In the realm of outdoor power equipment, ensuring optimal performance and longevity is crucial for users. This guide serves as a comprehensive resource for individuals seeking to enhance their understanding of maintenance techniques and problem-solving strategies. Whether you are a seasoned operator or a novice, familiarizing yourself with essential practices can greatly extend the lifespan of your equipment.

Proper care and attention to detail are vital when it comes to keeping your tools in peak condition. Common issues can arise over time, but with the right knowledge, many of these challenges can be effectively addressed. This resource delves into the nuances of common operational concerns, offering practical solutions that empower users to take charge of their equipment’s health.

By following a structured approach to upkeep, operators can prevent minor setbacks from escalating into major failures. Understanding the inner workings of your machinery, along with the recommended procedures for maintenance, is essential. This guide aims to provide valuable insights and actionable steps to help you navigate the complexities of your outdoor power tools with confidence.

Understanding Stihl BR 380 Features

The equipment in question boasts a variety of characteristics that enhance its functionality and user experience. By exploring these attributes, users can gain insight into how this tool operates and how it can be best utilized for various tasks. Each feature is designed to improve efficiency, comfort, and overall performance, making it a valuable asset for both professionals and hobbyists alike.

Power and Performance: The engine’s robust design ensures reliable operation, delivering the necessary power to handle demanding jobs. With optimal fuel efficiency, users can expect extended run times, reducing interruptions during work.

Ergonomics: The lightweight construction and well-thought-out grip design allow for prolonged use without causing undue fatigue. An adjustable harness system further enhances comfort, making it easier to maneuver during operation.

Versatility: This model is equipped with interchangeable nozzles and attachments, enabling it to tackle a variety of tasks, from leaf blowing to clearing debris. This adaptability makes it suitable for different environments and seasonal needs.

Maintenance Features: Designed with user convenience in mind, the tool includes easy-access components for simple maintenance. Regular upkeep can be performed without specialized tools, ensuring that the equipment remains in peak condition.

Understanding these attributes not only helps in maximizing the potential of the equipment but also empowers users to make informed decisions regarding its application and care.

Common Issues with Stihl BR 380

Understanding typical challenges associated with this popular model can significantly enhance maintenance and prolong its lifespan. Here are some frequent problems users may encounter, along with their potential causes and solutions.

- Starting Difficulties:

- Clogged fuel filter can restrict flow.

- Old or contaminated fuel may affect performance.

- Improper choke usage during start-up.

- Loss of Power:

- Dirty air filter may reduce airflow.

- Worn spark plug can lead to inefficient combustion.

- Fuel lines may have leaks or blockages.

- Excessive Vibration:

- Loose components may cause instability.

- Imbalanced cutting tools can lead to uneven operation.

- Overheating:

- Insufficient lubrication can increase friction.

- Blocked cooling fins may prevent proper airflow.

- Fuel Leaks:

- Worn gaskets or seals may allow leakage.

- Punctured fuel lines can cause spills.

Regular checks and timely interventions can help mitigate these issues, ensuring smoother operation and better efficiency.

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right instruments is crucial for effective service. Whether addressing minor issues or undertaking comprehensive maintenance, a well-equipped toolkit can significantly enhance efficiency and ensure quality outcomes. This section outlines the key instruments necessary for successful tasks, helping you to tackle various challenges with confidence.

Basic Hand Tools

Every toolkit should begin with fundamental hand instruments. These include wrenches, screwdrivers, and pliers, which are essential for loosening and tightening components. A set of high-quality sockets and a ratchet can greatly aid in accessing hard-to-reach areas. Additionally, a reliable set of hex keys is vital for tasks that involve hex screws, commonly found in many machines.

Specialized Equipment

In addition to basic tools, certain specialized equipment can facilitate more intricate procedures. A torque wrench is essential for applying specific tension to bolts, ensuring proper assembly without causing damage. Safety goggles and gloves should also be included to protect yourself during maintenance activities. Moreover, having a multimeter can be beneficial for diagnosing electrical issues, allowing for accurate troubleshooting and resolution.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. This guide provides a comprehensive approach to maintaining your device, focusing on key tasks that will enhance its performance and reliability. By following these systematic procedures, you can avoid common issues and extend the life of your machinery.

Essential Maintenance Tasks

Performing routine maintenance tasks can significantly improve functionality. Below is a table outlining critical tasks and their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Inspect air filter | Every 25 hours |

| Clean spark plug | Every 50 hours |

| Check fuel lines | Every 100 hours |

| Sharpen blades | As needed |

Step-by-Step Procedures

Follow these procedures for effective maintenance:

- Start by disconnecting the power source to ensure safety.

- Inspect the air filter for dirt and debris, and clean or replace as necessary.

- Remove the spark plug, clean it thoroughly, and check for wear. Replace if needed.

- Examine fuel lines for any signs of wear or leaks and replace them if necessary.

- Sharpen the blades using a suitable sharpening tool, ensuring a clean edge for optimal performance.

How to Troubleshoot Engine Problems

Diagnosing issues with small engines can be a challenging yet rewarding task. Identifying the root cause of performance problems is crucial for effective resolution. This guide will help you systematically address common engine-related issues.

Start by observing the engine’s behavior. Take note of any unusual sounds, vibrations, or changes in power output. Then, follow these steps:

- Check Fuel Quality:

- Ensure the fuel is fresh and free from contaminants.

- Verify that the correct fuel type is being used.

- Inspect the Air Filter:

- Remove and clean or replace the air filter if it’s dirty.

- Ensure proper airflow to the engine.

- Examine the Spark Plug:

- Check for wear or carbon buildup on the spark plug.

- Replace it if it appears damaged or worn out.

- Look for Fuel Leaks:

- Inspect fuel lines and connections for any signs of leakage.

- Tighten loose fittings or replace damaged components.

- Test the Battery:

- Ensure the battery is fully charged and connections are secure.

- Replace the battery if it fails to hold a charge.

By following these steps, you can effectively identify and resolve common engine issues. Always consult an expert if problems persist after troubleshooting, ensuring the longevity and reliability of your equipment.

Replacing the Fuel System Components

Maintaining optimal performance in outdoor power equipment often requires the replacement of various fuel system elements. Ensuring that these components function effectively is crucial for the reliability and efficiency of the device. This section will guide you through the necessary steps to successfully replace these parts, enhancing the overall functionality of your equipment.

Identifying Components for Replacement

Before proceeding with the replacement, it’s essential to identify which elements of the fuel system need attention. Common components that may require replacement include fuel filters, lines, and the fuel pump. Regular inspections can help detect signs of wear, leaks, or blockages, prompting timely intervention to prevent further damage.

Step-by-Step Replacement Process

To begin the replacement, gather the necessary tools and new components. First, disconnect the fuel lines carefully to avoid spillage. Then, remove the old filter and replace it with a new one, ensuring a snug fit. Next, inspect the fuel pump and replace it if there are any signs of malfunction. After all components are replaced, reattach the fuel lines securely, and perform a test run to confirm everything is functioning as expected. Always remember to follow safety precautions throughout the process.

Cleaning and Maintaining Air Filters

Regular upkeep of air filters is essential for optimal performance and longevity of outdoor power equipment. Clean filters ensure that the engine receives adequate airflow, preventing overheating and enhancing efficiency. Neglecting this vital component can lead to poor performance and increased wear and tear.

Steps for Cleaning Air Filters

To maintain the effectiveness of air filters, follow these straightforward steps:

| Step | Description |

|---|---|

| 1 | Remove the air filter cover carefully, following the manufacturer’s guidelines. |

| 2 | Take out the air filter and inspect it for dirt and damage. |

| 3 | Gently tap the filter to dislodge debris or use compressed air for a more thorough clean. |

| 4 | If necessary, wash the filter with soapy water, rinse, and allow it to dry completely. |

| 5 | Reinstall the filter and cover securely to ensure proper sealing. |

Frequency of Maintenance

It is advisable to check and clean the air filter after every few hours of operation, or more frequently in dusty conditions. Establishing a routine helps maintain the ultimate performance and extends the life of the equipment.

Guidelines for Spark Plug Replacement

Replacing the ignition component is a crucial task that ensures optimal performance of your outdoor equipment. Regular maintenance of this part can significantly enhance engine efficiency and reliability. Following the right procedures will help you achieve a smooth operation and extend the lifespan of your machinery.

Step 1: Gather the Necessary Tools

Before starting, make sure you have the appropriate tools at hand. You will need a socket wrench, a gap gauge, and a clean cloth. Having everything ready will streamline the process and minimize delays.

Step 2: Remove the Old Component

Start by disconnecting the spark plug wire. Use the socket wrench to carefully unscrew the old part. Avoid applying excessive force, as this could damage the surrounding components.

Step 3: Inspect the Area

Once the old part is removed, take a moment to check the surrounding area for any debris or carbon buildup. Cleaning the area will help prevent future issues and ensure a proper seal when the new component is installed.

Step 4: Prepare the New Part

Before installation, verify that the new ignition component is the correct type. Use a gap gauge to adjust the electrode gap if necessary, ensuring it meets the manufacturer’s specifications for optimal performance.

Step 5: Install the New Component

Carefully insert the new part into the designated opening. Use the socket wrench to tighten it securely, but be cautious not to overtighten, as this can lead to damage.

Step 6: Reconnect the Wire

After the new component is securely in place, reconnect the spark plug wire. Ensure it fits snugly to maintain a good electrical connection.

Step 7: Test the Equipment

Finally, start the engine to ensure everything is functioning correctly. Listen for any irregular sounds and check for smooth operation. If any issues arise, recheck your installation steps.

By following these guidelines, you can effectively replace the ignition component and keep your equipment running efficiently.

Understanding Safety Precautions

Ensuring safety while operating machinery is crucial for both the user and those nearby. Proper awareness and adherence to safety measures can significantly reduce the risk of accidents and injuries. It is essential to familiarize oneself with the necessary precautions before engaging with any equipment.

Personal Protective Equipment (PPE) is a vital aspect of safety. Always wear appropriate gear, such as gloves, goggles, and hearing protection, to shield yourself from potential hazards. This equipment is designed to minimize exposure to harmful elements and provide a barrier against physical injuries.

Additionally, environmental awareness plays a critical role in safe operation. Always assess the surrounding area for obstacles, bystanders, or hazards that may interfere with the task. A clear workspace not only enhances safety but also improves efficiency and focus.

Furthermore, it is important to understand the operating procedures specific to the equipment in use. Familiarizing yourself with the functions, controls, and features will help in making informed decisions and reduce the likelihood of errors during operation.

Lastly, regular maintenance and inspections are paramount. Ensuring that all components are functioning correctly can prevent malfunctions and promote safe usage. Being proactive in upkeep reflects a commitment to safety and responsibility.

When to Seek Professional Help

Understanding the limitations of your skills is essential when tackling complex machinery. Sometimes, despite your best efforts, certain issues may require the expertise of a trained technician. Knowing when to call for assistance can save you time, prevent further damage, and ensure safe operation.

Signs That Indicate Professional Assistance is Needed

When you notice persistent performance problems, unusual noises, or leaks, it’s crucial to consider expert intervention. Additionally, if the equipment has been involved in an accident or has sustained visible damage, seeking a professional evaluation is wise.

The Ultimate Benefits of Consulting an Expert

Engaging a skilled technician not only guarantees a thorough diagnosis but also provides peace of mind. Professionals often have access to specialized tools and resources, ensuring that repairs are carried out efficiently and effectively.

Parts Identification

Understanding the various components of a specialized tool is essential for effective maintenance and optimal performance. Proper identification of each part not only aids in troubleshooting but also ensures that replacements are accurate and timely.

Key Components

- Engine Assembly

- Fuel Tank

- Air Filter

- Throttle Control

- Handle Grip

- Start Mechanism

- Blower Tube

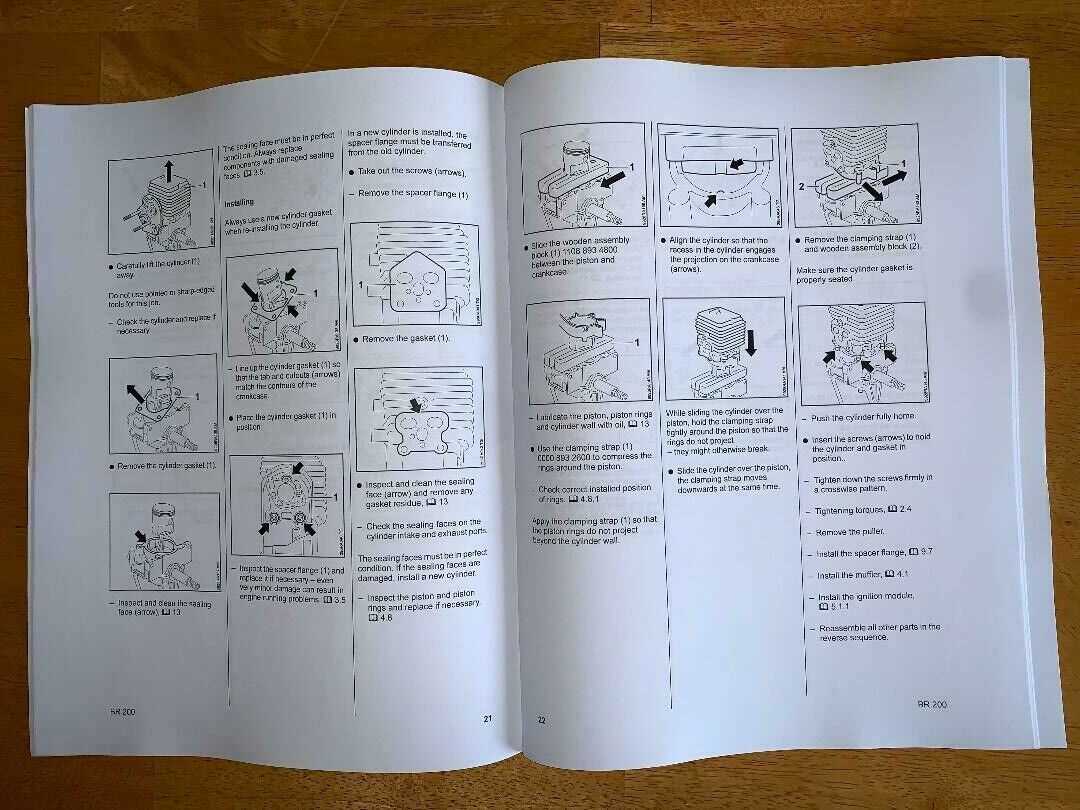

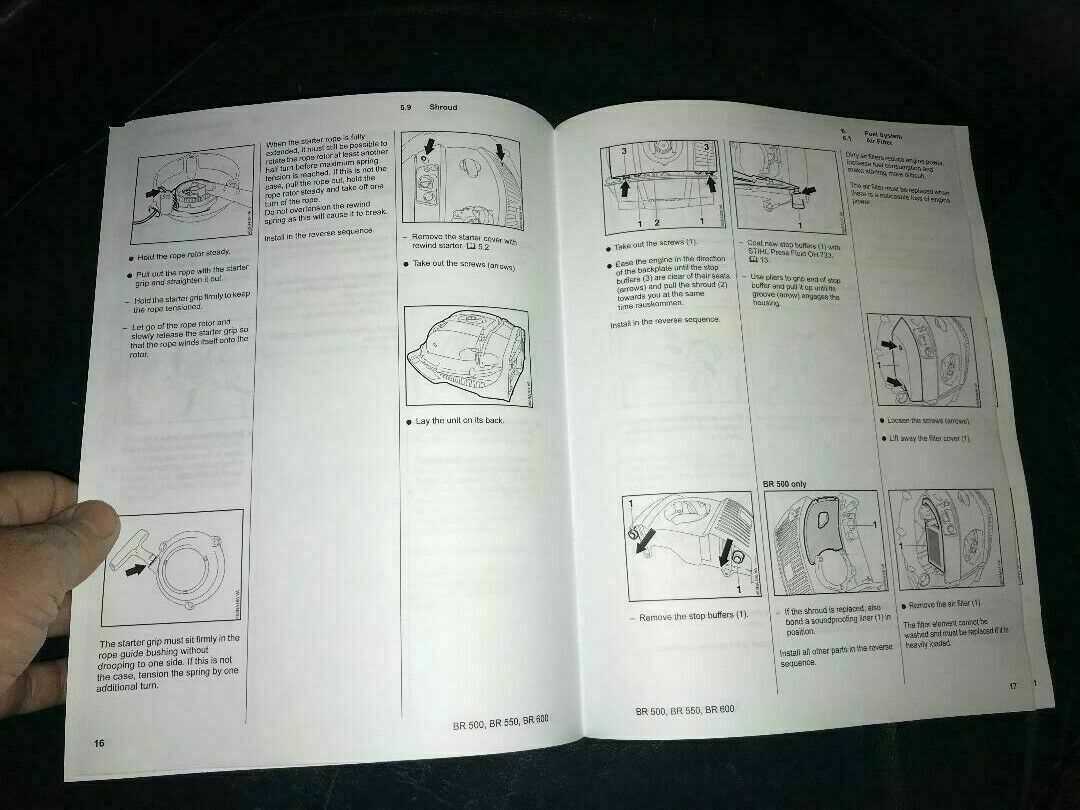

Parts Diagram

A visual representation can significantly enhance understanding. Refer to diagrams that label each section clearly. Familiarizing yourself with these illustrations can streamline the identification process during repairs.

For detailed identification, consider the following categories:

- Power System: Includes the engine, spark plug, and ignition components.

- Fuel Delivery: Comprises the fuel lines, filter, and tank.

- Airflow Components: Features the blower tube and air filter.

- Control Elements: Encompasses the throttle and choke controls.

Accurate knowledge of these parts will enhance your ability to perform maintenance and ensure longevity for the equipment.

Helpful Resources for Owners

For enthusiasts and users of outdoor power equipment, having access to reliable information can greatly enhance the experience of ownership and maintenance. Various resources are available to assist with understanding, troubleshooting, and optimizing the performance of these machines. Whether you are seeking expert advice, community support, or instructional materials, a wealth of options can help you become a more informed and effective operator.

Online Communities

Joining online forums and communities can provide invaluable insights and tips from fellow users. These platforms often feature discussions about common issues, upgrades, and best practices.

Official Websites and Documentation

Manufacturer websites frequently offer downloadable guides, FAQs, and product specifications that can help clarify any uncertainties. Accessing official documentation is essential for understanding the capabilities and limitations of your equipment.

| Resource Type | Description | Link |

|---|---|---|

| Forums | Community-driven discussions for troubleshooting and advice. | Visit Forum |

| Official Documentation | Access to manuals and specifications directly from the manufacturer. | Visit Docs |

| Video Tutorials | Step-by-step guides available on popular video platforms. | Watch Tutorials |