In the world of textile artistry, having reliable tools is essential for creating beautiful pieces. When these tools encounter issues, it can be frustrating for both novice and experienced creators. This section aims to provide comprehensive insights into troubleshooting common problems, ensuring that your crafting sessions remain uninterrupted and enjoyable.

Understanding the intricacies of your device is crucial for effective maintenance. By familiarizing yourself with the various components and their functions, you can identify malfunctions more easily. This knowledge not only helps in resolving current issues but also prevents future complications, allowing for a smoother crafting experience.

Moreover, learning how to care for your apparatus can enhance its longevity and performance. From simple adjustments to more complex interventions, this guide will walk you through the necessary steps. Embrace the opportunity to deepen your understanding and skills, transforming challenges into rewarding solutions.

Understanding Usha Sewing Machines

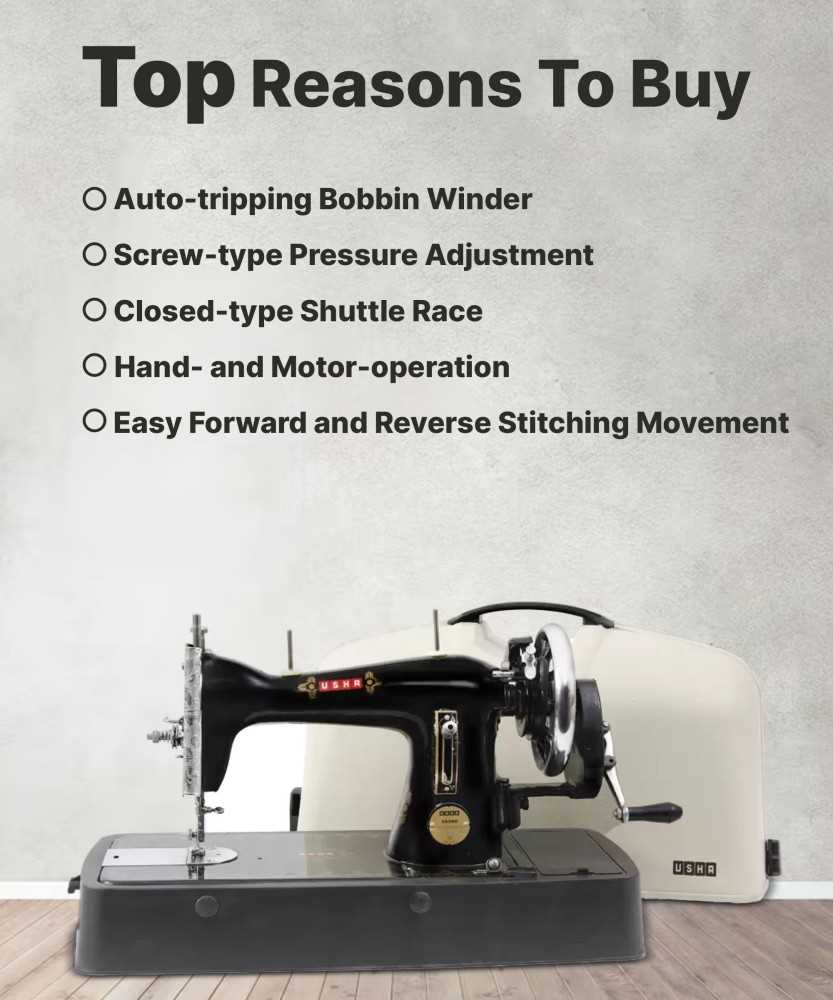

This section provides an insightful overview of a popular brand that specializes in crafting devices for textile manipulation. Renowned for their reliability and user-friendly design, these instruments cater to a diverse range of sewing enthusiasts, from beginners to seasoned professionals. The intricate balance of functionality and durability sets them apart in the world of fabric work.

Features and Benefits

One of the standout characteristics of these devices is their versatility. Equipped with various functions, they allow users to perform an array of stitching techniques with ease. Efficiency is another hallmark, as they often come with powerful motors that ensure consistent performance. Additionally, their ergonomic designs enhance comfort during prolonged usage, making them suitable for various projects.

Common Issues and Solutions

While these tools are designed for longevity, users may occasionally encounter challenges. Common problems can include thread tension issues or needle misalignment. Understanding the basic components and their functions can aid in troubleshooting. For instance, adjusting the tension dial can often resolve stitching irregularities. Regular maintenance, such as cleaning and oiling, is essential to prolong the lifespan and maintain optimal performance.

Common Issues with Usha Models

Various complications can arise with certain types of textile crafting devices, often leading to frustration among users. Understanding these frequent challenges can help in identifying solutions more effectively.

Frequent Complications

- Thread jams causing interruption during usage.

- Inconsistent stitch quality leading to uneven fabric handling.

- Noise during operation indicating potential mechanical issues.

Possible Solutions

- Regularly clean and lubricate moving parts to prevent jams.

- Check tension settings and adjust for better stitch consistency.

- Inspect for any loose components that may be causing noise.

Tools Needed for Basic Repairs

Having the right instruments is essential for performing effective maintenance and troubleshooting tasks. A well-equipped toolkit can significantly simplify the process and enhance your ability to address various issues efficiently.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To tighten or loosen screws for accessing components. |

| Needle Nose Pliers | For grasping and manipulating small parts. |

| Scissors | To trim threads and other materials as needed. |

| Measuring Tape | For accurate measurements of fabric and components. |

| Lubricant | To ensure smooth operation of moving parts. |

| Cleaning Brush | To remove dust and debris from the interior. |

| Replacement Parts | To swap out damaged or worn components. |

Step-by-Step Troubleshooting Guide

When a device encounters issues, systematic analysis is crucial for identifying and resolving problems. This guide provides a structured approach to diagnosing and fixing common faults, ensuring efficient operation and prolonging lifespan.

Common Issues and Solutions

| Issue | Possible Causes | Solutions |

|---|---|---|

| Thread Bunching | Incorrect threading, poor tension | Re-thread and adjust tension settings |

| Skipping Stitches | Dull needle, improper needle type | Replace needle with the correct size |

| Jamming | Lint buildup, incorrect fabric | Clean area and use suitable materials |

| No Power | Faulty plug, damaged cord | Check power source and inspect cord |

Further Steps

If issues persist after following the above suggestions, consider consulting an expert or examining the device for internal malfunctions. Regular maintenance can prevent many common problems and enhance performance.

How to Clean Your Sewing Machine

Maintaining your crafting tool is essential for optimal performance and longevity. Regular cleaning helps prevent the buildup of dust and lint, which can interfere with functionality and lead to potential issues. Here’s a step-by-step guide to ensure your device remains in top condition.

Gather Your Supplies

Before you begin, collect the necessary items. You will need a small brush, soft cloths, tweezers, and a vacuum cleaner attachment designed for delicate areas. These tools will assist you in removing debris without causing any harm.

Cleaning Process

Start by unplugging the device to ensure safety. Remove the cover and any detachable parts. Use the small brush to gently sweep away any lint and dust from the interior components. Pay special attention to the feed dogs and tension mechanisms. For areas that are hard to reach, use tweezers to pull out larger clumps of debris. Finally, wipe down surfaces with a soft cloth, making sure to avoid any electrical components.

Regular maintenance not only enhances performance but also prolongs the life of your tool. A clean unit will work more efficiently, allowing you to focus on your creative projects.

Replacing the Needle Safely

Changing the sharp component is an essential task that ensures optimal performance and safety. Following proper procedures minimizes the risk of injury and maximizes effectiveness. This section outlines the necessary steps to perform this task correctly.

Before you begin, gather the following tools:

- New sharp component

- Screwdriver

- Clean cloth

- Protective gloves (optional)

Follow these steps for a safe and effective replacement:

- Power off the device and unplug it from the electrical outlet to eliminate any risk of accidental activation.

- Carefully remove the old sharp component by loosening the securing screw with a screwdriver. Keep the screw in a safe place for later use.

- Inspect the area for any debris or leftover pieces and clean it with a cloth to ensure a smooth installation.

- Insert the new sharp component, ensuring it is aligned correctly, and tighten the screw securely without over-tightening.

- Double-check the alignment and the tightness of the screw before plugging the device back in.

By following these guidelines, you can replace the sharp component effectively and safely, ensuring that your equipment operates at its best.

Fixing Tension Problems Easily

Achieving the perfect balance in thread tightness is crucial for flawless stitching. When issues arise, it can lead to frustration and unsatisfactory results. This section provides straightforward methods to troubleshoot and resolve these common challenges effectively.

Identifying Tension Issues

Before addressing the problem, it’s essential to recognize the signs of improper tightness. Typical indicators include uneven stitches, thread breakage, and puckering of fabric. By closely examining your work, you can determine whether the upper or lower thread is causing the discrepancies.

Adjusting Thread Tightness

Once you have identified the issue, follow these steps to correct it:

| Problem | Possible Cause | Solution |

|---|---|---|

| Loose stitches | Upper thread tension too low | Increase upper tension setting slightly |

| Puckered fabric | Upper thread tension too high | Decrease upper tension setting gradually |

| Thread breakage | Incorrect threading or tension | Re-thread according to guidelines and adjust tension |

| Skipped stitches | Needle or thread issues | Replace needle and check thread quality |

By following these guidelines, you can quickly resolve tension-related challenges, ensuring a smoother and more enjoyable crafting experience.

Updating Software for Smart Models

Keeping the software of advanced devices up to date is essential for enhancing performance and ensuring access to the latest features. Regular updates can fix bugs, improve security, and optimize functionality, leading to a better user experience.

Why Updates Are Important

Software updates play a crucial role in the overall efficiency of smart devices. Here are several key reasons for performing these updates:

- Enhanced Security: Updates often include patches for vulnerabilities.

- Improved Functionality: New features and enhancements can be added.

- Bug Fixes: Updates resolve existing issues and improve reliability.

- Compatibility: Keeping software current ensures compatibility with new technologies.

How to Update Software

Updating the software on your advanced devices is typically a straightforward process. Follow these general steps:

- Check for Updates: Navigate to the settings menu and look for a software update option.

- Download: If an update is available, select the download option.

- Install: Follow the prompts to install the update.

- Restart: After installation, restart the device to complete the process.

By regularly updating the software, users can ensure their devices remain efficient, secure, and equipped with the latest functionalities.

Maintaining Your Sewing Machine Regularly

Consistent upkeep is essential for ensuring the longevity and performance of your stitching device. By adopting a routine maintenance schedule, you can enhance functionality, reduce the risk of malfunctions, and ultimately enjoy a smoother crafting experience. Below are some key practices to incorporate into your maintenance regimen.

Daily Care Tips

- Clean the exterior to remove dust and lint.

- Check the needle for any signs of wear or damage.

- Ensure that the threading is correct and properly tensioned.

Weekly Maintenance Steps

- Remove the bobbin case and clean out any accumulated debris.

- Oil moving parts as recommended by the manufacturer.

- Inspect and replace the needle if necessary.

By following these guidelines regularly, you will help maintain optimal performance and prolong the life of your crafting equipment.

When to Seek Professional Help

Knowing when to consult an expert can save time and resources, ensuring optimal functionality. Certain situations call for experienced hands to prevent further complications.

Signs You Should Consider Professional Assistance

- Persistent issues despite troubleshooting efforts

- Unusual noises or malfunctions during operation

- Damage that requires specialized tools or knowledge

Benefits of Expert Intervention

- Access to specialized skills and experience

- Efficient resolution of complex problems

- Potential to extend the lifespan of the equipment

Finding Replacement Parts Online

Locating components for your equipment can be a straightforward process if you know where to look. The internet offers a plethora of resources that can assist you in sourcing the right elements to ensure your device operates smoothly. With a little research and attention to detail, you can find suitable alternatives that meet your needs.

Start by identifying the specific parts you require. Gather all relevant information, such as model numbers and descriptions, to make your search more efficient. This knowledge will help you filter results and narrow down your options effectively.

Utilize specialized websites and forums dedicated to your equipment type. These platforms often feature listings for both new and refurbished components. Engaging with communities can also provide valuable insights and recommendations on where to find reliable parts.

Additionally, consider checking major online marketplaces. These platforms usually have extensive inventories and user reviews, allowing you to compare prices and quality. Be sure to verify the seller’s reputation to avoid any potential issues.

Finally, don’t overlook local suppliers. Some businesses may have an online presence or offer delivery services, enabling you to obtain parts without the wait associated with shipping. By leveraging these various sources, you can successfully locate the components you need.

Usha Machine Warranty Information

This section provides essential insights into the protection plan that covers your device. Understanding the terms and conditions of the warranty is crucial for ensuring peace of mind regarding potential issues that may arise during regular use.

Coverage Period: Typically, the warranty lasts for a specified duration from the date of purchase. This period may vary depending on the specific model and type of product.

Inclusions: The warranty generally covers manufacturing defects and failures that occur under normal operating conditions. It ensures that you can receive necessary services or replacements without incurring additional costs.

Exclusions: It’s important to note that damages caused by misuse, accidents, or unauthorized modifications usually fall outside the scope of the warranty. Familiarizing yourself with these exclusions helps in maintaining the integrity of the coverage.

Claim Process: To initiate a claim, you typically need to present proof of purchase along with any relevant documentation. Following the outlined procedures will help expedite the process and ensure that you receive the assistance you require.

Remember to keep the warranty information safe and refer to it whenever needed to fully understand your rights and responsibilities.