Ensuring the optimal performance of your two-wheeled vehicle is essential for a smooth riding experience. This section provides a comprehensive overview of the essential care practices necessary to keep your machine in peak condition. From routine checks to addressing common issues, a solid understanding of maintenance can significantly extend the life of your vehicle.

By familiarizing yourself with key components and their functions, you will be better equipped to handle various challenges that may arise. The information outlined here emphasizes the importance of preventive measures and highlights straightforward troubleshooting techniques. Whether you’re a novice or an experienced enthusiast, following these guidelines will enhance your knowledge and confidence in maintaining your equipment.

With the right approach and dedication, you can achieve a reliable and enjoyable riding experience. Taking the time to engage with the maintenance process not only fosters a deeper connection with your vehicle but also ensures safety on the road. This guide is designed to empower you with the skills needed to address issues effectively and maintain your machine’s performance over time.

Understanding Roketa MC 08 50 Basics

This section aims to provide an overview of essential aspects related to a specific type of two-wheeled vehicle. It highlights the fundamental components, functionality, and features that users should be familiar with to enhance their experience and ensure optimal performance.

At the core of this vehicle lies a compact engine, which is designed for efficiency and reliability. Understanding its operation can significantly impact maintenance and usability. Key elements include the fuel system, ignition mechanism, and exhaust setup, each playing a vital role in overall functionality.

Moreover, grasping the significance of the transmission system is crucial for smooth rides and effective power delivery. Knowledge of the braking system is equally important, as it directly affects safety and control. Users should also be aware of the importance of regular inspections to identify wear and tear in various components.

In summary, familiarizing oneself with these foundational concepts will not only improve the riding experience but also contribute to the longevity of the vehicle.

Common Issues with Roketa MC 08 50

The vehicle may experience several frequent problems that could affect its performance and reliability. Understanding these issues can help in identifying and resolving them effectively, ensuring a smoother operation and enhancing the overall driving experience.

One common issue is related to the fuel system. Clogs in the fuel lines or a malfunctioning fuel pump can lead to insufficient fuel delivery, resulting in poor engine performance. Regular checks and maintenance of the fuel system components are crucial.

Another prevalent concern involves the electrical system. Faulty wiring or issues with the battery can lead to starting difficulties or intermittent electrical failures. Ensuring all connections are secure and the battery is in good condition can mitigate these problems.

Additionally, the braking system may present challenges, such as squeaking noises or reduced stopping power. This often indicates worn brake pads or fluid leaks. Timely inspections and replacements are essential for maintaining safety on the road.

Lastly, tire wear and alignment problems can impact handling and fuel efficiency. Regular tire rotation and alignment checks can prevent uneven wear and enhance driving stability.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right set of instruments is crucial for achieving optimal results. Properly equipped, individuals can effectively address various challenges and ensure that the components function smoothly. A well-organized toolkit not only facilitates the work but also enhances safety and efficiency.

Basic Hand Tools are fundamental in any toolkit. A variety of wrenches, screwdrivers, and pliers can tackle most tasks. Ensure that these tools are of good quality and suitable for the specific job at hand.

Specialty Instruments may be required for more intricate procedures. These can include torque wrenches, multimeters, and compression testers, which help diagnose issues that standard tools might not address effectively.

Safety Gear is another essential component of the toolkit. Protective goggles, gloves, and masks should be worn to prevent injuries during maintenance activities. Always prioritize personal safety to avoid accidents.

Finally, having a workbench or stable surface to operate on can significantly ease the process. A well-lit area with ample space allows for better visibility and organization, reducing the chances of losing small components during the work.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the optimal performance and longevity of your vehicle. Regular upkeep is essential for preventing issues and enhancing efficiency. Following a structured maintenance routine can help you identify potential problems early and address them effectively.

Begin by inspecting fluid levels regularly, including oil, coolant, and brake fluid. Keeping these fluids at the appropriate levels is vital for the smooth operation of the engine and other critical components.

Next, check the tire pressure and tread depth to ensure proper handling and safety. Maintaining the correct pressure enhances fuel efficiency and extends tire life.

Additionally, regularly examine the brakes for wear and replace them as necessary. Ensuring that your braking system is in top condition is crucial for your safety and that of others on the road.

Lastly, schedule periodic inspections of the electrical system, including lights and signals, to guarantee visibility and communication with other drivers. Address any issues promptly to maintain safety and functionality.

How to Troubleshoot Engine Problems

Identifying issues with an engine can be a challenging yet crucial task. Understanding common symptoms and applying systematic approaches can help in pinpointing the root cause of performance problems. This section provides guidance on recognizing engine difficulties and suggests effective troubleshooting steps.

Common Symptoms to Watch For

- Difficulty starting the engine

- Unusual noises during operation

- Excessive smoke or odors

- Poor acceleration or stalling

- Unexpected fluctuations in engine temperature

Troubleshooting Steps

- Check the fuel supply and ensure there is enough fuel in the tank.

- Examine electrical connections, including the battery and ignition system, for any signs of damage or corrosion.

- Inspect air filters and intake systems for blockages that may hinder airflow.

- Look for any leaks in the cooling system that could affect performance.

- Review engine oil levels and quality, as inadequate lubrication can lead to significant issues.

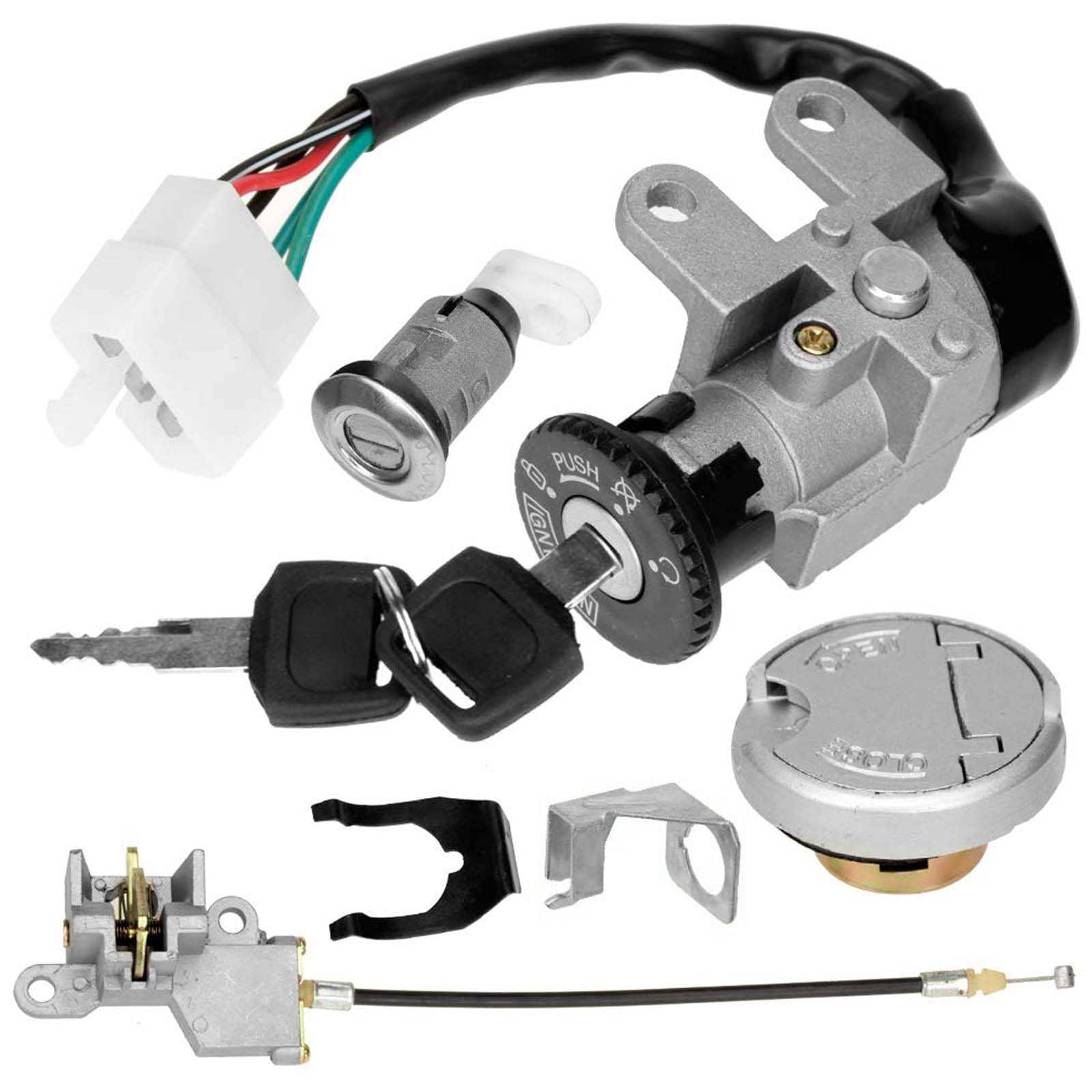

Electrical System Repair Techniques

Maintaining and troubleshooting the electrical system of a vehicle is essential for ensuring optimal performance and safety. Understanding the core components and their functions helps in diagnosing issues effectively. Proper techniques can enhance longevity and reliability, providing peace of mind for the user.

When addressing electrical faults, it is crucial to start with a systematic approach. Begin by inspecting all wiring and connections for signs of wear, corrosion, or damage. A multimeter can be invaluable in testing voltage and continuity, allowing for precise identification of problematic areas.

In cases where components are malfunctioning, consider replacing them with high-quality alternatives to ensure compatibility and efficiency. Regular maintenance, including cleaning connections and checking fuses, can prevent many common issues from arising.

Documentation of previous work and repairs assists in tracking recurring problems, enabling a more focused strategy for future interventions. By employing these methods, users can maintain the integrity of their vehicle’s electrical system and enhance its overall functionality.

Replacing the Fuel System Components

The fuel system is a critical aspect of any engine’s performance. Ensuring its components are functioning correctly is essential for optimal operation. This section outlines the process of replacing essential elements within the fuel system, which may include filters, pumps, and lines, thereby enhancing the efficiency and reliability of the engine.

Before commencing the replacement, it’s vital to gather the necessary tools and components. A proper understanding of the system will facilitate a smooth and efficient replacement process.

| Component | Description | Replacement Steps |

|---|---|---|

| Fuel Filter | Removes impurities from the fuel to ensure clean fuel delivery. | 1. Locate the filter. 2. Disconnect fuel lines. 3. Remove and replace the filter. 4. Reconnect fuel lines. |

| Fuel Pump | Delivers fuel from the tank to the engine at the required pressure. | 1. Disconnect the battery. 2. Remove the pump assembly. 3. Install the new pump. 4. Reconnect the battery. |

| Fuel Lines | Transport fuel from the tank to the engine and back. | 1. Check for leaks and damage. 2. Disconnect old lines. 3. Install new lines. 4. Ensure all connections are secure. |

Brake System Inspection Procedures

The brake system is a critical component for ensuring safe operation and control of any vehicle. Regular inspection of this system is essential to identify wear, damage, or malfunctions that could compromise performance. Following systematic procedures can help maintain optimal braking efficiency and enhance safety.

Visual Inspection

Begin with a thorough visual examination of the brake components. Look for any signs of wear, such as cracks or leaks in the brake lines and pads. Check the condition of the rotors or drums, ensuring they are free from deep grooves or discoloration. Pay attention to the brake fluid reservoir; it should be filled to the recommended level and free from contamination.

Functional Testing

After completing the visual assessment, conduct a functional test of the braking system. Start by applying the brakes at low speeds to gauge their responsiveness. Listen for any unusual noises, such as grinding or squeaking, which may indicate the need for replacement parts. Ensure that the brake pedal feels firm and does not sink to the floor when pressed, as this could suggest air in the brake lines or a fluid leak.

Transmission Adjustments and Repairs

This section covers the essential aspects of tuning and fixing the transmission system of your vehicle. Proper alignment and function of the transmission are crucial for optimal performance and longevity. Addressing any issues promptly can prevent more significant problems down the line and ensure a smoother driving experience.

Regular maintenance is vital to keep the transmission functioning correctly. It involves checking fluid levels, adjusting cables, and inspecting for wear and tear. Below is a summary of the common adjustments and necessary actions for transmission upkeep:

| Action | Description | Frequency |

|---|---|---|

| Fluid Level Check | Ensure the transmission fluid is at the correct level for optimal lubrication. | Monthly |

| Cable Adjustment | Adjust the shift cables to ensure precise gear engagement. | As needed |

| Seal Inspection | Check for leaks around seals and gaskets; replace if necessary. | Every 6 months |

| Filter Replacement | Replace the transmission filter to prevent debris buildup. | Every 30,000 miles |

By adhering to these guidelines, you can enhance the reliability of the transmission system and extend its operational lifespan. Regular checks and adjustments are the keys to maintaining excellent performance.

Wiring Diagrams for Easy Reference

Wiring diagrams serve as essential tools for understanding electrical connections within various systems. They provide visual representations that help users quickly identify circuits, components, and their interrelationships. Utilizing these diagrams can greatly enhance troubleshooting efficiency and facilitate maintenance efforts.

Understanding the Components

To effectively use wiring diagrams, it’s crucial to familiarize oneself with common symbols and terminology. Each symbol represents a specific component, such as resistors, capacitors, or connectors. Recognizing these symbols allows for a clearer interpretation of the diagrams, enabling smoother navigation through the electrical layout.

Sample Wiring Diagram

| Component | Description | Symbol |

|---|---|---|

| Battery | Stores electrical energy | ⚫ |

| Resistor | Limits current flow | ⎕ |

| Capacitor | Stores and releases energy | || |

| Ground | Reference point for voltage | ⏚ |

Preventive Measures for Longevity

Maintaining optimal performance and extending the lifespan of any vehicle requires proactive strategies. By adopting a routine of care and attention, owners can significantly reduce the likelihood of issues arising, ensuring a smoother and more reliable experience. This section outlines essential practices that can enhance durability and functionality over time.

Regular Maintenance Checks

Frequent inspections play a crucial role in identifying potential problems before they escalate. Schedule periodic reviews of key components such as the engine, transmission, and brakes. Ensure that all fluids are at appropriate levels and replace filters as needed. Staying vigilant can prevent minor concerns from becoming major repairs.

Proper Storage Conditions

Storing the vehicle in a suitable environment is vital for its preservation. Keep it in a cool, dry place away from direct sunlight and extreme weather conditions. Protecting the exterior from harsh elements helps maintain its finish, while avoiding moisture accumulation prevents corrosion. This simple step can significantly enhance the overall longevity of the machine.

Finding Replacement Parts Efficiently

Locating the right components for your vehicle can significantly enhance its performance and longevity. Streamlining this process not only saves time but also ensures that you obtain high-quality parts that fit seamlessly. Below are some effective strategies for sourcing the necessary elements efficiently.

- Online Marketplaces: Explore various e-commerce platforms dedicated to automotive parts. These sites often provide extensive catalogs, competitive pricing, and customer reviews.

- Local Retailers: Visit nearby automotive supply stores. Engaging with knowledgeable staff can help you find suitable parts and receive valuable advice.

- Specialized Forums: Join online communities and discussion boards focused on your vehicle type. Members frequently share recommendations and sources for hard-to-find components.

- Manufacturer Websites: Check official websites of parts manufacturers. They often list authorized dealers and provide detailed product information.

- Junkyards and Salvage Yards: Consider visiting local junkyards. These locations can be treasure troves for second-hand parts that are still in good condition.

Utilizing these resources can facilitate a smoother search for replacement parts, ultimately contributing to the effective maintenance of your vehicle.

Resources for Further Assistance

When seeking additional guidance or support for your vehicle, various options are available to enhance your understanding and skills. These resources can provide valuable insights and information, ensuring that you have access to the necessary tools for effective maintenance and troubleshooting.

Online Forums and Communities

Engaging with online platforms can be highly beneficial for gathering information from fellow enthusiasts and experts. These communities often share experiences, solutions, and tips that can aid in resolving issues or enhancing performance.

Instructional Videos

Video tutorials offer a visual and practical approach to learning. They can demonstrate various procedures and techniques, making complex tasks easier to comprehend and execute.

| Resource Type | Description | Examples |

|---|---|---|

| Forums | Online communities where users discuss experiences and solutions. | Dedicated vehicle forums, social media groups |

| Videos | Visual tutorials demonstrating maintenance and repair techniques. | YouTube channels, educational websites |

| Books | Printed or digital guides providing comprehensive information. | Manuals, maintenance books |

| Workshops | Hands-on training sessions for practical experience. | Local classes, community colleges |