Maintaining a chainsaw is crucial for ensuring its longevity and optimal performance. Whether you are a seasoned professional or a weekend warrior, understanding the intricacies of your cutting tool can make a significant difference in efficiency and safety. This guide aims to provide essential insights and step-by-step instructions for troubleshooting common issues and conducting regular upkeep.

In the realm of power equipment, familiarity with the components and functionality of your device is paramount. Knowing how to address minor malfunctions and perform routine checks not only enhances the reliability of the tool but also boosts your confidence in handling it. With the right approach, you can tackle various challenges that may arise during operation.

This resource will delve into key aspects of maintenance, from basic cleaning techniques to more involved adjustments. Each section is designed to equip you with the knowledge necessary to keep your equipment in peak condition, ensuring that every cutting session is smooth and effective. By following the guidelines presented, you can extend the life of your chainsaw and maximize its performance.

Understanding the Stihl MS 271

The machine in focus represents a blend of efficiency and reliability, designed for a variety of tasks in forestry and landscaping. Its robust construction and advanced features make it suitable for both professionals and enthusiasts who seek high performance in their outdoor projects.

Equipped with a powerful engine, this tool ensures optimal cutting speed and efficiency, allowing users to tackle thick branches and heavy logs with ease. Its ergonomic design minimizes fatigue, enhancing user comfort during prolonged operation. Additionally, innovative technologies incorporated into the device promote lower emissions and improved fuel consumption, making it an environmentally friendly choice.

Understanding the key components of this equipment is crucial for maximizing its potential. Features such as the automatic oiling system and easy-access air filter contribute to hassle-free maintenance, ensuring the tool remains in top condition. By familiarizing oneself with these elements, users can ensure longevity and consistent performance in various applications.

Common Issues and Troubleshooting

Understanding frequent problems that may arise with your chainsaw can enhance its performance and prolong its lifespan. This section outlines typical challenges users encounter and provides guidance for effective resolution.

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Hard starting | Old fuel, clogged air filter, faulty spark plug | Replace fuel, clean or replace air filter, check and replace spark plug if necessary |

| Loss of power | Dull chain, dirty carburetor, air filter obstruction | Sharpen chain, clean carburetor, replace or clean air filter |

| Excessive vibration | Worn out parts, unbalanced chain | Inspect and replace worn parts, ensure chain is properly tensioned and balanced |

| Fuel leaks | Damaged fuel lines, loose connections | Inspect fuel lines for damage, tighten or replace loose connections |

| Chain not moving | Blocked chain path, broken drive links | Clear any obstructions, inspect chain for damage and replace if necessary |

By addressing these common issues promptly, users can maintain their equipment efficiently and avoid more serious problems down the line.

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right instruments is crucial for ensuring effective servicing and longevity. A well-equipped toolkit not only simplifies the process but also enhances the quality of the work performed. Here are some fundamental tools that every enthusiast should consider for their maintenance tasks.

Basic Hand Tools

- Screwdrivers: A variety of flathead and Phillips screwdrivers is essential for loosening or tightening screws.

- Wrenches: Adjustable and socket wrenches are vital for handling nuts and bolts of different sizes.

- Pliers: Needle-nose and standard pliers can be used for gripping and manipulating small parts.

Specialized Equipment

- Torque Wrench: This tool ensures that fasteners are tightened to the correct specifications, preventing damage.

- Chain Breaker: Useful for adjusting or replacing chains, making the process quicker and more efficient.

- Fuel Mixing Bottle: Essential for accurately measuring fuel and oil ratios, ensuring optimal performance.

Investing in these tools will significantly ease the upkeep of your equipment, allowing for smoother operations and fewer issues in the long run.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. This guide provides a systematic approach to maintaining your device, focusing on key tasks that enhance its reliability and efficiency. By following these steps, you can minimize the risk of issues and maximize functionality.

Essential Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Oil Check | After every use | Inspect oil levels and refill if necessary to ensure proper lubrication. |

| Air Filter Cleaning | Every 10 hours | Remove and clean the air filter to prevent debris buildup that can hinder performance. |

| Chain Tension Adjustment | Before each use | Ensure the chain is properly tensioned for safe operation. |

| Spark Plug Inspection | Every 25 hours | Check the spark plug for wear and replace if necessary for efficient ignition. |

Tools Needed for Maintenance

Having the right tools on hand is crucial for effective upkeep. Here’s a list of essential items you’ll need:

- Wrench set

- Screwdriver

- Cleaning brush

- Oil for lubrication

- Replacement spark plugs

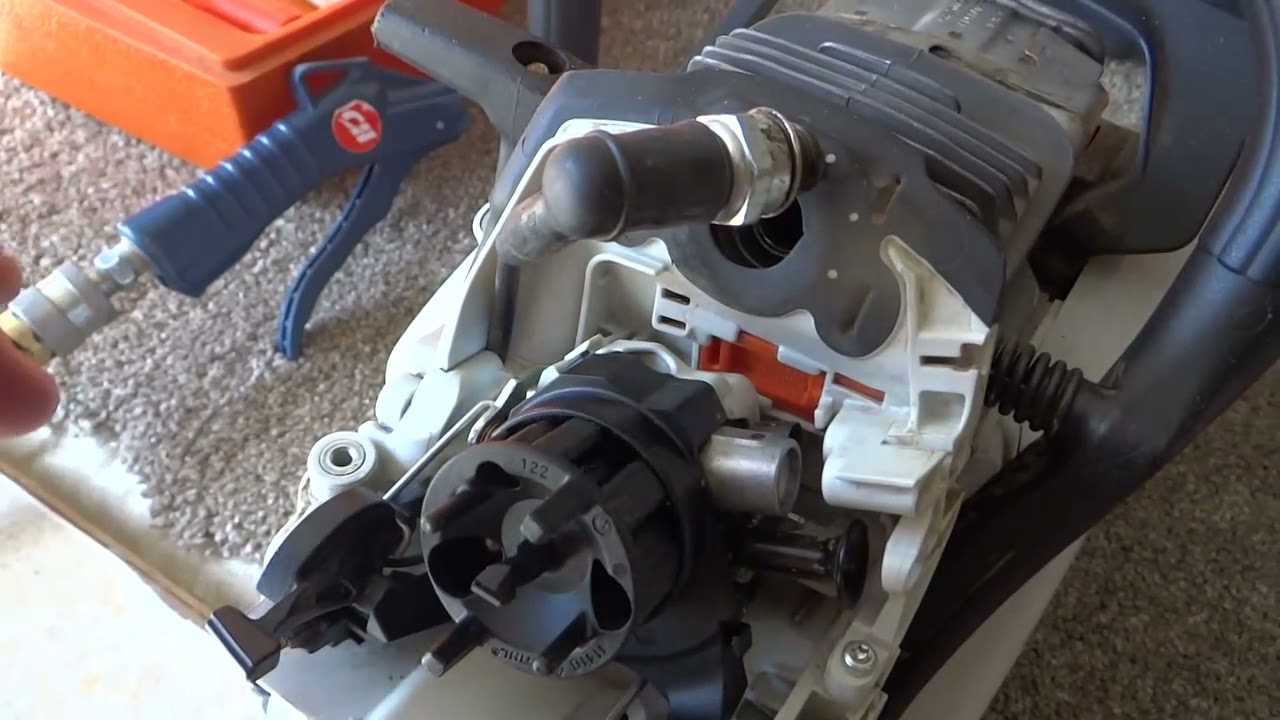

Parts Replacement Process Explained

When it comes to maintaining outdoor power equipment, understanding the procedure for exchanging components is crucial. This section outlines a systematic approach to ensure effective and safe replacement of various parts, promoting longevity and optimal performance of the machine.

Preparation Steps

Before beginning the replacement process, it’s essential to gather all necessary tools and components. This includes verifying that you have the correct parts and ensuring that your workspace is clean and organized. Following these preliminary steps helps streamline the entire procedure.

Replacement Procedure

Once you are ready, follow these structured steps for successful part exchange:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental activation. |

| 2 | Remove the damaged part using appropriate tools, taking care not to damage surrounding components. |

| 3 | Install the new part, ensuring a secure fit and proper alignment. |

| 4 | Reconnect the power source and test the equipment to ensure functionality. |

Following this comprehensive approach helps in maintaining equipment efficiently, ensuring that each part functions as intended for optimal performance.

Safety Precautions During Repairs

Ensuring personal safety while performing maintenance tasks is crucial for preventing accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with handling tools and equipment. It is essential to create a safe work environment and to use appropriate protective gear throughout the process.

Personal Protective Equipment

Wearing suitable personal protective equipment (PPE) is fundamental. This includes safety goggles to protect your eyes from debris, gloves to prevent cuts and abrasions, and sturdy footwear to safeguard your feet. Additionally, ear protection should be considered if the tools produce high noise levels, ensuring you maintain your hearing health.

Workspace Safety

Maintain a clean and organized workspace to minimize hazards. Ensure that the area is well-lit and free of clutter, which can cause tripping or accidents. Always have a first aid kit nearby, and be familiar with its contents. Lastly, keep all tools in good condition and use them for their intended purpose to avoid malfunction and injuries.

Cleaning Your Chainsaw Effectively

Maintaining the cleanliness of your cutting tool is crucial for its optimal performance and longevity. Regularly removing debris, sap, and oil buildup not only enhances efficiency but also prevents potential damage to vital components. An effective cleaning routine ensures that your equipment operates smoothly and safely, providing you with reliable service during your tasks.

Start by disconnecting the spark plug to eliminate any accidental starts while you work. Carefully remove the bar and chain, setting them aside for individual attention. Use a soft brush or compressed air to eliminate dirt and sawdust from the guide bar and other accessible areas. For stubborn residue, a mixture of warm soapy water can help dissolve grease and sticky substances.

Once the bar is clean, inspect it for wear and tear. Pay special attention to the oiling holes to ensure they are free from blockages. Next, turn your focus to the cutting chain. Wipe it down thoroughly and check for any damaged links or dull blades. Sharpening the chain as needed will further enhance its cutting capabilities.

Finally, reassemble the tool by reattaching the chain and bar. Fill the oil reservoir with the appropriate lubricant, ensuring all parts are in good condition. Regular cleaning not only boosts performance but also extends the lifespan of your cutting equipment, making it a worthwhile part of your maintenance routine.

Engine Specifications and Requirements

This section outlines the essential characteristics and necessary conditions for optimal engine performance. Understanding these specifications is crucial for ensuring efficiency and longevity in operation.

The engine typically operates on a two-stroke cycle, which allows for a compact design while delivering high power output relative to size. A displacement of approximately 50 cubic centimeters is common, providing a balance between power and fuel efficiency.

Fuel type is an important consideration; the recommended blend is usually a mixture of gasoline and a high-quality two-stroke oil, often in a ratio of 50:1. This ensures proper lubrication and minimizes wear on internal components.

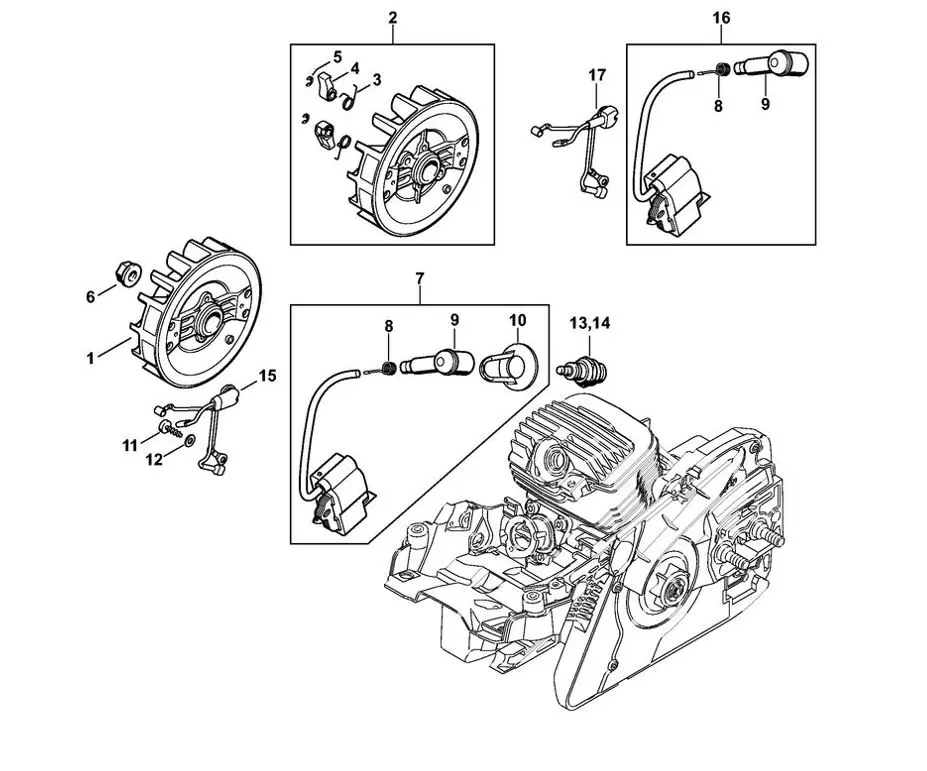

Moreover, the ignition system is designed for reliable starts and smooth operation, utilizing a magneto for generating spark. Proper maintenance of the spark plug is necessary for maintaining optimal ignition performance.

Cooling is facilitated by an air-cooled system, which requires unobstructed airflow to prevent overheating during prolonged use. Regular checks of the air filter are essential to ensure efficient airflow and prevent dirt accumulation.

Overall, adhering to these specifications and requirements is vital for achieving peak performance and extending the lifespan of the engine in various applications.

Identifying Wear and Tear Signs

Recognizing the signs of degradation in equipment is essential for maintaining optimal performance and longevity. Regular inspections can help identify potential issues before they escalate into more significant problems. This section outlines key indicators that suggest your machine may require attention.

Common Indicators of Degradation

- Unusual Noises: Listen for any unexpected sounds during operation, such as grinding or rattling, which may indicate internal issues.

- Reduced Efficiency: A noticeable drop in performance or power output can signal wear in critical components.

- Excessive Vibration: Increased vibration levels may suggest loose parts or imbalances that need addressing.

- Visual Damage: Inspect for cracks, chips, or signs of corrosion on the exterior and moving parts.

Key Areas to Inspect

- Cutting Edge: Check for dullness or damage, as this affects cutting efficiency.

- Fuel System: Look for leaks or blockages that can impede operation.

- Air Filter: A clogged air filter can lead to performance issues and should be examined regularly.

- Drive Mechanism: Inspect belts and chains for signs of wear that could affect power transmission.

By regularly monitoring these signs, you can ensure your equipment remains in peak condition, ultimately extending its service life and improving safety during use.

Operating Guidelines for Longevity

To ensure optimal performance and extend the lifespan of your equipment, following specific operating guidelines is essential. These practices not only enhance efficiency but also minimize the risk of damage, ensuring that your machine remains reliable for years to come.

- Regular Maintenance: Schedule routine checks and maintenance tasks to keep components in good condition. This includes cleaning filters, checking for wear, and ensuring lubrication is adequate.

- Proper Fuel Usage: Always use the recommended fuel type and ensure it is fresh. Old or incorrect fuel can lead to performance issues and potential engine damage.

- Safe Operating Techniques: Familiarize yourself with safe handling and operation methods. Avoid forcing the equipment beyond its designed capabilities, which can lead to premature wear.

- Environmental Considerations: Operate the machine in suitable conditions. Extreme temperatures, wet environments, or excessive dust can adversely affect functionality.

By adhering to these guidelines, you can significantly enhance the durability and efficiency of your equipment, making it a trustworthy companion for your tasks.

Upgrading Components for Better Performance

Enhancing the capabilities of your equipment can lead to significant improvements in efficiency and longevity. By carefully selecting and upgrading certain parts, users can experience a boost in power, reduced emissions, and an overall smoother operation. This section explores various components that can be upgraded to achieve superior performance.

Engine Modifications: One of the most impactful areas for enhancement is the engine. Upgrading to a high-performance air filter can increase airflow, allowing for better combustion and improved power output. Additionally, tuning the carburetor can optimize fuel delivery, resulting in a more responsive throttle and increased torque.

Bar and Chain Improvements: The cutting efficiency can also be enhanced by selecting a better-quality bar and chain. Using a lightweight, durable bar can reduce the overall weight of the setup, while a chain designed for faster cutting can save time and effort in your tasks. Opting for a low-vibration chain can further enhance comfort during extended use.

Upgrading the Ignition System: The ignition system plays a critical role in engine performance. Replacing stock components with high-output ignition coils and advanced spark plugs can improve starting efficiency and engine response. This can lead to a noticeable difference in the smoothness of operation.

Enhancing the Fuel System: Upgrading fuel lines and filters can also contribute to better performance. High-quality lines reduce the risk of clogs and leaks, ensuring a steady flow of fuel. Additionally, using premium fuels can lead to cleaner combustion and increased power.

By considering these upgrades, users can maximize the performance of their equipment, making tasks easier and more efficient. A focus on quality components ensures not just immediate benefits but also long-term reliability and satisfaction.

Finding Replacement Parts Online

Locating spare components for outdoor power equipment has become increasingly straightforward with the rise of online marketplaces. Whether you’re a seasoned technician or a casual user, having access to a wide range of parts through digital platforms simplifies the process of maintaining and enhancing your machinery. This section will guide you on effectively navigating these resources to find the right items for your needs.

Identifying Reputable Sources

When searching for components, it is crucial to start with reputable websites that specialize in outdoor equipment. Look for platforms that offer detailed descriptions, part numbers, and customer reviews. Trusted suppliers often provide guarantees or return policies, which can be beneficial in ensuring you receive the correct items without hassle.

Using Part Numbers for Precision

To streamline your search, utilize the specific part numbers associated with your equipment. Inputting these numbers into search fields can lead you directly to compatible options. Additionally, familiarizing yourself with alternative names and compatible models can expand your search results and help you discover suitable replacements that may not be immediately apparent.