Maintaining and revitalizing classic photographic equipment can be a rewarding endeavor for enthusiasts and professionals alike. This section delves into the intricacies of enhancing vintage optical devices, providing essential insights and techniques to breathe new life into them. Whether you’re a seasoned technician or a curious novice, understanding the processes involved in this journey is key to achieving optimal results.

Expertise in Equipment Care is crucial when handling delicate mechanisms and components. Familiarity with the structure and function of these items allows for a more effective approach to their upkeep. This guide offers step-by-step instructions to navigate the complexities of disassembly, cleaning, and reassembly, ensuring that each piece functions flawlessly.

Moreover, preserving the integrity of vintage apparatus not only enhances their performance but also contributes to the appreciation of their historical significance. By mastering the techniques outlined here, you will be well-equipped to tackle various challenges, restoring functionality and aesthetic appeal while honoring the craftsmanship of yesteryear.

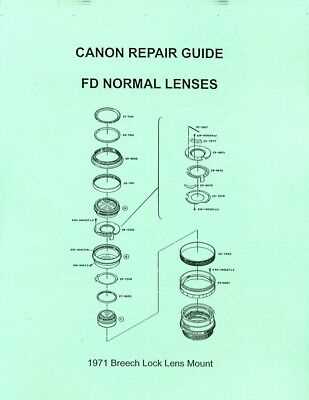

Understanding Canon FD Lens Components

When delving into the intricacies of optical instruments, it’s essential to familiarize oneself with the various elements that contribute to their functionality. These instruments consist of multiple parts, each playing a crucial role in capturing images with precision and clarity. By examining these components, users can gain insight into how they work together to produce high-quality photographs.

Optical Elements are at the heart of any imaging device, designed to manipulate light effectively. These pieces are crafted with precision, allowing for various focal lengths and apertures. The arrangement of these elements determines the characteristics of the resulting images, including sharpness and distortion levels.

Mounting Systems serve as the interface between the device and the body, ensuring a secure connection. A robust mounting system is vital for maintaining alignment during use, which directly affects the performance of the optical elements.

Diaphragm Mechanisms regulate the amount of light entering the instrument, impacting exposure and depth of field. This component is crucial for creative control, enabling users to adjust settings based on the desired outcome of their images.

Lastly, housing structures provide protection and stability to the internal components. A well-designed exterior not only safeguards delicate parts but also contributes to the overall usability and handling of the device, enhancing the user experience.

Common Issues with FD Lenses

Owners of vintage optical devices often encounter a variety of challenges that can affect performance and image quality. Understanding these typical problems can help users identify symptoms and explore potential solutions effectively.

Mechanical Failures

One of the most frequent issues arises from mechanical failures, which can include sticking aperture blades or a malfunctioning focusing mechanism. These problems often result from the accumulation of dust and debris, leading to a decrease in functionality.

Optical Distortions

Optical distortions are another common challenge. Users may notice issues such as blurry images or unwanted artifacts in photographs. These symptoms can be traced back to misalignment or damage to the internal components.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Sticking aperture blades | Inconsistent exposure, dark images | Cleaning and lubrication |

| Focusing mechanism failure | Difficulty in achieving sharp focus | Adjustment or replacement of parts |

| Optical misalignment | Blurry images, distortion | Realignment and calibration |

Essential Tools for Repairing Lenses

Successful restoration of optical devices requires a specific set of instruments that facilitate precise handling and adjustment. Understanding these essential tools can greatly enhance the quality of your work and ensure effective outcomes.

Basic Instruments

- Precision screwdrivers: Vital for accessing and tightening small fasteners.

- Tweezers: Useful for manipulating tiny components without causing damage.

- Cleaning cloths: Essential for maintaining clear surfaces during the process.

Advanced Equipment

- Magnifying glass: Allows for detailed inspection of intricate parts.

- Caliper: Helps measure dimensions accurately for replacement components.

- Desoldering pump: Facilitates the removal of solder when needed for electronic elements.

Step-by-Step Disassembly Process

This section outlines the detailed procedure for carefully taking apart the optical device, ensuring that each component is handled with precision. Following these steps will aid in identifying potential issues and facilitate effective maintenance.

Preparation and Tools

Before beginning, gather the necessary tools including a set of small screwdrivers, tweezers, and a clean workspace. Proper preparation is essential to avoid damaging delicate parts. Make sure to document the process with photographs or notes to assist in reassembly.

Disassembly Steps

Start by removing any outer casing screws and gently prying apart the components. Pay attention to the order of disassembly, as this will simplify the reassembly. Be cautious with any internal parts, as they may be fragile and require special handling. Once the device is fully disassembled, inspect each element for wear and tear, noting any that may need replacement or additional attention.

Cleaning Techniques for Optical Elements

Maintaining the clarity of optical components is essential for optimal performance. This section discusses various methods and tools that can be employed to ensure these elements remain free of contaminants and function effectively.

Before starting the cleaning process, it is crucial to assess the type of dirt or residue present. Different materials may require specific techniques to avoid damage. Below is a summary of common cleaning methods:

| Technique | Description | Recommended Tools |

|---|---|---|

| Air Blowing | Using a gentle stream of air to dislodge dust particles without physical contact. | Hand pump blower or compressed air canister |

| Microfiber Cloth | Wiping the surface with a soft, lint-free cloth to remove smudges. | Microfiber cloth |

| Lens Cleaning Solution | Applying a few drops of specialized cleaning fluid to a cloth for more thorough cleaning. | Optical cleaning solution, microfiber cloth |

| Cotton Swabs | Carefully using swabs for tight areas or hard-to-reach spots. | Cotton swabs, cleaning fluid |

Always ensure that any cleaning method employed is suitable for the specific type of optical component being serviced. Regular maintenance using these techniques can significantly prolong the lifespan and enhance the performance of the elements.

Realigning Lens Elements Properly

Achieving optimal performance from optical devices often necessitates precise adjustments of their components. This section focuses on the methodology for repositioning the various sections within the assembly to ensure clarity and functionality.

Before initiating the alignment process, it is crucial to gather the necessary tools and understand the specific requirements of your device. Proper organization and preparation can significantly enhance the outcome.

- Tools Required:

- Screwdriver set

- Alignment jig

- Magnifying glass

- Cleaning cloth

- Preparation Steps:

- Carefully disassemble the unit, noting the position of each part.

- Inspect components for damage or wear, cleaning them as necessary.

- Use the alignment jig to hold elements in place during adjustment.

After setting up, follow these guidelines to ensure correct repositioning:

- Align the optical components by sighting through the assembly to check for parallelism.

- Adjust each element slightly, checking the visual output to determine clarity.

- Secure the parts once the ideal position is achieved, ensuring not to overtighten.

Finally, reassemble the device carefully, verifying that all components are in their correct orientation. Conduct a test to confirm that the adjustments have yielded the desired results.

Lubrication Methods for Smooth Operation

Ensuring optimal functionality of optical instruments requires proper maintenance, particularly in the lubrication of moving components. The right approach to applying lubricants can significantly enhance the overall performance, leading to smoother adjustments and prolonged lifespan of the equipment.

Various techniques can be employed to achieve effective lubrication. Here are some commonly used methods:

| Method | Description |

|---|---|

| Grease Application | Thick, viscous substance ideal for areas requiring long-lasting lubrication and resistance to wear. |

| Oil Application | Fluid lubricant that provides quick coverage and is suitable for high-speed moving parts. |

| Brush Method | Using a fine brush to apply lubricant ensures precision, especially in tight spaces. |

| Drop Method | Applying a small amount of liquid lubricant directly to the components for targeted application. |

| Spray Method | A convenient way to cover larger areas quickly, ideal for general maintenance tasks. |

Selecting the appropriate method depends on the specific requirements of the mechanisms involved. Regular maintenance and attention to lubrication can prevent issues and ensure that the apparatus operates seamlessly.

Testing Functionality After Repair

Ensuring optimal performance after servicing is crucial for any optical equipment. This section outlines the essential steps to verify that the instrument operates correctly and meets the expected standards.

The testing process typically involves several key procedures:

- Visual Inspection: Examine the external condition for any signs of damage or misalignment.

- Operational Check: Activate the device to confirm that all mechanical parts function smoothly.

- Image Quality Assessment: Capture test images to evaluate clarity, focus, and color accuracy.

- Focusing Accuracy: Test the ability to focus at various distances to ensure precision.

Additionally, performing these checks will help identify any remaining issues:

- Check for consistent performance across different settings.

- Monitor for unusual sounds or vibrations during operation.

- Evaluate overall usability and comfort during handling.

By following these guidelines, users can confirm that their optical device is functioning properly and is ready for use.

Preventative Maintenance Tips for Longevity

Regular care and mindful upkeep play a crucial role in ensuring that your equipment continues to perform optimally over time. Consistent attention to small details can significantly extend the operational life and quality of your gear. Simple steps for maintaining parts and protecting sensitive areas help to avoid common issues and ensure smooth function through frequent use.

Keep Surfaces Clean: Gently remove dust and particles with a soft, lint-free cloth. Avoid abrasive materials that may cause wear on delicate components. Regular cleaning helps prevent buildup that could interfere with performance.

Store in a Controlled Environment: To protect against environmental damage, keep your gear in a stable, dry location when not in use. Avoid exposure to extreme temperatures, moisture, and direct sunlight, which can degrade materials over time.

Check Moving Parts: Inspect any moving components periodically to ensure smooth operation. Apply a suitable lubricant if needed, but sparingly, to avoid attracting dust or residue that could impair functionality.

Handle with Care

Resources for Canon FD Enthusiasts

Discover a wealth of valuable information tailored for those deeply interested in the world of FD equipment. From dedicated forums to specialized publications, there is a range of sources available for enthusiasts eager to deepen their knowledge and refine their technical skills.

Online Communities and Forums

Many online communities bring together seasoned hobbyists and new users alike, fostering an environment to exchange tips, techniques, and personal experiences. These platforms provide detailed insights and discussions, helping enthusiasts expand their understanding through direct engagement with others who share similar interests.

Comprehensive Guides and Tutorials

For those looking to build expertise, numerous guides and tutorials offer step-by-step instructions across various aspects of FD use and maintenance. These resources, crafted by skilled experts, are invaluable for learning advanced techniques, helping users keep their equipment in top condition and performing at its best.

Safety Precautions During Repair

Performing maintenance on intricate optical equipment requires careful adherence to safety guidelines to prevent accidental damage to the components and ensure personal well-being. Understanding how to handle delicate parts and being mindful of potential hazards are essential steps in successful maintenance.

Essential Preparation

Before beginning, create a clean, organized workspace to minimize risks of contamination. Always use tools specifically designed for handling sensitive mechanisms and ensure hands are free from oils or residues. Wearing antistatic gloves can help prevent the buildup of static, which may harm internal electronics.

Handling Fragile Components

Delicate elements require precise handling to avoid scratches or misalignment. If disassembling parts, utilize a soft, lint-free cloth or specialized tweezers, and store any removed components in a safe, dust-free environment. Avoid using excess force, and proceed with gentle adjustments to maintain original positioning.

By following these guidelines, you can enhance both the safety and efficiency of the

Finding Replacement Parts Easily

Locating the necessary pieces for optical equipment restoration is a critical step in ensuring long-lasting performance. Quality components help maintain the functionality of classic models and allow for smooth and effective handling over time. Understanding where and how to find reliable replacements can greatly streamline the refurbishment process and improve results.

Researching Reliable Sources

Begin with trusted suppliers and specialized shops that offer authentic and compatible parts. Online platforms dedicated to vintage equipment often provide a wide selection of components, including hard-to-find items. Reviews and community feedback can be valuable in identifying the best sources and avoiding potential mismatches or low-quality parts.

Considering Compatibility and Quality

When choosing replacement items, prioritize compatibility to prevent operational issues. Sometimes, older models require specific fittings that modern parts may not support. Look for detailed descriptions and check the compatibility lists provided by sellers. Ensuring high quality is equally essential; original pieces or high-grade replicas can enhance durability and provide reliable performance for years.

Pro tip: Join forums or social media groups focused on vin