For those passionate about sewing, maintaining the precision and functionality of a cherished machine can make all the difference in crafting projects with ease and confidence. Over time, various elements may require attention or adjustments to preserve optimal performance. This guide aims to assist you in identifying potential issues and ensuring smooth operation, enhancing your machine’s longevity.

Whether it’s addressing minor irregularities or conducting a thorough check-up, understanding the inner mechanisms will help restore each part to its best working condition. We’ll cover essential steps and offer insights into fine-tuning, cleaning, and troubleshooting, equipping you with practical knowledge for ongoing care.

Explore the intricacies of routine maintenance and targeted fixes as you learn how to address common problems that may arise during regular use. With detailed instructions and clear explanations, this resource empowers you to keep your sewing tool in top shape, ready for any creative endeavor.

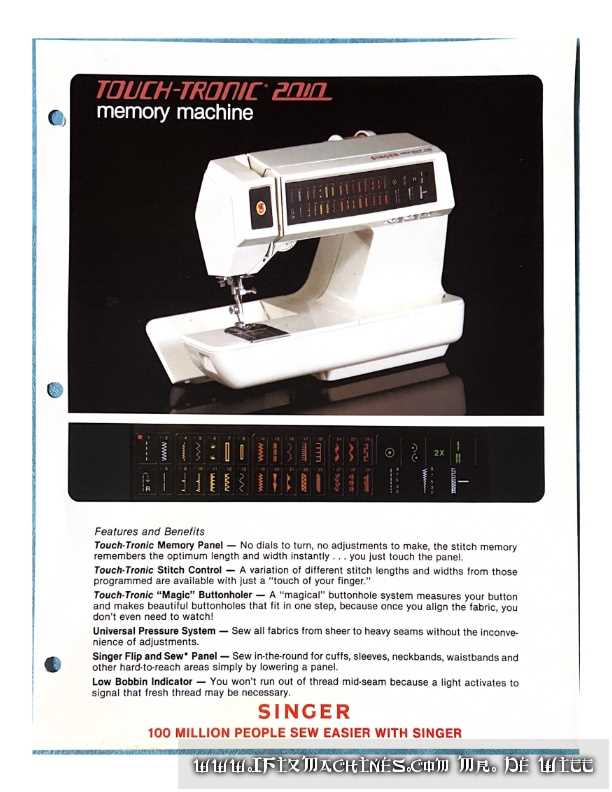

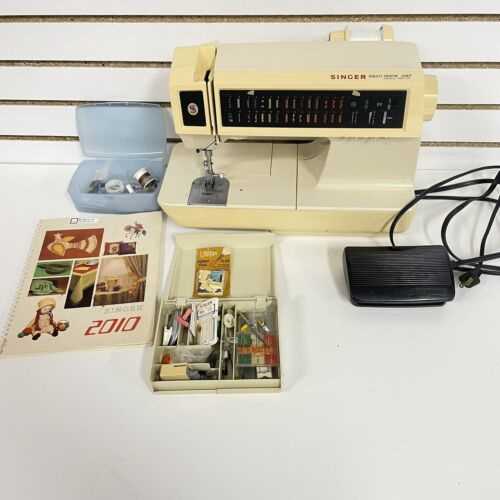

Understanding the Electronic Sewing Device Model

This section provides an overview of the features and functionality of an advanced sewing device model. Known for its versatility, this machine combines mechanical precision with digital adjustments, making it suitable for a wide range of fabric projects and sewing techniques.

- Digital Controls: This model offers automated settings that allow users to select stitching options and adjust fabric handling seamlessly, reducing manual adjustments.

- Programmed Stitch Patterns: Equipped with various pre-set stitching styles, the device allows for creativity and experimentation with different sewing patterns at the touch of a button.

- Automated Needle Functions: Users can expect features like automatic needle positioning and thread management, helping to speed up the sewing process and maintain consistent results.

With these capabilities, this model caters to both beginners seeking simplicity and experienced tailors looking for precision in complex sewing projects.

Diagnosing Common Machine Issues

Identifying frequent operational issues in sewing devices is essential for maintaining their efficiency and ensuring long-term functionality. Through a systematic approach, users can troubleshoot and address typical challenges without the need for professional assistance.

| Issue | Possible Cause | Suggested Solution | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Breaking | Incorrect threading or tension settings | Re-thread the machine and adjust tension to appropriate levels | ||||||||||||||||||||||

| Skipped Stitches | Blunt or bent needle | Replace the needle with a new one suitable for the fabric type | ||||||||||||||||||||||

| Fabric Not Feeding | Feed dogs lowered or dusty | Raise feed dogs and clean any lint buildup | ||||||||||||||||||||||

Machine

Essential Tools for Machine RepairTo successfully address issues in sewing equipment, it’s important to be equipped with a variety of specialized tools. Having the right resources on hand ensures effective troubleshooting, precise adjustments, and overall ease in restoring the equipment’s functionality. Basic Hand Tools

A core set of screwdrivers, needle-nose pliers, and a wrench is crucial for accessing internal components, adjusting small parts, and maintaining stability. Screwdrivers come in different shapes, allowing you to handle various screws with precision, while pliers are ideal for gripping, bending, or adjusting small pieces. Precision Tools for Accuracy

Accurate repairs often require calipers, tweezers, and a magnifying glass. Calipers help in measuring dimensions with precision, ensuring parts fit seamlessly. A pair of tweezers allows Replacing Worn Parts Effectively

Over time, certain components in sewing equipment can become worn, impacting performance and precision. Knowing how to replace these elements properly can extend the machine’s lifespan and ensure smooth operation. This section provides key guidelines for identifying and handling worn components, enabling you to restore functionality with minimal disruption. Identifying Worn Components

Early identification of deteriorating parts is crucial to maintain optimal operation. Look for signs of wear, such as inconsistent stitches, unusual sounds, or decreased efficiency. Regularly inspecting these components allows you to catch issues before they worsen, preventing further damage to surrounding parts. Best Practices for ReplacementsWhen replacing old elements, ensure that you use compatible parts suited to your specific model. Precision in installation is essential, so follow exact instructions to avoid misalignment or performance issues. Using quality replacements not only restores original efficiency but also minimizes the need for frequent adjustments, allowing the equipment to function smoothly over a prolonged period. Pro Tip: Keep essential Guide to Machine CalibrationEnsuring precise alignment and smooth functionality in sewing devices requires regular calibration. This process fine-tunes various settings to ensure the equipment operates efficiently, producing high-quality stitching results. Calibration involves adjusting key components to achieve consistent performance and avoid common sewing issues. First, examine the machine’s tension settings. Thread tension is crucial for balanced stitching and prevents fabric puckering or loose stitches. Adjust the tension dial gradually and test on scrap fabric to find the ideal setting for different materials. Next, focus on the needle alignment. Proper needle positioning ensures smooth fabric feeding and prevents skipped stitches. Adjustments may involve repositioning the needle or making slight modifications to the feed dogs to keep fabric moving evenly. Finally, check the feed dog height. This part controls fabric movement under the needle, so correct calibration helps achieve uniform stitching. If the feed dogs are too high or low, it can lead to irregular stitching or damage the fabric. Ad Proper Threading TechniquesCorrectly threading a sewing machine is essential for achieving optimal performance and quality in your projects. Understanding the steps involved ensures smooth operation and prevents common issues such as thread breaking or uneven stitching. This section outlines effective methods for properly threading a machine, promoting better results in your sewing endeavors. Steps for Effective Threading

Following a systematic approach when threading will enhance your sewing experience. Here are key steps to keep in mind:

Troubleshooting Common Issues

If you encounter problems such as thread jams or skipped stitches, revisit your threading process. Ensure that each step is meticulously followed and that the thread is properly seated in all tension areas. Regularly checking the threading method can significantly improve the functionality of your machine. Cleaning and Lubricating the Mechanism

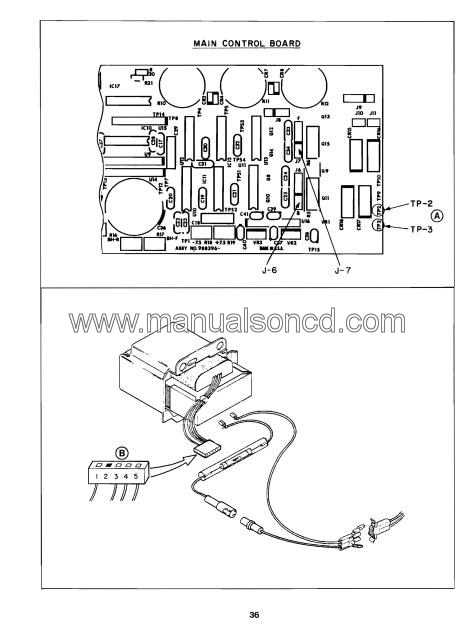

Maintaining the inner workings of your sewing machine is essential for ensuring its smooth operation and longevity. Regular cleaning and lubrication help to prevent wear and tear, ensuring that all components function harmoniously. A well-maintained mechanism not only enhances performance but also contributes to the quality of your sewing projects. Begin by disconnecting the machine from the power source to ensure safety. Remove any fabric and threads from the machine. Use a soft brush or a lint remover to carefully clear away dust and debris from the surface and inside the mechanism. Pay close attention to the feed dogs, bobbin area, and other hard-to-reach places where lint can accumulate. Once the cleaning is complete, proceed to lubricate the moving parts. Use a high-quality sewing machine oil, applying it sparingly to the designated areas as specified in your device’s guidelines. Avoid over-oiling, as this can attract dust and cause additional buildup. Proper lubrication will help reduce friction and ensure that the components move freely, contributing to a smoother sewing experience. Handling Electrical Problems Safely

When dealing with issues related to electrical equipment, it is crucial to prioritize safety to prevent accidents or injuries. Understanding the fundamental precautions and protocols can help ensure a secure working environment. This section highlights essential steps to take when troubleshooting electrical components, focusing on minimizing risks. Before attempting any maintenance or inspection, it is vital to disconnect the device from the power source. This action significantly reduces the likelihood of electrical shocks. Additionally, using insulated tools can provide an extra layer of protection while handling wires or circuit boards.

By adhering to these guidelines, individuals can significantly enhance their safety while addressing electrical challenges. It is always advisable to seek professional assistance if there is any uncertainty about handling electrical components. Fixing Tension Adjustment Errors

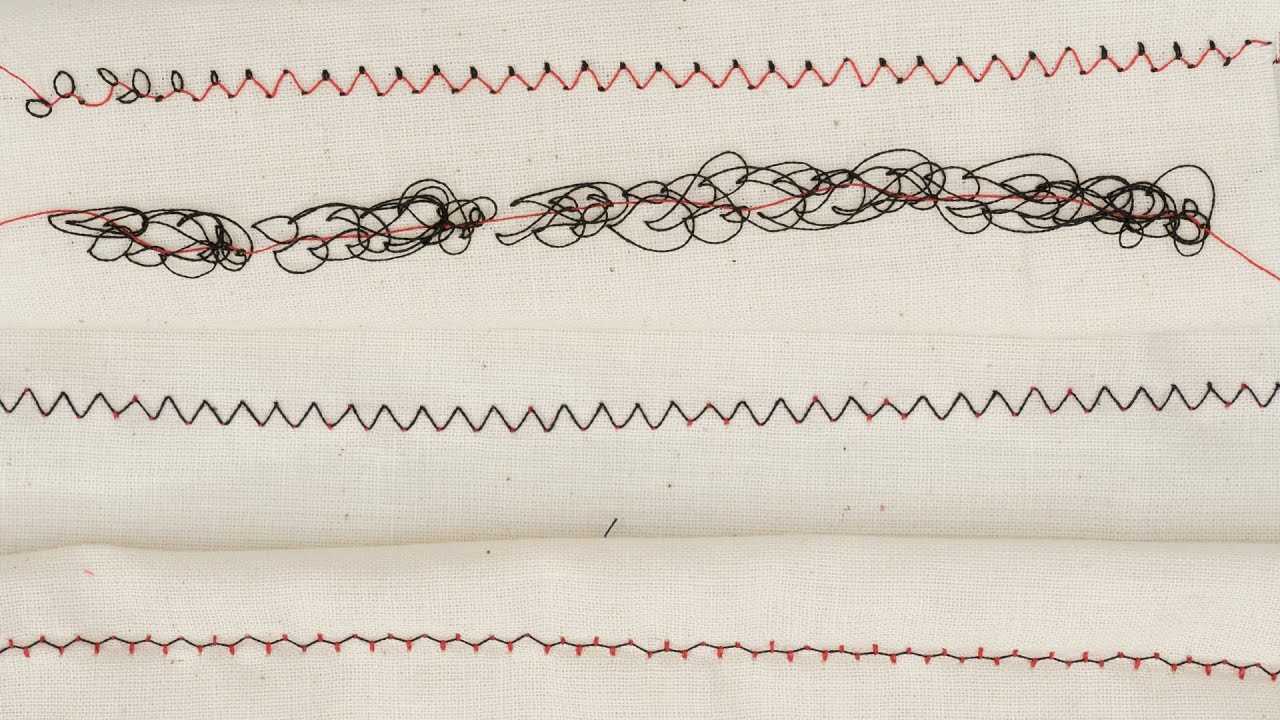

Proper tension settings are crucial for achieving optimal stitching results. When the thread tension is incorrect, it can lead to various issues, such as uneven stitches, puckering fabric, or thread breakage. Understanding how to troubleshoot and rectify these tension-related problems will enhance the overall sewing experience. Common Symptoms of Tension Issues

Steps to Correct Tension Settings

Restoring Motor PerformanceEnhancing the efficiency of the motor is crucial for ensuring optimal functionality and longevity of the device. Various factors can contribute to a decline in performance, including wear and tear, lack of maintenance, and external environmental influences. Addressing these issues systematically can help restore the motor’s capabilities and enhance its overall reliability. Identifying Performance IssuesThe first step in revitalizing motor performance is to identify any underlying problems. Common signs of reduced functionality may include unusual noises, inconsistent speed, or overheating. Conducting a thorough inspection can help pinpoint specific areas that require attention, such as electrical connections, lubrication levels, or the condition of internal components. Implementing SolutionsOnce issues have been identified, appropriate measures should be taken to rectify them. This may involve cleaning electrical contacts, applying suitable lubricants to moving parts, or replacing worn-out components. Regular maintenance practices, such as timely oil changes and inspections, can prevent future problems and ensure that the motor operates at peak efficiency. Maintaining Bobbin and Shuttle Systems

Proper upkeep of the bobbin and shuttle mechanisms is essential for ensuring smooth operation and optimal performance of your sewing device. These components play a crucial role in creating stitches and must be regularly monitored to prevent issues such as thread jams or uneven tension. To maintain these systems effectively, consider the following steps:

By following these maintenance tips, you can prolong the lifespan of your sewing machine’s bobbin and shuttle systems, ensuring that your stitching projects proceed smoothly and efficiently. Tips for Smooth Stitch OperationAchieving seamless stitching is essential for any sewing enthusiast. Proper preparation and maintenance can greatly enhance the performance of your machine, ensuring a flawless finish on every project. This section provides valuable insights to help you maintain optimal function and avoid common pitfalls that can disrupt the stitching process. Regular Maintenance

Consistent upkeep is crucial for smooth operation. Clean the machine regularly to remove lint and dust, which can accumulate in the bobbin area and around the feed dogs. Lubricate moving parts as per the manufacturer’s guidelines to reduce friction and wear. Inspect the needle frequently, replacing it as needed to prevent skipped stitches or uneven sewing. Thread and Fabric Choices

Selecting the right thread and fabric is vital for achieving desired results. Use high-quality thread that matches the weight and type of fabric being used. Make sure to properly thread the machine, following the threading path precisely to avoid tension issues. Additionally, adjusting the tension settings based on fabric thickness can make a significant difference in stitch quality. Preventing Future Sewing Machine IssuesMaintaining optimal performance of your sewing device is essential for ensuring longevity and efficiency. By adopting proactive measures, users can significantly reduce the likelihood of encountering mechanical problems. Regular attention to care and upkeep can lead to smoother operation and a more enjoyable sewing experience. Regular Maintenance Practices

Implementing routine checks is crucial. Cleaning the machine regularly, especially the feed dogs and bobbin area, prevents lint and debris buildup. Additionally, oiling moving parts according to the manufacturer’s recommendations will keep everything running smoothly. Always refer to the guidelines provided for specific maintenance schedules to maximize the lifespan of your equipment. Using Quality MaterialsChoosing high-quality fabrics and threads can have a significant impact on the performance of your device. Inferior materials may cause tension issues or result in unnecessary wear and tear. Investing in reliable supplies not only enhances the sewing experience but also minimizes the risk of complications arising from subpar components. |