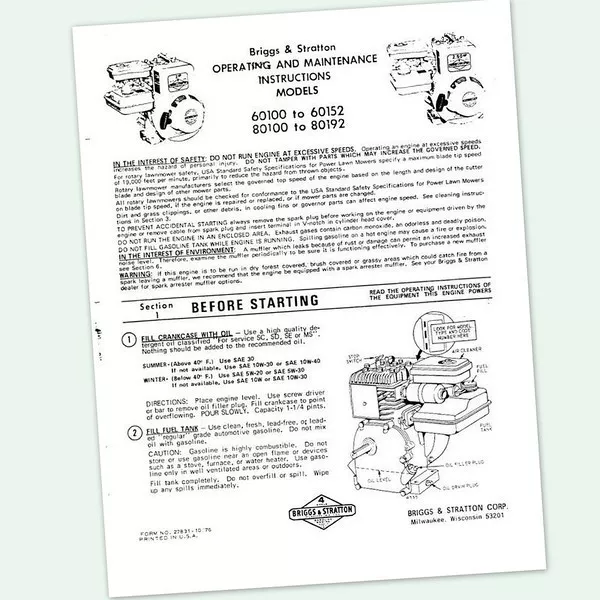

Ensuring the longevity and optimal performance of machinery often hinges on understanding intricate systems and addressing potential issues. A thorough exploration of the relevant technical documents can provide invaluable insights into the workings of complex devices, facilitating informed decisions during upkeep and repairs.

This section delves into essential techniques and procedures that aid in diagnosing problems and executing necessary interventions. By familiarizing oneself with detailed guidelines and illustrations, operators can navigate challenges with confidence and precision.

Utilizing well-organized reference materials can significantly enhance one’s ability to tackle malfunctions effectively. With a focus on practical applications, this guide aims to equip users with the knowledge needed to maintain their equipment efficiently and prolong its operational life.

Understanding the 126T02 0675 B2 Model

The model in question represents a sophisticated piece of equipment, designed for specific applications in its field. Its intricate construction and advanced functionalities make it a valuable asset for professionals. A comprehensive understanding of its components and operational principles is essential for effective utilization and maintenance.

Key Features

- Robust design ensuring durability and reliability.

- Advanced technology for enhanced performance.

- User-friendly interface for easier operation.

- Versatile applications across various sectors.

Operational Insights

Familiarity with the operational aspects of this model enhances its usability. Key elements to consider include:

- Understanding the control mechanisms for efficient functioning.

- Identifying essential components for troubleshooting.

- Regular maintenance practices to ensure longevity.

Common Issues and Solutions

This section addresses typical problems encountered with the specific model and provides practical solutions to resolve them effectively.

-

Overheating:

Excessive heat can lead to performance issues. Ensure proper ventilation and check for any obstructions in the cooling system.

-

Electrical Malfunctions:

Faulty wiring or connections can disrupt functionality. Inspect all electrical components and replace any damaged parts.

-

Fluid Leaks:

Leaks can compromise performance. Regularly check seals and gaskets for wear, and replace them as needed.

-

Unresponsive Controls:

If controls are not functioning correctly, examine the control module and wiring for issues. Resetting the system may also help.

Addressing these issues promptly can prevent further complications and ensure optimal operation of the equipment.

Essential Tools for Effective Repair

Having the right equipment is crucial for achieving successful maintenance outcomes. The appropriate instruments not only enhance efficiency but also ensure that tasks are completed safely and accurately. Below is a list of fundamental items that every technician should consider incorporating into their toolkit.

- Screwdrivers: A variety of types and sizes to handle different fasteners.

- Wrenches: Adjustable and fixed wrenches for loosening and tightening bolts and nuts.

- Pliers: Needle-nose and slip-joint pliers for gripping and manipulating components.

- Socket Set: A range of sockets for tackling various sizes of nuts and bolts.

- Multimeter: Essential for measuring voltage, current, and resistance in circuits.

- Torque Wrench: To ensure that fasteners are tightened to the manufacturer’s specifications.

In addition to the core tools, having access to specialized instruments can further enhance the quality of work performed. Consider the following:

- Heat Gun: Useful for shrinking tubing and softening materials for easier manipulation.

- Wire Strippers: Essential for preparing electrical connections by removing insulation from wires.

- Toolbox: A durable storage solution to keep all instruments organized and easily accessible.

Investing in quality tools not only aids in effective maintenance but also contributes to the longevity of the items being serviced. Proper care and regular updates to your toolkit can greatly impact overall productivity and outcomes.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing issues effectively. Following a structured method ensures that every stage of the process is covered, minimizing the risk of oversight.

1. Initial Assessment: Begin by examining the unit thoroughly. Identify any visible damage or irregularities that may require attention. Document your findings to guide the subsequent steps.

2. Disassembly: Carefully dismantle the components, ensuring that all screws and parts are kept organized. Utilize appropriate tools to avoid damage to delicate elements.

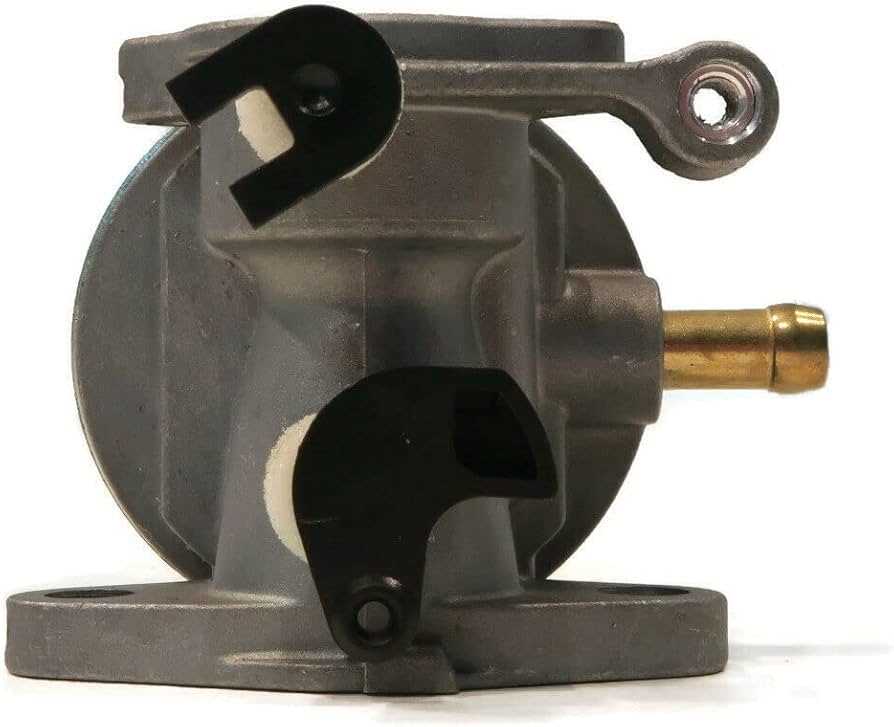

3. Diagnosis: Analyze the internal mechanisms to pinpoint the source of the malfunction. Employ diagnostic tools as needed to assist in this evaluation.

4. Component Replacement: Once the faulty parts are identified, replace them with high-quality substitutes. Ensure compatibility with existing components to maintain functionality.

5. Reassembly: After replacing any necessary components, begin reassembling the unit. Follow your documentation closely to ensure all parts are returned to their proper locations.

6. Final Testing: Once fully reassembled, conduct a comprehensive test to verify that the unit operates as intended. Pay attention to any anomalies and make adjustments as necessary.

7. Documentation: Finally, record the repairs made and any observations during the process. This will serve as a valuable reference for future maintenance and troubleshooting.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment involves regular attention and care. Implementing effective maintenance practices can significantly extend the lifespan of your device, preventing costly replacements and enhancing reliability.

Regular Inspections

Conduct frequent evaluations of your unit to identify any signs of wear or potential issues. Checking for loose connections, frayed wires, or other irregularities allows for timely intervention, helping to avoid more serious problems down the line.

Proper Cleaning

Keep the equipment clean and free from dust and debris. Utilize appropriate cleaning materials and techniques to maintain both aesthetics and functionality. Regular cleaning helps prevent overheating and ensures that components operate efficiently.

Safety Precautions During Repairs

Ensuring a safe working environment is paramount when undertaking maintenance tasks. Adhering to specific guidelines can significantly reduce the risk of accidents and enhance the overall effectiveness of the process. It is essential to prepare adequately and remain vigilant throughout the procedure.

General Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and dust masks.

- Ensure that the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Keep the area organized and free from clutter to prevent tripping hazards.

- Disconnect power sources and allow components to cool before beginning work.

Handling Tools and Components

- Inspect tools for damage before use; replace any that are worn or broken.

- Use tools as intended to avoid accidents and ensure efficiency.

- Store hazardous materials in clearly labeled containers, away from work areas.

- Be mindful of sharp edges and moving parts to avoid injuries.

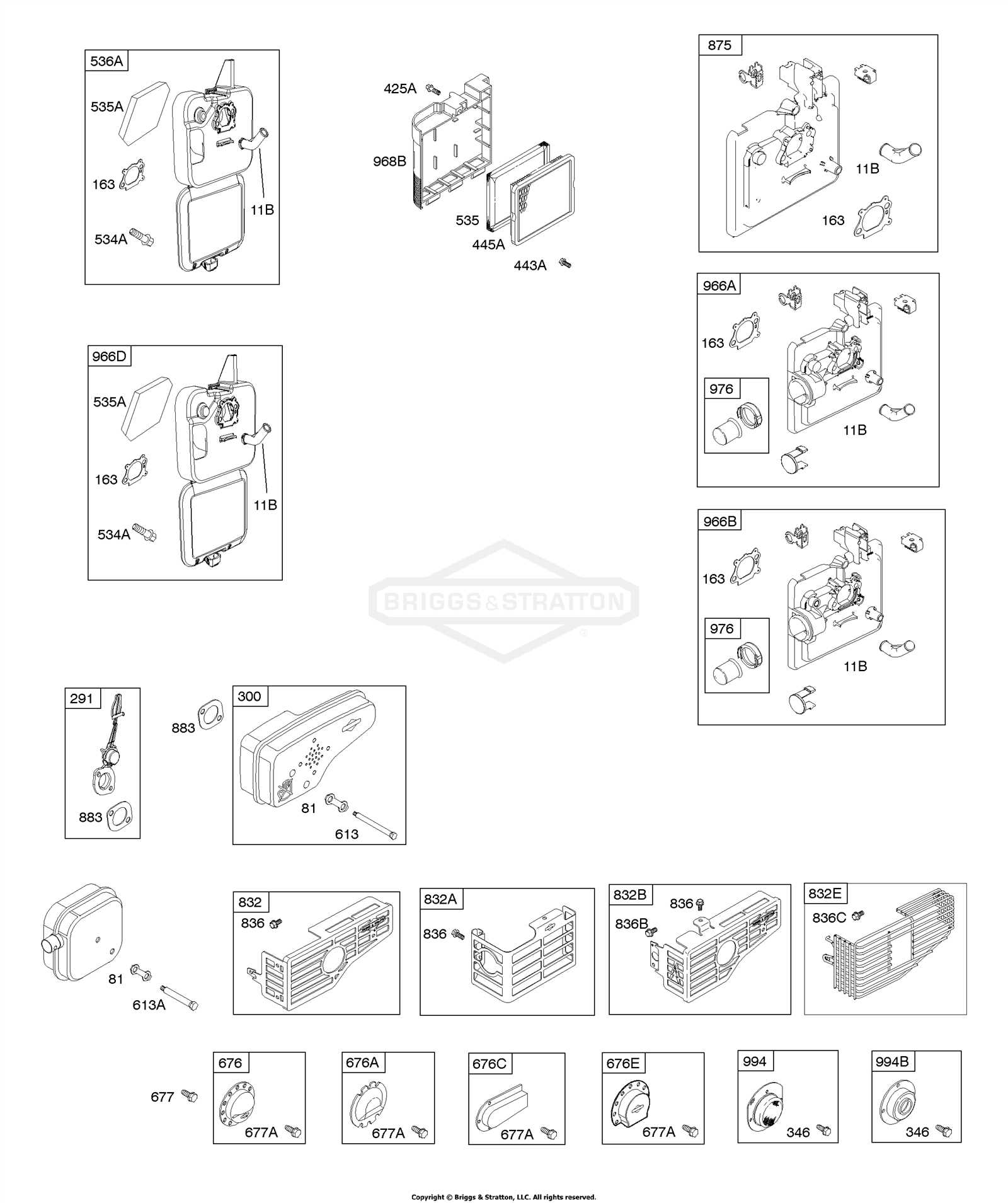

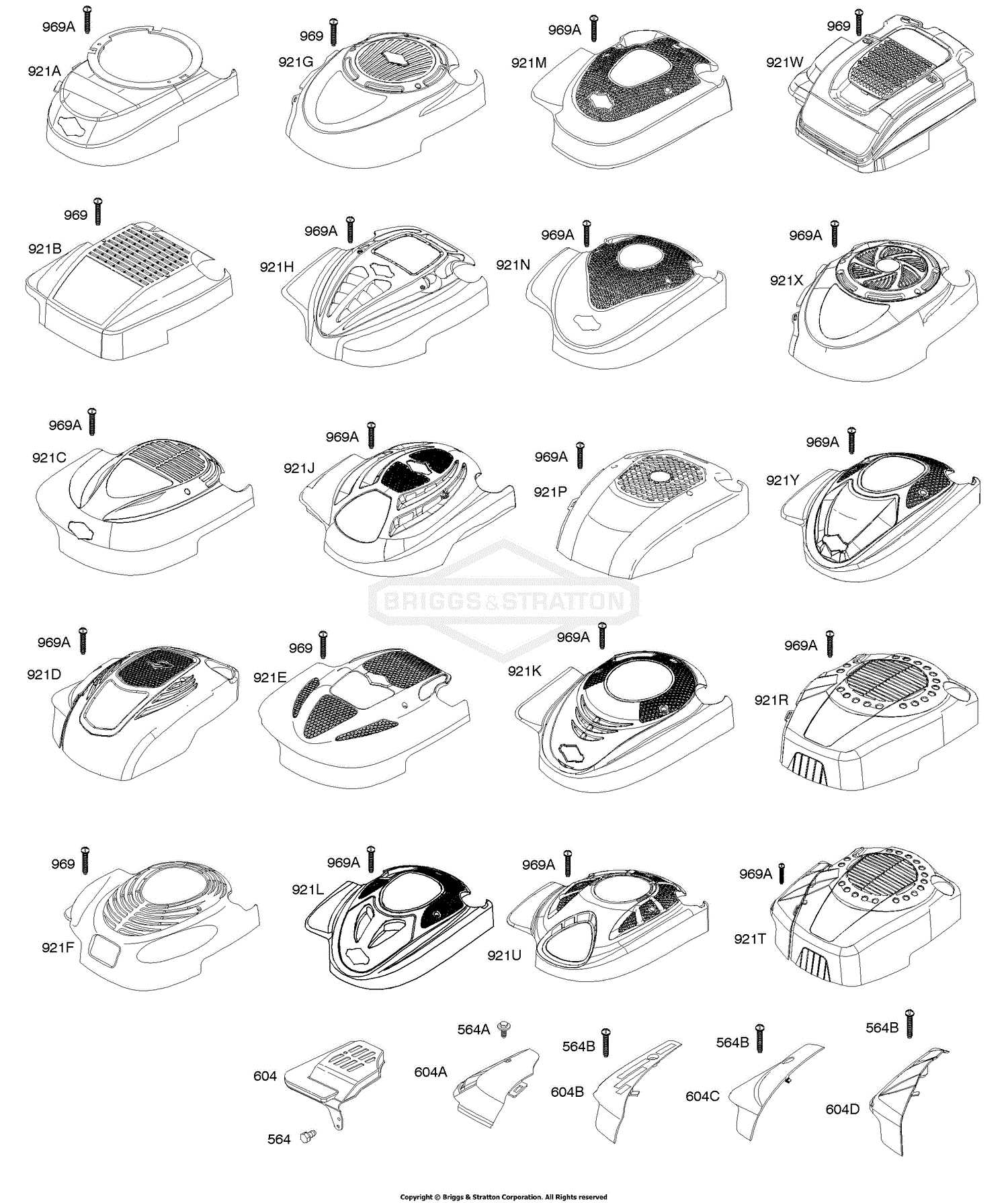

Parts Replacement Guide

This section provides essential information for replacing various components within the system. Understanding the necessary procedures and best practices will ensure optimal performance and longevity of the device.

Begin by identifying the specific part that requires attention. Refer to the relevant diagrams or charts to locate the component accurately. It’s crucial to have the correct tools at hand to facilitate a smooth replacement process.

When removing a component, take care to disconnect any electrical connections carefully. Ensure that the power source is turned off to prevent any accidents. After the faulty part is removed, inspect the surrounding area for any signs of damage or wear that may need addressing.

Once the new part is ready for installation, align it properly with the existing framework. Secure it in place, making sure all connections are tight and correct. After the installation is complete, perform a thorough test to verify functionality.

Regular maintenance and timely replacement of parts can significantly enhance the overall efficiency of the unit. Keeping a checklist of components and their expected lifespan can aid in proactive management and prevent unexpected failures.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is essential for maintaining the functionality of any device. This section provides guidance on how to effectively diagnose and rectify common electrical malfunctions that may arise.

Follow these steps to address electrical faults:

- Visual Inspection:

- Check for visible damage to wires and connectors.

- Look for signs of corrosion or loose connections.

- Test Components:

- Use a multimeter to check the voltage and continuity of circuits.

- Assess individual components for functionality.

- Review Circuit Diagrams:

- Consult circuit schematics to understand the layout and connections.

- Trace the paths to identify any discrepancies.

- Substitute Parts:

- Replace suspected faulty components with known working ones.

- Observe any changes in performance.

- Document Findings:

- Keep a record of symptoms, tests performed, and outcomes.

- This documentation can assist in future troubleshooting.

By systematically following these steps, one can effectively pinpoint and resolve electrical issues, ensuring reliable operation.

Optimizing Performance After Repair

Ensuring optimal functionality following maintenance work is crucial for the longevity and efficiency of any device. Implementing effective strategies can enhance performance and minimize the likelihood of future issues. This section outlines key practices to consider after completing necessary interventions.

Regular Maintenance Checks

Establishing a routine for inspections can significantly impact overall performance. Regular assessments allow for early detection of potential problems and help maintain the system in peak condition.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Monthly | Identifies wear and tear |

| Component Cleaning | Quarterly | Improves efficiency and prevents buildup |

| Performance Testing | Biannually | Ensures all parts are functioning correctly |

Implementing Upgrades

Consider integrating enhancements to boost efficiency. Upgrades can provide better performance and extend the lifespan of the system. Researching available options and compatibility is vital before making changes.

Frequently Asked Questions

This section addresses common inquiries regarding maintenance and troubleshooting for the specified model. Understanding these aspects can enhance the overall performance and longevity of the equipment.

What are the most common issues that can arise?

Typical challenges include electrical malfunctions, mechanical wear, and fluid leaks. Identifying these problems early can help prevent further complications and ensure efficient operation.

How can I access replacement parts?

Replacement components can usually be sourced through authorized dealers, online retailers, or specialized distributors. It’s essential to verify compatibility with your specific equipment before purchasing any parts.