Understanding the intricacies of engine upkeep is essential for ensuring optimal performance and longevity. This section delves into essential practices and strategies that can significantly enhance the functionality of small engines, focusing on troubleshooting and maintenance techniques.

Effective management of engine components not only improves efficiency but also reduces the likelihood of unexpected failures. By familiarizing yourself with common issues and their resolutions, you can extend the life of your equipment while saving time and resources.

Through comprehensive insights and practical advice, this guide aims to equip you with the knowledge necessary for successful engine care. Engaging with these techniques fosters a proactive approach to maintenance, ultimately leading to smoother operation and increased reliability.

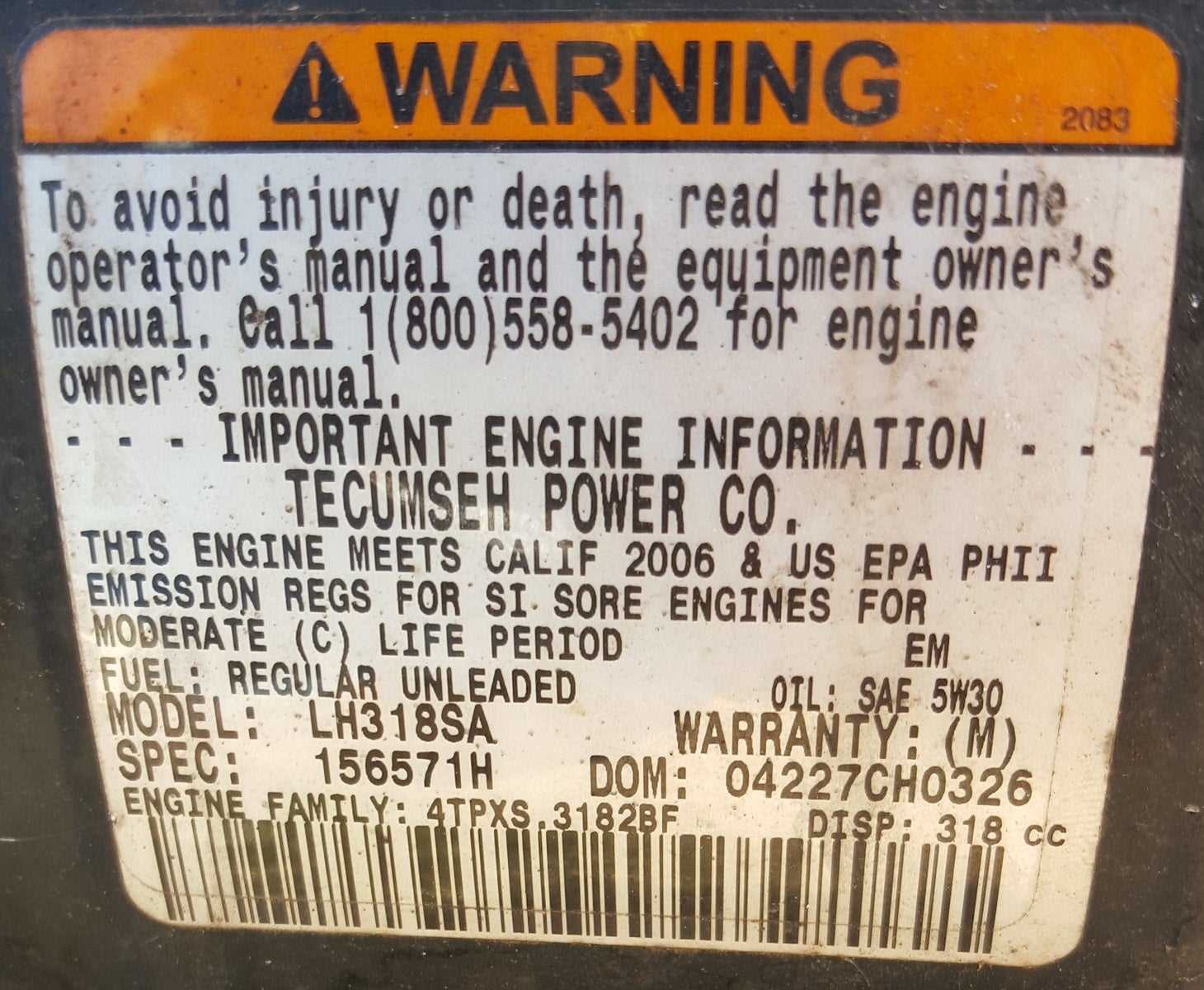

This section aims to provide a comprehensive overview of a specific engine model, focusing on its components, functionality, and maintenance practices. Understanding the intricacies of this machinery is essential for both novice users and experienced technicians alike.

- Introduction to the Engine Model: Overview of the engine’s purpose and applications.

- Key Features and Specifications: Highlighting important characteristics and technical details.

- Common Issues and Troubleshooting: Identifying frequent problems and solutions.

- Maintenance Tips and Best Practices: Guidelines for keeping the engine in optimal condition.

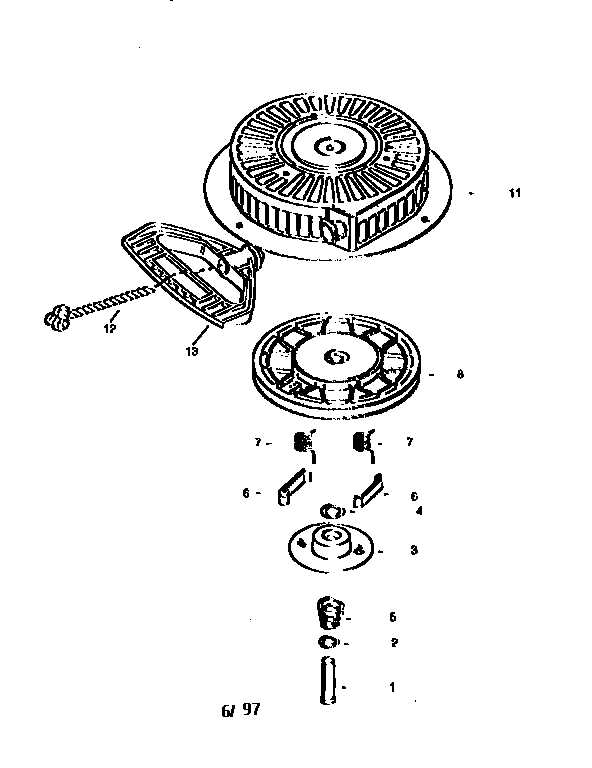

- Disassembly and Assembly Procedures: Step-by-step instructions for taking apart and reassembling the engine.

- Essential Tools Required: Listing necessary tools for maintenance and repair tasks.

- Safety Precautions: Important safety measures to follow while working with the engine.

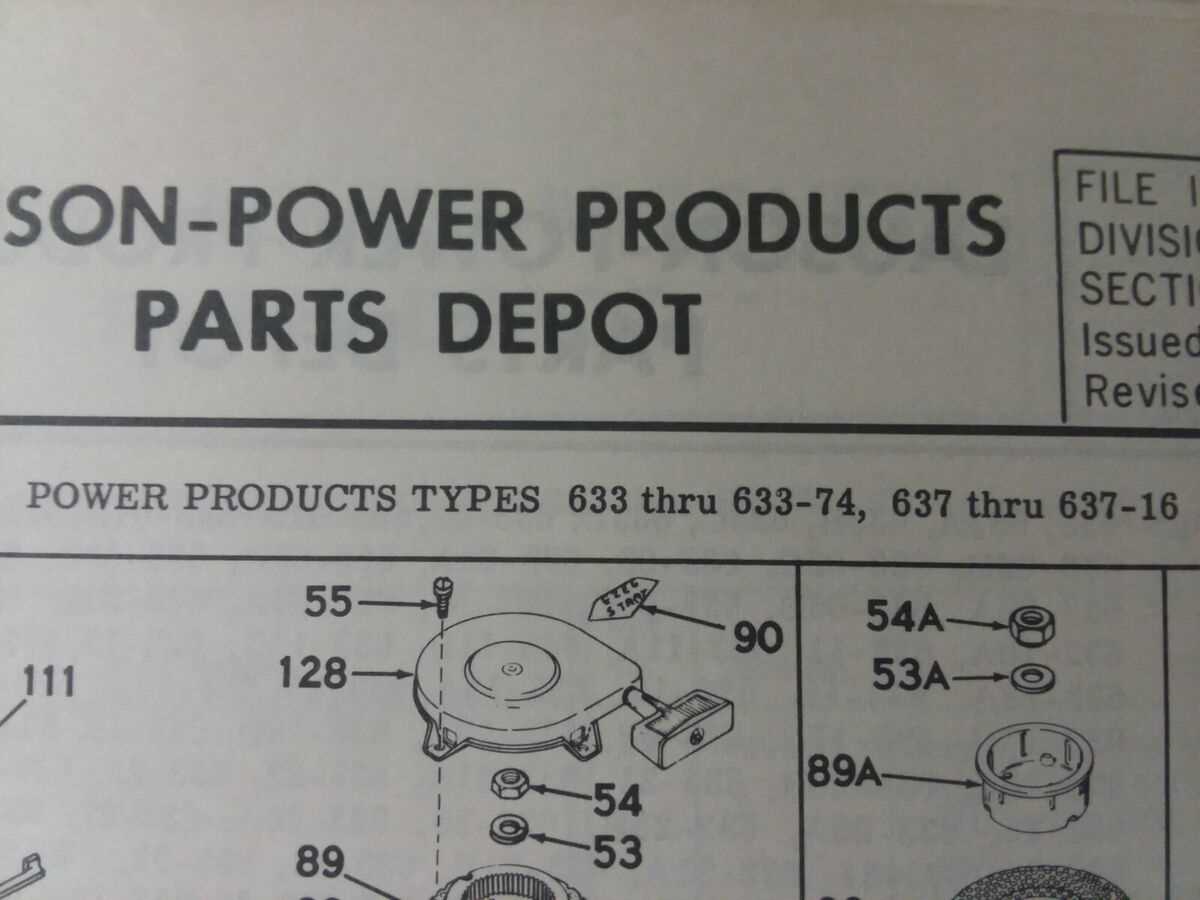

- Parts Replacement Guide: Tips for sourcing and replacing worn or damaged components.

- Performance Enhancements: Suggestions for modifications to improve efficiency and output.

- FAQs and Expert Advice: Commonly asked questions and insights from experienced users.

- Warranty and Service Information: Understanding coverage and available support options.

- Conclusion and Resources: Summarizing key points and directing readers to additional materials.

Common Issues with Tecumseh Engines

Engines of this type are known for their reliability, yet they can still encounter various challenges over time. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their machinery.

- Starting Difficulties: Many users report issues with the engine failing to start, often due to fuel delivery problems or electrical faults.

- Overheating: Engines can overheat for several reasons, including inadequate cooling, low oil levels, or blockages in the cooling system.

- Unusual Noises: Strange sounds during operation may indicate worn components or misalignment, which should be addressed promptly.

- Excessive Vibration: High levels of vibration can signal an imbalance or loose parts, leading to further damage if not corrected.

- Fuel Leaks: Leaking fuel can be a serious issue, often arising from deteriorated seals or gaskets, requiring immediate attention.

Addressing these challenges early can prevent more severe problems and ensure smooth operation. Regular maintenance checks and prompt repairs are crucial for keeping these engines in peak condition.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your engine requires regular care and attention. By following a few essential practices, you can enhance its efficiency and prevent premature wear. Regular maintenance not only saves time and money but also contributes to a smoother operation over the years.

Regular Oil Changes

Changing the oil at recommended intervals is crucial for maintaining optimal performance. Fresh oil lubricates moving parts effectively, reducing friction and heat buildup. Make it a habit to check the oil level frequently and replace it when it appears dirty or contaminated.

Air Filter Maintenance

Keeping the air filter clean is vital for ensuring adequate airflow to the engine. A clogged filter can hinder performance and fuel efficiency. Inspect the air filter regularly and clean or replace it as necessary to keep your engine running smoothly.

Tools Required for Repairs

When undertaking maintenance tasks on small engine units, having the right instruments is essential for achieving successful outcomes. Properly equipped, you can efficiently address issues and ensure optimal performance. Below is a list of essential tools to have on hand for such tasks.

| Tool | Purpose |

|---|---|

| Socket Set | For removing and tightening bolts and nuts. |

| Wrench Set | To adjust and secure various components. |

| Fuel Line Pliers | For disconnecting fuel lines without damage. |

| Screwdriver Set | For fastening and loosening screws. |

| Torque Wrench | To ensure bolts are tightened to the correct specifications. |

| Multimeter | For checking electrical connections and diagnostics. |

Having these tools readily available will streamline your process, allowing for effective troubleshooting and adjustments.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues that may arise in small engines. By following a systematic process, users can effectively identify the root cause of malfunctions and implement solutions to restore functionality.

Identifying Common Symptoms

- Engine fails to start

- Unusual noises during operation

- Overheating

- Loss of power

Troubleshooting Steps

- Check Fuel Supply: Ensure that the fuel tank is full and that there are no blockages in the fuel lines.

- Inspect Spark Plug: Remove the spark plug and examine it for wear or damage. Replace if necessary.

- Examine Air Filter: A clogged air filter can restrict airflow. Clean or replace the filter as needed.

- Test Electrical Connections: Ensure all wiring and connections are secure and free from corrosion.

- Look for Leaks: Check for any signs of leaking fuel or oil, which can indicate a problem.

By following these guidelines, users can systematically address issues and ensure their equipment operates efficiently.

Rebuilding the Carburetor Explained

Revitalizing a fuel delivery component is a crucial process for ensuring optimal performance in various small engines. This task not only enhances efficiency but also prolongs the lifespan of the machinery. Understanding the steps involved can simplify what may initially seem daunting.

To effectively rebuild this component, follow these essential steps:

- Gather Tools and Materials:

- Socket set

- Screwdrivers

- Carburetor cleaner

- Replacement gaskets

- Fuel lines

- Disassemble the Component:

- Carefully remove the assembly from the engine.

- Take apart the housing and detach the float chamber.

- Clean the Parts:

- Use a suitable cleaner to eliminate any deposits and dirt.

- Inspect all components for wear or damage.

- Replace Worn Parts:

- Install new gaskets and seals as needed.

- Ensure that all moving parts are functioning smoothly.

- Reassemble and Test:

- Carefully put the assembly back together.

- Reconnect it to the engine and perform a test run.

By following these steps diligently, the functionality of the engine will be significantly enhanced, leading to better fuel efficiency and overall performance. Regular maintenance of this vital component can save time and resources in the long run.

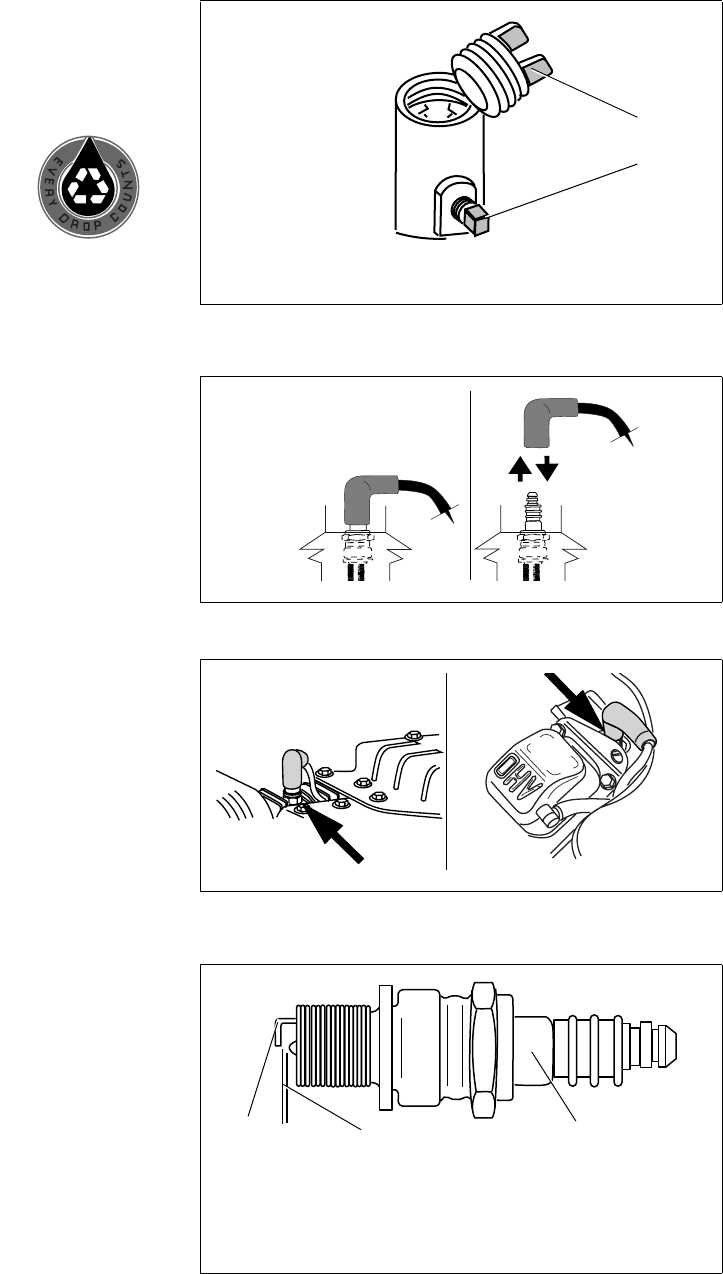

Replacing the Spark Plug

Maintaining optimal engine performance often involves changing the ignition component that ignites the fuel mixture. This task is essential for ensuring smooth operation and efficient fuel consumption.

Before starting, gather the necessary tools, including a socket wrench and a new spark component. First, ensure the engine is cool and disconnected from any power source. Locate the ignition part, which is typically found near the engine’s cylinder.

Using the socket wrench, carefully unscrew the old part from its position. Take note of any debris and clean the area to prevent contamination. Insert the new ignition component by hand to avoid cross-threading, then tighten it securely with the wrench. Finally, reconnect the power source and check the engine for proper functioning.

Oil Change Procedures and Recommendations

Regular maintenance of the engine’s lubrication system is essential for optimal performance and longevity. Changing the oil not only ensures that the internal components are well-lubricated but also helps in removing contaminants that can accumulate over time. Following the appropriate procedures can significantly enhance the efficiency and reliability of the equipment.

Steps for Oil Change

- Gather necessary tools and materials, including an oil filter, new oil, a wrench, and a drain pan.

- Warm up the engine slightly to thin the oil, making it easier to drain.

- Turn off the engine and allow it to cool for a few minutes.

- Locate the drain plug and remove it carefully, allowing the old oil to flow into the drain pan.

- Replace the drain plug once all oil has been drained.

- Remove the old oil filter and replace it with a new one, ensuring a tight seal.

- Pour the new oil into the designated fill cap, using the recommended type and amount.

- Check the oil level using the dipstick and add more if necessary.

Recommendations

- Change the oil every 50 hours of operation or as specified by the manufacturer.

- Use high-quality oil that meets the specifications for the engine type.

- Always dispose of used oil and filters properly at designated recycling centers.

- Inspect the oil level regularly to ensure proper lubrication.

Adjusting the Governor Settings

Properly configuring the governor is essential for ensuring optimal performance of the engine. This component regulates the speed, maintaining stability during operation. A well-adjusted governor can enhance fuel efficiency and prevent potential damage due to over-revving.

Understanding Governor Functionality

The governor functions by controlling the throttle in response to engine speed. When adjustments are necessary, it’s important to follow specific procedures to achieve accurate settings. Regular checks can prevent irregularities and promote longevity of the engine.

Adjustment Procedure

To adjust the governor settings, follow these steps:

| Step | Description |

|---|---|

| 1 | Locate the governor linkage attached to the throttle. |

| 2 | Loosen the adjustment screw on the governor arm. |

| 3 | Move the arm slightly to the desired position. |

| 4 | Tighten the adjustment screw to secure the position. |

| 5 | Test the engine operation to ensure proper responsiveness. |

Following these steps will help maintain the engine’s efficiency and reliability, contributing to its overall performance.

Safety Precautions During Repair

Ensuring safety is paramount when undertaking maintenance on equipment. Proper precautions can prevent accidents and injuries, safeguarding both the individual and the machinery involved. Following recommended guidelines helps create a secure working environment.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, goggles, and sturdy footwear. This equipment minimizes exposure to harmful substances and reduces the risk of injury from sharp edges or moving parts. Ensure that all gear is in good condition and fits properly.

Work Area Safety

Maintain a clean and organized workspace to avoid hazards. Remove any unnecessary tools or materials that may obstruct movement or create tripping risks. Ensure adequate ventilation, especially when dealing with flammable liquids or chemicals. Always have a first aid kit nearby to address any minor injuries promptly.

Where to Find Replacement Parts

When it comes to maintaining small engine equipment, sourcing quality components is essential for optimal performance. Finding the right parts can enhance efficiency and extend the lifespan of your machine. Here are some reliable options for locating the necessary replacements.

- Authorized Dealers: Visit local dealers who specialize in outdoor power equipment. They often carry a wide range of original components and can assist with specific needs.

- Online Retailers: Numerous websites specialize in aftermarket parts. Search for reputable suppliers that offer detailed product descriptions and customer reviews.

- Local Repair Shops: Many repair shops maintain a stock of frequently needed components. Consulting with a technician may provide insights into reliable brands and options.

- Manufacturer Websites: Directly checking the manufacturer’s official site can yield valuable information regarding available parts and recommended suppliers.

By utilizing these resources, you can ensure that your equipment remains in peak condition with high-quality components.

Frequently Asked Questions

This section addresses common inquiries related to troubleshooting and maintenance of small engines. Here, you will find answers to typical concerns that users encounter, providing clarity and assistance in ensuring optimal performance.

Common Issues and Solutions

Users often face a variety of challenges while operating their equipment. Below are some frequent problems and their corresponding solutions:

| Issue | Solution |

|---|---|

| Engine won’t start | Check fuel levels and ensure the ignition system is functioning properly. |

| Excessive smoke | Inspect for oil leakage or overfilled oil levels in the crankcase. |

| Unusual noises | Examine components for wear and tear; ensure all parts are securely fastened. |

Maintenance Tips

Regular upkeep is essential for extending the lifespan of your machinery. Here are some helpful guidelines:

| Task | Frequency |

|---|---|

| Change the oil | Every 50 hours of operation |

| Clean the air filter | Every 25 hours of use |

| Inspect spark plug | Every season |