This section provides essential insights into the upkeep and troubleshooting of hydraulic lifting devices. Understanding the mechanisms and components of these tools is crucial for ensuring their longevity and optimal performance.

Regular maintenance not only enhances the efficiency of lifting systems but also contributes to the safety of operations. In this guide, users will find valuable information on identifying common issues, performing routine checks, and implementing effective solutions to keep the equipment functioning smoothly.

By following the outlined procedures, operators can minimize downtime and reduce the risk of unexpected failures. This comprehensive resource aims to empower users with the knowledge needed to maintain their lifting apparatus effectively.

Understanding Common Pallet Jack Issues

When utilizing equipment designed for material handling, various complications may arise that can hinder performance and efficiency. Recognizing these common challenges is essential for maintaining optimal operation and ensuring safety in the workplace.

Below are some frequent concerns encountered with such machinery:

- Hydraulic Problems: Issues with lifting capacity or uneven movements often stem from hydraulic fluid leaks or air trapped in the system.

- Wheel Wear: Over time, wheels can become worn or damaged, affecting maneuverability and stability.

- Fork Misalignment: Misalignment can lead to difficulty in positioning and loading items, causing inefficiency during operations.

- Handle Issues: Problems with the handle, such as stiffness or failure to engage the lifting mechanism, can disrupt usage.

- Brake Malfunctions: Ineffective braking can result from worn components or fluid leaks, compromising safety.

Addressing these issues promptly can prolong the lifespan of the equipment and enhance its performance. Regular maintenance and inspections are recommended to mitigate these common challenges.

Tools Required for Effective Repairs

Ensuring efficient maintenance and restoration tasks requires a variety of essential instruments. The right tools not only facilitate the process but also enhance the quality of the outcomes. Familiarizing oneself with the necessary equipment can significantly improve the efficiency and effectiveness of the work performed.

Essential Hand Tools

Basic hand tools are indispensable for any maintenance job. Wrenches, screwdrivers, and pliers are fundamental in addressing various tasks, allowing for adjustments and component replacements. Additionally, having a reliable hammer and a set of torque wrenches is crucial for securing and loosening fasteners without causing damage.

Specialized Equipment

Incorporating specialized instruments can further enhance repair capabilities. Tools such as hydraulic lifts and diagnostic devices are beneficial for identifying issues and facilitating access to hard-to-reach areas. Moreover, a comprehensive toolkit that includes various attachments and accessories will ensure that every task can be approached with confidence.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues associated with handling equipment. By following these organized steps, users can efficiently pinpoint malfunctions and implement effective solutions.

Start by observing the equipment in operation. Look for unusual noises, irregular movements, or any signs of malfunction. Document these observations as they can provide crucial clues.

Next, check the power source. Ensure that all connections are secure and that the power supply is functioning properly. Inspect the battery, if applicable, to confirm it is charged and in good condition.

Examine the hydraulic system for leaks or blockages. Inspect hoses and connections, ensuring they are intact and not damaged. If fluid levels are low, replenish them according to the specifications.

Inspect the wheels and casters for wear or debris that might hinder movement. Ensure that they rotate freely and are properly aligned. Cleaning and lubricating these components can often resolve mobility issues.

If the equipment still does not function correctly, consult the troubleshooting charts for guidance on specific problems. These resources can provide detailed steps tailored to identified symptoms.

Finally, if issues persist despite following these steps, consider seeking assistance from a qualified technician. They can provide expert analysis and solutions for complex problems that may require specialized knowledge.

Replacing Worn-Out Wheels and Rollers

Over time, the components that facilitate movement can wear down, impacting performance and maneuverability. Addressing this issue promptly is essential to maintain efficiency and ensure safe operation. This section provides guidance on how to effectively replace these crucial elements.

Identifying Worn Components

Begin by inspecting the wheels and rollers for signs of damage or excessive wear. Look for uneven surfaces, cracks, or significant flat spots. If the wheels no longer rotate smoothly or if you notice instability during use, it’s likely time for a replacement.

Gathering Necessary Tools

Before proceeding, ensure you have the appropriate tools on hand. Commonly required items include a socket wrench, screwdrivers, and replacement wheels or rollers that match the specifications of the device.

Removing Old Components

Carefully lift the unit to access the wheels and rollers. Use the socket wrench to remove any fasteners holding the worn components in place. Keep track of all hardware for reinstallation.

Installing New Wheels and Rollers

Align the new wheels or rollers with the mounting points. Secure them using the previously removed fasteners, ensuring they are tightened properly for stability. Double-check that each component spins freely without obstruction.

Final Inspection

After installation, conduct a thorough inspection to ensure everything is in place and functioning as intended. Test the unit by moving it forward and backward to confirm smooth operation. Regular maintenance checks will help prolong the lifespan of the new components.

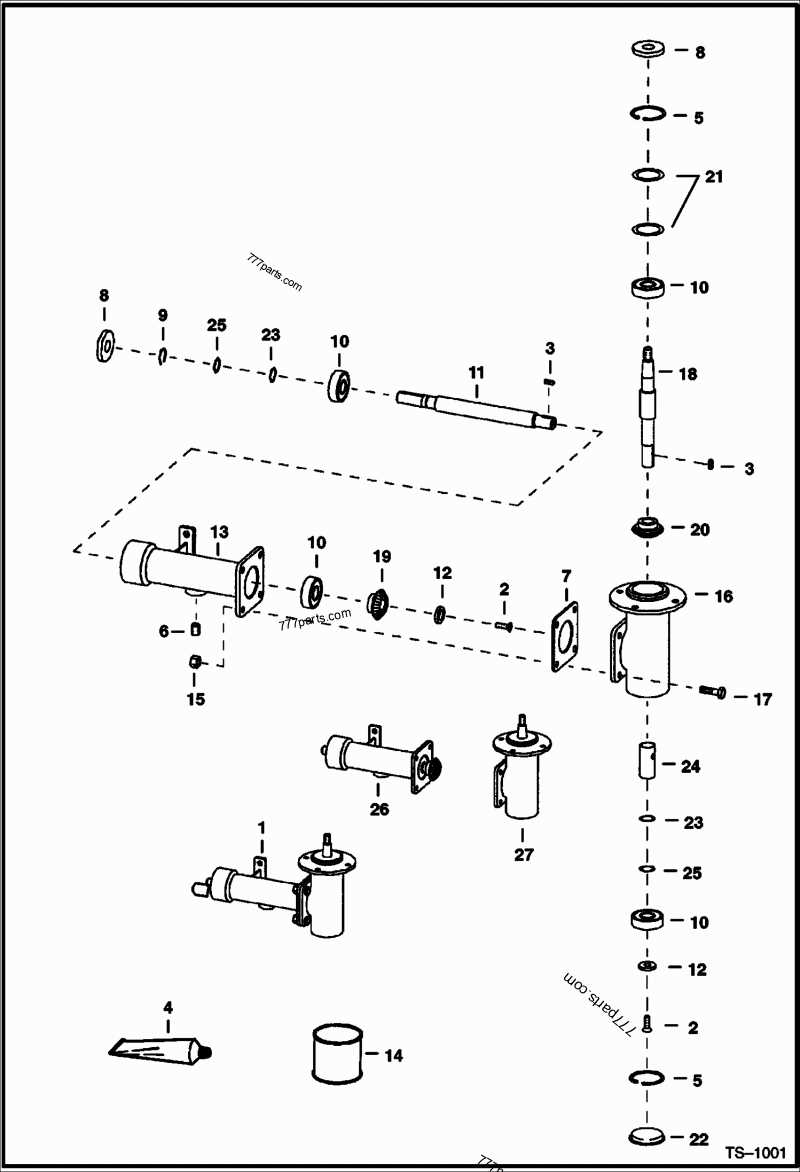

Hydraulic System Maintenance Techniques

Maintaining a hydraulic system is essential for ensuring its efficiency and longevity. Regular attention to this system can prevent costly breakdowns and enhance operational performance. Below are key techniques to effectively maintain hydraulic components.

- Regular Fluid Checks: Monitor fluid levels frequently to ensure optimal performance. Low fluid can lead to increased wear and tear on the system.

- Contamination Prevention: Keep the hydraulic fluid clean by using proper filtration methods. Contaminants can significantly impair the system’s functionality.

- Leak Detection: Regularly inspect for any signs of leaks in hoses and connections. Addressing leaks promptly can prevent fluid loss and maintain pressure.

- Seal Inspection: Check seals and gaskets for wear or damage. Replacing worn seals can help maintain pressure and prevent fluid escape.

- Routine Testing: Conduct periodic performance tests to assess the system’s efficiency. Identifying issues early can save time and resources.

Implementing these maintenance techniques will contribute to the smooth operation of hydraulic systems, ensuring they remain reliable and effective over time.

Electrical Components and Their Functions

This section explores the essential electrical elements that facilitate the efficient operation of handling equipment. Understanding these components and their roles is crucial for optimal functionality and maintenance.

Key Electrical Elements

- Power Supply: Provides the necessary energy to operate various functions.

- Control Unit: Manages the overall operation and coordination of different systems.

- Motors: Drive the movement of the equipment, converting electrical energy into mechanical motion.

- Sensors: Monitor parameters such as weight and position, ensuring accurate performance.

- Wiring: Connects components, allowing for efficient electrical flow and communication.

Functions of Each Component

- Power Supply: Converts alternating current (AC) to direct current (DC) for equipment usage.

- Control Unit: Processes input signals and sends commands to other components.

- Motors: Enable lifting and lowering actions, as well as forward and backward movement.

- Sensors: Provide feedback for safety and operational efficiency.

- Wiring: Ensures secure and reliable connections, reducing the risk of electrical faults.

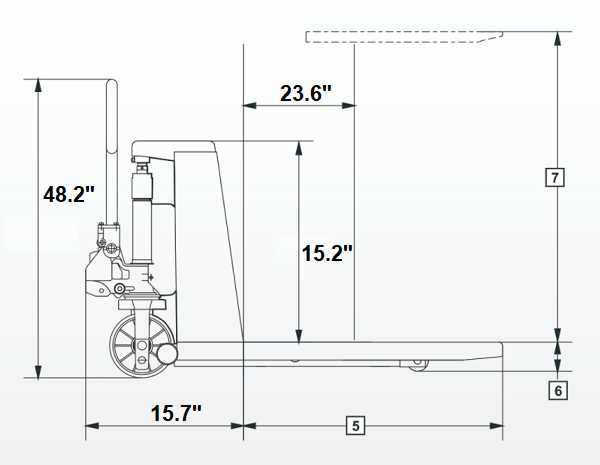

Adjusting Lift Height Mechanisms

Ensuring optimal functionality of elevation systems is crucial for efficient operations. This process involves fine-tuning various components that dictate how high the platform can rise. Proper adjustments not only enhance performance but also contribute to safety during use.

To initiate the adjustment, it is essential to inspect the hydraulic cylinder and related fittings. Checking for any wear or damage will help identify necessary repairs before proceeding with height modifications. Once confirmed, locate the adjustment screws or knobs that regulate lift height.

When adjusting, turn the screws gradually, monitoring the elevation during each increment. It is vital to maintain balance and ensure that the system operates smoothly without excessive resistance or unexpected movements. Periodic testing after each adjustment can help achieve the desired lift height effectively.

Finally, once the ideal elevation is reached, secure all components and conduct a thorough inspection. Regular maintenance of these mechanisms will prolong their lifespan and enhance overall functionality, ensuring reliable performance in various applications.

Checking for Frame Integrity

Ensuring the structural soundness of the lifting mechanism is crucial for safe and efficient operation. A thorough inspection helps identify any signs of wear, damage, or deformation that could compromise performance and safety. Regular assessments can prevent costly breakdowns and enhance longevity.

Visual Inspection

Begin by conducting a visual examination of the framework. Look for any noticeable cracks, dents, or rust that could indicate underlying issues. Pay attention to welds and joints, as these are critical areas that often bear the brunt of stress during operation.

Structural Assessment

In addition to visual checks, perform a structural assessment to verify the overall integrity. Use a measuring tool to check alignment and ensure that all components are securely attached. Any misalignment can lead to uneven weight distribution and operational hazards.

| Inspection Aspect | Action Required |

|---|---|

| Cracks and Dents | Repair or replace affected parts |

| Rust Formation | Sand down and apply protective coating |

| Weld Integrity | Reinforce or redo weak welds |

| Alignment Issues | Realign and secure components |

Safety Protocols During Repairs

Ensuring a safe working environment is crucial when addressing maintenance tasks. Proper precautions help prevent accidents and ensure the well-being of all personnel involved in the process.

Essential Guidelines

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats.

- Ensure the work area is well-ventilated to avoid inhaling harmful fumes.

- Keep the workspace organized and free from hazards to minimize risks of trips or falls.

Pre-Operation Checks

- Inspect tools and equipment for damage before use.

- Confirm that emergency stop mechanisms are functional.

- Review safety procedures with all team members prior to starting work.

Preventative Maintenance Best Practices

Implementing effective upkeep strategies is crucial for ensuring the longevity and reliability of equipment. Regular attention to maintenance tasks not only enhances performance but also minimizes the risk of unexpected breakdowns, leading to increased productivity and safety in the workplace.

Regular Inspections: Conduct thorough assessments at scheduled intervals to identify wear and tear before they escalate into significant issues. Look for signs of damage, loose components, or irregularities that could affect functionality.

Lubrication: Proper lubrication of moving parts reduces friction and prolongs the life of the machinery. Adhere to the manufacturer’s recommendations regarding lubrication schedules and types of lubricants to use.

Cleaning: Keep all surfaces clean and free of debris. Accumulated dirt can hinder operation and lead to mechanical failures. Regularly clean critical components to ensure optimal performance.

Battery Maintenance: If the equipment relies on batteries, monitor their charge levels and condition. Follow guidelines for maintenance, including proper charging techniques and storage practices, to extend battery life.

Documentation: Maintain detailed records of all maintenance activities. Document inspections, repairs, and parts replacements to establish a history that can aid in troubleshooting and planning future maintenance efforts.

By adhering to these best practices, operators can enhance the performance and reliability of their equipment, ultimately reducing downtime and associated costs.

Finding Replacement Parts Efficiently

Locating components for equipment can be a straightforward process if approached systematically. Understanding where to search and what resources to utilize will streamline the acquisition of necessary elements. This section outlines effective strategies to ensure quick access to the parts you need.

Utilizing Online Resources

The internet offers a vast array of platforms where spare parts can be sourced. Manufacturer websites often provide catalogs, while specialized retailers may have a wider selection. Additionally, online marketplaces can connect you with various sellers.

Local Suppliers and Distributors

Exploring nearby suppliers is also beneficial. Many local distributors maintain an inventory of essential components and can offer immediate assistance. Building relationships with these providers can lead to quicker turnaround times and personalized support.

| Resource Type | Advantages |

|---|---|

| Online Retailers | Wide selection, often competitive pricing |

| Manufacturer Websites | Direct access to original components |

| Local Suppliers | Immediate availability and personalized service |

| Online Marketplaces | Variety of sellers, potential for good deals |