Ensuring the optimal functionality of your outdoor machinery is essential for effective yard care. This segment focuses on providing valuable insights into troubleshooting and enhancing the performance of your equipment. Whether you are dealing with minor adjustments or more significant challenges, understanding the nuances of your tools will lead to better results.

Throughout this guide, you will discover practical advice aimed at helping you navigate common issues and enhance the longevity of your equipment. From identifying potential problems to implementing solutions, each step is designed to empower you with the knowledge needed for effective upkeep.

By following the suggested approaches, you can ensure your machinery operates smoothly and efficiently, enabling you to maintain a pristine landscape with ease. The content is structured to cater to both novice users and seasoned enthusiasts, ensuring that all readers find valuable information tailored to their needs.

Essential Tools for MTD Mower Repair

When maintaining outdoor equipment, having the right instruments is crucial for achieving efficient and effective results. This section highlights the key implements that will assist in addressing common challenges associated with these machines.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners. |

| Screwdrivers | To work with various types of screws, essential for disassembly. |

| Wrenches | Useful for gripping and turning nuts and bolts. |

| Torque Wrench | To apply a specific torque to fasteners, ensuring proper tightness. |

| Pliers | For gripping, bending, and cutting wires or components. |

| Multimeter | To measure voltage, current, and resistance for electrical diagnostics. |

| Cleaning Supplies | For maintaining cleanliness and preventing debris buildup. |

| Safety Gear | Includes gloves and goggles to protect the user during tasks. |

Utilizing the right assortment of tools enhances efficiency and ensures that tasks are performed correctly, ultimately extending the lifespan of the equipment.

Understanding Common Mechanical Issues

When operating outdoor lawn equipment, various mechanical challenges can arise, affecting performance and functionality. Recognizing these common problems is essential for ensuring longevity and optimal operation.

- Engine Performance:

- Difficulty starting

- Uneven power delivery

- Excessive vibration

- Transmission Troubles:

- Slipping gears

- Inconsistent speed control

- Unusual noises during operation

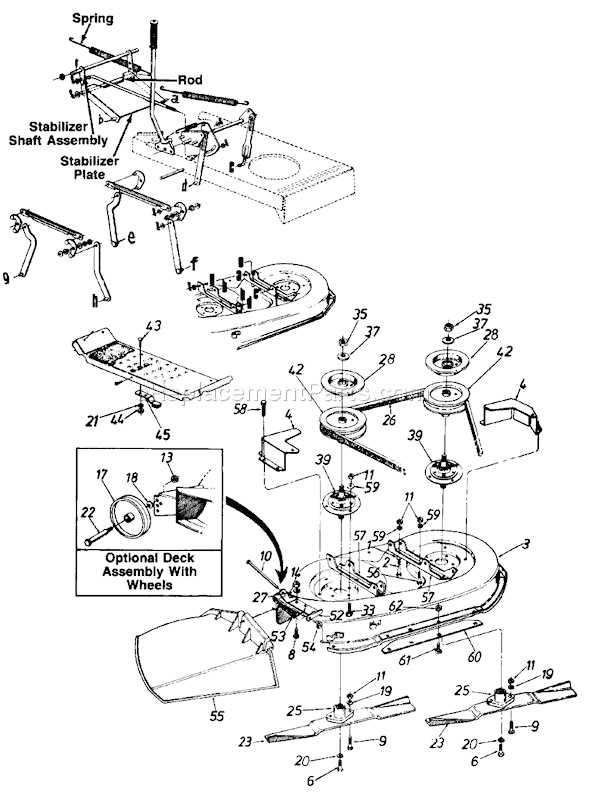

- Cutting Mechanism Issues:

- Inefficient cutting height adjustment

- Clogs in the cutting deck

- Worn or damaged blades

- Electrical System Failures:

- Battery drainage

- Faulty wiring connections

- Issues with the ignition system

Identifying these mechanical challenges early can help in addressing them promptly, leading to better performance and an extended lifespan for your equipment.

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Following a structured approach can help in identifying potential issues before they escalate, thus enhancing reliability and efficiency.

-

Check Fluid Levels

- Inspect oil levels and replace if necessary.

- Examine coolant levels and top off as needed.

- Ensure fuel is clean and adequate for operation.

-

Inspect Belts and Cables

- Look for wear and tear on all belts.

- Check cables for any signs of fraying or damage.

- Adjust tension where applicable to maintain efficiency.

-

Sharpen Blades

- Remove blades carefully following safety protocols.

- Use a sharpening tool to ensure a clean edge.

- Reattach blades securely after sharpening.

-

Clean Air Filter

- Remove the air filter and inspect for dirt and debris.

- Clean or replace the filter based on condition.

- Ensure proper sealing to prevent contaminants from entering.

-

Examine Tires

- Check tire pressure and inflate to recommended levels.

- Inspect for any punctures or excessive wear.

- Rotate tires if needed to promote even wear.

By adhering to these essential procedures, you can help maintain the efficiency and performance of your equipment, ensuring a smoother operation for years to come.

Diagnosing Electrical Problems in Mowers

Identifying issues within the electrical system of grass-cutting machines is essential for maintaining their performance and longevity. This process involves a systematic approach to uncover potential faults that could hinder operation, ensuring optimal functionality.

Common Symptoms of Electrical Issues

Several indicators may signal that something is amiss within the electrical components. Users might notice problems such as difficulty starting, dim lights, or erratic performance during use. Recognizing these signs early can prevent further complications and extend the life of the equipment.

Step-by-Step Troubleshooting Guide

To effectively diagnose electrical concerns, begin with a thorough inspection of all connections and wiring. Check for loose or corroded terminals that could impede electrical flow. Next, test the battery voltage using a multimeter; a reading below the recommended level indicates a need for charging or replacement. Additionally, examine fuses and relays, replacing any that appear damaged. Following these steps will help pinpoint the root cause of the problem.

Emphasizing regular maintenance can significantly reduce the likelihood of electrical failures. Keeping connections clean and secure, as well as routinely checking the battery, contributes to smoother operation.

Replacing Blades and Accessories

Maintaining optimal performance of your lawn equipment involves periodic updates to essential components. This process ensures that your equipment operates efficiently, delivering the best results while enhancing longevity. Proper attention to these elements not only improves cutting efficiency but also contributes to a safer experience during operation.

Tools and Materials Needed

Before beginning the replacement process, gather the necessary tools and components. Essential items include a socket wrench, safety gloves, and new blades or accessories. Additionally, having a clean workspace will facilitate a smoother procedure.

Step-by-Step Replacement Process

Begin by safely elevating the unit to access the blades. Remove any fasteners securing the old blades, taking care to remember the order of disassembly. Once removed, compare the new components to ensure compatibility. Secure the new blades in place using the appropriate hardware, ensuring they are tightened firmly to prevent any movement during operation. After installation, lower the equipment and perform a quick test run to confirm proper function.

Note: Regular inspection of blades and accessories can prevent potential issues and maintain high performance.

Fuel System Cleaning and Maintenance

Ensuring the longevity and efficiency of the fuel delivery system is essential for optimal performance. Regular upkeep and thorough cleansing of this critical component can prevent common issues and enhance the overall functionality of the equipment.

Inspection and Assessment: Begin by examining the entire system for signs of wear or contamination. Look for leaks, cracks, or any foreign substances that may have entered the fuel lines. Addressing these concerns promptly can help avoid more significant complications down the line.

Cleaning the Fuel Filter: A clogged filter can hinder fuel flow, so it is important to replace or clean it as necessary. Follow the guidelines specific to your equipment to ensure proper installation and functionality.

Checking Fuel Lines: Inspect the hoses for any blockages or damage. If you notice any debris or buildup, carefully clean the lines to restore proper flow. In some cases, replacing damaged hoses may be necessary to maintain system integrity.

Fuel Tank Maintenance: Periodically drain and clean the fuel tank to eliminate sediment and contaminants that can affect performance. Use a suitable cleaning solution and ensure the tank is completely dry before refilling it with fresh fuel.

Final Checks: After completing maintenance, run the engine to ensure that everything operates smoothly. Listen for unusual noises and monitor for any signs of leaks or performance issues. Regular attention to these details will contribute to a more reliable and efficient operation.

Adjusting the Drive Belt Properly

Ensuring optimal performance of your machine requires precise attention to the drive mechanism. The drive belt plays a crucial role in transmitting power, and proper tension and alignment are essential for smooth operation. In this section, we will explore the necessary steps to achieve the correct adjustments.

Tools Needed

Before starting the adjustment process, gather the following tools: a wrench set, a screwdriver, and a tension gauge. Having these items at hand will streamline the procedure and make it more efficient.

Step-by-Step Adjustment

Begin by disconnecting the power source to ensure safety. Next, locate the drive belt assembly and examine its condition. If the belt shows signs of wear or damage, replacement may be necessary. If the belt is intact, proceed to adjust the tension. Loosen the adjustment bolts slightly and use the tension gauge to ensure the correct tightness. After adjusting, tighten the bolts securely to maintain the new setting. Finally, recheck the alignment of the belt with the pulleys to prevent slipping during operation.

Regular maintenance of the drive mechanism not only enhances performance but also prolongs the lifespan of your equipment. Adhering to these guidelines will help ensure effective power transmission and overall efficiency.

Winter Storage Tips for Mowers

As the colder months approach, proper preparation is essential to ensure that your outdoor equipment remains in optimal condition. Following a few key steps can help safeguard your machinery from the harsh winter elements, preserving its functionality for the upcoming season.

Clean Thoroughly

Before storing, it’s crucial to give your equipment a thorough cleaning. Remove any grass, dirt, or debris that may have accumulated during use. This will prevent rust and corrosion, ensuring that the surfaces remain intact. Use a brush or cloth to reach tight spots, and consider rinsing with water if necessary.

Fuel Care

Fuel quality can significantly impact performance. Consider adding a fuel stabilizer to the tank to prevent degradation over the winter months. Alternatively, you may choose to drain the tank completely. This step will help avoid potential issues with old fuel when you bring your equipment out of storage.

Battery Maintenance is also vital. Disconnect the battery and store it in a cool, dry place. Ensure that it is charged periodically to maintain its health.

By taking these precautions, you can extend the lifespan of your equipment and ensure it’s ready for action when the time comes to resume your outdoor activities.

Finding Replacement Parts Online

Locating suitable components for your outdoor equipment can be a straightforward process when you utilize the right online resources. The vast array of websites dedicated to parts sales makes it easy to identify what you need, ensuring your machine continues to operate efficiently.

Utilizing Trusted Websites

Start by visiting reputable retailers that specialize in garden machinery. Websites like Amazon, eBay, and dedicated parts suppliers often have comprehensive selections. Be sure to read customer reviews and check ratings to gauge the reliability of both the part and the seller.

Exploring Manufacturer Resources

Another excellent approach is to explore the official website of the equipment’s manufacturer. Many manufacturers provide online catalogs of available parts, along with detailed descriptions. This can help you find the exact component you require while ensuring compatibility with your equipment. Additionally, contacting customer service can yield useful insights regarding availability and options.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when addressing maintenance tasks. Adhering to specific guidelines helps mitigate risks and enhances safety throughout the process. Understanding potential hazards and taking proactive measures is essential for a successful experience.

General Guidelines

Before starting any maintenance, it’s important to familiarize yourself with the equipment and its components. Always wear appropriate personal protective equipment to safeguard against injuries. Clear the workspace of any clutter and ensure that the area is well-lit to avoid accidents.

Common Safety Tips

| Precaution | Description |

|---|---|

| Disconnect Power | Always disconnect the power source before beginning work to prevent accidental starts. |

| Use Proper Tools | Utilize the correct tools for the job to avoid damage and injury. |

| Check for Leaks | Inspect for any fluid leaks that may pose slip hazards or indicate issues. |

| Follow Instructions | Refer to the guidelines for specific procedures to ensure safety and efficiency. |

By implementing these safety measures, individuals can work confidently and effectively while minimizing the likelihood of incidents.