Ensuring the longevity and optimal performance of heavy machinery is crucial for any operation. Proper care and understanding of your equipment can significantly reduce downtime and enhance productivity. This section delves into essential aspects of upkeep, focusing on various techniques and best practices.

Effective management of your machinery involves not only routine checks but also a thorough grasp of each component’s function. By familiarizing yourself with operational nuances, you can preemptively address potential issues, leading to smoother workflows.

In this guide, we will explore common troubleshooting methods, essential tools for maintenance, and the significance of adhering to recommended procedures. Emphasizing preventive measures ensures that your equipment remains in peak condition, ultimately safeguarding your investment.

Proper upkeep of heavy machinery requires specific instruments to ensure efficiency and longevity. This section will highlight essential implements that every operator should have on hand for effective maintenance tasks.

- Wrenches: Various sizes to adjust nuts and bolts.

- Screwdrivers: Both flat-head and Phillips for general assembly and disassembly.

- Pliers: Ideal for gripping and twisting components.

- Socket Set: Useful for tasks requiring additional torque.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Multimeter: Essential for diagnosing electrical issues.

- Hydraulic Oil: Necessary for maintaining hydraulic systems.

- Grease Gun: Helps lubricate moving parts effectively.

- Cleaning Supplies: Brushes and cloths for keeping surfaces tidy.

- Safety Gear: Helmets, gloves, and goggles to protect the operator during maintenance activities.

Common Backhoe Issues and Solutions

Operators often encounter various challenges with their excavation equipment, impacting performance and efficiency. Identifying these frequent complications and implementing effective remedies can significantly enhance productivity and extend the lifespan of the machinery.

Hydraulic System Failures

A prevalent issue arises from the hydraulic system, which can experience leaks or loss of pressure. Regularly inspecting hoses and connections for signs of wear can prevent unexpected breakdowns. Additionally, ensuring proper fluid levels and replacing filters as needed will maintain optimal functionality.

Engine Performance Problems

Engine-related difficulties, such as rough idling or stalling, may indicate fuel or air filter blockages. Regular maintenance of these components, along with timely oil changes, will help avoid severe engine issues. Keeping an eye on warning indicators can also alert operators to potential problems before they escalate.

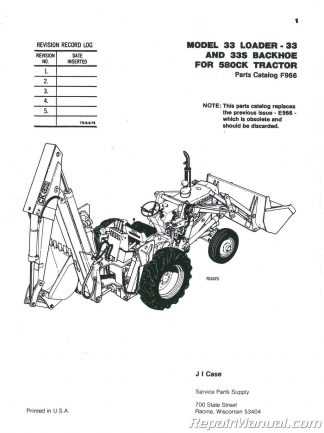

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing issues encountered in heavy machinery maintenance. By following detailed instructions, operators can effectively troubleshoot and resolve common problems, ensuring optimal functionality.

1. Initial Assessment: Begin by thoroughly examining the equipment to identify visible signs of wear or malfunction. Take note of any unusual sounds or behaviors during operation.

2. Disassembly: Carefully dismantle the affected components using appropriate tools. Ensure that all parts are organized to facilitate reassembly later.

3. Inspection: Inspect each component for damage, wear, or obstructions. Pay particular attention to seals, bearings, and hydraulic systems.

4. Cleaning: Clean all parts meticulously to remove dirt, grease, and debris. Use suitable solvents and brushes for effective results.

5. Replacement: Replace any damaged or worn components with new, high-quality parts. Ensure that all replacements meet manufacturer specifications.

6. Reassembly: Carefully reassemble the components in the reverse order of disassembly. Confirm that all fasteners are tightened to the specified torque.

7. Testing: Conduct a thorough test of the machinery to verify that all systems are functioning correctly. Monitor for any signs of issues during operation.

8. Documentation: Record all actions taken during the maintenance process, including parts replaced and any observations made. This documentation is valuable for future reference.

Preventative Maintenance Best Practices

Implementing effective strategies for regular upkeep is essential to ensure optimal performance and longevity of equipment. By adhering to specific routines, operators can identify potential issues before they escalate, thus minimizing downtime and costly repairs.

Regular Inspections

Conducting frequent assessments of machinery components is crucial. These evaluations should focus on critical parts such as hydraulic systems, filters, and hoses. Early detection of wear and tear can prevent significant malfunctions.

Scheduled Servicing

Establishing a timely service schedule based on operational hours is recommended. This practice includes oil changes, fluid checks, and the replacement of worn-out parts. Staying proactive with servicing can greatly enhance the overall efficiency of the equipment.

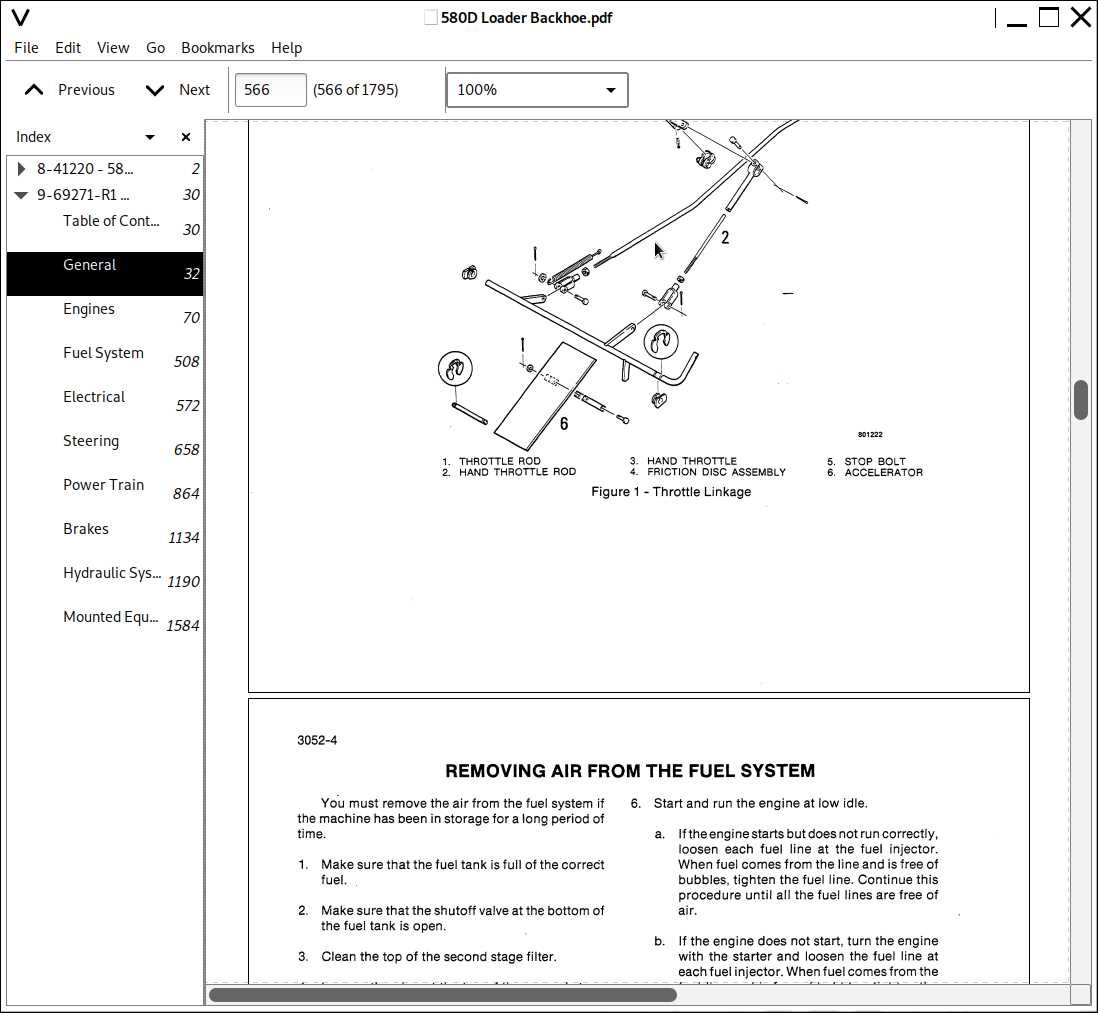

Understanding Backhoe Hydraulics

The hydraulic system in heavy machinery plays a crucial role in enhancing performance and efficiency. This complex network enables the machine to perform various tasks by converting fluid power into mechanical work. Understanding how this system operates is essential for optimizing functionality and addressing any issues that may arise.

Components of the Hydraulic System

At the heart of hydraulic systems are several key components, each serving a unique purpose. The interaction between these elements ensures smooth operation and reliable performance. Below is a summary of the primary components:

| Component | Function |

|---|---|

| Hydraulic Pump | Generates fluid flow by converting mechanical energy into hydraulic energy. |

| Hydraulic Cylinders | Convert hydraulic energy back into mechanical energy to perform lifting and digging operations. |

| Valves | Control the direction and flow of hydraulic fluid within the system. |

| Hydraulic Fluid | Transmits power and lubricates components, ensuring smooth operation. |

Common Hydraulic Issues

Identifying and addressing hydraulic problems is vital for maintaining optimal performance. Common issues include leaks, pressure loss, and inefficient operation. Regular inspection and maintenance can prevent these problems, ensuring the system remains reliable and effective.

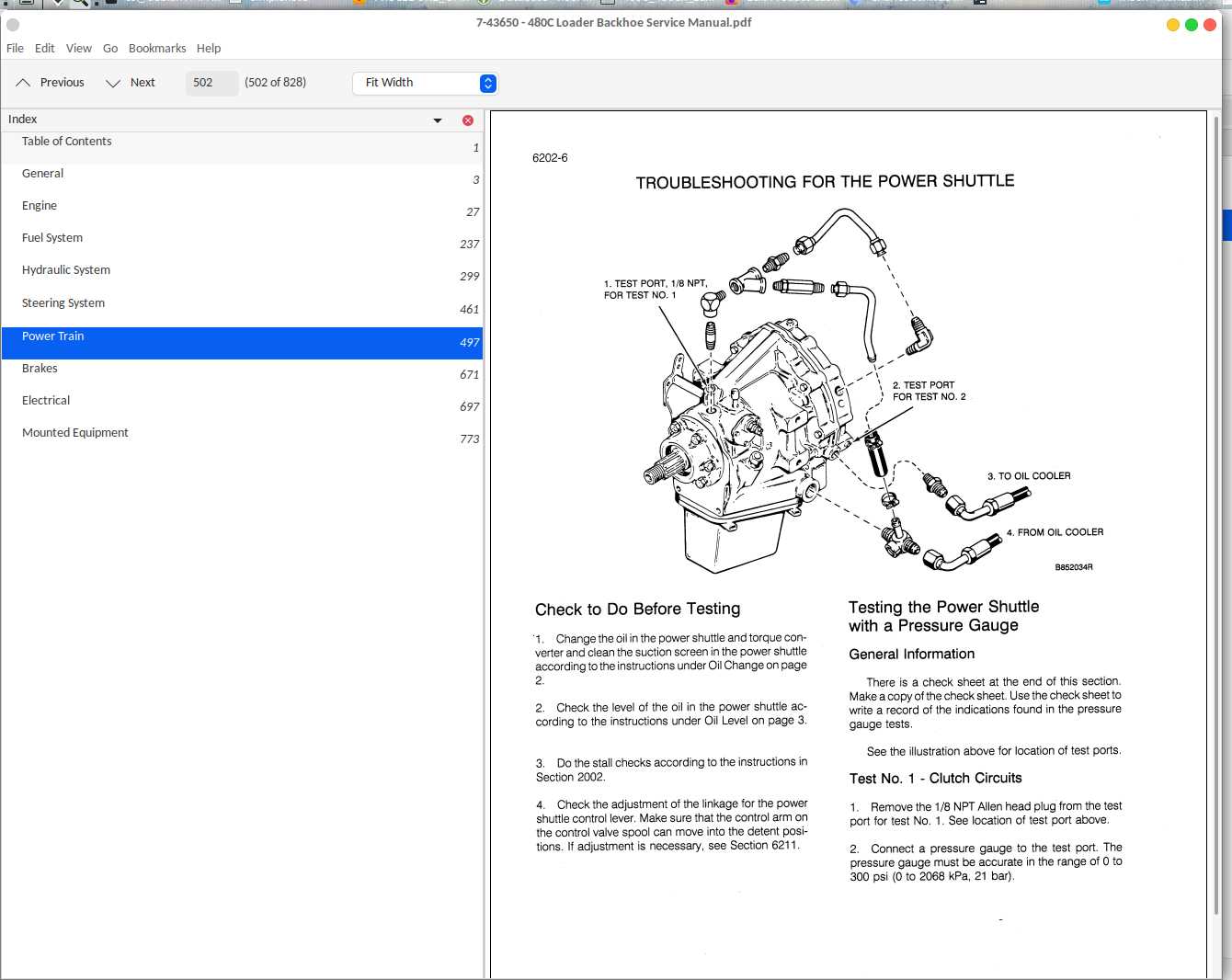

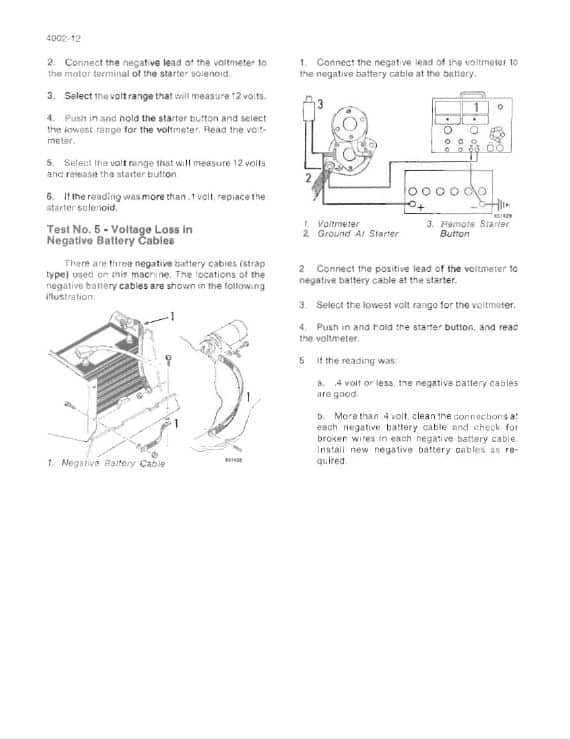

Electrical System Troubleshooting Tips

Diagnosing issues within electrical systems can be challenging, yet essential for optimal performance. Understanding the fundamental principles of electrical components and their interactions can significantly aid in identifying and resolving problems efficiently.

Common Symptoms and Diagnoses

Recognizing symptoms such as flickering lights, unresponsive controls, or unexpected power losses is crucial. These signs often indicate underlying faults, which may range from loose connections to faulty wiring. Conducting a thorough inspection of the wiring harness and connectors can help uncover these hidden issues.

Testing and Verification Methods

Utilizing multimeters and other diagnostic tools allows for precise testing of circuits and components. Check voltage levels, continuity, and resistance to ensure each part functions correctly. Systematic testing helps isolate the source of the problem and leads to effective solutions.

Replacing Major Components Guide

When it comes to maintaining heavy machinery, understanding how to effectively swap out significant parts is crucial. This section aims to provide essential insights into the processes involved in component replacement, ensuring optimal functionality and longevity of your equipment.

Preparation and Safety Measures

Before beginning any replacement tasks, it’s vital to prioritize safety. Always wear appropriate personal protective equipment (PPE) and ensure that the machine is turned off and properly secured. Familiarize yourself with the specific components you will be working on, and gather all necessary tools and materials beforehand.

Step-by-Step Replacement Process

Begin by removing the existing component carefully. Follow the manufacturer’s guidelines for disassembly to avoid any damage. Once the old part is removed, clean the surrounding area to prevent debris from interfering with the installation of the new part. Install the new component by aligning it properly and securing it according to the specifications provided.

Final Check: After installation, double-check all connections and ensure that everything is tightened securely. Perform a functional test to verify that the machinery operates smoothly.

Importance of Regular Inspections

Conducting frequent assessments of machinery is crucial for ensuring optimal performance and longevity. By prioritizing these evaluations, operators can identify potential issues before they escalate into significant problems, ultimately saving time and resources.

Benefits of Routine Evaluations

- Early Detection: Identifying minor faults can prevent costly repairs.

- Enhanced Safety: Regular checks help maintain safe operating conditions.

- Improved Efficiency: Well-maintained equipment operates more effectively.

Recommended Inspection Practices

- Inspect hydraulic systems for leaks and functionality.

- Check all moving parts for wear and tear.

- Ensure that safety features are fully operational.

- Review fluid levels and condition regularly.

Safety Protocols During Repairs

Ensuring a secure environment is essential when performing maintenance tasks on heavy machinery. Proper precautions not only protect the individual working on the equipment but also safeguard those nearby.

Before commencing any work, adhere to the following safety guidelines:

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and helmets.

- Conduct a thorough inspection of the work area to identify potential hazards.

- Ensure all tools and equipment are in good condition and suitable for the task at hand.

- Notify all personnel in the vicinity of the maintenance activities to prevent accidents.

Additionally, consider these crucial practices:

- Maintain clear communication with team members during operations.

- Follow manufacturer guidelines and recommended procedures strictly.

- Keep emergency contact information easily accessible.

By implementing these protocols, the risk of accidents and injuries can be significantly minimized, fostering a safer working atmosphere.

Finding Genuine Replacement Parts

Ensuring the longevity and efficiency of your equipment requires sourcing authentic components. Using genuine parts not only maintains performance but also safeguards your investment over time. This section outlines effective strategies for locating reliable replacement items.

Understanding the Importance of Authentic Components

Authenticity in components plays a crucial role in overall machinery performance. Here are key benefits:

- Quality Assurance: Genuine items meet strict manufacturing standards.

- Compatibility: These parts are specifically designed to fit seamlessly with your machinery.

- Longevity: Authentic components typically have a longer lifespan than counterfeit alternatives.

Where to Find Genuine Components

Here are effective avenues to explore for sourcing authentic replacement parts:

- Authorized Dealers: Seek out authorized dealerships that specialize in your machinery brand.

- Manufacturer’s Website: Visit the official website of the manufacturer for direct purchasing options.

- Reputable Online Retailers: Look for well-known online platforms that guarantee authenticity.