Understanding the intricacies of air compressor systems is crucial for ensuring optimal performance and longevity. Proper care and attention to these powerful machines can prevent downtime and costly repairs. This section aims to provide comprehensive insights into troubleshooting and maintaining your equipment effectively.

Through this guide, users will gain knowledge about essential components, common issues, and recommended practices for upkeep. Emphasis will be placed on safety protocols and best methods to enhance operational efficiency, making it an invaluable resource for both novice and experienced operators.

With a focus on practical advice and step-by-step procedures, this content serves as a vital reference for anyone looking to maximize the functionality of their air compressor. Empowering users with the right tools and information ensures a smooth and effective maintenance process.

Overview of Ingersoll-Rand P185WJD

This section provides a comprehensive insight into a well-regarded piece of machinery known for its efficiency and reliability in various industrial applications. Designed to meet the needs of professionals, this equipment is built with a focus on performance and durability, making it a popular choice among users.

Key Features

- Robust construction ensuring long-lasting use.

- High operational efficiency for enhanced productivity.

- Versatile applications across different sectors.

- Easy maintenance procedures for user convenience.

Applications

- Construction sites for powering tools.

- Manufacturing environments requiring compressed air.

- Mining operations to support various tasks.

- Landscaping and outdoor projects needing reliable energy sources.

This machinery stands out due to its user-friendly design and adaptability, making it an essential asset in demanding work settings. Understanding its features and potential applications helps users maximize its capabilities effectively.

Common Issues and Troubleshooting Steps

Understanding frequent challenges encountered with portable air compressors can significantly enhance maintenance efficiency and operational reliability. This section outlines typical problems and provides actionable solutions to ensure optimal performance.

1. Insufficient Air Pressure: A common concern is the inability to generate adequate air pressure. This issue may stem from a faulty pressure regulator or leaks in the air lines. Inspecting the connections and replacing any damaged components can often resolve this problem.

2. Unusual Noises: Unexpected sounds during operation can indicate mechanical wear or misalignment. Regularly checking bearings and other moving parts for signs of damage can help identify the source of the noise and facilitate timely repairs.

3. Overheating: If the unit becomes excessively hot, it may lead to automatic shut-off. Ensure that the air intake is not obstructed and that the cooling system is functioning correctly. Cleaning air filters and ensuring proper ventilation are essential steps to prevent overheating.

4. Oil Leaks: Leaking oil can indicate worn seals or gaskets. Regular inspection and maintenance of these components are crucial to prevent further damage and maintain efficient operation.

5. Electrical Failures: Issues with starting or running the compressor may be related to electrical components. Checking the power supply and ensuring all connections are secure can help resolve these issues quickly.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of machinery. A well-equipped toolkit not only enhances efficiency but also ensures safety during the servicing process.

Here are some fundamental items to consider:

- Wrenches: A variety of sizes, including adjustable and socket wrenches, for loosening and tightening fasteners.

- Screwdrivers: A set of both flathead and Phillips screwdrivers in various sizes to address different screws.

- Pliers: Needle-nose and slip-joint pliers for gripping and manipulating components.

- Multimeter: An essential tool for measuring voltage, current, and resistance, aiding in electrical diagnostics.

- Torque Wrench: Ensures bolts and screws are tightened to the specified tension, preventing damage.

Additional tools that may be beneficial include:

- Hoses and Connectors: For managing air and fluid systems effectively.

- Replacement Parts: Keeping commonly needed components on hand can minimize downtime.

- Safety Gear: Gloves, goggles, and masks to protect against potential hazards.

Equipping yourself with these essentials can lead to more efficient service and longer-lasting performance of equipment.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the efficient operation of any machinery. A well-structured maintenance plan helps identify potential issues before they escalate, prolonging equipment life and enhancing reliability. This section outlines the recommended maintenance activities and their frequencies to maintain peak functionality.

Daily Checks

- Inspect fluid levels and top off as necessary.

- Examine hoses and connections for any signs of wear or leaks.

- Ensure all safety features are functioning correctly.

Weekly Maintenance

- Clean air filters to prevent dust accumulation.

- Check battery terminals for corrosion and clean if needed.

- Lubricate moving parts according to manufacturer guidelines.

Monthly Inspections

- Perform a comprehensive visual inspection of all components.

- Test electrical systems and connections for stability.

- Review and tighten all fasteners to ensure secure operation.

Adhering to this maintenance schedule will help optimize the performance of your equipment, minimize downtime, and reduce the likelihood of unexpected failures.

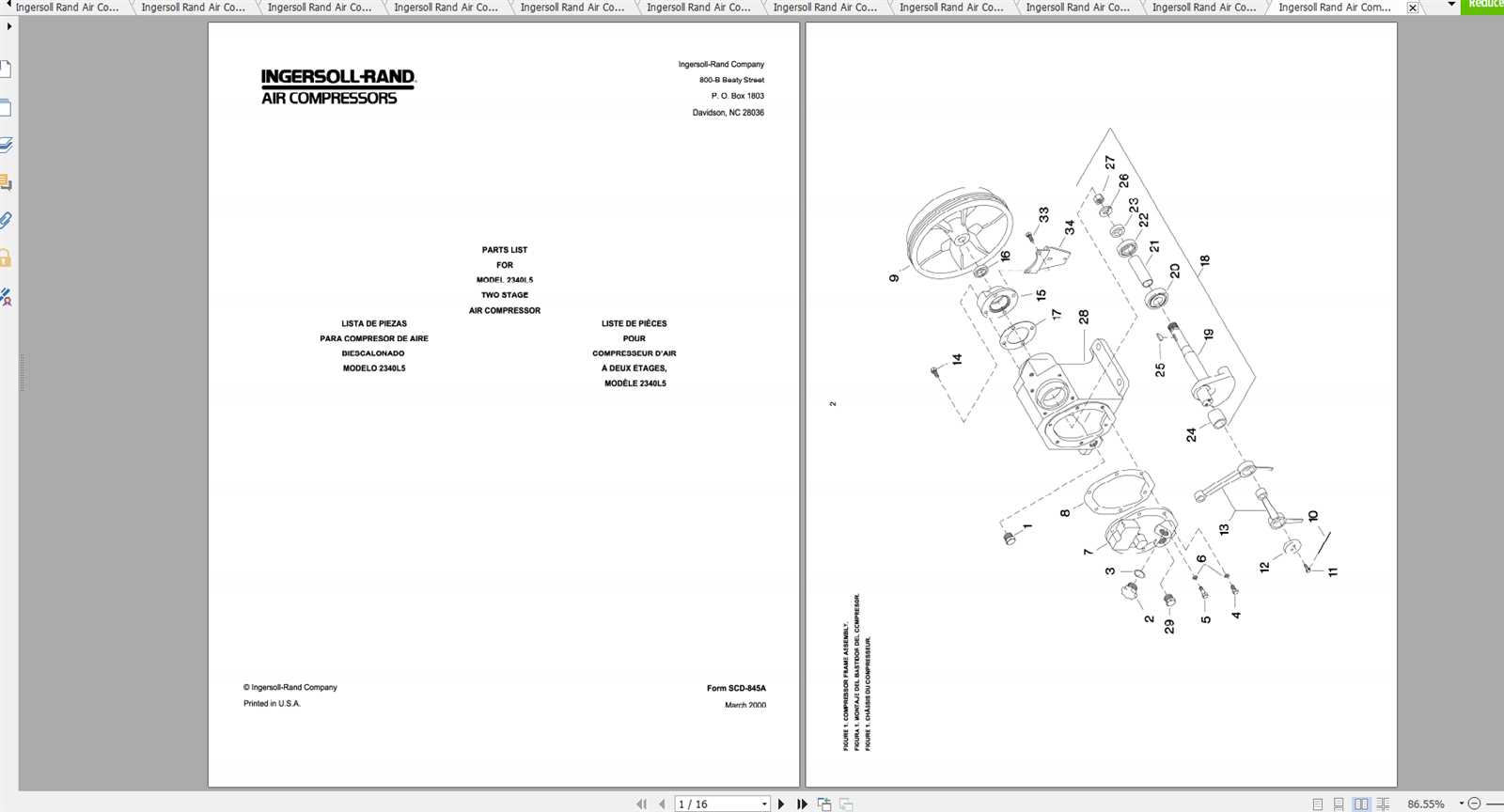

Detailed Repair Procedures Explained

This section outlines comprehensive methods for addressing common issues associated with heavy-duty equipment. Understanding these processes is essential for ensuring optimal functionality and longevity of machinery. Each step is crucial for restoring performance and reliability.

Initial Assessment

Before commencing any service, an accurate evaluation of the equipment’s condition is vital. Follow these steps:

- Inspect for visible signs of wear or damage.

- Check fluid levels and quality.

- Test operational functions under load.

Systematic Approach to Maintenance

Implementing a structured methodology can simplify the maintenance process. Consider the following stages:

- Disassembly: Carefully remove components while labeling parts for reassembly.

- Cleaning: Use appropriate solvents to remove dirt and contaminants.

- Replacement: Identify worn-out components and replace them with genuine parts.

- Reassembly: Follow the reverse order of disassembly, ensuring all connections are secure.

- Testing: Conduct thorough checks to confirm that all systems function correctly.

Replacement Parts: Where to Find Them

Finding suitable components for maintenance and restoration can be a challenging task. Knowing the right sources for these essential items ensures that equipment functions optimally and lasts longer.

Here are some reliable options for sourcing replacement parts:

- Authorized Dealers: Manufacturers often have a network of certified dealers who provide genuine components. This is one of the most dependable sources for obtaining high-quality parts.

- Online Retailers: Numerous e-commerce platforms specialize in industrial components. These websites frequently offer competitive prices and a wide selection of parts.

- Local Suppliers: Check with nearby supply stores that focus on industrial equipment. They may carry common parts or be able to order them for you.

- Aftermarket Providers: Many companies produce compatible components that can serve as cost-effective alternatives. Ensure to check the quality and warranty offered by these suppliers.

- Distributors: Wholesalers and distributors may stock a variety of parts. Building relationships with them can provide access to bulk discounts.

Before making a purchase, it’s wise to verify the compatibility of the parts with your specific equipment model. Reading customer reviews and seeking recommendations can also aid in selecting reputable sources.

Understanding the Electrical System

The electrical system plays a crucial role in the functionality of various machinery, ensuring seamless operation and performance. This intricate network is designed to manage power distribution, control functions, and facilitate communication between components. Understanding its components and their interrelationships is essential for effective troubleshooting and maintenance.

Power Source: The system typically relies on a primary power source, which may be an engine or generator, to supply electricity. This source converts mechanical energy into electrical energy, providing the necessary force for operation.

Wiring and Connectors: A complex array of wiring and connectors links various elements within the system. These components must be robust and well-insulated to prevent faults and ensure efficient energy transfer. Regular inspection can help identify wear and tear that could lead to electrical issues.

Control Panel: The control panel serves as the interface for operators, allowing them to monitor and manage system functions. This panel typically includes various switches, gauges, and indicators that provide real-time feedback on operational status.

Safety Features: Incorporating safety mechanisms is vital to protect both the equipment and operators. Circuit breakers and fuses are common components that prevent overloads and electrical failures, contributing to overall system reliability.

By familiarizing oneself with these key aspects of the electrical framework, operators can enhance their understanding and improve their ability to maintain optimal performance.

Air System Diagnostics and Fixes

Effective troubleshooting of air systems is crucial for ensuring optimal performance and longevity. Identifying issues early can prevent costly downtime and enhance efficiency. This section will cover common diagnostic techniques and solutions for air system anomalies.

Common Symptoms and Their Causes

- Insufficient Pressure: Often caused by leaks, blockages, or worn-out components.

- Excessive Noise: May indicate loose parts or failing machinery.

- Unusual Vibrations: Typically results from misalignment or imbalance in the system.

- Inconsistent Output: Can stem from fluctuating power sources or failing regulators.

Diagnostic Steps

- Inspect for visible leaks around hoses and fittings.

- Check pressure gauges to ensure readings are within acceptable limits.

- Listen for abnormal sounds during operation, noting the source and type of noise.

- Examine the system’s alignment and balance, especially if vibrations are present.

By systematically evaluating these factors, operators can effectively diagnose and address air system issues, maintaining reliable performance and extending equipment life.

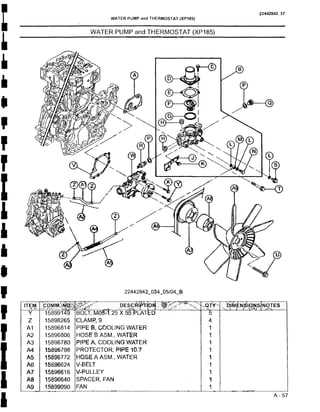

Engine Maintenance Tips and Tricks

Proper upkeep of your engine is essential for optimal performance and longevity. By following a few best practices, you can ensure that your machine runs smoothly and efficiently, reducing the likelihood of costly repairs.

Regular Inspection

- Check fluid levels frequently, including oil, coolant, and fuel.

- Inspect hoses and belts for wear or damage, replacing them as needed.

- Monitor the condition of air filters and clean or replace them to maintain airflow.

Scheduled Maintenance

- Follow the manufacturer’s recommendations for service intervals.

- Change the oil and filters regularly to prevent sludge buildup.

- Keep an eye on the exhaust system for leaks or corrosion.

By incorporating these practices into your routine, you can extend the life of your engine and enhance its efficiency, leading to improved overall performance.

Safety Precautions During Repairs

Ensuring a safe environment during maintenance tasks is paramount. Adopting proper precautions not only protects the technician but also enhances the efficiency of the work being conducted. Awareness of potential hazards and the implementation of safety measures can prevent accidents and injuries.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Ensure the work area is well-lit and free from clutter to minimize risks of slips or falls.

- Disconnect power sources and depressurize systems before starting any servicing activities.

- Familiarize yourself with emergency procedures and have first aid supplies readily available.

Hazard Awareness

- Identify and assess potential risks associated with the equipment being serviced.

- Maintain a safe distance from moving parts and hot surfaces.

- Keep flammable materials away from the work zone to prevent fire hazards.

- Use tools and equipment as intended, following the manufacturer’s guidelines to avoid malfunctions.

Performance Upgrades and Modifications

Enhancing the efficiency and capability of equipment can significantly improve productivity and extend its operational lifespan. By implementing various upgrades and modifications, users can optimize performance and tailor machinery to better meet specific requirements. This section explores practical enhancements that can be made to boost overall functionality.

Engine Improvements

One effective way to increase output is through engine modifications. Upgrading components such as air filters, fuel injectors, and exhaust systems can enhance airflow and combustion efficiency, resulting in improved power and fuel economy. Additionally, reprogramming the engine control unit (ECU) can optimize performance settings to match operational demands.

Mobility and Stability Enhancements

Enhancing mobility and stability can greatly affect operational efficiency. Installing larger, more durable tires can improve traction and reduce wear, while adjusting the suspension system can help maintain stability on uneven surfaces. Additionally, adding features like hydraulic outriggers can increase stability during operation, enabling safer and more effective use of the equipment.

Customer Support and Resources

This section provides essential information for users seeking assistance and resources related to their equipment. Accessing the right support can enhance the overall experience and ensure optimal performance.

For comprehensive help, various channels are available, including online platforms, customer service hotlines, and community forums. Users can benefit from detailed documentation, instructional videos, and troubleshooting tips designed to facilitate a better understanding of their equipment.

| Support Type | Description | Contact Information |

|---|---|---|

| Online Resources | Access to manuals, FAQs, and instructional content. | Visit Resources |

| Customer Service | Dedicated support team available for inquiries and assistance. | 1-800-555-0199 |

| Community Forum | Join discussions and share experiences with other users. | Join Forum |