Maintaining and troubleshooting garden cultivators is essential for achieving optimal performance in your gardening tasks. Understanding the intricacies of these machines can significantly enhance their efficiency and longevity. This section aims to provide essential insights into the common issues faced by cultivator users and the steps to address them effectively.

From routine maintenance to resolving specific mechanical challenges, a systematic approach can make a world of difference. Familiarity with the components and functions of your equipment will empower you to perform necessary adjustments and repairs confidently. By following the guidelines presented here, you can ensure your cultivator remains a reliable companion in your gardening endeavors.

This section provides a comprehensive introduction to a popular gardening tool designed for soil cultivation. The device is essential for efficiently breaking up hard earth and preparing it for planting, making it a valuable asset for both amateur and professional gardeners.

- Purpose: Primarily used for loosening soil, improving aeration, and incorporating organic matter.

- Features: Typically equipped with robust tines, adjustable depth settings, and various power sources.

- Types: Available in different sizes and configurations, suitable for diverse gardening tasks.

Understanding the functionality and specifications of this equipment is crucial for maintaining optimal performance and ensuring longevity. Regular checks and appropriate adjustments contribute to a more efficient gardening experience.

Common Issues with Tillers

Garden cultivation machines can encounter several challenges during operation. Understanding these typical problems can help users maintain their equipment effectively and ensure optimal performance. This section highlights frequent issues and potential solutions to enhance longevity and functionality.

Engine Troubles

One of the most common problems is engine failure. This may be caused by fuel issues, such as stale gasoline or clogged fuel lines. Regular maintenance and using fresh fuel can significantly mitigate these issues.

Transmission Problems

Transmission malfunctions can lead to difficulty in controlling the machine. Issues may arise from worn belts or gears. Inspecting and replacing damaged components promptly can prevent further complications.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine not starting | Stale fuel or clogged filter | Replace fuel and clean filters |

| Loss of power | Worn spark plug | Replace spark plug |

| Difficulty shifting gears | Worn transmission components | Inspect and replace parts |

Essential Tools for Repair

Having the right instruments is crucial for effectively addressing issues and maintaining garden equipment. A well-equipped toolkit can significantly simplify the process, ensuring that tasks are completed efficiently and correctly.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for any maintenance work. Additionally, specialized implements designed for specific tasks can enhance performance and accuracy. A quality set of replacement parts is also advisable to ensure that repairs are both swift and durable.

Furthermore, safety gear, including gloves and goggles, is essential to protect oneself during maintenance activities. Investing in a reliable toolkit not only saves time but also contributes to the longevity of your machinery.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues with garden cultivation equipment. By following these steps, users can effectively troubleshoot and resolve problems, ensuring optimal performance.

Initial Assessment

Begin by inspecting the unit thoroughly. Check for any visible damage or wear that could impact functionality. Ensure that all components are secure and properly aligned.

Necessary Tools and Materials

Gather the essential tools and replacement parts before commencing the work. This preparation will facilitate a smoother process. Below is a list of common items required:

| Tool/Part | Description |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver | For removing and securing screws |

| Replacement Belts | For worn or damaged drive systems |

| Oil | For lubricating moving parts |

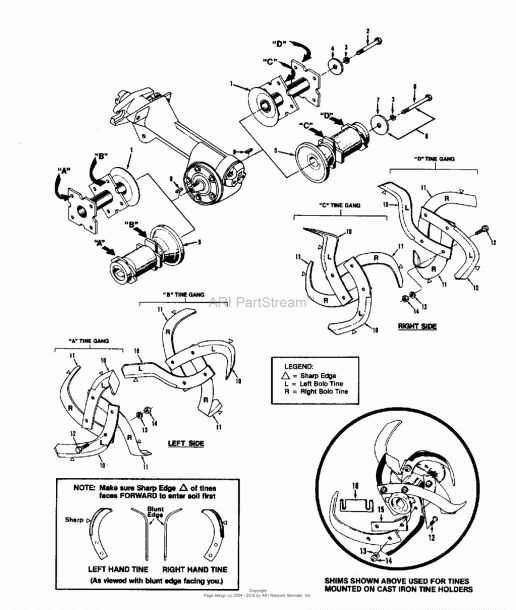

Replacing the Tiller Tines

Replacing the cutting implements is a vital task that enhances the performance and efficiency of your garden equipment. Over time, these components can become dull or damaged, affecting their ability to effectively cultivate soil. This section will guide you through the process of swapping out these essential parts, ensuring your equipment runs smoothly.

Tools and Materials Needed

Before beginning the replacement process, gather the necessary tools and materials. You will need a wrench, a replacement set of cutting implements, and safety gear such as gloves and goggles. Ensuring you have everything ready will streamline the task and make it safer.

Step-by-Step Replacement Process

Start by disconnecting the power source to avoid any accidents. Next, use the wrench to loosen the bolts holding the old implements in place. Carefully remove them and replace them with the new components, ensuring they are securely fastened. Double-check that all connections are tight and that nothing is out of place before reattaching the power source.

Regular maintenance and timely replacement of these components will contribute significantly to the longevity and effectiveness of your garden equipment.

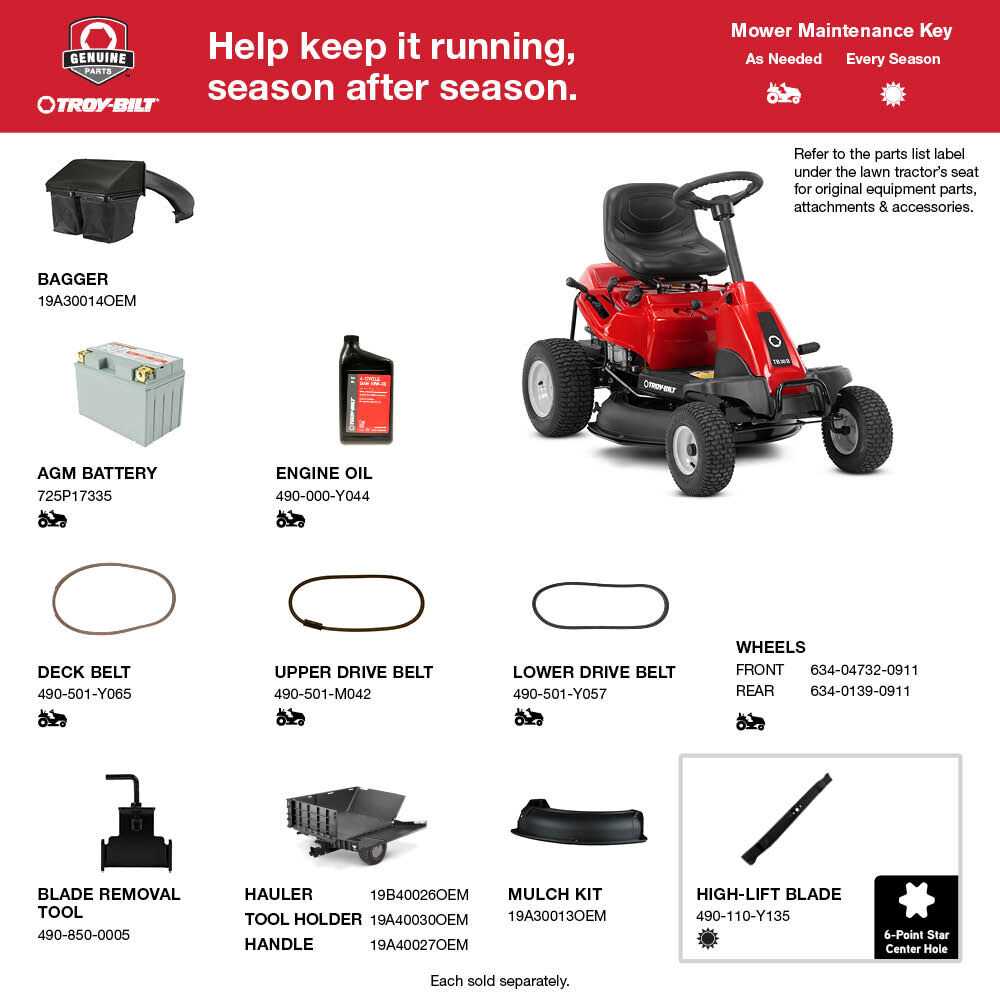

Engine Maintenance Guidelines

Regular upkeep of the power unit is essential for ensuring optimal performance and longevity. Following specific practices can help maintain the functionality of the engine, preventing potential issues before they arise.

Here are some key practices for maintaining the engine:

- Oil Changes: Regularly check and replace the oil according to the manufacturer’s recommendations to ensure smooth operation.

- Air Filter Inspection: Clean or replace the air filter to prevent dirt and debris from entering the engine, which can affect performance.

- Fuel System Maintenance: Use fresh fuel and consider adding a fuel stabilizer to prevent deterioration and clogs in the fuel lines.

- Spark Plug Checks: Inspect and replace spark plugs as needed to maintain efficient ignition and combustion.

- Cooling System Monitoring: Ensure that the cooling system is functioning properly to prevent overheating during operation.

By adhering to these guidelines, you can significantly enhance the reliability and efficiency of the engine, leading to better performance in various tasks.

Adjusting the Carburetor Settings

Fine-tuning the air-fuel mixture is crucial for optimal engine performance. Proper adjustments can enhance efficiency, improve starting, and reduce emissions. This process requires attention to detail and a basic understanding of engine components.

Understanding the Components

Before making adjustments, it’s essential to familiarize yourself with the key parts of the carburetor. The primary components involved in this process include the idle adjustment screw, the mixture screw, and the throttle lever. Each plays a significant role in regulating fuel flow and air intake.

Adjustment Procedure

Follow these steps to ensure accurate settings:

| Step | Action |

|---|---|

| 1 | Start the engine and allow it to reach operating temperature. |

| 2 | Locate the idle adjustment screw and turn it slowly until the engine runs smoothly. |

| 3 | Adjust the mixture screw to achieve the best performance without stalling. |

| 4 | Test the throttle response and make minor tweaks as necessary. |

Regular maintenance and adjustments will prolong the lifespan of the engine and improve overall functionality.

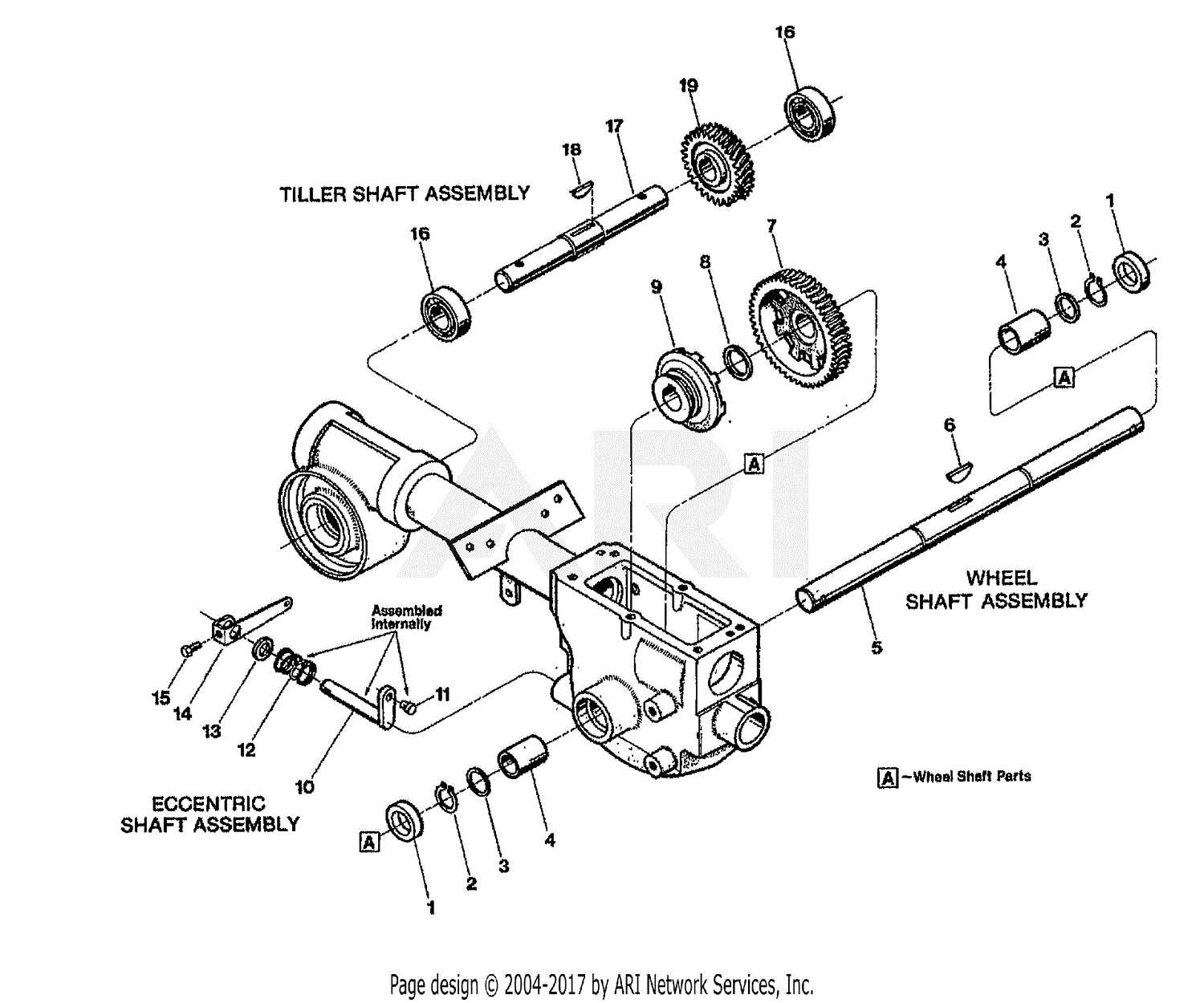

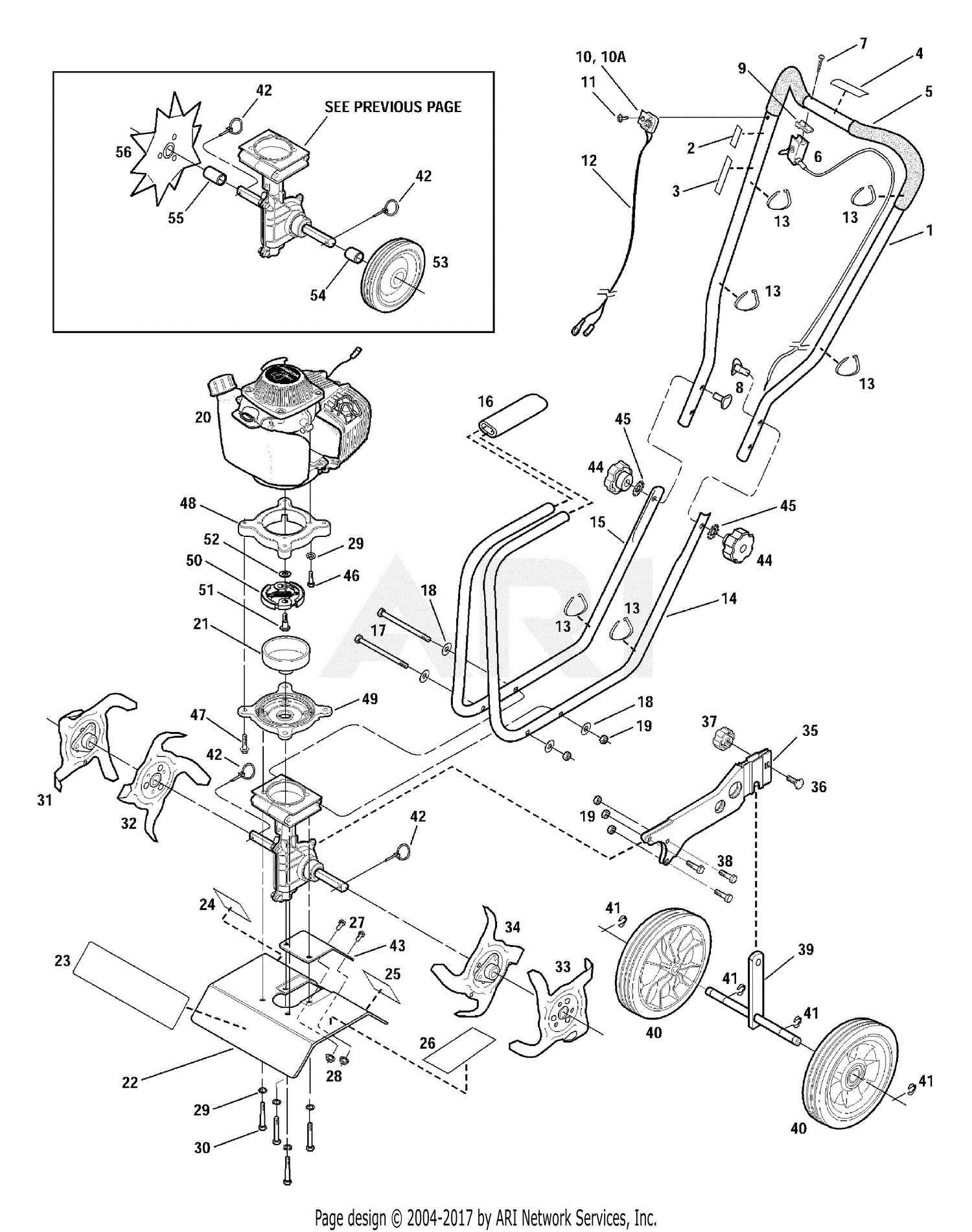

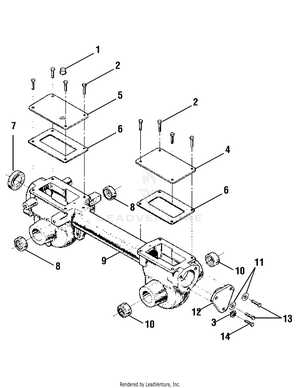

Inspecting the Drive System

Evaluating the drive mechanism is essential for ensuring optimal performance of your equipment. This process involves checking various components to identify potential issues that may affect functionality. Regular inspections can prevent minor problems from escalating into significant failures, enhancing the longevity of your machine.

Key Components to Examine

During the inspection, focus on the following critical parts:

| Component | Inspection Tips |

|---|---|

| Belt | Check for wear and proper tension; replace if frayed. |

| Gears | Look for signs of damage or excessive wear; ensure smooth operation. |

| Sprockets | Inspect for alignment and wear; lubricate as needed. |

Common Issues and Solutions

If any irregularities are detected during the inspection, it is crucial to address them promptly. Common problems may include slipping belts or misaligned gears, which can disrupt the drive system’s efficiency. Taking corrective action early can save time and resources in the long run.

Electrical System Troubleshooting

This section focuses on identifying and resolving common issues within the electrical components of garden equipment. Understanding the electrical system is essential for effective maintenance and optimal performance.

Common Issues and Symptoms

Frequent problems may include the inability to start, flickering lights, or unusual sounds. These symptoms often indicate underlying electrical faults that require careful inspection.

Diagnostic Steps

Begin by checking the battery connections for corrosion and tightness. Use a multimeter to assess voltage levels, ensuring the battery is adequately charged. If issues persist, inspect wiring for signs of wear or damage, as faulty connections can lead to operational failures.

Fuel System Cleaning Steps

Maintaining the fuel system is essential for optimal performance and longevity of your equipment. Regular cleaning helps to prevent buildup that can hinder functionality and efficiency. Below are the necessary steps to effectively clean the fuel system.

| Step | Description |

|---|---|

| 1 | Start by disconnecting the fuel lines to avoid spills and ensure safety. |

| 2 | Drain any remaining fuel from the tank and clean the interior with a suitable solvent. |

| 3 | Inspect the fuel filter and replace it if necessary to ensure proper flow. |

| 4 | Use a cleaning solution specifically designed for fuel systems to flush out any residue from the lines. |

| 5 | Reconnect the fuel lines and fill the tank with fresh fuel to complete the process. |

Storing Your Tiller Properly

Ensuring that your gardening equipment is stored correctly is essential for maintaining its functionality and longevity. Proper storage techniques can prevent damage and wear, allowing you to make the most of your investment.

Here are some key steps to follow for effective storage:

- Clean the equipment thoroughly to remove any dirt or debris.

- Inspect all parts for signs of wear and address any issues before storing.

- Drain any fluids, such as fuel and oil, to avoid leaks and deterioration.

- Store in a dry, cool place to protect from moisture and temperature extremes.

- Use a cover or tarp to shield from dust and potential scratches.

By following these guidelines, you can ensure that your equipment remains in excellent condition, ready for your next gardening project.

Safety Precautions During Repairs

When performing maintenance on garden equipment, it is crucial to prioritize safety. Following specific guidelines can help prevent accidents and ensure a smooth process while handling machinery.

- Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and disconnected from any power source before beginning work.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace clean and organized to minimize the risk of slips or falls.

- Read the manufacturer’s instructions thoroughly before proceeding with any tasks.

Taking these precautions seriously can help create a safe environment for maintenance activities and protect the individual performing the work.

When to Seek Professional Help

Knowing when to consult an expert can save time and ensure your equipment operates efficiently. There are specific situations where professional assistance is highly recommended to address issues effectively.

If you encounter persistent problems that basic troubleshooting cannot resolve, it may indicate a more serious underlying issue. Additionally, if you lack the necessary tools or experience to tackle a repair, enlisting the help of a professional can prevent further damage.

| Situation | Reason for Professional Help |

|---|---|

| Complex Malfunctions | Requires specialized knowledge and skills. |

| Safety Concerns | Potential hazards can arise without proper handling. |

| Lack of Time | Professional services can expedite the repair process. |

| Warranty Issues | Repairs by an expert may be necessary to maintain warranty coverage. |