Maintaining small two-wheeled vehicles can be an enjoyable and rewarding experience for enthusiasts and casual users alike. Understanding the intricacies of these compact machines not only enhances performance but also prolongs their lifespan. Whether you’re a seasoned mechanic or a novice, grasping the fundamental principles of upkeep is crucial.

In this comprehensive guide, we will delve into various aspects of service and enhancement for these dynamic machines. From troubleshooting common issues to performing routine checks, every detail is vital for ensuring optimal functionality. By familiarizing yourself with key techniques and practices, you’ll empower yourself to tackle any challenge that may arise.

Moreover, having access to accurate information allows owners to make informed decisions regarding modifications and upgrades. This not only boosts the efficiency of your vehicle but also contributes to a deeper understanding of its mechanics. Embrace the journey of discovery as you enhance your skills and knowledge in the realm of small engine care.

Pocket Bike Overview

This section provides a comprehensive look into a popular small-scale two-wheeled vehicle that captures the excitement of motorsport. These compact machines offer a unique blend of speed, agility, and fun, making them ideal for enthusiasts of all ages. Understanding their components and operation is essential for both enjoyment and maintenance.

Key Features

- Compact Size: Designed for easy maneuverability and storage.

- Lightweight Construction: Facilitates quick acceleration and handling.

- Powerful Engines: Typically equipped with small but efficient motors.

- Durable Materials: Built to withstand rigorous use while ensuring longevity.

Usage and Popularity

These mini vehicles have gained traction in various settings, from casual riding to competitive events. Their appeal lies in the thrilling experience they offer, allowing riders to enjoy a taste of speed without the commitment of larger motorcycles.

- Leisure Riding: Ideal for casual use in parks and backyards.

- Competitive Racing: Often seen in organized racing events.

- Skill Development: Great for beginners looking to hone their riding skills.

Common Issues with Pocket Bikes

Many enthusiasts encounter various challenges when operating small motorized vehicles. Understanding these common problems can help users maintain optimal performance and enjoy a smoother ride. This section outlines frequent issues that may arise, along with some insights into their causes.

One prevalent concern involves starting difficulties. If the engine fails to ignite, it could be due to a drained battery, faulty spark plug, or issues with the fuel system. Regular checks and maintenance of these components can often prevent such frustrations.

Another common issue is a lack of power during operation. This can manifest as sluggish acceleration or an overall decrease in speed. Causes may include fuel contamination, air filter blockages, or carburetor malfunctions. Addressing these factors promptly can restore the desired performance.

Users may also face challenges with braking. Worn-out brake pads or low fluid levels can compromise safety and control. Regular inspections of the braking system are essential to ensure reliability and responsiveness.

Lastly, tire problems are frequently reported, including punctures or improper inflation. Maintaining the correct tire pressure and promptly addressing any damage can significantly enhance stability and handling.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. Whether you’re addressing minor issues or performing comprehensive overhauls, a well-equipped toolkit can make all the difference in efficiency and outcomes. Below are some key instruments that every enthusiast should consider having on hand.

Basic Hand Tools

Fundamental instruments like wrenches, screwdrivers, and pliers form the backbone of any toolkit. These items enable you to tackle a variety of tasks, from tightening loose components to replacing faulty parts. It’s advisable to invest in a set that includes both metric and standard sizes to ensure compatibility with different fittings.

Specialized Equipment

In addition to basic tools, having specialized devices can enhance your ability to diagnose and fix more complex issues. Items such as torque wrenches, multimeters, and tire levers can help you achieve precise adjustments and perform thorough inspections. Keeping these specialized instruments organized will ensure that you can access them quickly when needed.

Step-by-Step Maintenance Guide

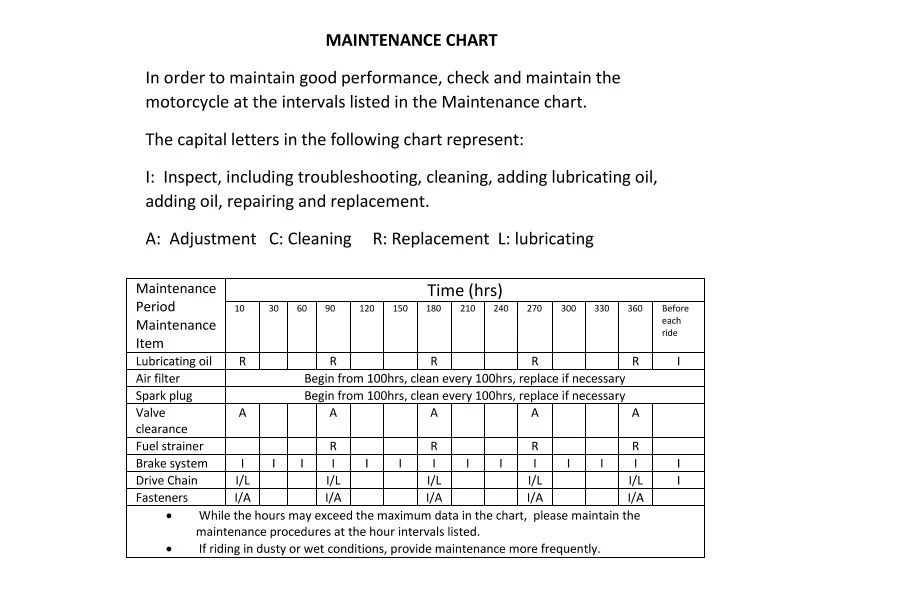

Regular upkeep is essential to ensure optimal performance and longevity of your miniature vehicle. By following a systematic approach, you can easily identify issues before they escalate and maintain a smooth operation. This guide outlines the necessary procedures to keep your machine in top shape, from routine checks to specific adjustments.

Start with a thorough inspection of the exterior and components. Check for any visible wear, damage, or loose parts. Ensuring everything is secure will prevent further complications during use. Pay close attention to the tires; maintaining proper pressure is crucial for safety and handling.

Next, focus on the engine. Regularly change the oil to keep it running smoothly, and replace the air filter as needed to ensure optimal airflow. Checking the fuel system for any leaks or blockages will help maintain efficiency and performance.

Don’t forget about the brakes. Inspect the pads for wear and ensure they engage properly. Regular maintenance of the braking system is vital for your safety and overall control.

Lastly, keep all moving parts lubricated to reduce friction and wear. A well-lubricated system will enhance performance and extend the lifespan of your vehicle. Regularly following these steps will contribute to a more enjoyable and reliable riding experience.

Engine Troubleshooting Techniques

Understanding how to diagnose and resolve issues related to the internal combustion unit is essential for maintaining optimal performance. Identifying symptoms and systematically addressing them can lead to efficient problem-solving, ensuring the longevity of the vehicle.

Initial Assessment: Begin by observing any irregularities during operation. Pay attention to unusual noises, vibrations, or changes in performance. These indicators can provide critical clues about underlying issues.

Fuel System Inspection: A common source of problems is the fuel supply. Check for blockages in the fuel lines, inspect the filter for contaminants, and ensure that the fuel is reaching the combustion chamber efficiently. Stale fuel can also lead to performance issues, so consider replacing it if necessary.

Electrical Components Check: Inspect the ignition system, including the spark plug and ignition coil. A faulty spark plug can cause misfiring, leading to a rough operation. Ensure connections are secure and free from corrosion.

Compression Test: Conduct a compression test to evaluate the health of the engine. Low compression can indicate wear on the piston rings or valves. This test can help identify whether the engine is functioning within optimal parameters.

Cooling System Evaluation: Overheating can cause significant damage. Verify that the cooling system is functioning correctly, checking for leaks, and ensuring that the coolant is at the appropriate level. Regular maintenance of this system is crucial.

By methodically addressing these areas, one can effectively pinpoint and rectify issues, ensuring the engine operates smoothly and reliably.

Adjusting the Carburetor Effectively

Fine-tuning the fuel delivery system is crucial for optimal engine performance. Proper adjustments ensure that the air-fuel mixture is balanced, leading to improved efficiency and responsiveness. This section provides a step-by-step guide to achieving effective calibration.

Understanding Key Components

Before making adjustments, it’s essential to familiarize yourself with the main elements of the fuel system:

- Jetting: Determines the amount of fuel delivered at various throttle positions.

- Mixture Screws: Control the ratio of air to fuel in idle and low-speed conditions.

- Throttle Position: Affects overall performance during acceleration.

Steps for Adjustment

- Start the engine and allow it to warm up for a few minutes.

- Identify the idle mixture screw and make small adjustments.

- Monitor the engine’s response; aim for a smooth, steady idle.

- Adjust the main jet if necessary, considering the desired power output.

- Test the throttle response by gradually accelerating and decelerating.

- Reassess the mixture and throttle settings based on performance feedback.

Regular maintenance and precise adjustments will lead to enhanced performance and longevity of the engine. Take your time and ensure each setting is tailored to your specific needs.

Brake System Inspection Process

The effectiveness of a vehicle’s stopping mechanism is crucial for safety and performance. A thorough evaluation of this system ensures reliable operation and helps identify potential issues before they escalate. Regular inspections can prolong the lifespan of components and enhance overall riding experience.

Visual Examination

Functional Testing

After the visual check, perform a functional test by applying the brakes while stationary and in motion. Listen for unusual noises and monitor the responsiveness. Pay attention to any vibrations or pulling to one side, as these can indicate underlying issues that require further attention.

Replacing Tires on Your Pocket Bike

Maintaining optimal performance requires periodic attention to essential components, including the rubber that connects your miniature vehicle to the ground. Over time, wear and tear can lead to reduced traction and safety concerns, making timely replacement crucial for an enjoyable ride. This section will guide you through the steps to effectively change the wheels, ensuring a smooth and safe experience.

Tools and Materials Needed

Before starting, gather the necessary tools and components. You will need a suitable wrench or socket set to remove the fasteners, a tire lever for easing off the old rubber, and a new tire that matches the specifications of your model. Additionally, having lubricant can facilitate the installation process.

Step-by-Step Replacement Process

Begin by ensuring the vehicle is stable and secure, preferably on a flat surface. Loosen and remove the bolts holding the existing tire in place. Once detached, use the tire lever to carefully pry off the old rubber, taking care not to damage the rim. Clean the rim thoroughly before positioning the new tire. Apply lubricant to the bead of the tire to aid in fitting. Finally, secure the new tire by tightening the bolts to the manufacturer’s recommended torque specifications.

Electrical Components and Diagnostics

This section delves into the various electrical elements essential for the operation of small motorized vehicles. Understanding these components is crucial for effective troubleshooting and ensuring optimal performance. A solid grasp of the electrical system helps in identifying issues and executing repairs with confidence.

Key Electrical Elements

The primary components include the battery, ignition system, wiring harness, and various sensors. The battery provides the necessary power to start the engine and operate accessories. The ignition system plays a pivotal role in initiating combustion, while the wiring harness facilitates communication between different parts. Sensors monitor various parameters, ensuring the vehicle operates within safe limits.

Diagnostic Techniques

To effectively diagnose electrical problems, it’s important to utilize tools such as multimeters and diagnostic scanners. These instruments can measure voltage, current, and resistance, helping to pinpoint faults in the electrical circuit. Regular inspections and testing of components can prevent major failures and enhance the longevity of the vehicle.

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity of the engine. Regular cleaning can prevent clogs, improve fuel efficiency, and ensure smooth operation. This section outlines the steps necessary to effectively clean the fuel delivery components.

| Step | Procedure | Tools Needed |

|---|---|---|

| 1 | Disconnect the fuel lines and remove the fuel filter. | Wrench set, screwdriver |

| 2 | Flush the fuel lines with a suitable cleaning solvent. | Cleansing solvent, container |

| 3 | Inspect and clean the fuel injectors if applicable. | Injector cleaner kit |

| 4 | Replace the fuel filter and reconnect the lines. | New fuel filter, wrench |

| 5 | Test the system for leaks and proper operation. | Safety glasses, rag |

Upgrading Performance Parts

Enhancing the capabilities of your two-wheeled vehicle can significantly improve its overall performance. By selecting the right components, you can achieve better speed, handling, and acceleration, creating a more exhilarating riding experience. This section will explore various upgrades that can take your ride to the next level.

- Engine Modifications:

- Install a high-performance carburetor for improved fuel delivery.

- Upgrade the exhaust system to enhance airflow and reduce back pressure.

- Consider a big bore kit to increase displacement and power output.

- Suspension Enhancements:

- Replace stock springs with performance-grade ones for better stability.

- Install adjustable shocks to customize your ride height and damping.

- Brake System Improvements:

- Upgrade to larger brake rotors for increased stopping power.

- Use high-performance brake pads to enhance grip and responsiveness.

- Tires and Wheels:

- Choose lightweight alloy wheels to reduce unsprung weight.

- Select performance tires for better traction and handling.

Implementing these enhancements will not only improve the performance of your machine but also contribute to a more enjoyable and dynamic riding experience. Always ensure that upgrades are compatible and installed correctly for optimal results.