical role in ensuring vehicle stability, handling, and overall ride comfort. Understanding its components and how to maintain them can greatly enhance driving safety and experience. Regular attention to this system helps to prevent excessive wear and tear, making for a smoother ride over time.

Key Components Overview: The suspension system comprises several key elements, each contributing to stability and shock absorption. These include springs, struts, shocks, control arms,

Electrical System Diagnostics

This section focuses on the methods and techniques used to evaluate the functionality of an automobile’s electrical components. Proper diagnostics are essential to ensure that all electronic systems operate efficiently and reliably. By understanding the intricate network of circuits and devices, technicians can identify issues that may affect performance or safety.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical system problems is crucial for timely intervention. Common indicators include flickering lights, erratic behavior of electronic controls, or difficulty starting the engine. These symptoms may signal underlying issues, such as faulty wiring, dead batteries, or malfunctioning sensors, which require thorough examination and troubleshooting.

Diagnostic Tools and Techniques

Various diagnostic tools, including multimeters and diagnostic scanners, are employed to assess the electrical system. Technicians utilize these instruments to measure voltage, current, and resistance, allowing for accurate identification of faults. Understanding the flow of electricity through circuits and connections is fundamental in diagnosing issues effectively.

Brake Replacement and Adjustment

Proper maintenance of the braking system is essential for ensuring the safety and performance of any vehicle. This section provides guidance on how to effectively replace and adjust brake components, enhancing their functionality and extending their lifespan. Understanding the process not only contributes to safer driving but also promotes the overall health of the vehicle’s braking system.

Tools and Materials Needed

- Jack and jack stands

- Socket set and wrenches

- Brake pads and rotors

- Brake cleaner

- Torque wrench

- Grease

- Safety goggles and gloves

Steps for Brake Replacement

- Begin by lifting the vehicle using a jack and secure it with jack stands.

- Remove the wheel to access the braking components.

- Detach the caliper by unscrewing the bolts and gently slide it off the rotor.

- Remove the old brake pads from the caliper bracket.

- If necessary, replace the rotor by unscrewing it from the hub assembly.

- Install the new rotor and secure it in place.

- Attach the new brake pads to the caliper bracket.

- Reattach the caliper over the new pads and tighten the bolts to the manufacturer’s specifications.

- Repeat the process on the opposite side of the vehicle.

- Once all components are replaced, lower the vehicle and test the brakes before driving.

Regular checks and adjustments of the braking system are crucial for optimal performance. Ensure to check the fluid levels and inspect for any wear on components regularly.

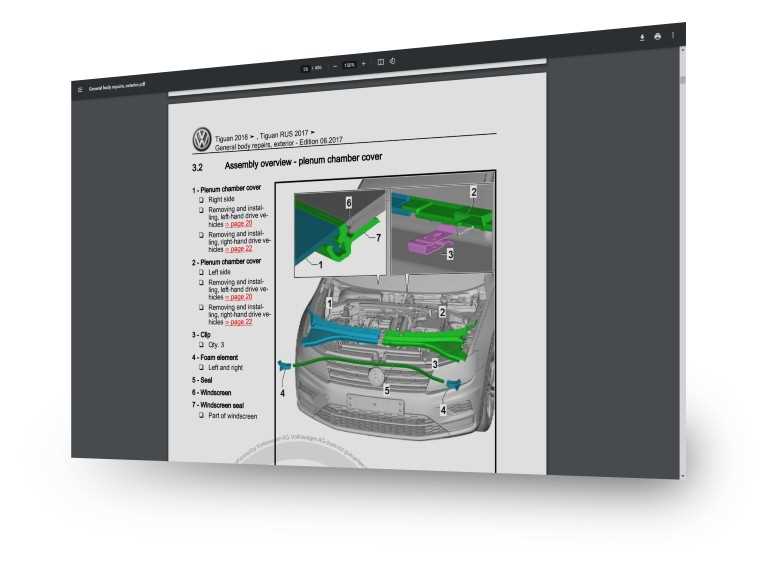

Interior and Exterior Restoration

Restoring both the interior and exterior of a vehicle enhances its overall aesthetic appeal and functionality. This process involves meticulous attention to detail, ensuring that every component, from the upholstery to the paintwork, is addressed. A well-executed restoration not only improves the look of the car but also increases its value, making it more enjoyable for the owner and attractive to potential buyers.

The interior restoration typically focuses on refurbishing seats, dashboards, and other surfaces. Cleaning, repairing, or replacing materials such as fabric, leather, and plastics can revitalize the cabin environment. Additionally, updating technology, like the audio system or dashboard displays, can significantly enhance the driving experience.

On the exterior side, the restoration process may include paint correction, dent removal, and thorough cleaning of the bodywork. Restoring the vehicle’s exterior involves ensuring that all parts are in good condition, from bumpers to windows. Applying protective coatings can help maintain the finish and shield against environmental damage, ensuring a long-lasting, pristine appearance.

Overall, a comprehensive restoration approach blends functionality with visual appeal, creating a vehicle that stands out on the road while providing an enjoyable driving experience.

Cooling System Service Instructions

The maintenance of the cooling system is essential for ensuring optimal engine performance and longevity. Regular checks and servicing help prevent overheating and related issues. This section outlines the necessary procedures to effectively manage the cooling system components, ensuring they function correctly.

Begin by inspecting the coolant level in the reservoir. If the level is low, it may indicate a leak or evaporation. Top up the coolant with the recommended type as specified in your vehicle’s specifications. Always check for any signs of leakage around hoses, joints, and the radiator, which could compromise the cooling efficiency.

Regular flushing of the cooling system is vital to remove debris and deposits that can hinder performance. This should be performed according to the manufacturer’s recommendations, typically every few years. Ensure to use the appropriate coolant type during this process to maintain system integrity.

| Service Task |

Frequency |

Notes |

| Check coolant level |

Monthly |

Look for leaks if low |

| Flush cooling system |

Every 2-3 years |

Use specified coolant type |

| Inspect hoses and connections |

Every service |

Replace if cracked or worn |

| Thermostat check |

As needed |

Replace if faulty |

Monitoring the operation of the water pump is equally crucial. Listen for unusual noises that might indicate wear. In case of suspected malfunction, replace the water pump to avoid cooling system failures.

Fuel System Cleaning and Repair

Maintaining the integrity of the fuel system is essential for optimal engine performance. Regular cleaning and servicing can help prevent issues related to fuel delivery, such as clogging and reduced efficiency. This section outlines effective techniques and considerations for ensuring a clean and functional fuel system.

Over time, deposits can accumulate in the fuel injectors, fuel lines, and other components. Cleaning these elements not only restores proper flow but also enhances combustion efficiency. Various methods are available for this purpose, including chemical cleaning agents and ultrasonic cleaners.

| Cleaning Method |

Description |

Benefits |

| Chemical Cleaning |

Involves using specialized solvents that dissolve carbon deposits and other impurities. |

Effective for thorough cleaning; can be performed without disassembling the system. |

| Ultrasonic Cleaning |

Utilizes high-frequency sound waves in a cleaning solution to remove deposits. |

Gentle yet effective; reaches intricate areas that are difficult to clean manually. |

| Fuel Additives |

Additives can be mixed with fuel to help clean the injectors and combustion chamber. |

Convenient; helps maintain cleanliness over time with regular use. |

In addition to cleaning, regular inspections of the fuel filter and lines are crucial. A clogged filter can impede fuel flow, leading to performance issues. Replacing the fuel filter at recommended intervals can prevent such problems. Ensuring that the fuel lines are free from leaks and blockages is also vital for the overall health of the fuel system.

Common Issues and Solutions

This section provides insights into typical challenges faced by vehicle owners, along with effective remedies. Understanding these common problems can assist in maintaining optimal performance and longevity of the automobile.

Frequent Problems

- Engine Performance Issues

- Electrical System Malfunctions

- Transmission Difficulties

- Suspension Noise

- Air Conditioning Failures

Suggested Solutions

- For engine performance issues, regular maintenance, including oil changes and filter replacements, is essential. Conduct diagnostic tests to identify underlying causes.

- Check fuses and wiring for electrical malfunctions. Replacing faulty components can resolve many issues.

- If transmission problems arise, ensure that the fluid levels are adequate. Flushing the transmission fluid may also be beneficial.

- Suspension noise can often be traced back to worn-out shock absorbers or struts. Regular inspections can prevent major repairs.

- For air conditioning failures, check the refrigerant levels and look for leaks in the system. Routine servicing can help maintain efficiency.