Exploring the upkeep and fine-tuning of a rugged off-road vehicle offers invaluable insights into keeping it resilient and reliable over the years. This guide provides a structured approach to essential maintenance tasks and troubleshooting tips, empowering vehicle owners to address common challenges and prevent potential issues.

From examining engine health to ensuring robust suspension and secure brake systems, this guide covers a range of tasks aimed at optimizing performance. Detailed steps and clear instructions make complex processes easier to handle, even for those without extensive mechanical expertise.

Owners will also find tips for tackling frequent wear and tear, seasonal maintenance practices, and advice on the right tools and products to use. Following this guidance not only enhances the lifespan of the vehicle but also ensures a safer and more reliable driving experience in a variety of terrains.

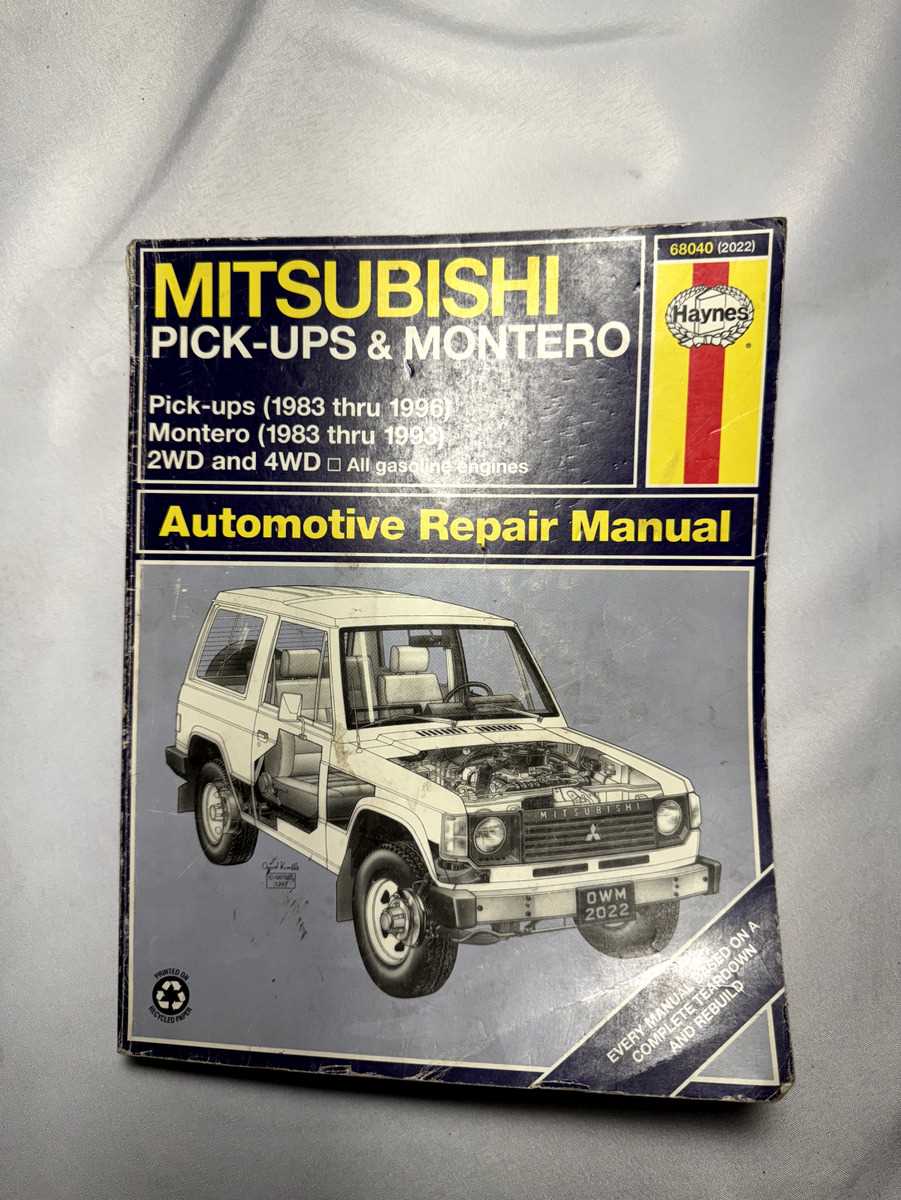

1996 Mitsubishi Montero Repair Guide

In this section, you’ll find guidance on troubleshooting and maintaining one of the reliable SUVs from the mid-90s. Designed for both rugged trails and everyday roads, this vehicle often requires targeted care to keep it running smoothly. Below, essential areas of upkeep and common mechanical issues are covered to support ongoing performance and longevity.

Engine Care and Maintenance

For optimal function, regular attention to the engine is crucial. Inspect components like belts, hoses, and fluid levels, making sure each is in good condition. Replace fluids as recommended to avoid overheating or internal wear. Routine inspections can help detect minor issues before they grow into costly repairs.

Transmission and Drivetrain

Given its capability on various terrains, the transmission and drivetrain require consistent inspection. Check for any signs of unusual noises or lag in shifting, which may indicate wear. Applying the correct fluid type and following a strict service schedule will reduce wear on these components, prolonging their effectiveness.

Suspension and Braking Systems

Both the suspension and braking systems are essential for safety, especially when driving off-road. Regularly test brake pads, rotors, and suspension parts to ensure they respond correctly. Examine for any unusual vibrations or decreased braking power, as these could point to worn parts needing immediate attention.

Following these maintenanc

Engine Maintenance Tips

Regular upkeep of the engine ensures smooth operation, longevity, and reliable performance on any journey. Following a consistent maintenance routine is essential for preserving engine efficiency and minimizing potential issues.

Check Oil Levels Regularly: Engine oil is crucial for reducing friction and preventing overheating. Make it a habit to inspect oil levels and quality. Refill or replace as needed to keep all components well-lubricated and performing optimally.

Inspect Air Filters: A clean air filter allows the engine to “breathe” easily, improving combustion and efficiency. Dirty filters reduce airflow, so check and replace them periodically to maintain fuel efficiency and power.

Monitor Cooling System: The cooling system prevents overheating and helps regulate engine temperature. Check coolant levels and inspect hoses and the radiator for signs of leaks or wear. Addressing any issues in the cooling system promptly can prevent costly repairs.

Examine Belts and Hoses: Belts and hoses play a critical role in engine operation. Look for signs of wear, such as cracks or fraying. Replace any worn-out parts to avoid unexpected breakdowns.

Listen for Unusual Sounds: Any un

Transmission Troubleshooting and Solutions

The transmission system plays a crucial role in ensuring smooth gear shifting and optimal power transfer. Identifying and resolving transmission issues early can prevent costly repairs and extend the lifespan of the vehicle’s drive system. This section covers common problems and effective solutions for diagnosing and maintaining the transmission.

Identifying Common Transmission Issues

Unusual sounds like grinding or whining often indicate issues within the transmission. These sounds may occur during gear changes or while accelerating. Delays or difficulty in shifting gears can signal internal problems, including fluid contamination or worn-out components. Low or discolored transmission fluid is also a sign that the system may not be properly lubricated, leading to further complications.

Practical Solutions for Transmission Problems

Regular maintenance is essential for a well-functioning transmission. Start by checking the fluid level and ensuring the fluid is clean. Replacing old fluid can alleviate minor shifting issues. If noises or delays persist, inspect for leaks and examine the clutch and gears for any visible wear. For automatic systems, consider a professional assessment, as internal parts may require specialized attention.

Electrical System Inspection Guide

Regular checks of the electrical system are essential to maintain reliable performance and prevent unexpected issues. This guide provides a systematic approach for examining key components, ensuring functionality, and spotting early signs of wear or damage.

- Battery Condition: Inspect the battery terminals and cables for corrosion or looseness. Ensure that the battery holds a sufficient charge and shows no signs of swelling or leakage.

- Alternator Output: Check the alternator’s output voltage using a multimeter. It should fall within the manufacturer’s recommended range when the engine is running.

- Fuses and Relays: Inspect each fuse for continuity and replace any blown fuses with the appropriate type. Verify that relays are functioning and securely seated in their sockets.

- Wiring Inspection: Visually examine wiring for any signs of fraying, cracking, or loose connections. Pay special attention to high-heat areas where insulation might degrade over time.

- Lighting and Indicators: Ensure that all exterior and interior lights, as well as dashboard indicators, are operational. Replace burnt-out bulbs and clean contact points if necessary.

- Ignition System: Test the ignition coil, spark plugs, and related connections. Look for any buildup or wear that could affect the quality of the spark.

Following these steps can help identify potential issues before they escalate, ensuring a reliable and efficient electrical system.

Suspension Components Replacement

Ensuring that your vehicle’s suspension system is in optimal condition is essential for a smooth and safe driving experience. Over time, various parts within the suspension framework can wear down due to regular use and environmental factors, which may lead to reduced stability, uncomfortable rides, and potentially compromised safety. This section provides guidance on how to inspect, replace, and maintain key elements of the suspension system to keep your vehicle’s performance at its best.

Identifying Worn Suspension Parts

Start by examining common wear points within the suspension system, such as the bushings, ball joints, and shock absorbers. Signs of wear may include unusual sounds, handling difficulties, or visible deterioration of parts. It’s crucial to inspect these components regularly to prevent further issues and maintain proper vehicle alignment.

Steps to Replace Key Components

When replacing elements like the shock absorbers, begin by securely lifting the vehicle and ensuring proper safety measures. Remove the worn shock absorbers by detaching the mounting bolts, then carefully install new parts, ensuring they are firmly aligned and secured. For bushings and ball joints, specialized tools may be necessary for safe removal and installation. After replacing these parts, it’s advisable to check the alignment to maintain balanced

Brake System Maintenance Procedures

Proper upkeep of the braking system is crucial for ensuring vehicle safety and performance. Regular maintenance not only enhances braking efficiency but also prolongs the lifespan of various components, minimizing the risk of failure. Understanding the procedures involved can help drivers maintain optimal functionality and respond effectively to any issues that may arise.

Inspection of Brake Components

Routine examination of brake pads, rotors, and calipers is essential. Look for signs of wear, such as uneven surfaces, cracks, or excessive thinning of pads. Ensure that the brake fluid is at the appropriate level and free from contaminants, as this can affect braking performance.

Replacement and Adjustment

When necessary, replace worn brake pads and rotors following the manufacturer’s guidelines. Proper installation and adjustment are vital for maintaining balance and efficiency in braking. Additionally, bleeding the brake system periodically will ensure that air does not compromise brake fluid, allowing for smooth operation.

Cooling System Repair Steps

This section outlines the essential procedures for addressing issues within the temperature regulation system of your vehicle. Proper maintenance of this system is crucial for ensuring optimal engine performance and preventing overheating.

Begin by thoroughly examining the cooling system components, including the radiator, hoses, and thermostat. Look for signs of wear, leaks, or damage. Replacing any faulty parts promptly is vital to maintaining system integrity.

Next, drain the coolant from the radiator by locating the drain valve. Ensure that you have a suitable container to collect the fluid. Once drained, flush the system with water to remove any accumulated debris or sediment. After flushing, refill the system with a high-quality coolant mixture, ensuring the correct ratio of water and antifreeze.

Inspect the radiator for blockages, and clean it if necessary. Also, check the condition of the water pump, ensuring it functions correctly without any signs of leakage. Lastly, bleed the system to remove any air pockets, which can lead to overheating. Monitor the temperature gauge during operation to confirm that the system operates within the normal range.

Exhaust System Adjustment Guide

This section provides essential information for fine-tuning the exhaust system of your vehicle. Proper adjustment is crucial for optimal performance and compliance with emission standards. Following these guidelines ensures that the system operates efficiently, reducing noise and enhancing engine effectiveness.

Tools and Equipment Needed

To achieve accurate adjustments, gather the following tools:

- Wrench set

- Socket set

- Torque wrench

- Exhaust clamp tool

- Safety goggles

- Jack and jack stands

Adjustment Procedure

Follow these steps to adjust the exhaust system:

- Start by lifting the vehicle and securely supporting it with jack stands.

- Inspect the exhaust system for any signs of damage or wear.

- Loosen the clamps connecting the exhaust components.

- Align the exhaust pipes for optimal fitment.

- Tighten the clamps to the manufacturer’s specifications.

| Component | Adjustment Specification |

|---|---|

| Exhaust Pipe | Ensure proper clearance from the chassis |

| Silencer | Check alignment with hangers |

| Connections | Tighten to the torque specification |

Fuel System Cleaning Techniques

Maintaining a clean fuel system is crucial for optimal engine performance and efficiency. Various methods can be employed to ensure that the components of the fuel system remain free from contaminants and deposits, which can hinder functionality and reduce fuel economy.

Here are some effective techniques for cleaning the fuel system:

- Fuel Additives: Utilizing specialized cleaning additives can help dissolve carbon deposits and other impurities in the fuel lines and injectors.

- Injector Cleaning: Professional cleaning services can thoroughly clean fuel injectors using ultrasonic equipment or chemical solutions to restore their optimal spray patterns.

- Fuel Filter Replacement: Regularly replacing the fuel filter prevents clogging and ensures that clean fuel reaches the engine.

- Thorough System Flush: A comprehensive flush of the entire fuel system can remove accumulated deposits and improve overall performance.

- Visual Inspection: Regularly checking fuel lines, connections, and the fuel tank for leaks or damage can help identify potential issues early.

Implementing these techniques can significantly enhance the efficiency and longevity of the fuel system, ensuring a smoother operation and better fuel consumption.

Steering Mechanism Maintenance

Regular upkeep of the steering system is essential for ensuring optimal performance and safety. This section highlights the key aspects of maintaining the steering components to prevent wear and tear, enhance responsiveness, and prolong the lifespan of the system.

Inspection of Components

Begin by examining the various parts of the steering assembly, including the steering wheel, column, and rack. Look for signs of damage, such as cracks or excessive play, which can indicate a need for adjustment or replacement. Additionally, check for any fluid leaks that may compromise the functionality of the system.

Lubrication and Adjustments

Proper lubrication is crucial for the smooth operation of the steering mechanism. Apply high-quality grease to the moving parts as recommended by the manufacturer. Furthermore, periodic adjustments may be necessary to maintain precise alignment and responsiveness. Ensure that all bolts and fasteners are tightened to the specified torque settings to prevent loosening during use.

Body Panel Restoration Tips

Restoring body panels can significantly enhance the overall appearance and value of a vehicle. This process involves a series of careful steps that focus on addressing imperfections, rust, and damage while ensuring the structural integrity of the vehicle is maintained. Proper techniques and tools are essential for achieving a professional finish.

Preparation Steps

Before starting the restoration, it’s crucial to prepare the workspace and gather all necessary materials. Ensure the area is clean and well-ventilated. Begin by removing any loose paint, rust, or debris using appropriate tools. Sandpaper of varying grits will be useful in smoothing out rough surfaces. Masking tape can protect areas that do not require treatment.

Finishing Techniques

After preparing the surface, applying a suitable primer is vital to promote adhesion for the paint. Once the primer has dried, use high-quality automotive paint for a durable finish. Consider multiple thin layers rather than one thick coat to avoid runs and ensure an even application. Lastly, finish with a clear coat for added protection and shine.

Interior Trim Replacement Guide

This section provides essential information for individuals looking to enhance or restore the interior elements of their vehicle. Proper replacement of interior trim components can significantly improve the aesthetics and functionality of the cabin, ensuring a more enjoyable driving experience. Whether you’re dealing with worn-out panels or updating your vehicle’s look, understanding the process is crucial for a successful outcome.

Before beginning the replacement process, gather the necessary tools and materials. Common items needed include screwdrivers, trim removal tools, and adhesive, depending on the type of trim being replaced. Additionally, it is advisable to have replacement parts readily available to minimize downtime.

Start by carefully removing any existing trim pieces. Use appropriate trim tools to prevent damage to surrounding areas. Take your time to locate and unscrew any fasteners that secure the trim in place. Once detached, inspect the underlying surfaces for any dirt or damage that may need attention before installing new components.

When installing new trim, ensure that each piece fits snugly and aligns correctly with other interior elements. Follow manufacturer instructions where available, and apply adhesive as needed for a secure hold. After installation, double-check all fasteners and ensure that everything is in place before concluding the process.

Finally, clean any fingerprints or debris from the newly installed trim to maintain a pristine appearance. Regular maintenance and prompt replacement of damaged interior components will enhance the overall ambiance and value of your vehicle.