Understanding the intricacies of your equipment is essential for ensuring optimal performance and longevity. This section provides valuable insights into the care and troubleshooting of a popular outdoor power tool designed for various gardening tasks. With the right information at hand, users can enhance their familiarity with the machine, ultimately leading to better results and efficiency.

In the following paragraphs, we will delve into common challenges faced by users and offer guidance on how to address them effectively. By following these practical tips, you can ensure that your tool remains in peak condition, ready to tackle any task that comes its way. Whether it’s basic upkeep or resolving issues, having a solid understanding of your equipment can make a significant difference in its operation.

Equipped with knowledge about the various components and their functions, you will be better prepared to maintain and optimize your tool’s performance. This comprehensive overview aims to empower users with the skills needed to handle everyday situations with confidence and ease, leading to a more satisfying experience in your gardening endeavors.

This section aims to provide a comprehensive introduction to a popular gardening tool designed for various outdoor tasks. It highlights the key features, functionalities, and the overall design that make this tool a valuable asset for users seeking efficiency in their yard work.

Key Features

- Lightweight construction for ease of use

- Powerful engine for effective cutting

- Versatile attachments for different tasks

- User-friendly controls for effortless operation

Benefits of Using This Tool

- Enhanced productivity in maintaining gardens and lawns

- Reduced fatigue due to ergonomic design

- Long-lasting performance with proper care

- Easy to maneuver in tight spaces

Common Issues with the FS 40

When operating a grass trimmer, users may encounter several recurring problems that can affect performance and efficiency. Understanding these common challenges can help in troubleshooting and ensuring optimal functionality.

| Issue | Description |

|---|---|

| Hard Starting | The device may struggle to start, often due to fuel or ignition system issues. |

| Uneven Cutting | The trimmer may leave patches of grass uncut, which can be attributed to dull blades or improper height settings. |

| Excessive Vibration | Increased vibration can indicate problems with the cutting head or mounting hardware. |

| Overheating | Running the unit for extended periods can lead to overheating, often caused by inadequate airflow or debris buildup. |

| Fuel Leaks | Leaks can occur from the fuel lines or tank, posing safety hazards and reducing efficiency. |

Essential Tools for Repair

When maintaining and restoring outdoor equipment, having the right tools is crucial for ensuring effective operation and longevity. The following implements are fundamental for performing various tasks, making the process smoother and more efficient.

| Tool | Description |

|---|---|

| Wrench Set | Essential for loosening and tightening nuts and bolts, allowing access to internal components. |

| Screwdriver Set | Used for removing and securing screws, vital for accessing different parts of the device. |

| Socket Set | Facilitates working with various sizes of nuts, enhancing the ease of disassembly and reassembly. |

| Plier Set | Helpful for gripping, twisting, and cutting wire, essential for electrical connections and adjustments. |

| Cleaning Brush | Important for clearing debris and dirt from components, ensuring optimal performance. |

| Multimeter | A diagnostic tool for measuring voltage, current, and resistance, useful for troubleshooting electrical issues. |

| Lubrication Oil | Necessary for maintaining moving parts, reducing friction and wear for smoother operation. |

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise during the use of your outdoor power equipment. By following a systematic method, you can efficiently diagnose problems and implement effective solutions to restore optimal performance.

Common Issues and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Fuel issues | Check fuel level and quality. Replace stale fuel. |

| Excessive vibration | Worn or damaged parts | Inspect and replace any worn components. |

| Loss of power | Clogged air filter | Clean or replace the air filter as needed. |

| Strange noises | Loose fasteners | Tighten all screws and bolts securely. |

Steps for Effective Diagnosis

Begin by observing the equipment while it operates. Note any unusual behaviors or sounds. Next, refer to the common issues listed in the table to correlate symptoms with potential causes. Following this, perform necessary checks or adjustments to rectify the identified problem. If the issue persists, consider consulting a professional for further assistance.

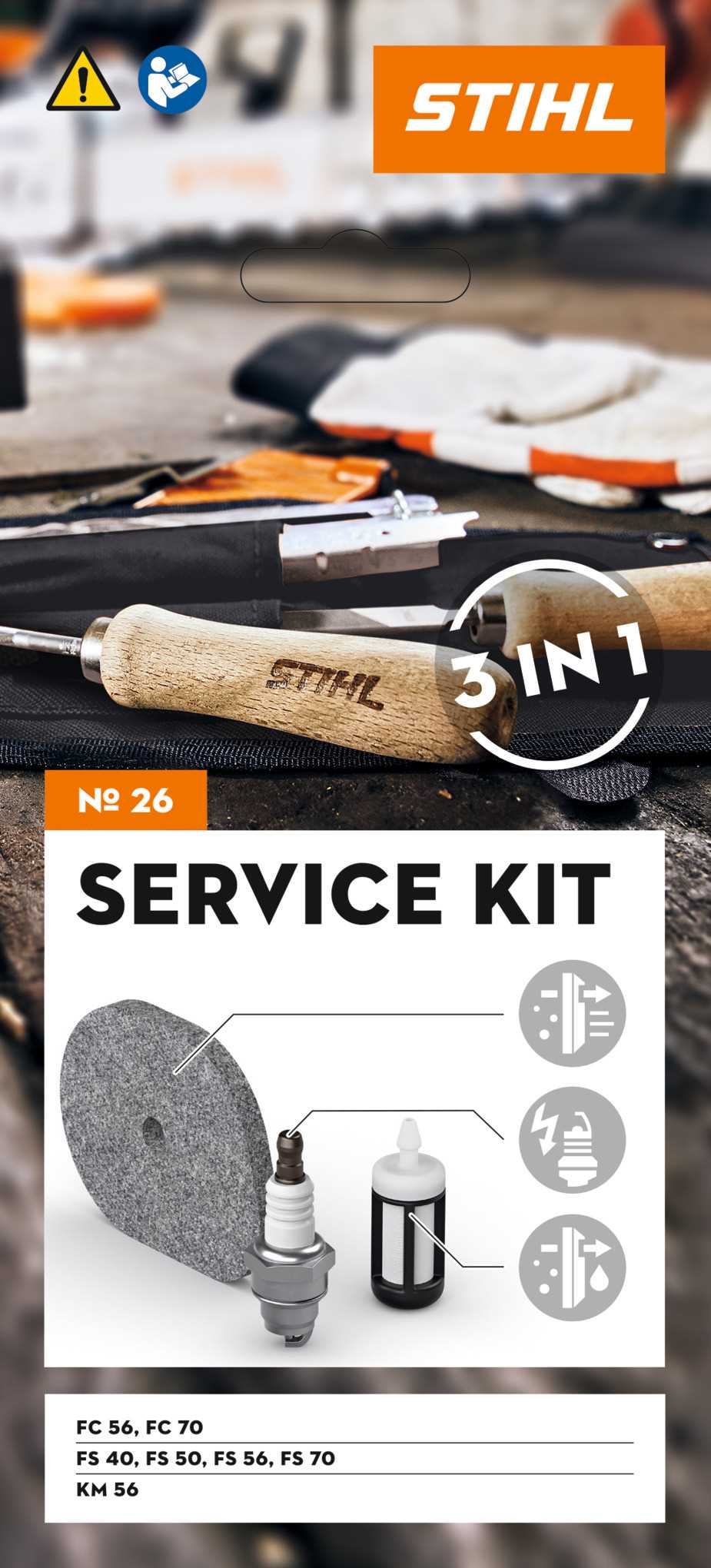

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your gardening equipment. Regular attention to key components not only enhances performance but also prevents unexpected failures. Implementing straightforward maintenance practices can significantly improve efficiency and durability.

Regular Cleaning

Routine cleaning is vital for maintaining optimal functionality. After each use, remove any debris and dirt that may accumulate on the device. Use a soft brush or cloth to clean hard-to-reach areas, as this prevents the buildup of residues that can impair performance.

Periodic Inspections

Conduct frequent checks on all parts, including blades, filters, and fuel lines. Look for signs of wear or damage, and replace any worn components promptly. This proactive approach can save time and resources in the long run, ensuring your equipment remains reliable and effective.

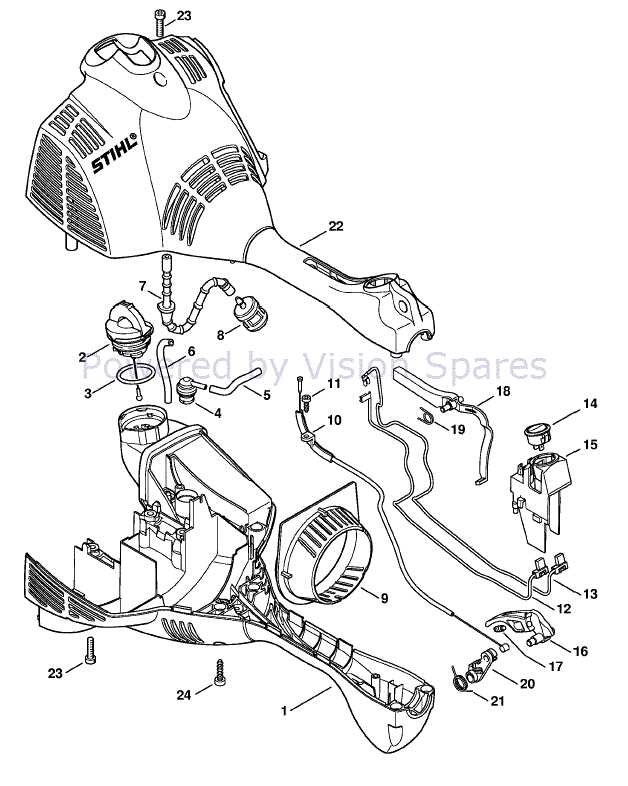

Replacing Worn Parts Safely

When equipment components become worn out, ensuring their replacement is done correctly is vital for optimal performance and safety. Proper procedures not only enhance the lifespan of the device but also minimize the risk of accidents during operation. This section outlines essential practices to follow when swapping out outdated elements, ensuring a seamless and secure experience.

Preparation and Inspection

Before starting the replacement process, it’s important to prepare adequately. Begin by disconnecting the power source to prevent accidental activation. Next, conduct a thorough inspection of the device, identifying all parts that require attention. Documenting the condition and placement of these components can aid in a smooth reassembly. Additionally, gather all necessary tools and replacement parts to streamline the procedure.

Safe Removal and Installation

When removing worn components, follow the manufacturer’s guidelines to avoid damaging surrounding areas. Use appropriate tools to loosen and detach the parts gently. Once the old pieces are removed, install the new ones with care, ensuring they fit securely and align properly. After installation, double-check all connections and perform a final inspection before reconnecting the power source to guarantee everything is in order.

Cleaning the Carburetor Effectively

Maintaining optimal performance of a small engine requires regular attention to the carburetor. This essential component is responsible for mixing air and fuel, ensuring efficient combustion. Over time, dirt and debris can accumulate, leading to issues such as poor starting and reduced power output. Thus, thorough cleaning is crucial to restore functionality and enhance engine longevity.

Steps for Effective Cleaning

- Gather the necessary tools and materials:

- Screwdrivers

- Carburetor cleaner

- Soft brush or cloth

- Protective gloves

- Clean workspace

- Jets and passages

- Float and needle valve

- Gaskets and seals

Tips for Optimal Results

- Always work in a well-ventilated area to avoid inhaling harmful fumes.

- Regular maintenance can prevent buildup and ensure smooth operation.

- Consider using a fuel stabilizer to reduce the likelihood of gumming.

Fuel System Maintenance Procedures

Proper upkeep of the fuel system is essential for optimal performance and longevity of your equipment. Regular attention to this component ensures efficient operation and minimizes potential issues related to fuel delivery and combustion.

The following steps outline key practices for maintaining the fuel system:

-

Inspect Fuel Lines:

- Check for any signs of wear or damage.

- Ensure there are no leaks or cracks.

- Replace any compromised lines promptly.

-

Clean Fuel Filter:

- Remove the filter from the system.

- Use appropriate solvents to clean it thoroughly.

- Replace it if cleaning does not restore functionality.

-

Check Fuel Quality:

- Use fresh fuel to avoid contamination issues.

- Avoid using fuel that has been stored for extended periods.

- Inspect for water or debris in the fuel.

-

Examine Fuel Tank:

- Inspect for corrosion or damage to the tank.

- Ensure the cap seals properly to prevent evaporation.

- Clean the interior if sediment is present.

-

Maintain Fuel Pump:

- Ensure the pump operates smoothly without unusual noises.

- Replace any faulty components as needed.

- Check connections for secure attachment.

Following these guidelines will help maintain the fuel system’s efficiency, promoting reliable performance and reducing the likelihood of breakdowns.

Electrical Components and Repairs

This section delves into the various electrical parts found in a typical outdoor power tool, focusing on their function, potential issues, and approaches to troubleshooting and maintenance. Understanding these components is essential for ensuring optimal performance and longevity of the equipment.

Common Electrical Components

The electrical system of outdoor power equipment comprises several key elements. Each component plays a vital role in the overall functionality of the machine. Below is a summary of these essential parts:

| Component | Function |

|---|---|

| Ignition Coil | Generates the high voltage needed to ignite the fuel-air mixture. |

| Starter Motor | Engages the engine to start the operation. |

| Battery | Provides electrical power for starting and operating electronic components. |

| Wiring Harness | Connects various electrical parts and ensures proper signal flow. |

Troubleshooting Electrical Issues

Identifying and addressing electrical faults is crucial for maintaining equipment functionality. Common issues may include poor starting, intermittent operation, or complete failure. Here are some steps to diagnose and resolve these problems:

- Check connections for corrosion or damage.

- Inspect the battery for charge and proper installation.

- Test the ignition coil with a multimeter for proper voltage output.

- Examine the wiring harness for frays or breaks.

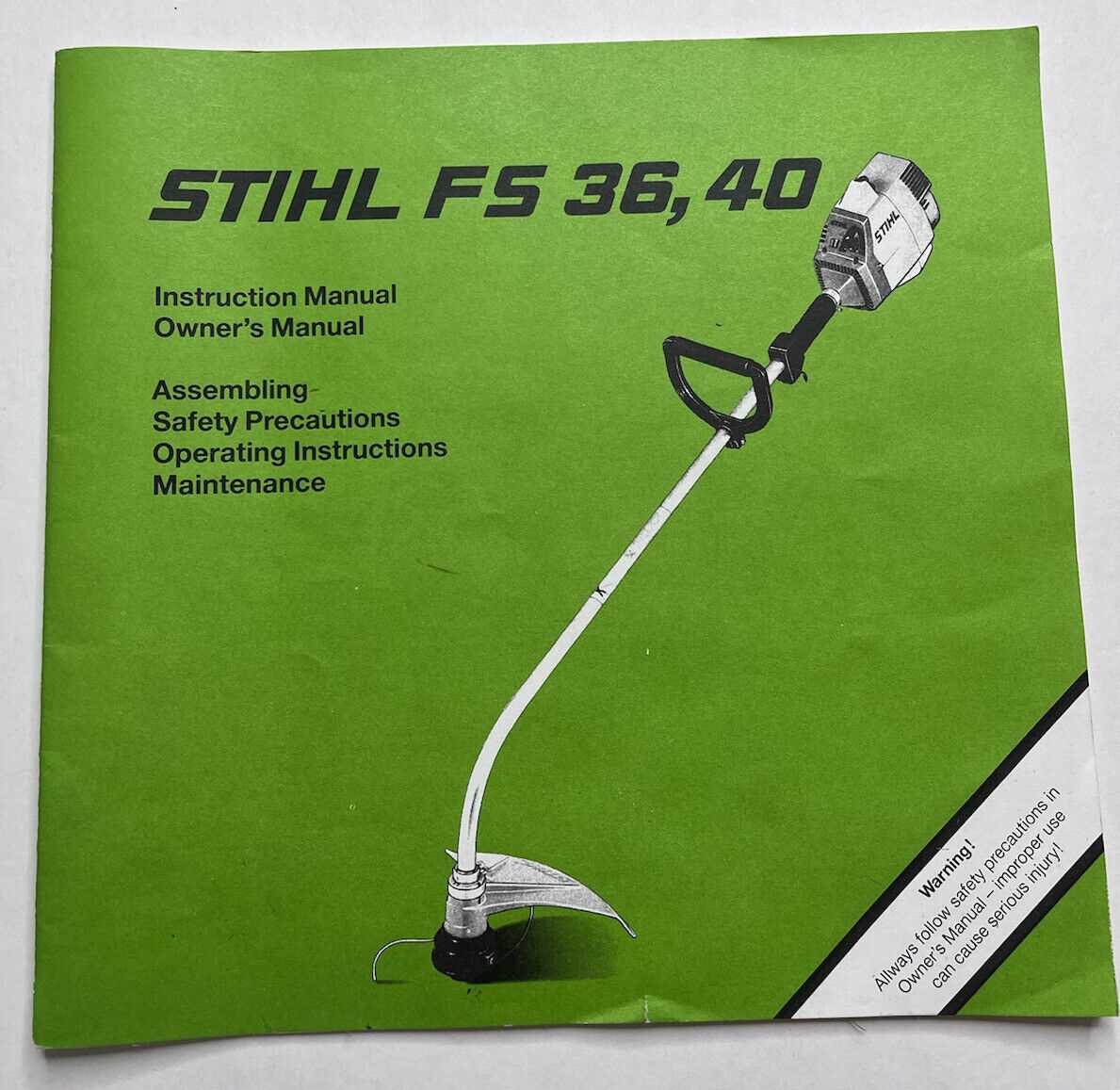

Understanding the User Manual

A user guide serves as an essential resource for operators, providing vital information about the equipment’s features, functions, and safe handling procedures. It acts as a roadmap for effective usage and maintenance, ensuring that users can maximize the performance of their tools.

Familiarizing yourself with the guide can significantly enhance your experience, making it easier to navigate various tasks. Key sections often include operational instructions, troubleshooting tips, and safety precautions, all designed to prevent accidents and ensure optimal performance.

| Section | Description |

|---|---|

| Introduction | Overview of the equipment and its intended use. |

| Safety Guidelines | Essential precautions to ensure safe operation. |

| Operating Instructions | Step-by-step procedures for effective usage. |

| Troubleshooting | Common issues and solutions to enhance performance. |

| Maintenance Tips | Recommended practices for upkeep and longevity. |

Frequently Asked Questions

This section aims to address common inquiries and concerns related to the operation and maintenance of grass trimming equipment. Whether you are experiencing issues or seeking general information, the following questions provide helpful insights.

General Inquiries

- What are the key features of this equipment?

- How often should I perform maintenance tasks?

- What type of fuel is recommended for optimal performance?

Troubleshooting Common Issues

- What should I do if the engine won’t start?

- Check the fuel level and quality.

- Inspect the spark plug for wear and damage.

- How can I resolve poor cutting performance?

- Ensure that the cutting blade is sharp and properly installed.

- Adjust the line length as needed for efficiency.

Resources for Further Assistance

When encountering challenges with your equipment, it is essential to have access to reliable resources that can provide guidance and support. Whether you are looking for troubleshooting tips, maintenance advice, or expert assistance, there are various avenues to explore for help.

Online Forums and Communities

Joining online groups dedicated to gardening tools can be beneficial. Members often share their experiences and solutions to common issues.

- Check platforms like Reddit or specialized gardening forums.

- Participate in discussions to gain insights from experienced users.

- Post your questions and receive feedback from the community.

Official Support Channels

For those seeking professional help, consider utilizing official support channels. These resources often offer direct assistance and detailed information.

- Visit the manufacturer’s website for product support sections.

- Contact customer service via phone or email for personalized help.

- Look for authorized service centers in your area for hands-on assistance.