For those who rely on precise and swift document binding in a professional setting, the durability and performance of their fastening tools are essential. Even the most dependable devices can occasionally experience operational issues, which can disrupt productivity and cause frustration. Understanding basic maintenance practices, as well as steps for diagnosing common malfunctions, can help keep these devices in optimal working condition.

In this guide, we cover foundational troubleshooting approaches that can be applied to address common concerns with high-use binding devices. Whether it’s clearing a jam or adjusting settings, these straightforward strategies can extend the longevity of your equipment and ensure reliable performance over time.

From inspecting components for wear to implementing cleaning practices, the tips provided here empower users to handle simple adjustments without requiring professional service. With a few practical steps, you can maintain smooth, hassle-free operation and keep your office workflows efficient.

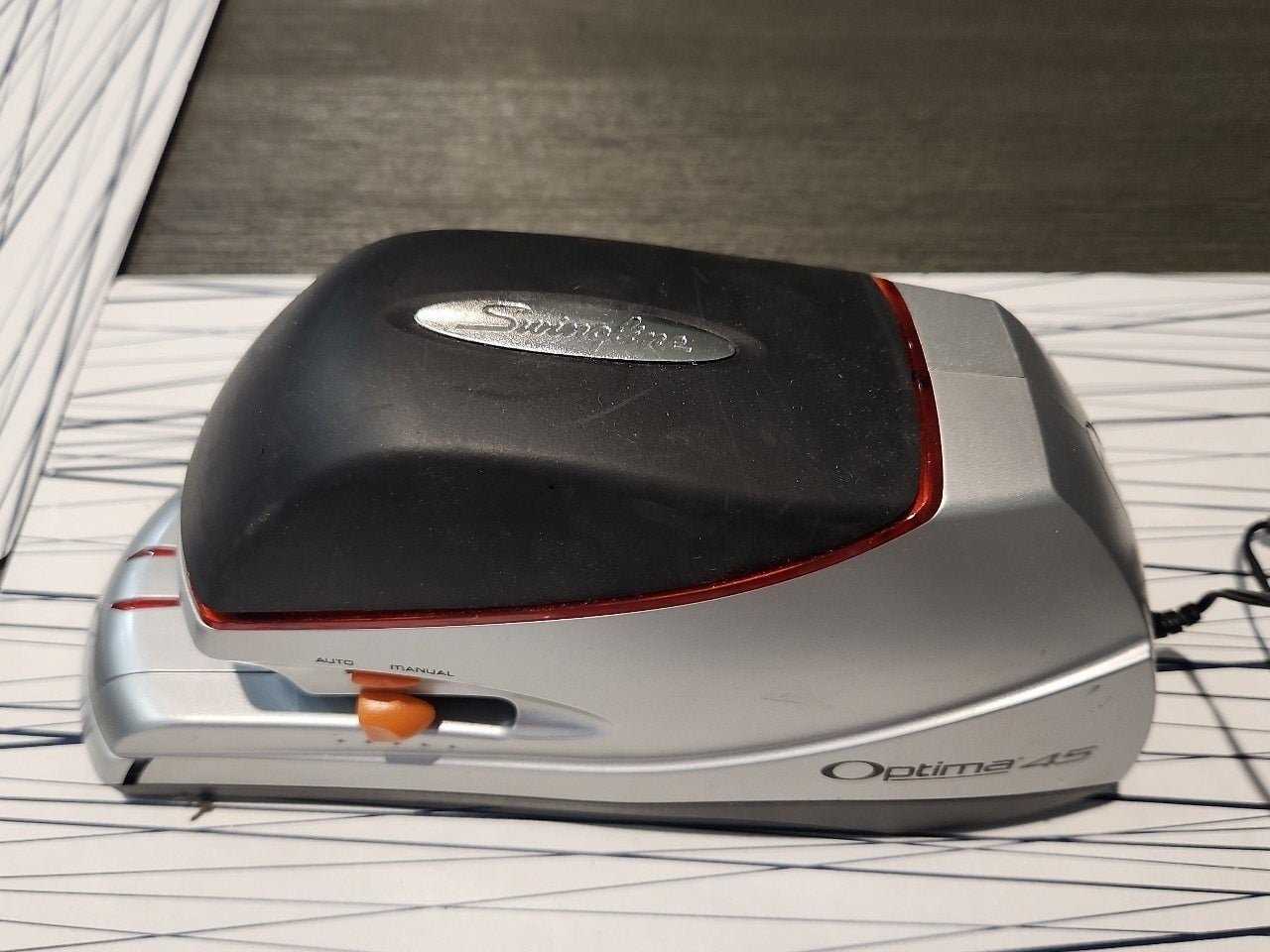

Swingline Optima 20 Electric Stapler Repair Guide

In this section, we provide a clear overview on troubleshooting and maintaining your stapling tool to ensure consistent functionality and prolonged usage. Below, you’ll find steps to identify potential issues, perform maintenance, and carry out basic fixes to keep your device in top condition.

Identifying Common Malfunctions

To keep your tool operating efficiently, it’s crucial to understand the typical signs of malfunction. Below are several indicators and what they might mean:

- Jamming: Occurs if multiple staples get lodged within the unit. Clearing the pathway and using the correct staple type often resolves this.

- Staple Misalignment: If staples are not placed accurately, check the loading tray for alignment issues or misplaced components.

- No Response

Common Issues with Swingline Optima 20

When using this device, a few common operational setbacks may arise that users should be aware of. Recognizing these typical challenges can help ensure smoother performance and reduce interruptions.

- Jamming: Occasionally, the device may experience paper jams, especially if overloaded with sheets. Clearing the path and reducing the load can minimize these occurrences.

- Power Supply Problems: Power interruptions or inconsistent power can lead to malfunctioning. Regularly inspect the power connection and replace any faulty cords to maintain continuous functionality.

- Staple Misalignment: Misalignment of staples may result in irregular or incomplete binding. Ensure proper alignment and, if needed, adjust the internal mechanism to avoid this issue.

- Low Staple Capacity: Users ma

Troubleshooting Stapler Jamming Problems

Frequent jamming issues can hinder smooth and efficient stapling. Understanding potential causes and solutions helps maintain uninterrupted operation. This guide provides insights into addressing common jamming situations, ensuring seamless performance for prolonged use.

Check the Paper Load: Overloading with too many sheets can increase the likelihood of jams. Always ensure the load is within recommended limits and positioned properly to allow easy, smooth function.

Inspect the Staples: Low-quality or incompatible staples may cause misalignment and jamming. Use staples recommended by the manufacturer to reduce the risk of malfunction. Also, avoid using partially used strips as these may not seat properly.

Clean the Mechanism: Dust, debris, or small staple fragments can obstruct operation. Periodically clean the device’s interior using a soft brush or compressed air to prevent buildup that can lead to frequent jams.

Verify Alignment: Sometimes, minor misalignments in the mechanism can result in j

Replacing Worn Parts in the Stapler

Over time, certain components may wear down, affecting the smooth operation of your device. By recognizing which elements are prone to wear and how to address them, you can restore functionality and extend the life of your machine.

Identifying Commonly Worn Parts

Before beginning any replacement, it’s essential to determine which components show the most signs of wear. Frequent use often impacts specific parts more than others, and focusing on these can help in restoring peak performance.

- Staple Driver: This part is crucial for pushing staples through material. If it appears dull or misaligned, consider replacing it to improve precision.

- Internal Springs: Springs help with retraction and smooth motion. When they become loose or lose tension, they shou

Cleaning and Maintenance Tips

Regular upkeep is essential for any device to ensure longevity and smooth performance. Taking a few simple steps to clean and maintain your equipment can help prevent common issues and keep it operating efficiently.

Start by gently wiping the surface with a soft, lint-free cloth to remove dust and residue. Avoid using harsh chemicals, as they can damage sensitive parts. For internal cleaning, use compressed air to clear out any debris that may have accumulated inside, paying close attention to hard-to-reach areas.

Routine lubrication of moving parts, where applicable, will reduce friction and wear, allowing for smoother operation. Be sure to use a lubricant suitable for delicate mechanisms, and apply sparingly to avoid buildup.

Lastly, inspect the power cord and plug regularly for any signs of wear or damage, as a faulty connection can impact the device’s function. Keeping these maintenance practices in mind will h

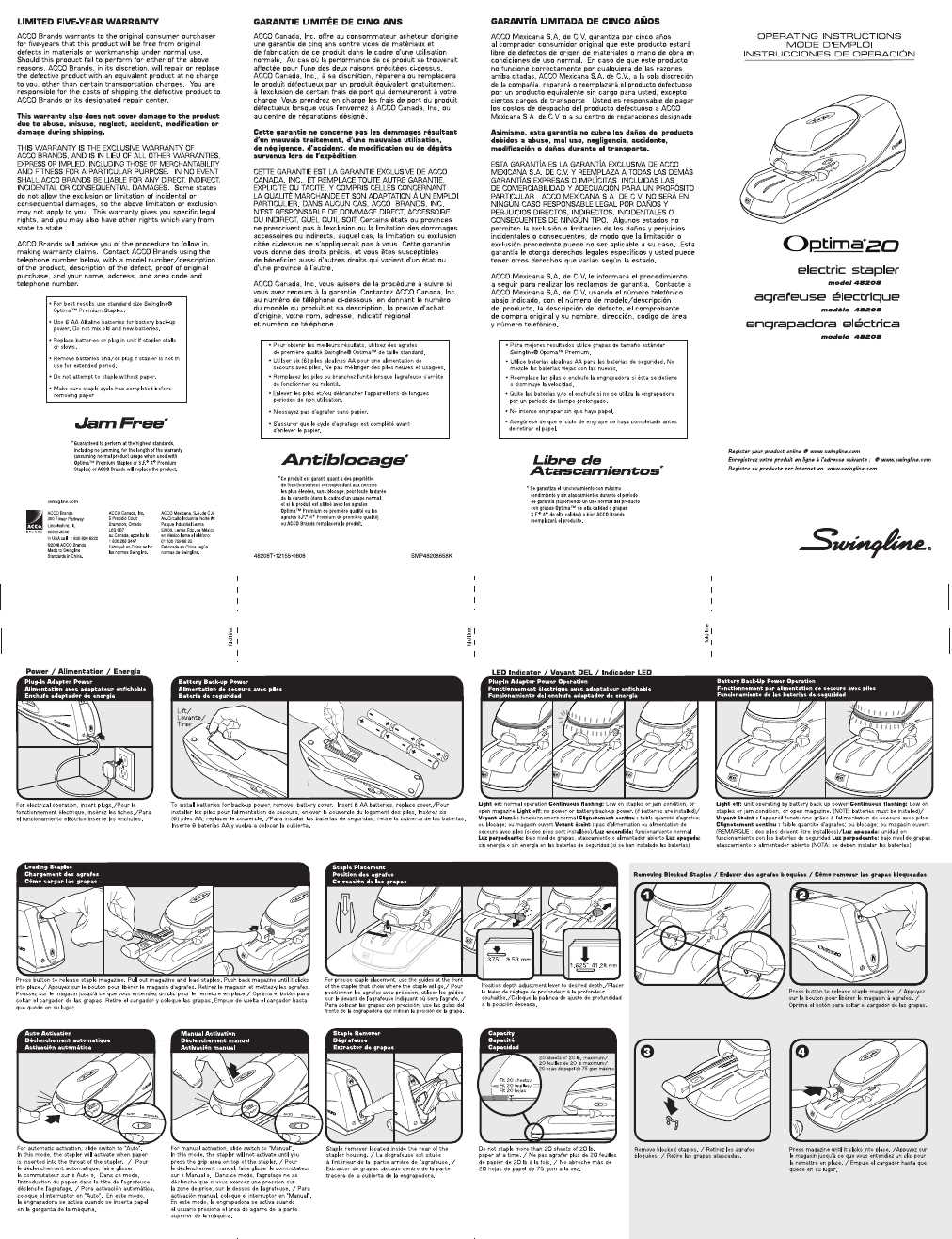

Power Supply and Battery Solutions

In this section, we will explore the various options available for powering your device, focusing on both direct power sources and battery alternatives. Understanding the functionality and compatibility of these power solutions is crucial for ensuring optimal performance and longevity of the equipment.

Direct power connections are often the most reliable option, providing consistent energy to the device. However, when a portable or flexible solution is needed, batteries come into play. Below is a comparison of different power supply methods:

Power Source Type Advantages Disadvantages AC Adapter Stable power, no need for frequent changes Dependent on wall outlet availability Rechargeable Battery Portable, can be used anywhere Limited runtime, requires regular charging Disposable Batteries Easy to replace, widely available Costly over time, environmental impact Choosing the right power solution depends on your specific needs and usage patterns. Consider the advantages and drawbacks of each method to find the best fit for your device’s requirements.

Testing Stapler Performance After Repair

Evaluating the functionality of the device following maintenance is crucial to ensure optimal operation. This assessment involves a series of tests designed to verify that the unit is performing as expected, delivering accurate and consistent results with each use.

The following table outlines the key parameters to assess during the performance evaluation:

Test Parameter Description Expected Outcome Feed Mechanism Check if materials are fed smoothly without jams. Materials should advance seamlessly for each cycle. Punching Power Evaluate the strength of the mechanism in securing items. All items should be securely fastened with no slippage. Noise Level Listen for any unusual sounds during operation. The device should operate quietly without excessive noise. Durability Test Run multiple cycles to assess wear and functionality. All tests should yield consistent results without degradation. After completing these assessments, it is important to document any irregularities observed during testing. Should any issues arise, further investigation may be required to restore full functionality.

Adjusting the Stapling Mechanism

Ensuring optimal performance of your binding device is crucial for achieving clean and precise results. Proper calibration of the fastening system can prevent issues such as misalignment and inconsistent pressure. This section will guide you through the steps to fine-tune the mechanism effectively.

First, locate the adjustment dial or lever typically found on the side or bottom of the unit. This component is designed to modify the depth of the fasteners, allowing you to customize how far the fasteners penetrate the material being secured.

Next, prepare a small stack of paper to test the adjustments. Gradually turn the dial or move the lever to achieve your desired fastening depth. It is advisable to perform this calibration incrementally, checking the results with each adjustment to ensure accuracy.

Finally, after achieving the desired settings, conduct a few test bind operations to confirm that the mechanism operates smoothly. If you notice any irregularities, further adjustments may be necessary. Regular maintenance and periodic recalibration will help prolong the lifespan of your binding device and maintain its efficiency.

Safety Precautions During Repair

Ensuring safety while conducting maintenance tasks is paramount to prevent accidents and injuries. Adhering to specific guidelines can significantly minimize risks associated with handling electrical devices.

Always disconnect the power source before beginning any work on the equipment. This step is crucial to prevent unintended activation, which could lead to harm. Make it a habit to double-check that the device is unplugged.

Utilize appropriate tools designed for the job. Using the right instruments not only enhances efficiency but also reduces the likelihood of damaging the device or causing personal injury. Ensure that tools are in good condition and suited for the task at hand.

Wear protective gear such as gloves and safety glasses. This precaution is vital to shield yourself from potential hazards, including sharp components or electrical shocks. Proper attire can significantly enhance your safety while working.

Maintain a clean workspace to avoid tripping hazards or accidental contact with tools and materials. A tidy environment enables better focus and reduces the chances of mistakes during the maintenance process.

By following these essential precautions, you can create a safer working environment and enhance the overall efficiency of your maintenance tasks.

Understanding Stapler Internal Components

To grasp the mechanics of a binding device, it is essential to explore the various internal elements that work in unison to achieve precise fastening. Each component plays a crucial role, ensuring efficiency and effectiveness in its operation. By familiarizing oneself with these parts, users can better understand how to maintain and troubleshoot their devices.

Main Components

The core components of a binding device include the following:

Component Function Base Provides stability and support for the entire unit. Magazine Holds the staples in place and feeds them into position for use. Pusher Moves staples forward as they are used, ensuring a continuous supply. Driver Controls the movement that drives the staple into the paper. Spring Mechanism Helps return the driver to its original position after a staple is deployed. Understanding the Mechanism

Each part interacts seamlessly to create a smooth binding experience. The base anchors the device, while the magazine and pusher work together to supply staples as needed. The driver, activated by a spring mechanism, ensures staples are securely fastened, demonstrating the harmonious operation of these internal elements.

Tools Needed for Stapler Repairs

When it comes to fixing binding devices, having the right instruments at hand can make a significant difference. Proper tools not only enhance the efficiency of the task but also ensure that the device is restored to optimal functionality. Below is a list of essential implements commonly used for maintenance and troubleshooting.

1. Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for accessing the internal components. These tools allow you to easily remove screws and gain entry to the mechanism inside.

2. Pliers: Pliers can assist in gripping and manipulating various parts, especially when dealing with tight spaces. Needle-nose pliers are particularly useful for reaching into narrow areas.

3. Lubricants: Applying a suitable lubricant can help in ensuring smooth operation. It reduces friction among moving parts and prolongs the life of the device.

4. Cleaning Materials: Keeping the equipment clean is vital for its longevity. A soft cloth or brush can help remove dust and debris that may interfere with the functionality.

5. Replacement Parts: Having compatible components on hand can facilitate quicker fixes. Whether it’s springs, pins, or other essential parts, having these readily available saves time during the process.

Equipped with these tools, you can confidently tackle any issues that arise and maintain the efficiency of your binding devices.

When to Seek Professional Help

There are moments when a device may encounter issues that exceed the scope of basic troubleshooting and maintenance. In such cases, it is advisable to consider enlisting the expertise of a trained technician. Recognizing the right time to seek assistance can save both time and potential damage.

If you find that the problem persists despite following standard guidelines or if the unit exhibits unusual behavior, it may be time to consult a professional. Signs such as unusual noises, persistent jams, or electrical malfunctions are indicators that expert intervention may be necessary.

Additionally, if the unit is still under warranty, reaching out to the manufacturer or authorized service centers is often the best course of action. They can provide specialized support and may offer repairs or replacements at no additional cost.

Overall, when faced with complex malfunctions or safety concerns, turning to a professional can ensure that the device is handled properly and restored to optimal functioning.