Over time, even the most reliable household devices may show signs of wear, affecting their performance and usability. This guide provides insights on how to bring your appliance back to optimal working order, helping you troubleshoot common issues and maintain its quality over the long term. Proper care and attention can often resolve issues, saving both time and resources.

In this section, you will find clear, step-by-step instructions for identifying and addressing typical malfunctions. From understanding which components may need attention to recognizing early indicators of potential issues, this guide aims to simplify the process of assessing and refreshing your device’s functionality.

Regular maintenance and prompt action are essential in keeping your appliance efficient and reliable. Follow along to learn helpful tips and practical methods to extend its lifespan and improve its overall performance.

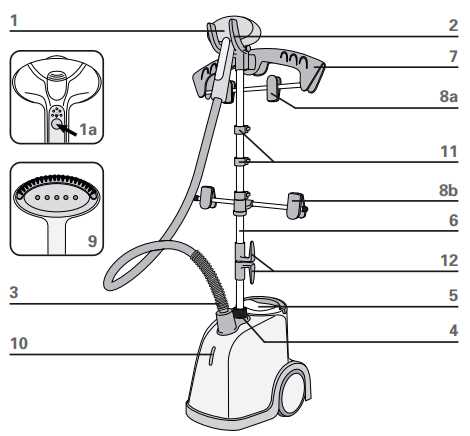

Efficient Maintenance Guide for Your Fabric Steamer

Proper care and upkeep extend the lifespan and efficiency of any garment-steaming appliance. Regular maintenance prevents common issues, ensuring smooth functionality and optimal performance over time. This guide highlights essential steps to keep your device working at its best.

Basic Cleaning Routine

Keeping the water reservoir and steam channels clear is fundamental to maintaining effectiveness. Follow these steps routinely:

- Empty the water reservoir after each use to prevent buildup.

- Rinse the reservoir with distilled water weekly.

- For mineral deposits, use a mild vinegar solution, filling the tank halfway, letting it sit for an hour, and rinsing thoroughly.

Preventing Mineral Accumulation

Mineral buildup from hard water can affect the device’s performance. To avoid this, consider these practices:

- Opt for distilled or filtered water whenever possible.

- If using tap water, perform a descaling treatment monthly to remove any deposits.

- Clean the soleplate regularly with a soft, damp cloth to prevent mineral spotting.

With consistent care, your garment-steaming tool will stay reliable and ready for use, preserving both fabrics and efficiency.

Common Issues with Steam Irons

When it comes to maintaining home appliances, a few recurring challenges are commonly encountered. Regular usage and exposure to high temperatures often lead to wear, causing specific difficulties that may affect performance. Understanding these potential problems can help with early identification and effective troubleshooting.

Water Leakage: One frequently reported issue is unwanted dripping during use. This can occur due to improper settings or when water accumulates in undesired areas, often related to maintenance lapses or blockages in the water flow system.

Uneven Heating: Another challenge is inconsistent temperature across the surface, which can affect the efficiency. This is typically caused by sediment buildup in heating components or issues within the internal wiring, which may require thorough cleaning or inspection.

Mineral Buildup: Appliances that utilize water may accumulate mineral deposits over time. This buildup can obstruct various parts, impacting overall functionality. Using filtered water and cleaning regularly can mitigate this common concern.

Button Malfunction: Usage over time may also cause button-related issues, including sticking or a lack of responsiveness. Often, this results from debris or dust inside the controls, which can be resolved with careful cleaning or part replacement.

Identifying Signs of Malfunction

Understanding the early indications of issues in your device can help prevent more significant problems over time. By recognizing subtle changes in performance and unexpected behaviors, you can address potential malfunctions promptly and ensure the equipment operates effectively for a longer period.

Common Performance Issues

One of the first signs of trouble often includes inconsistent heating, which may lead to uneven results. If you notice fluctuations in temperature or the device not maintaining its usual efficiency, it could indicate an underlying issue. Additionally, unusual sounds or vibrations might suggest internal components require attention.

Visual and Operational Clues

Visible wear, like minor leaks or cracks, should be taken seriously as they might worsen with time. Other indicators include a sudden change in the device’s response time or a noticeable decline in its smooth operation. Paying attention to these signs will help you maintain the appliance in optimal condition.

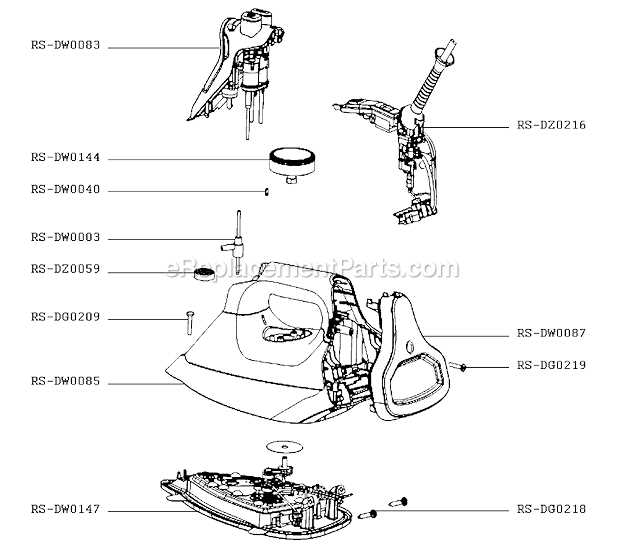

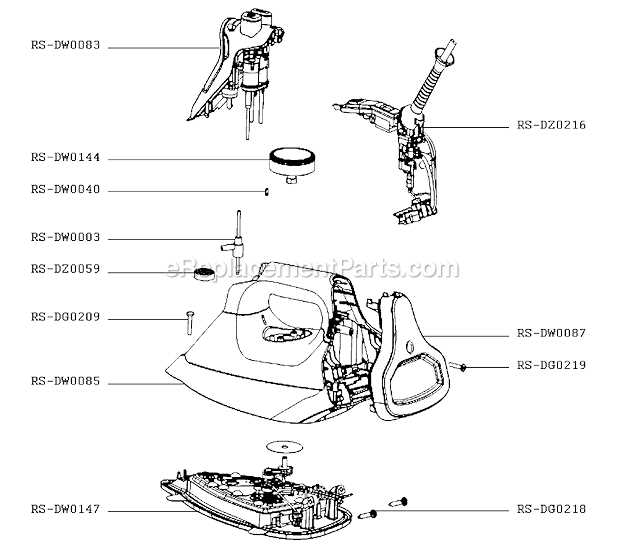

How to Disassemble a Clothes Pressing Device

Disassembling a household pressing device requires attention to detail and care to avoid damaging its internal components. Here is a step-by-step approach to help you safely dismantle it for maintenance or inspection purposes.

- Unplug the device and allow it to cool completely. Ensure it’s on a stable, flat surface with sufficient lighting.

- Turn the device upside down to access the baseplate. Locate and remove the screws securing the plate, often hidden under protective caps or covers.

- Gently pry the plate off using a plastic tool to avoid scratching. Avoid using sharp objects to prevent damage to the casing.

- With the baseplate removed, look for additional screws or fasteners holding the internal sections together. Remove these carefully and set them aside in a safe place.

- Slowly separate the upper casing from the body. Take note of any wires or small components attached; handle these parts delicately to avoid disconnection or damage.

- If further access to internal parts is needed, proceed with caution, examining each section and noting the layout for reassembly.

Throughout the disassembly process, it is important to handle each part carefully and keep track of removed screws and parts. This organized approach will make reassembly much smoother and reduce the risk of misplacing any components.

Essential Tools for Iron Repairs

For any home repair project, having the right equipment is crucial for efficient and safe work. When dealing with household appliances, specific tools allow for accurate adjustments, secure component handling, and ensure each step is properly executed without damaging delicate parts.

Basic Tools for Disassembly

Starting with the dismantling process, it’s helpful to have basic tools ready. These include small screwdrivers, pliers, and a soft cloth to protect surfaces. A precision screwdriver set can assist in accessing small screws, while pliers help with loosening bolts or other fasteners. A gentle cloth provides a safe area to place removed parts.

Testing and Inspection Tools

To examine and verify the condition of electrical elements, a few specialized tools become essential. A multimeter is highly useful for testing electrical continuity and voltage, ensuring components are functional. Additionally, a magnifying glass can aid in spotting minor wear or damage in small parts, helping to identify issues before reassembly.

| Tool |

Purpose |

| Precision Screwdriver Set |

Accessing small screws and precise disassembly |

| Pliers |

Cleaning the Water Tank Safely

Maintaining the cleanliness of the reservoir is essential for optimal performance and longevity of your appliance. Regular cleaning helps prevent the buildup of mineral deposits and ensures that the device operates efficiently. Here’s a guide on how to clean the water chamber without any risks.

Essential Tools and Materials

- Distilled water

- White vinegar

- A soft cloth or sponge

- Small brush (optional)

Step-by-Step Cleaning Process

- Ensure the appliance is turned off and unplugged to avoid any electrical hazards.

- Remove any remaining water from the tank. Tilt the device to ensure all liquid is drained.

- Prepare a cleaning solution by mixing equal parts of distilled water and white vinegar.

- Pour the mixture into the tank, filling it halfway.

- Let the solution sit for about 30 minutes to dissolve any mineral deposits.

- Gently shake the device to distribute the cleaning solution, then empty the tank completely.

- Rinse the reservoir thoroughly with distilled water to remove any vinegar residue.

- Wipe the exterior with a soft cloth to keep it clean and dry.

Regularly cleaning the water compartment not only enhances functionality but also extends the life of your appliance. Following these steps will ensure safe maintenance and prevent potential issues.

Replacing a Broken Power Cord

When an appliance experiences power issues, one common culprit is a damaged electrical cable. This section provides guidance on how to replace a faulty cord to restore functionality. A well-functioning cord is crucial for ensuring safety and performance in any electrical device.

Tools and Materials Needed

- New power cord

- Screwdriver (appropriate size)

- Wire stripper

- Electrical tape or heat shrink tubing

- Multimeter (optional for testing)

Steps to Replace the Power Cord

- Unplug the device from the wall socket to ensure safety.

- Use the screwdriver to remove any screws securing the cover of the appliance.

- Carefully detach the old power cord from its connection points inside the device.

- Strip the ends of the new power cord to expose the wires.

- Connect the new cord to the appropriate terminals, ensuring correct polarity.

- Secure the connections with electrical tape or heat shrink tubing to prevent exposure.

- Reassemble the appliance by placing the cover back and securing it with screws.

- Plug the device back into the socket and test for proper operation.

Fixing Steam Output Problems

Issues with moisture emission can significantly affect the efficiency of the appliance. Identifying and resolving these problems ensures optimal performance and helps in achieving better results during the ironing process.

Common Causes

- Clogged vents or nozzles may restrict the flow of moisture.

- Inadequate water levels can lead to insufficient output.

- Incorrect temperature settings might hinder the vaporization process.

- Worn-out components can result in malfunctioning mechanisms.

Steps to Resolve Issues

- Check the water reservoir and fill it to the appropriate level.

- Inspect the vents and nozzles for any blockages. Clean them carefully.

- Adjust the temperature settings to match the fabric type being used.

- Examine the appliance for any worn-out parts that may need replacement.

- Run the device for a few minutes to see if the issue persists.

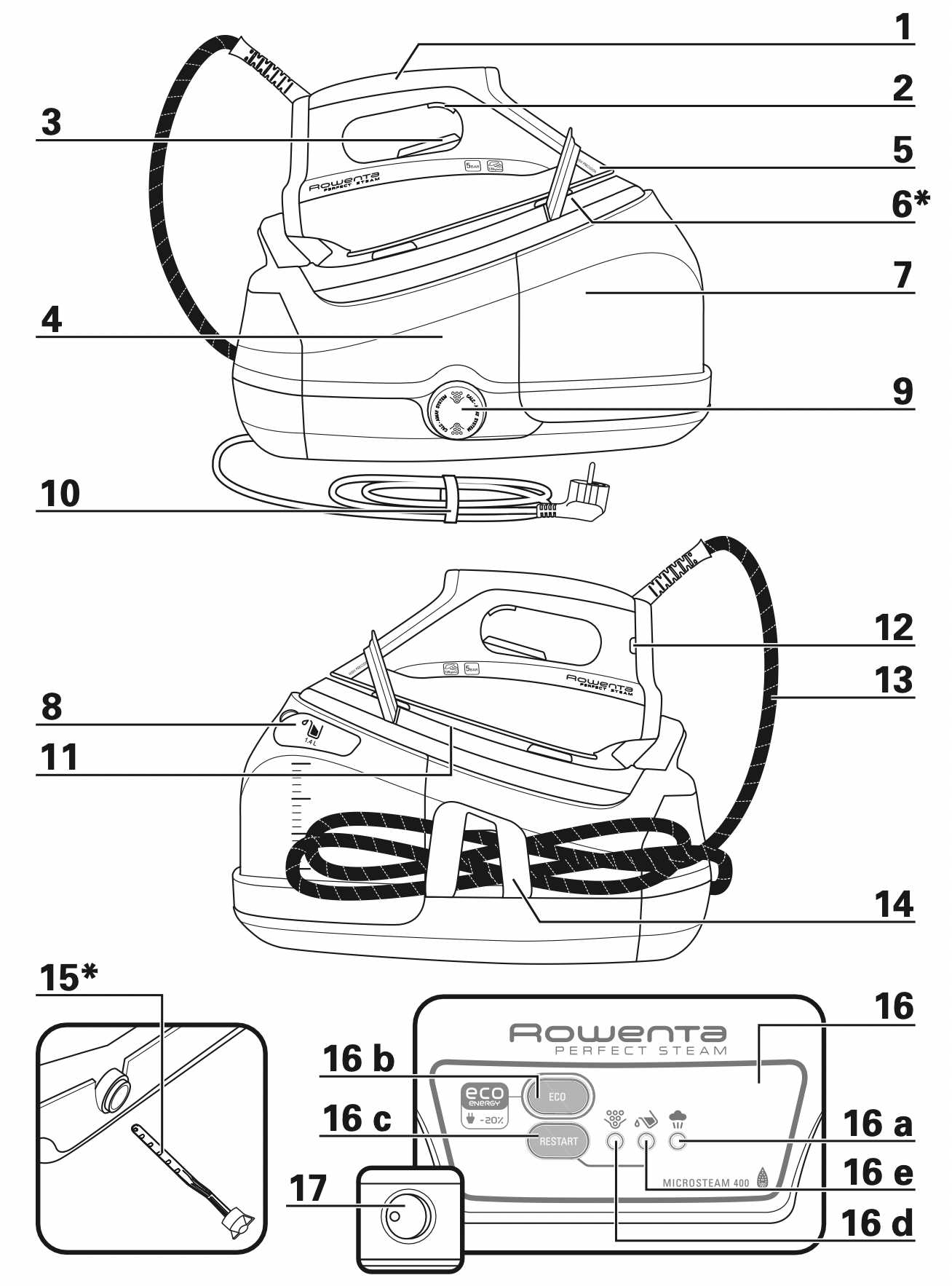

Handling Thermostat Adjustments

Thermostat adjustments are essential for maintaining optimal performance in heating appliances. Understanding how to calibrate these settings can enhance the functionality and efficiency of your device. This section will guide you through the process of making necessary modifications to ensure accurate temperature control.

Identifying the Thermostat Location

Before making any adjustments, it’s crucial to locate the thermostat on your appliance. Typically, it can be found on the body or near the base. Ensure the unit is unplugged to avoid any accidents during inspection.

Making the Adjustments

Once you have identified the thermostat, gently turn the adjustment knob to modify the temperature setting. Always start with small increments to avoid drastic changes. After making adjustments, plug in the appliance and allow it to reach the desired temperature, checking the functionality as you go. Regular checks on the thermostat will help maintain consistent performance over time.

Tips for Avoiding Overheating

Preventing excessive heat is essential for ensuring the longevity and effective performance of your appliance. By following a few straightforward practices, you can minimize the risk of overheating and enhance your user experience.

Firstly, always use the device according to the manufacturer’s specifications. Make sure to adjust the temperature settings based on the fabric you are working with. Higher settings are unnecessary for delicate materials and can lead to overheating.

Additionally, keep the appliance clean and free from any build-up that might obstruct airflow. Regular maintenance ensures efficient operation and helps prevent overheating. Moreover, avoid leaving the appliance unattended for long periods, as this can increase the risk of overheating.

Finally, always check the power cord and plug for any signs of damage. A faulty power supply can lead to irregular heating. By being vigilant and proactive, you can safeguard your device from overheating issues.

Reassembling Your Iron Correctly

Putting your appliance back together properly is crucial for its efficient operation and longevity. This process involves ensuring that all components are aligned and secured correctly. By following the right steps, you can avoid potential issues and enhance the performance of your device.

Steps to Follow

Start by carefully inspecting each part, making sure there is no damage or wear that could affect functionality. Begin reassembling by connecting the main body and ensuring all internal components are seated correctly. Follow the manufacturer’s guidelines for securing screws and attachments to prevent any loose parts.

Final Checks

After reassembly, double-check that all elements are securely in place. Look for any irregularities or misalignments that could hinder operation. Testing the appliance briefly can help confirm that it is functioning as intended before putting it back into regular use.

Testing for Optimal Performance

Ensuring that your appliance operates efficiently involves a series of evaluations to identify any potential issues affecting its functionality. These assessments can help maintain peak efficiency and prolong the life of the device, ensuring it meets your expectations during use.

Initial Inspection

Start by conducting a thorough visual check of the device. Look for any signs of wear, damage, or obstruction. Ensure that all components are securely connected and that there are no visible leaks. This preliminary assessment sets the stage for more detailed performance tests.

Performance Evaluation

Next, conduct a functionality test. This may involve examining the temperature settings, water distribution, and overall operation. Utilize a suitable fabric to gauge how well the device handles different materials. Pay attention to any irregularities such as uneven heating or insufficient moisture release, which could indicate underlying issues.

By following these steps, you can effectively determine the operational state of your appliance and address any concerns before they escalate.