Maintaining outdoor equipment can significantly enhance its lifespan and ensure optimal functionality. This section provides insights into various techniques for addressing common issues, improving overall performance, and implementing regular upkeep practices. Whether it’s dealing with basic upkeep tasks or troubleshooting minor operational challenges, following structured steps can streamline the process.

Regular maintenance plays a vital role in preventing wear and tear, keeping tools running smoothly for years. By understanding the essential components, lubrication needs, and cleaning methods, users can minimize unexpected breakdowns. Simple adjustments and inspections are often all that’s needed to restore efficient operation, saving time and costs associated with more extensive repairs.

In addition, a few practical tips on part replacements, safety precautions, and proper storage will help users handle routine issues confidently. This approach not only enhances the equipment’s functionality but also contributes to safer and more efficient use, allowing for a seamless gardening experience year after year.

Ryobi Tiller 410r Repair Manual

Maintaining efficient equipment is essential for productive and smooth garden work. Ensuring consistent upkeep, addressing common issues, and understanding optimal adjustments can extend the lifespan of tools, keeping them in prime condition for varied tasks.

Essential Maintenance Steps

Regular care can prevent extensive wear, enhancing performance and minimizing breakdowns. Consider these key maintenance practices:

- Inspect moving parts regularly to identify any wear or looseness.

- Lubricate joints and other mechanical sections to prevent rust and friction.

- Ensure that all fastenings are secure to avoid operational issues during use.

Troubleshooting Common Issues

Addressing frequent challenges as they arise can save time and reduce repair needs. Here are some common issues and solutions:

- Engine starts but stops quickly: Check fuel quality and clear any obstructions in the intake areas.

- Decreased cutting efficiency: Sharpen the blades periodically and ensure they’re well-aligned.

- Unusual vibrations: Examine for loose components or unbalanced sections that may need readjustment.

Basic Maintenance Tips

Regular upkeep ensures the longevity and efficiency of your equipment. By taking a few simple steps, you can keep the machinery running smoothly, helping to avoid unexpected issues during operation. Below are practical guidelines for basic care that you can easily incorporate into your maintenance routine.

Inspect and Clean Regularly

Before and after each use, inspect key parts of the equipment. Look for any debris or dirt buildup around moving parts, as these can hinder performance. Cleaning these areas with a soft brush or cloth can prevent wear and ensure optimal operation. Pay special attention to areas prone to dust accumulation.

Check and Replace Worn Components

Periodically examine components that may experience wear, such as belts or blades. If you notice signs of deterioration, it’s best to replace them promptly to avoid further damage. Following a replacement schedule for consumable parts helps in maintaining peak efficiency and reducing the risk of malfunction.

Troubleshooting Common Issues

Regular maintenance can prevent many issues, but sometimes unexpected problems can still occur. This section outlines effective methods for identifying and addressing frequent issues that may arise during use, helping to keep equipment running smoothly.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine Won’t Start | Empty fuel tank, clogged air filter, or faulty spark plug | Refuel, clean or replace the air filter, check and replace the spark plug if needed |

| Unsteady Operation | Loose parts or incorrect settings | Tighten all bolts and screws, and adjust settings as per maintenance guide |

| Overheating | Blocked ventilation or excessive use | Clear ventilation areas, allow equipment to cool, and avoid continuous heavy use |

| Unusual Vibrations | Damaged blade or misalignment | Inspect and replace the blade if damaged, or realign parts as needed |

Replacing Worn-Out Parts

Regular replacement of components that endure significant wear is essential to ensure optimal performance and longevity. Keeping these parts in good condition minimizes breakdowns and allows for smoother operation, making tasks more efficient and safer.

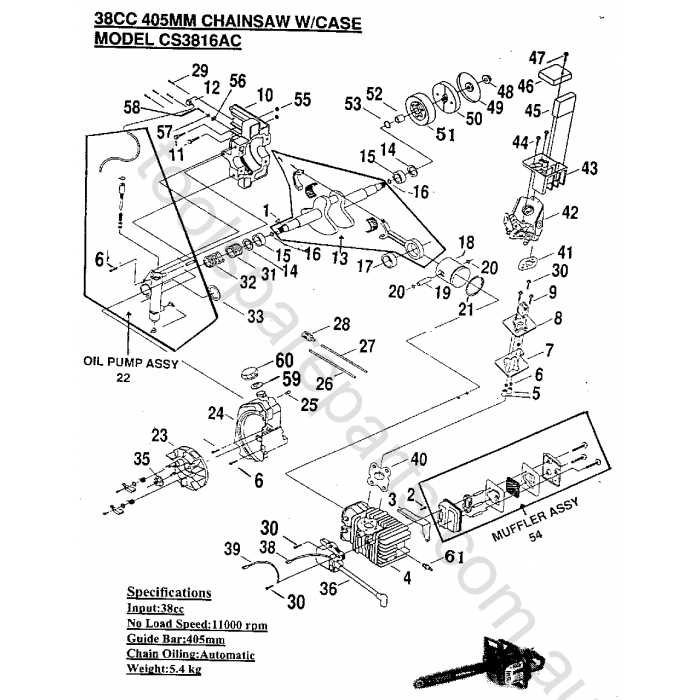

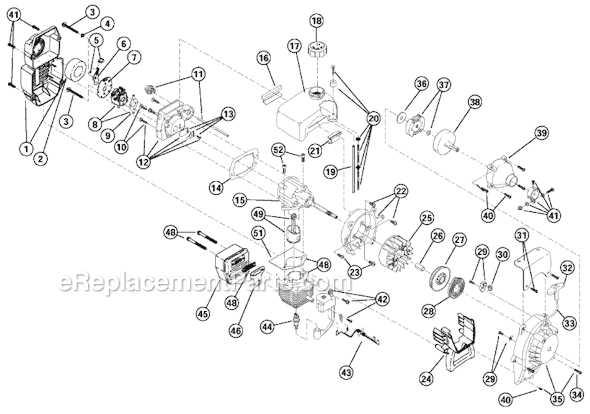

Identifying Components in Need of Replacement

Over time, certain parts experience wear and may begin to show signs of deterioration, such as visible damage, reduced functionality, or unusual noises. Recognizing these signs early can prevent further issues and extend the equipment’s lifespan. Examining each component periodically allows you to identify which pieces require replacement before they affect other parts of the machine.

Steps for Effective Part Replacement

Once worn components are identified, ensure you have suitable replacement parts that match the specifications of the original ones. Begin by carefully removing the old part, following appropriate guidelines to avoid damaging surrounding mechanisms. Next, install the new component, securing it in place, and conduct a test run to confirm it functions smoothly. Regularly inspecting and replacing worn parts not only enhances performance but also improves safety and reliability.

Engine Care Essentials

Regular engine maintenance is crucial for ensuring optimal performance and extending the lifespan of any machine. With consistent upkeep, you can avoid common issues, reduce wear, and keep the engine running smoothly over time.

Keep the Air Filter Clean: The air filter prevents dust and debris from entering the engine. Cleaning or replacing it periodically ensures better air circulation, which is essential for efficient combustion and fuel economy.

Check Oil Levels Regularly: Engine oil lubricates internal components, reducing friction and preventing overheating. Regularly checking and changing the oil maintains engine efficiency and reduces the risk of damage.

Inspect Fuel System: A clean fuel system enhances engine performance and prevents clogs. Use high-quality fuel and clean the tank to avoid residue build-up, which can cause starting issues or poor performance.

Scheduled care not only boosts performance but also helps identify potential issues early. Following these simple steps contributes to an engine’s durability and reliable operation in the long term.

Fuel System Cleaning Guide

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity of your equipment. Regular cleaning helps prevent clogs, ensures efficient fuel flow, and enhances the overall functionality of the engine.

This guide will walk you through the necessary steps to effectively clean the fuel system. Follow these instructions to keep your machinery running smoothly.

Materials Needed

- Fuel system cleaner

- Clean rags

- Container for old fuel

- Protective gloves

- Safety goggles

Step-by-Step Cleaning Process

- Ensure the equipment is turned off and cool.

- Disconnect the fuel line from the fuel tank.

- Drain any old fuel into the container.

- Apply the fuel system cleaner according to the manufacturer’s instructions.

- Reconnect the fuel line securely.

- Start the engine and let it run for a few minutes to circulate the cleaner.

- Turn off the engine and inspect for leaks.

- Dispose of the old fuel and cleaning materials properly.

Regularly cleaning the fuel system will help maintain your engine’s efficiency and prevent potential issues in the future. Incorporate this practice into your maintenance routine to ensure optimal performance.

Understanding Transmission Problems

Transmission issues can significantly impact the performance of your equipment, leading to reduced efficiency and potential mechanical failures. Recognizing the signs of transmission malfunction is essential for timely intervention and maintenance. This section will explore common transmission challenges and their symptoms, enabling you to diagnose problems effectively.

Common Symptoms of Transmission Issues

There are several indicators that may suggest the presence of transmission problems. Observing unusual behavior in your machinery can help pinpoint these issues early. Some typical signs include:

| Symptom | Description |

|---|---|

| Slipping Gears | When the equipment unexpectedly changes gears or fails to maintain a gear, it may indicate a transmission issue. |

| Unusual Noises | Grinding, whining, or clunking sounds can suggest internal transmission damage or wear. |

| Fluid Leaks | Pooling of transmission fluid underneath the machinery can signify a leak, which may lead to inadequate lubrication and overheating. |

| Delayed Engagement | If there is a noticeable lag when shifting from neutral to drive, this could indicate a problem within the transmission system. |

Causes of Transmission Malfunctions

Understanding the potential causes of transmission problems is crucial for effective troubleshooting. Common contributors to transmission malfunctions include:

| Cause | Details |

|---|---|

| Low Fluid Levels | Insufficient fluid can lead to overheating and inadequate lubrication, resulting in damage to the transmission components. |

| Worn Components | Over time, gears, clutches, and seals can wear down, leading to ineffective transmission operation. |

| Contaminated Fluid | Debris or dirt in the transmission fluid can cause damage to internal parts and affect overall performance. |

Blade Sharpening Techniques

Proper maintenance of cutting implements is crucial for achieving optimal performance. Keeping the edges sharp ensures efficient operation and extends the lifespan of your tools. This section will explore various methods and best practices for honing and maintaining sharpness, enabling users to work effectively and safely.

One of the most effective ways to sharpen blades is by using a sharpening stone. The process involves several steps:

| Step | Description |

|---|---|

| 1 | Choose the appropriate grit for your sharpening stone, with coarse grit for initial shaping and fine grit for finishing. |

| 2 | Secure the tool to prevent movement during sharpening. This can be done using a vise or clamp. |

| 3 | Maintain the correct angle while sharpening, typically between 20 and 30 degrees, to achieve the desired edge. |

| 4 | Use consistent strokes along the blade, applying even pressure to create a uniform edge. |

| 5 | Finish with a honing or polishing step to refine the edge and enhance cutting performance. |

Regularly inspecting and sharpening the blades not only improves functionality but also enhances safety by reducing the risk of accidents caused by dull cutting edges. Implementing these techniques can greatly improve your working experience and the overall effectiveness of your tools.

Electric Start System Repairs

The electric starting mechanism is a crucial component that enhances the convenience of operating gardening machinery. Ensuring this system functions correctly is vital for seamless use and efficiency. In this section, we will explore common issues and solutions related to this essential feature.

Identifying Common Issues

One of the primary problems encountered with electric starting systems is a lack of response when the ignition switch is engaged. This can result from a drained battery, corroded connections, or faulty wiring. Regularly checking the battery voltage and inspecting connections for wear can prevent these issues from escalating.

Conducting Basic Troubleshooting

To address the lack of power, first, examine the battery condition. If the battery is low, recharge or replace it as necessary. Additionally, ensure all connections are tight and free from corrosion. Cleaning the terminals and securing any loose wires can often resolve functionality problems. Should issues persist, further investigation of the starter motor and related components may be required.

Checking and Changing Belts

Maintaining the performance of your equipment involves regular inspection and replacement of essential components. Among these, the belts play a crucial role in ensuring smooth operation and efficiency. Properly functioning belts prevent slippage and wear, which can lead to further complications if neglected.

To check the condition of the belts: start by visually inspecting them for any signs of wear, such as fraying or cracking. Ensure that they are properly tensioned, as loose belts can slip during operation. If you notice any issues, it is advisable to replace them promptly to maintain optimal functionality.

When replacing belts: follow the manufacturer’s guidelines for removal and installation. Ensure that the new belts are the correct size and type for your equipment. Once installed, adjust the tension as needed to ensure proper operation. Regular checks and timely replacements will extend the lifespan of your machinery and enhance its performance.

Inspecting the Carburetor

Examining the fuel delivery system is crucial for ensuring optimal performance of your garden equipment. This component plays a vital role in mixing air and fuel, which directly affects the engine’s efficiency. A thorough inspection can help identify any issues that may hinder its functionality.

Signs of Malfunction

Before proceeding with the examination, it’s essential to be aware of the common indicators that may suggest a problem with the fuel delivery mechanism. Some signs include:

| Symptoms | Possible Causes |

|---|---|

| Engine difficulty starting | Clogged jets or improper fuel mixture |

| Inconsistent engine performance | Air leaks or damaged gaskets |

| Unusual fuel consumption | Faulty float or stuck needle valve |

Inspection Procedure

To conduct a proper examination, follow these steps: first, remove the air filter to gain access. Next, visually inspect for dirt or debris, then proceed to check the fuel lines for cracks or leaks. If necessary, disassemble the component for a more detailed cleaning and evaluation.

Adjusting Handlebar Alignment

Ensuring proper alignment of the handlebars is essential for achieving optimal control and comfort during operation. Misalignment can lead to difficulties in maneuverability and may cause strain during use. This section outlines the necessary steps to adjust the handlebar position effectively.

To begin, gather the necessary tools for the adjustment process. You will typically need:

- A suitable wrench

- A measuring tape

- Possibly a screwdriver for minor adjustments

Follow these steps to achieve proper alignment:

- Begin by inspecting the current position of the handlebars in relation to the body of the equipment.

- Loosen the securing bolts or clamps that hold the handlebars in place, allowing for adjustment.

- Carefully reposition the handlebars to achieve a straight alignment, ensuring they are parallel to the frame.

- Utilize the measuring tape to verify that both sides of the handlebars are equidistant from the frame.

- Tighten the bolts or clamps securely to maintain the new position, ensuring that there is no wobble.

Once the adjustment is complete, perform a test run to confirm that the handlebars are functioning correctly and that the alignment feels comfortable. Regular checks and adjustments will help maintain performance and enhance the user experience.

Safety Precautions for Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions must be taken before starting any work on machinery. This section outlines essential guidelines to follow when engaging in servicing activities.

General Guidelines

Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and sturdy footwear. Before beginning any task, familiarize yourself with the machinery and its components to avoid mishandling. It is also vital to work in a well-ventilated area, free from hazards such as flammable materials.

Maintenance Checklist

| Precaution | Description |

|---|---|

| Disconnect Power Source | Ensure the device is unplugged or the battery is removed to prevent accidental activation. |

| Use Tools Properly | Select the correct tools for the task and maintain them in good condition to avoid accidents. |

| Follow Manufacturer Instructions | Consult the guidelines provided by the manufacturer for specific safety information and recommendations. |

| Keep Workspace Organized | A tidy workspace minimizes the risk of slips, trips, and falls during servicing tasks. |