When it comes to ensuring the longevity and optimal performance of your vehicle, having a reliable source of information is crucial. This section aims to provide enthusiasts and owners with detailed insights into the nuances of upkeep and common issues that may arise over time. With the right knowledge, maintaining peak functionality becomes a more approachable task.

Understanding the intricacies of your vehicle’s systems allows for informed decision-making when it comes to addressing challenges. From routine inspections to in-depth diagnostics, having access to structured guidance can save both time and resources. The goal is to empower users with the tools needed to tackle various situations confidently.

In this guide, readers will find step-by-step instructions, helpful tips, and practical advice that cover essential aspects of maintenance. Whether you’re looking to perform basic checks or delve deeper into more complex repairs, this resource is designed to enhance your familiarity with the equipment and support you throughout your ownership experience.

Common Issues and Troubleshooting Tips

When dealing with off-road vehicles, enthusiasts often encounter a range of common complications that can hinder performance. Understanding these typical problems and having effective strategies for resolving them can significantly enhance the ownership experience. This section aims to provide insights into prevalent issues and practical solutions.

Starting Difficulties

One frequent challenge faced by users is difficulty in starting the engine. This can stem from various factors such as a weak battery, faulty connections, or issues with the ignition system. Regular maintenance of the electrical components is crucial. Ensure that the battery is fully charged and connections are clean. If the problem persists, examining the ignition system may be necessary.

Suspension and Handling Concerns

Another area of concern often relates to suspension performance and handling. Users may notice a decline in ride quality or responsiveness. This can be attributed to worn-out shock absorbers or improper tire pressure. Routine inspections of the suspension system and maintaining correct tire inflation can alleviate many handling issues. Additionally, consult the vehicle specifications for optimal settings.

Step-by-Step Maintenance Procedures

This section outlines essential upkeep tasks designed to enhance performance and extend the lifespan of your vehicle. Following these systematic steps will ensure that all critical components are functioning optimally, promoting both safety and efficiency.

Regular Inspection

Conducting routine checks is vital for identifying potential issues early. Here are the key areas to focus on:

- Check fluid levels (oil, coolant, brake fluid).

- Inspect tires for wear and proper inflation.

- Examine brakes for signs of wear or damage.

- Review battery connections and charge levels.

Scheduled Servicing

Adhering to a maintenance schedule is crucial. Follow these steps to ensure comprehensive servicing:

- Change engine oil and replace the filter every 3,000 to 5,000 miles.

- Replace air filters as needed to maintain airflow.

- Flush and refill the coolant system regularly.

- Inspect and replace spark plugs according to the service interval.

By implementing these procedures, you can significantly improve the reliability and performance of your vehicle.

Safety Precautions During Repairs

When undertaking maintenance tasks on any machinery, it is essential to prioritize safety. Proper precautions can help prevent accidents and injuries, ensuring a smooth and effective process. Adhering to guidelines will protect both the individual performing the work and the equipment itself.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear. Using gloves will shield your hands from sharp edges and hazardous substances, while safety goggles protect your eyes from flying debris. Reliable footwear provides necessary traction and support during the work.

Work Environment Considerations

Maintain a clean and organized workspace to reduce risks. Ensure adequate lighting to improve visibility and minimize hazards. Keep all tools and materials neatly stored to avoid tripping or falling. Additionally, having a fire extinguisher and first aid kit readily accessible can be invaluable in emergencies.

Understanding the Engine Components

In any vehicle, the powertrain is a vital element that directly influences performance and reliability. This section explores the essential parts that work in unison to ensure optimal functionality and efficiency. A clear comprehension of these components is crucial for effective maintenance and troubleshooting.

Core Elements of the Powertrain

The heart of any powertrain is the internal combustion mechanism. This system is responsible for converting fuel into motion, driving the vehicle forward. Key elements include the cylinders, where the combustion process occurs, and the pistons, which transform the explosive energy into mechanical power. Understanding the interplay between these components provides insight into how the engine operates under various conditions.

Supporting Systems

Equally important are the auxiliary systems that enhance performance and ensure longevity. The cooling system prevents overheating, while the fuel delivery system regulates the mixture of air and fuel for efficient combustion. Additionally, the exhaust system plays a crucial role in directing emissions away from the engine, contributing to overall performance and environmental compliance. Familiarity with these supporting structures is essential for diagnosing issues and implementing effective solutions.

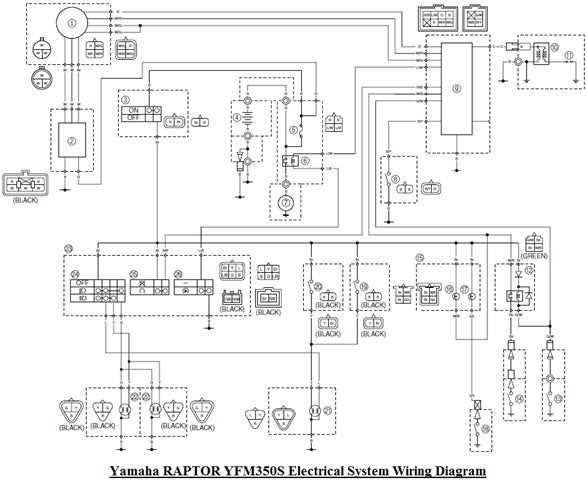

Electrical System Diagnostics Guide

This section aims to provide insights into evaluating the electrical components of your vehicle. Understanding how to identify and troubleshoot issues in the electrical system is essential for maintaining optimal performance and preventing future malfunctions.

To effectively diagnose problems, it’s important to follow a systematic approach. Begin by checking the battery condition, ensuring connections are secure and free from corrosion. Next, evaluate the fuses and wiring for any signs of damage. Use the following table as a reference for common electrical issues and their potential solutions:

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Dim Lights | Weak battery, faulty alternator | Test battery voltage, inspect alternator output |

| No Start | Dead battery, starter failure | Check battery charge, test starter function |

| Blown Fuses | Short circuit, overloaded circuit | Identify and repair short circuits, replace fuses |

| Intermittent Electrical Issues | Poor connections, damaged wiring | Inspect and repair connections, replace damaged wires |

Following these guidelines will help ensure a thorough examination of the electrical system, enhancing the longevity and reliability of your vehicle.

How to Change the Oil

Regular maintenance of your vehicle’s lubrication system is essential for optimal performance and longevity. Changing the fluid not only ensures that the engine runs smoothly but also helps to prevent wear and tear on critical components. Below are the steps to effectively perform this task.

Tools and Materials Needed

- Oil filter wrench

- Socket set

- Drain pan

- New lubricant

- New oil filter

- Funnel

- Rags or paper towels

Step-by-Step Guide

- Ensure the vehicle is on a level surface and the engine is warm, but not hot.

- Locate the drain plug under the engine and position the drain pan underneath.

- Remove the drain plug using the appropriate socket and allow the old lubricant to fully drain into the pan.

- Once drained, replace the drain plug and tighten it securely.

- Using the oil filter wrench, remove the old filter. Make sure to lubricate the rubber gasket of the new filter with a bit of fresh oil.

- Install the new filter by hand, tightening it until snug.

- Using a funnel, pour the new lubricant into the engine through the designated fill cap.

- Start the engine and let it run for a few minutes. Check for leaks around the filter and drain plug.

- Turn off the engine and wait a few moments. Check the oil level using the dipstick and add more lubricant if necessary.

Following these steps will help maintain the efficiency of your machine, ensuring that it runs smoothly for years to come.

Brake System Inspection Techniques

Ensuring the optimal performance of the stopping mechanism is essential for safety and efficiency. Regular evaluation of this system allows for the early detection of potential issues that could lead to significant problems if left unaddressed. Proper inspection involves a systematic approach to assessing various components and their functionality.

Visual Assessment

The initial step in the examination process is a thorough visual inspection. Look for signs of wear, damage, or fluid leaks around the braking components. Ensure that all parts are securely mounted and that no unusual debris is present.

Performance Testing

Following the visual check, conducting performance tests is crucial. This involves assessing the responsiveness of the mechanism under different conditions. Measure the stopping distance and evaluate the feel of the lever or pedal. Any inconsistencies may indicate underlying issues.

| Component | Inspection Method | Signs of Issues |

|---|---|---|

| Pads | Visual check and thickness measurement | Uneven wear, cracks, or low thickness |

| Rotors | Surface examination and runout measurement | Scoring, warping, or discoloration |

| Lines | Leak inspection and pressure test | Visible leaks or soft feel |

| Fluid | Fluid level and condition check | Low level, discoloration, or contamination |

Adjusting Suspension Settings Effectively

Optimizing the settings of your vehicle’s suspension is crucial for enhancing performance and comfort. Proper adjustments can significantly influence handling, ride quality, and stability. Understanding the various components involved and how they interact allows for tailored configurations that suit individual riding styles and conditions.

Understanding Suspension Components

The suspension system consists of several key elements, each playing a vital role in vehicle dynamics. Familiarity with these parts is essential for effective adjustments.

| Component | Function |

|---|---|

| Shock Absorber | Controls the compression and rebound of the suspension. |

| Spring | Supports the vehicle’s weight and absorbs impacts. |

| Linkages | Connects the various suspension elements, allowing movement. |

Steps for Effective Adjustment

To achieve the desired performance, follow these steps when adjusting suspension settings:

- Start by assessing the current setup and noting any issues.

- Adjust the preload of the springs to achieve the correct ride height.

- Fine-tune the compression and rebound damping settings based on personal preferences and terrain conditions.

- Test the adjustments in a safe environment and make further tweaks as necessary.