This section aims to provide essential insights and guidelines for keeping your aquatic vehicle in optimal condition. Understanding the various components and their functions is crucial for ensuring longevity and performance. Regular upkeep not only enhances safety but also significantly improves the overall riding experience.

In the following paragraphs, we will delve into common issues that owners may encounter, as well as practical solutions and preventive measures. From troubleshooting mechanical challenges to routine checks, this guide serves as a comprehensive resource for enthusiasts and novices alike. Mastering the basics of maintenance can empower you to take charge of your watercraft’s care, allowing for more enjoyable adventures on the water.

This section delves into the various parts and assemblies that constitute the watercraft, emphasizing their functions and interactions. Understanding these components is crucial for effective troubleshooting and maintenance, ensuring optimal performance and longevity of the vessel.

Key Elements of the Watercraft

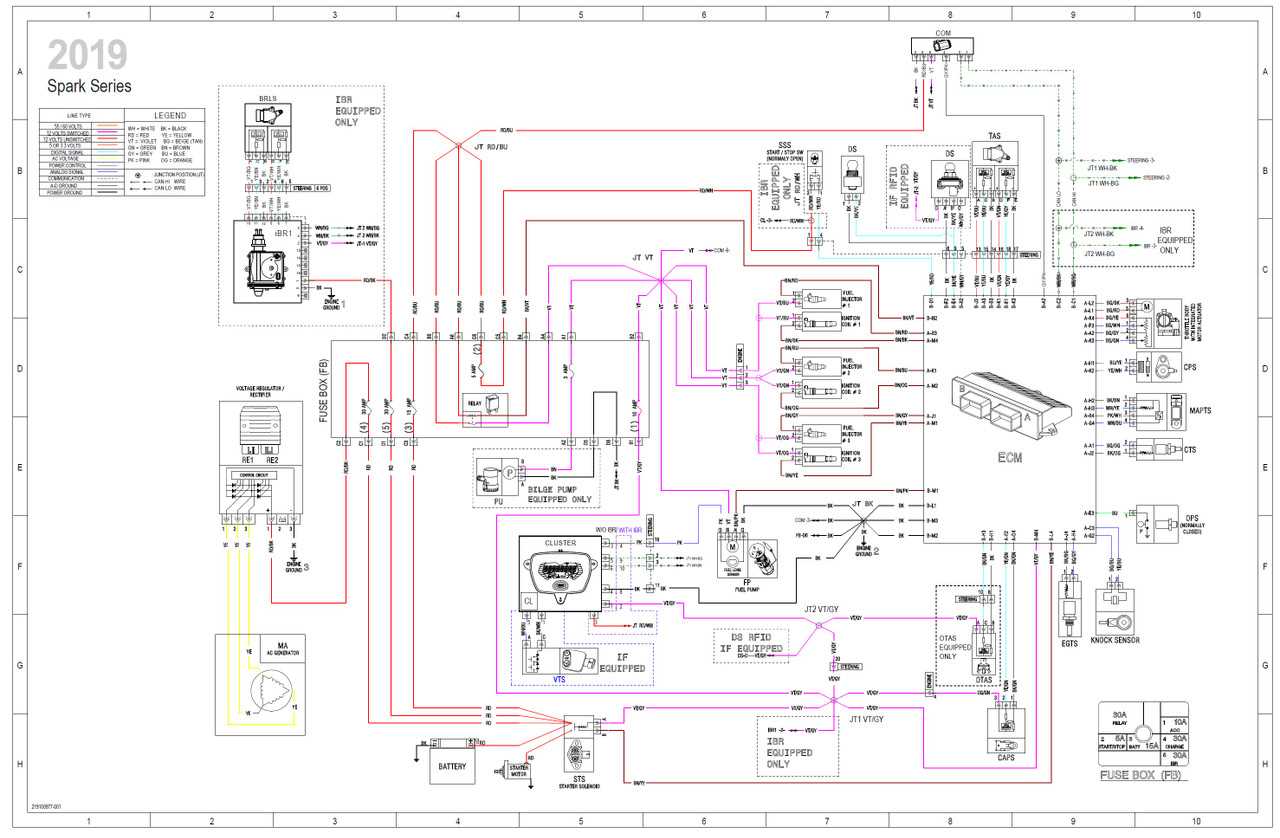

Among the essential parts, the propulsion system plays a vital role in determining the vessel’s speed and maneuverability. In addition, the electrical system powers critical components such as lights and instrumentation, while the hull design influences stability and handling.

Maintenance of Core Parts

Regular inspection of these primary elements is important for early detection of potential issues. By ensuring that each component is functioning correctly, one can prevent more significant problems down the line and maintain the overall integrity of the watercraft.

Common Issues with Seadoo Spark

Owners of personal watercraft often encounter various challenges that can impact performance and enjoyment. Understanding these common issues is essential for effective troubleshooting and maintenance. This section explores typical problems faced by operators of these aquatic vehicles, along with potential solutions.

- Engine Problems:

Frequent issues include difficulties starting the engine or unusual noises during operation. These symptoms may indicate underlying mechanical issues or fuel system problems.

- Electrical Failures:

Malfunctions in the electrical system can lead to battery drainage or ignition failures. Regular inspections can help identify and rectify these issues early.

- Handling Difficulties:

Poor steering response or instability in the water can be alarming. Such issues often stem from misaligned components or inadequate maintenance of the steering system.

- Fuel Efficiency:

Reduced fuel efficiency can result from clogged filters or improper tuning of the engine. Keeping the fuel system clean is crucial for optimal performance.

- Corrosion and Wear:

Exposure to water can lead to corrosion on various parts. Regular cleaning and protective measures can help prolong the lifespan of the craft.

Addressing these issues promptly ensures the longevity and reliability of personal watercraft, allowing for a more enjoyable experience on the water.

Step-by-Step Repair Process

The process of fixing your personal watercraft can seem daunting, but breaking it down into manageable steps makes it easier to tackle. This section outlines a systematic approach to troubleshooting and addressing common issues, ensuring that you can effectively restore your vessel’s performance.

Begin by gathering all necessary tools and materials. A well-equipped workspace will facilitate the task and keep everything organized. Next, assess the condition of the watercraft. Identify any symptoms of malfunction, such as unusual noises or performance issues, to pinpoint the source of the problem.

Once you have identified the issue, consult relevant resources for detailed instructions specific to the components involved. Follow these guidelines carefully to dismantle the affected parts. Always keep track of screws and components as you work, using labeled containers if necessary.

After disassembly, inspect each component for wear or damage. Clean parts thoroughly to remove any debris or corrosion. If any parts require replacement, ensure you acquire high-quality substitutes that meet the manufacturer’s specifications.

Reassemble the watercraft in reverse order, double-checking connections and fittings. Before taking it back to the water, perform a series of tests to confirm that everything operates as intended. Regular maintenance and proper care can prolong the lifespan of your vessel, ensuring countless enjoyable outings on the water.

Essential Tools for Repairs

When working on watercraft maintenance, having the right instruments at your disposal is crucial for effective troubleshooting and upkeep. This section outlines the key implements necessary to carry out tasks efficiently, ensuring both safety and precision in your work.

| Tool | Description |

|---|---|

| Wrench Set | Various sizes to fit different bolts and nuts, essential for loosening and tightening components. |

| Screwdriver Set | Includes Phillips and flathead types for removing screws from panels and machinery. |

| Socket Set | Used for applying torque to fasteners, making it easier to reach tight spaces. |

| Multimeter | A vital tool for diagnosing electrical issues by measuring voltage, current, and resistance. |

| Pliers | Helpful for gripping, bending, and cutting wires or components as needed. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage. |

| Oil Filter Wrench | Specialized tool for removing and installing oil filters with ease. |

| Cleaning Supplies | Includes brushes and solvents for maintaining and cleaning parts effectively. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your watercraft. By following a few simple guidelines, you can ensure that your vehicle remains in excellent condition and performs at its best for years to come.

- Regular Inspections: Conduct frequent checks on all components, including the engine, fuel system, and electrical systems, to identify any potential issues early.

- Cleaning: After each use, rinse the watercraft thoroughly to remove salt, sand, and debris that can cause corrosion and wear.

- Fluid Changes: Schedule routine oil changes and replace the coolant as necessary to maintain optimal performance and prevent overheating.

- Battery Maintenance: Keep the battery terminals clean and check the charge regularly to avoid starting issues.

- Protective Cover: When not in use, cover your watercraft to protect it from the elements and UV damage.

Following these maintenance tips will not only enhance the performance of your vessel but also ensure that it remains a reliable companion for all your adventures on the water.

Winterization Procedures Explained

Preparing watercraft for the cold season is essential to ensure its longevity and optimal performance. This process involves several critical steps to protect the engine and other components from freezing temperatures and moisture damage. By following these procedures, owners can avoid costly repairs and ensure a smooth start when the warmer months return.

Step-by-Step Preparation

The first step in the winterization process is to thoroughly clean the vessel, removing any dirt, debris, or marine growth. After cleaning, it is crucial to drain the engine and cooling system to eliminate any remaining water that could freeze. Next, adding antifreeze to the system prevents damage caused by ice expansion. Additionally, lubricating moving parts and replacing the oil and filter are vital to maintain engine health during the off-season.

Storage Considerations

Proper storage conditions play a significant role in the overall preservation of the watercraft. It is recommended to store the vessel in a dry, climate-controlled environment to prevent mold and corrosion. Covering the watercraft with a breathable cover protects it from dust and moisture while allowing any trapped humidity to escape. Regularly checking on the condition of the storage area can help prevent potential issues throughout the winter months.

Safety Precautions During Repairs

When undertaking maintenance on aquatic vehicles, adhering to safety measures is crucial to ensure the well-being of both the technician and the equipment. Proper precautions help prevent accidents, injuries, and further damage to the craft.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and durable clothing.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes or vapors from chemicals and fuels.

- Disconnect the battery before beginning any work to prevent electrical shocks or accidental starts.

- Keep a fire extinguisher nearby, especially when working with flammable materials.

Tool and Equipment Safety

- Use tools that are specifically designed for the task at hand to avoid mishaps.

- Inspect tools regularly for any damage or wear to ensure safe operation.

- Organize tools and equipment to minimize clutter and reduce the risk of accidents.

- Be cautious with sharp instruments and handle them carefully to prevent cuts and injuries.

Troubleshooting Electrical Problems

Electrical issues can be a common source of frustration for watercraft enthusiasts. Identifying and resolving these problems is essential for ensuring optimal performance and safety. This section outlines key strategies for diagnosing electrical malfunctions, helping you to get your vessel back on the water efficiently.

Common Symptoms

When facing electrical difficulties, certain indicators may suggest where the problem lies. Common signs include:

- Inconsistent Starting: Difficulty starting the engine can signal battery issues or faulty connections.

- Dim Lights: If the lights appear dim or flicker, it may indicate a weak battery or alternator problems.

- Electrical Shorts: Unusual noises or burning smells could suggest a short circuit.

Diagnosis and Solutions

To effectively address these issues, follow a systematic approach:

- Check the Battery: Ensure the battery is fully charged and terminals are clean and secure.

- Inspect Wiring: Look for frayed wires or loose connections that may cause disruptions.

- Test Components: Use a multimeter to check the voltage of various electrical components.

By methodically assessing these areas, you can pinpoint the source of electrical problems and take appropriate action to rectify them.

Engine Maintenance Best Practices

Regular upkeep of your watercraft’s powerplant is essential for ensuring optimal performance and longevity. By adhering to established guidelines, you can prevent common issues and enhance the overall efficiency of the engine.

Routine Inspections: Conducting frequent examinations of engine components is crucial. Check for any signs of wear, leaks, or corrosion that may affect functionality. Early detection can save time and resources in the long run.

Fluid Levels: Regularly monitor and maintain appropriate levels of essential fluids, including oil and coolant. Adequate lubrication is vital for preventing friction and overheating.

Filter Maintenance: Ensure that air and fuel filters are clean and replaced as needed. Clogged filters can restrict airflow and fuel delivery, leading to performance issues.

Battery Care: Keep the battery charged and free of corrosion. A well-maintained battery is vital for reliable starts and overall engine function.

Seasonal Checks: Before and after each season, perform a comprehensive inspection. This includes examining hoses, belts, and electrical connections to ensure everything is in good condition.

Implementing these best practices will contribute significantly to the efficiency and lifespan of your engine, providing you with a more enjoyable and trouble-free experience on the water.

Replacing Key Parts Efficiently

Efficiently swapping out essential components is crucial for maintaining optimal performance in any watercraft. By understanding the intricacies involved in this process, users can save time and effort while ensuring their vehicle runs smoothly.

Preparation Steps

- Gather all necessary tools and replacement parts before beginning the process.

- Consult documentation or online resources for specific guidelines related to the components being replaced.

- Ensure the workspace is clean and organized to prevent any loss of parts or tools.

Replacement Process

- Disconnect the power source to avoid any accidental starts during the process.

- Carefully remove the damaged or outdated component, taking note of how it is installed.

- Install the new part by reversing the removal steps, ensuring a secure fit.

- Reconnect the power source and conduct a thorough test to confirm proper functionality.

Following these steps will facilitate a smooth transition when replacing vital parts, ultimately enhancing the longevity and efficiency of the watercraft.

Upgrades to Enhance Performance

Improving the efficiency and capability of your watercraft can lead to an exhilarating experience on the water. Various enhancements can significantly boost speed, handling, and overall enjoyment, transforming your ride into a more powerful machine. Here are some effective modifications to consider for optimal performance.

Engine Enhancements

- High-Performance Air Intake: Upgrading to a high-flow air intake can increase airflow to the engine, resulting in better combustion and increased horsepower.

- ECU Tuning: Reprogramming the engine control unit (ECU) can optimize fuel maps and ignition timing for improved performance.

- Exhaust System Upgrade: Installing a performance exhaust system can reduce back pressure and enhance engine efficiency, allowing for a noticeable increase in power.

Weight Reduction

- Lightweight Components: Replacing stock parts with lightweight alternatives can improve acceleration and handling by reducing overall weight.

- Removing Unnecessary Accessories: Evaluate your equipment and consider removing items that are not essential to your ride, which can help in achieving better speed and agility.

Resources for Further Assistance

When encountering challenges with your watercraft, it’s essential to have access to a variety of resources that can provide guidance and support. These resources can help you gain a deeper understanding of your vehicle, troubleshoot issues, and perform maintenance effectively.

Online Communities

Engaging with online forums and social media groups can be an excellent way to connect with fellow enthusiasts. These platforms often host discussions on common problems, tips, and modifications, allowing you to benefit from the experiences of others.

Official Websites and Documentation

Manufacturer websites typically offer a wealth of information, including specifications, FAQs, and troubleshooting guides. These official resources are valuable for ensuring you follow best practices for maintenance and operation.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven discussions on various topics related to watercraft. | Visit Forum |

| Manufacturer’s Site | Official information regarding specifications and maintenance tips. | Visit Site |

| Video Tutorials | Visual guides for common maintenance tasks and troubleshooting. | Watch Tutorials |