Understanding the intricacies of machinery is essential for ensuring longevity and optimal performance. This section delves into the vital aspects of keeping your equipment in peak condition. By focusing on key elements of upkeep and common issues, users can enhance their skills and foster a deeper connection with their tools.

Proper servicing techniques and detailed diagnostics play a crucial role in maintaining functionality. Familiarizing oneself with the components and their interactions not only aids in resolving problems but also empowers individuals to undertake minor adjustments confidently. This guide offers insights into various procedures, emphasizing best practices and safety measures.

Whether you’re a seasoned professional or a novice, having a structured approach to maintenance can save time and resources. By equipping yourself with the necessary knowledge, you will be well-prepared to tackle challenges as they arise, ensuring that your equipment remains reliable and efficient.

Overview of Stihl 056 AV Features

This section provides an insight into the notable characteristics of a well-regarded model in the power equipment realm. Known for its robust performance and reliability, this unit has gained popularity among professionals and enthusiasts alike.

- Powerful Engine: The equipment boasts a high-performance engine designed to deliver exceptional torque and efficiency, making it suitable for demanding tasks.

- Advanced Vibration Control: Featuring innovative technology to minimize vibrations, it enhances user comfort during prolonged operation.

- Durable Construction: Built with high-quality materials, this model ensures longevity and withstands tough working conditions.

- User-Friendly Design: Ergonomically designed handles provide a comfortable grip, allowing for better maneuverability and control.

- Easy Maintenance: The unit includes features that simplify routine maintenance, ensuring optimal performance with minimal effort.

Overall, the impressive features of this power tool make it a top choice for those seeking efficiency and durability in their equipment.

Common Issues with Stihl 056 AV

When it comes to power equipment, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these frequent problems can help operators maintain their machines more effectively and prolong their lifespan.

Engine Performance Problems

One of the most common issues is related to engine performance. Users may notice that the machine struggles to start or runs inconsistently. This could stem from fuel contamination, clogged air filters, or issues with the ignition system. Regular maintenance, including replacing filters and checking spark plugs, can mitigate these problems.

Chain and Bar Issues

Another prevalent concern involves the cutting mechanism. Operators might experience inadequate chain lubrication or difficulty with chain tension. Insufficient oil can lead to overheating, while improper tension can cause excessive wear. Ensuring proper oil levels and adjusting the chain according to the manufacturer’s guidelines is essential for optimal function.

Step-by-Step Repair Procedures

This section provides a detailed guide to addressing common issues with your equipment. By following a systematic approach, you can effectively diagnose problems and implement solutions, ensuring optimal performance. Each step is designed to be clear and concise, allowing for straightforward execution.

Begin by gathering the necessary tools and materials. Ensure you have everything at hand before starting the process, as this will streamline your workflow and minimize interruptions.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to ensure safety during maintenance. |

| 2 | Inspect all external components for visible signs of wear or damage. |

| 3 | Remove any necessary covers to gain access to internal parts. |

| 4 | Carefully check the internal mechanisms for functionality and any potential issues. |

| 5 | Replace or repair damaged components as needed, ensuring proper fit and alignment. |

| 6 | Reassemble the unit, securing all covers and components appropriately. |

| 7 | Reconnect the power source and conduct a test run to confirm successful operation. |

By adhering to these guidelines, you can maintain the longevity of your equipment and enhance its reliability for future tasks.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment requires a set of fundamental instruments. These tools not only facilitate the cleaning and adjustment processes but also ensure the longevity and efficiency of the machinery. Having the right equipment on hand can make routine checks and repairs significantly easier, leading to a smoother operation and reduced risk of malfunctions.

Basic Hand Tools

Every maintenance kit should include a range of hand tools. Wrenches, screwdrivers, and pliers are essential for making adjustments and securing loose components. A good set of allen keys can also prove invaluable for accessing hard-to-reach areas. Ensuring that these tools are of high quality can prevent stripping and damage during use.

Specialized Equipment

In addition to basic hand tools, certain specialized instruments are necessary for more complex tasks. A reliable compression tester can help assess the engine’s performance, while a spark plug wrench is vital for maintaining optimal ignition conditions. Investing in a high-quality fuel system cleaner can also contribute to better engine efficiency and longevity.

How to Identify Engine Problems

Recognizing issues within an engine can prevent minor faults from escalating into major failures. Awareness of common symptoms allows for timely interventions, ensuring the longevity and efficiency of the machinery.

Common Symptoms to Look For

Several indicators can suggest underlying issues within the engine. Observing these signs closely can help diagnose problems early.

| Symptom | Possible Cause |

|---|---|

| Strange noises | Worn bearings or loose components |

| Excessive smoke | Oil leaks or fuel mixture problems |

| Poor performance | Clogged filters or fuel line issues |

Diagnostic Steps

To effectively identify problems, a systematic approach is essential. Start by checking fluid levels, inspecting for leaks, and listening for unusual sounds during operation.

Replacing Parts: A Guide

When maintaining your equipment, knowing how to effectively swap out components is crucial for optimal performance and longevity. This guide provides a structured approach to help you navigate the process of replacing various parts, ensuring your machinery runs smoothly and efficiently.

Before you begin, it’s essential to gather the necessary tools and components. Here’s a brief checklist to consider:

- Replacement parts specific to your model

- Basic hand tools (screwdrivers, wrenches, etc.)

- Safety gear (gloves, goggles)

- Owner’s documentation for reference

Follow these steps to ensure a successful replacement:

- Identify the Part: Determine which component needs to be replaced by conducting a thorough inspection.

- Gather Information: Consult the owner’s documentation to understand the specifications and replacement procedures.

- Disconnect Power: Always ensure the equipment is powered off and disconnected to prevent accidents.

- Remove the Old Part: Carefully take out the defective component, keeping track of any screws or fasteners.

- Install the New Part: Align the new component correctly and secure it in place using the original fasteners.

- Test Functionality: After installation, reconnect power and test the equipment to ensure everything operates as expected.

By following these guidelines, you can confidently replace parts, enhancing the reliability and functionality of your machinery for years to come.

Safety Tips During Repair

When undertaking maintenance tasks on power equipment, prioritizing safety is essential. A thorough understanding of potential hazards and implementing precautionary measures can significantly reduce the risk of accidents. By following specific guidelines, individuals can ensure a safer working environment and protect themselves while handling tools and machinery.

Essential Precautions

Before beginning any task, it’s crucial to prepare adequately. Here are some fundamental safety measures to keep in mind:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Wear appropriate gear such as gloves, goggles, and sturdy footwear to minimize injury risk. |

| Work Area | Ensure the workspace is clean and organized, free from clutter and obstructions that could cause accidents. |

| Tool Inspection | Examine all tools and equipment for damage before use to prevent malfunctions during operation. |

| Read Instructions | Familiarize yourself with guidelines and safety protocols related to the equipment before starting work. |

Emergency Preparedness

In addition to preventive measures, being prepared for emergencies is vital. Have a plan in place and ensure access to first aid supplies. Familiarize yourself with emergency contact numbers and the location of safety equipment, such as fire extinguishers. This readiness can make a significant difference in effectively addressing unforeseen situations.

Understanding the Fuel System

The fuel system is a critical component that ensures optimal performance and efficiency in outdoor power equipment. It facilitates the delivery of fuel to the engine, enabling it to operate smoothly and effectively. Understanding the intricacies of this system can help in diagnosing issues and maintaining the equipment’s longevity.

Components of the Fuel System

Typically, the fuel system consists of several key elements, including the fuel tank, lines, filter, pump, and carburetor. Each part plays a distinct role in transporting and managing fuel flow. The fuel tank stores the gasoline or mixed fuel, while the fuel lines connect the tank to the other components. A filter is essential for removing impurities, preventing potential damage to the engine.

Common Issues and Maintenance Tips

Over time, various problems may arise within the fuel system, such as clogs, leaks, or improper fuel delivery. Regular maintenance is vital to prevent these issues. Ensure the fuel filter is clean and replace it as necessary. Additionally, inspect the fuel lines for cracks or wear. Using the correct fuel mixture and keeping the fuel tank clean will also contribute to the system’s overall efficiency.

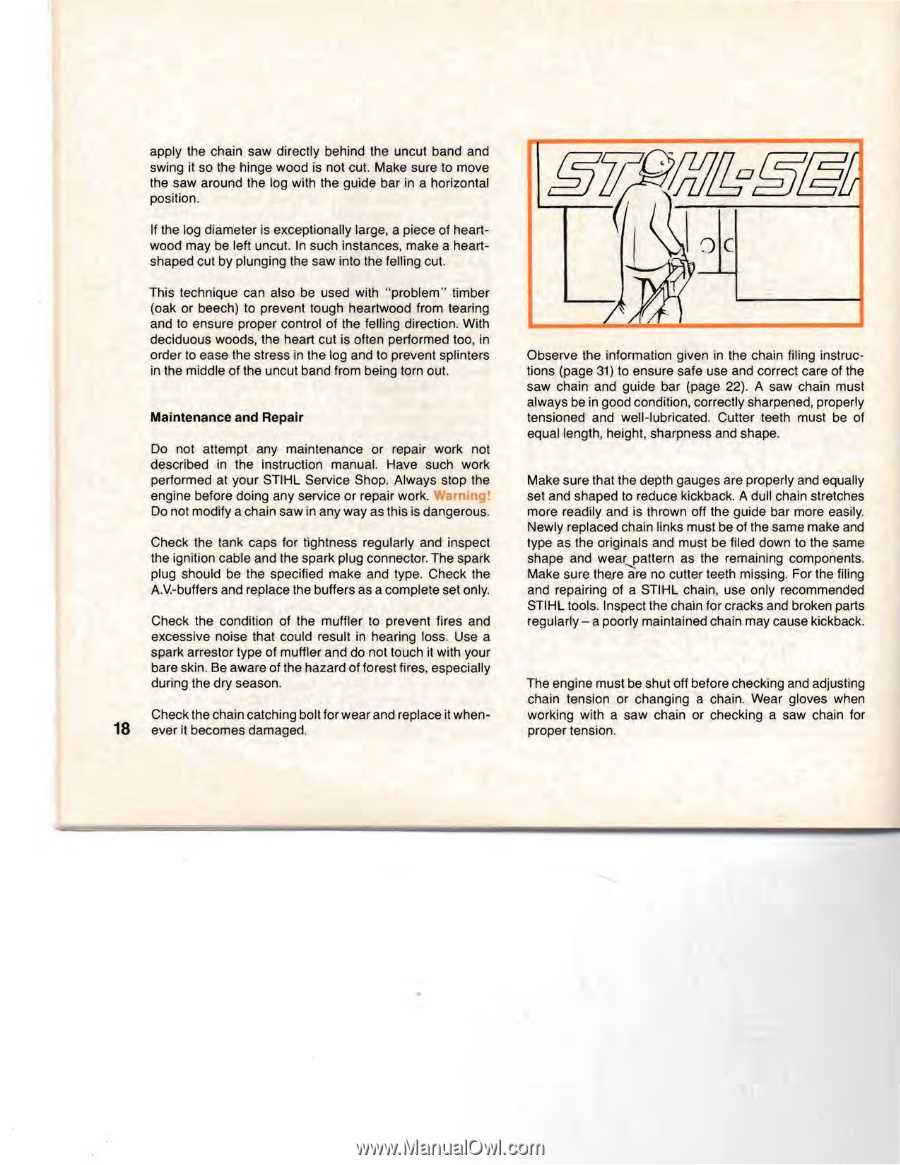

Cleaning and Servicing the Chainsaw

Regular maintenance is essential for optimal performance and longevity of any cutting tool. By keeping the equipment clean and well-serviced, users can ensure safety, efficiency, and reliability during operation. This section will guide you through the necessary steps to maintain your chainsaw in peak condition.

Initial Cleaning

Start by removing any debris from the exterior of the tool. Use a soft brush or cloth to eliminate dust, dirt, and wood chips that may have accumulated during use. Pay special attention to the air intake and exhaust areas, as these can affect the engine’s performance if obstructed.

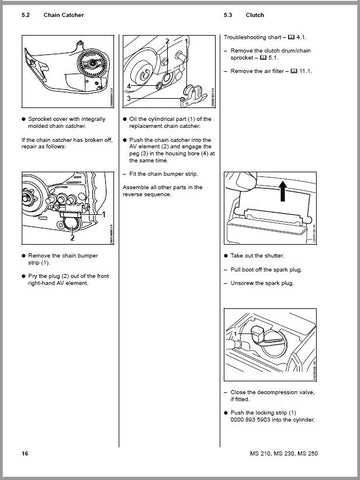

Chain Maintenance

The cutting chain requires regular inspection and cleaning. Remove the chain from the bar and wash it in a suitable solvent to remove sap and grime. After drying, apply a light coat of lubricant to ensure smooth operation. Check for any signs of wear or damage, and replace links if necessary.

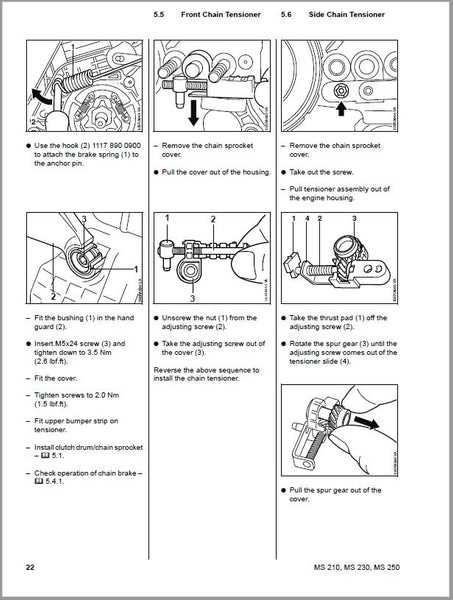

Bar and Chain Tension

Inspect the guide bar for wear and ensure the chain tension is appropriate. A loose chain can lead to poor cutting performance, while a chain that is too tight may cause damage. Adjust the tension according to the manufacturer’s specifications to maintain proper function.

Fuel System Care

Clean the fuel filter and inspect fuel lines for cracks or blockages. Ensure that the fuel used is fresh and properly mixed. Contaminated fuel can cause starting issues and affect engine performance, so regular checks are crucial.

Final Checks

After completing the cleaning process, conduct a final inspection of all components, including the spark plug, air filter, and safety features. Replace any worn parts as needed. A well-maintained chainsaw not only performs better but also enhances the safety of the user.

Finding Replacement Parts Online

Locating components for maintenance and repair tasks has become increasingly convenient thanks to the vast resources available on the internet. Whether you need essential items for machinery or other tools, online platforms provide numerous options that cater to various needs. Understanding where to look and what to consider can significantly enhance the replacement process.

When searching for parts online, it’s important to choose reliable sources. Here are some types of platforms that can be beneficial:

| Type of Source | Description |

|---|---|

| Official Websites | Manufacturers often have dedicated sites that offer original components, ensuring compatibility and quality. |

| Online Marketplaces | Platforms like eBay and Amazon provide a wide range of options from various sellers, including new and used parts. |

| Specialty Retailers | Websites that focus on specific categories of tools and machinery may have extensive inventories and expert advice. |

| Forums and Community Groups | Engaging with fellow enthusiasts can lead to recommendations for trusted sellers or even direct purchase opportunities. |

As you explore these avenues, remember to compare prices, check for warranties, and read reviews. This diligence will help ensure that the components you acquire are of high quality and meet your requirements.