When it comes to ensuring the longevity and performance of outdoor machinery, having a comprehensive resource at your disposal is essential. Such guides serve as invaluable companions for users looking to troubleshoot issues, conduct regular maintenance, or enhance the efficiency of their tools. With clear instructions and detailed diagrams, these resources can transform a daunting task into a manageable one.

Understanding the intricacies of your equipment can significantly reduce the risk of breakdowns and extend its lifespan. Whether you are a novice or an experienced user, access to well-structured guidance empowers you to tackle various challenges confidently. From routine inspections to more complex repairs, knowing what steps to take is crucial for effective management.

As you delve into the specifics of your machinery, you will discover techniques and tips that can simplify processes and improve functionality. Familiarity with the components and mechanisms not only enhances your skill set but also fosters a deeper appreciation for the technology behind your equipment. Embracing this knowledge can lead to more successful outcomes and a satisfying experience in maintaining your outdoor tools.

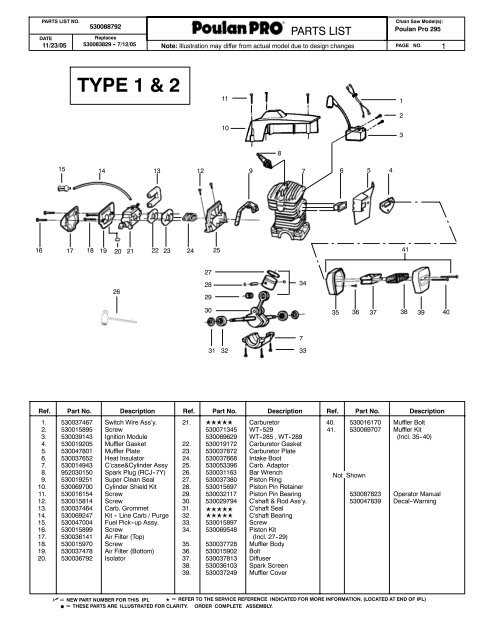

Poulan Pro 295 Repair Manual Overview

This section provides a comprehensive overview of the guidelines and procedures essential for maintaining and troubleshooting outdoor power equipment. The aim is to empower users with the necessary knowledge to effectively address common issues and ensure optimal performance.

Key Features

The document highlights various aspects, including step-by-step instructions, diagrams, and maintenance schedules. By following these detailed guidelines, users can enhance the longevity and efficiency of their equipment.

Benefits of Using the Guide

Utilizing this resource offers numerous advantages, such as improved understanding of the machinery, cost savings from performing self-service, and increased confidence in handling technical tasks. Adhering to the recommendations within can lead to a more reliable and efficient operation.

Common Issues with Poulan Pro 295

When working with outdoor power equipment, users may encounter various challenges that can affect performance and reliability. Understanding these potential problems can help in diagnosing issues quickly and ensuring proper functionality.

Frequent Problems

- Starting Difficulties: Many users report issues with the engine not starting, which may be caused by a faulty spark plug, clogged fuel filter, or inadequate fuel mixture.

- Power Loss: A drop in performance can occur due to air filter blockage, improper carburetor settings, or fuel line obstructions.

- Overheating: If the device runs too hot, it might be a sign of inadequate lubrication or a blocked cooling system.

- Vibrations: Excessive vibrations may indicate loose components, worn bearings, or imbalanced blades.

Maintenance Tips

- Regularly check and replace the spark plug as needed.

- Ensure the air filter is clean and free from debris.

- Monitor fuel quality and use the recommended mixture to avoid clogs.

- Inspect for loose parts and tighten as necessary to prevent vibrations.

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure the longevity and optimal performance of your equipment. By following a series of systematic steps, you can effectively maintain its functionality and prevent potential issues. This guide will outline the key procedures to keep your machine in top shape.

1. Cleaning the Air Filter

Start by removing the air filter to eliminate dirt and debris. Use a soft brush or compressed air to clean it thoroughly. Ensure the filter is completely dry before reinstallation to maintain proper airflow.

2. Checking the Spark Plug

Inspect the spark plug for wear and carbon buildup. If necessary, clean it with a wire brush or replace it entirely. A well-functioning spark plug is crucial for efficient engine ignition and performance. Replace it regularly to avoid starting issues.

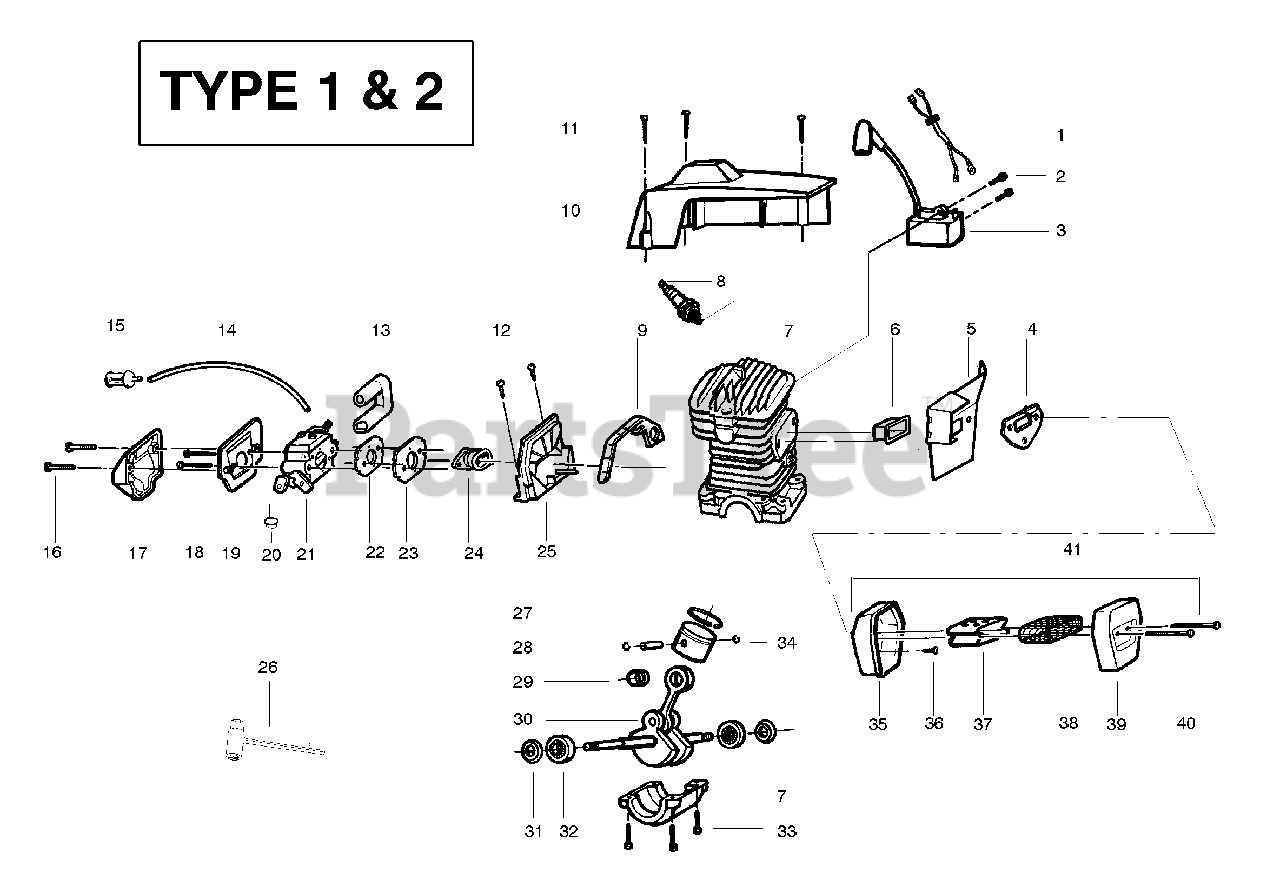

Parts Replacement for Optimal Performance

Maintaining the efficiency of any equipment is essential for achieving peak functionality. Regularly updating and substituting components ensures that the machine operates smoothly and effectively, prolonging its lifespan. This section highlights the significance of timely parts replacement and offers insights on essential components to focus on for enhanced performance.

Key Components to Consider

- Air Filter: A clean air filter prevents dirt and debris from entering the engine, improving airflow and efficiency.

- Fuel Filter: Replacing the fuel filter regularly helps maintain fuel quality, ensuring optimal combustion and performance.

- Spark Plug: A fresh spark plug guarantees proper ignition, which is vital for efficient operation.

- Blades: Dull or damaged blades should be replaced to ensure effective cutting performance and reduce strain on the engine.

Replacement Schedule

- Check the air and fuel filters every 25 hours of operation.

- Inspect the spark plug every 50 hours; replace it as needed.

- Assess blade condition before each use, replacing them if they show signs of wear.

Adhering to this replacement schedule not only maintains efficiency but also enhances safety and reliability during operation. Investing time in proper maintenance will yield significant returns in performance and durability.

Troubleshooting Engine Starting Problems

When an engine fails to start, it can be frustrating and time-consuming. Understanding the potential causes of starting issues is essential for effective diagnosis and resolution. This section will guide you through common problems and solutions that can help get your machine running smoothly again.

Common Causes of Starting Issues

There are several reasons why an engine might not start. A weak or dead battery, faulty ignition components, or a clogged fuel system are common culprits. Inspect the battery connections for corrosion, ensure the ignition switch functions correctly, and check for any blockages in the fuel lines. Addressing these factors can often resolve starting difficulties.

Steps to Diagnose the Problem

Begin by examining the electrical system. Test the battery voltage and connections, then move on to the ignition system, ensuring that all components are functioning properly. If electrical components are in order, focus on the fuel system, checking for fuel flow and cleanliness. By systematically evaluating each aspect, you can identify the root cause of the starting problem.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the integrity of the equipment. Adhering to specific guidelines can prevent accidents and injuries, fostering a secure working environment.

Before initiating any service work, it is vital to prepare adequately. This includes understanding the potential hazards associated with the machinery and employing appropriate protective gear.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always don safety glasses, gloves, and ear protection to shield against debris and loud noises. |

| Work in a Well-Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes or dust during maintenance activities. |

| Disconnect Power Sources | Always unplug the device or disconnect the battery before starting any disassembly to prevent accidental activation. |

| Keep Workspace Organized | Maintain a tidy work area to minimize trip hazards and easily locate tools and parts. |

| Follow Manufacturer Guidelines | Consult official documentation for specific instructions and safety measures relevant to the equipment being serviced. |

By following these essential safety practices, individuals can significantly reduce the risk of incidents, ensuring a smooth and efficient service process.

Essential Tools for Effective Repair

Having the right equipment is crucial for successful maintenance and restoration tasks. A well-equipped workspace enables efficient troubleshooting and problem-solving, leading to improved outcomes and extended longevity of the machinery. This section highlights the fundamental instruments required to ensure smooth operations during servicing tasks.

Key Instruments

Various tools play an important role in facilitating effective maintenance. Here are some essential instruments every technician should consider having on hand:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening nuts and bolts |

| Screwdriver Set | For various types of screws |

| Wrench | For gripping and turning fasteners |

| Pliers | For gripping and manipulating objects |

| Multimeter | For measuring electrical properties |

Safety Equipment

Ensuring safety during maintenance is equally important. Adequate protective gear not only safeguards the technician but also enhances focus and efficiency. Recommended safety items include:

| Safety Gear | Function |

|---|---|

| Gloves | To protect hands from cuts and abrasions |

| Safety Glasses | To shield eyes from debris |

| Ear Protection | To guard against loud noises |

Cleaning and Caring for Your Chainsaw

Regular maintenance is essential for ensuring the longevity and efficiency of your chainsaw. Proper cleaning and care not only enhance performance but also promote safety during operation. This section outlines the necessary steps and best practices to keep your tool in optimal condition.

After each use, it is important to perform a thorough cleaning of the chainsaw to remove any debris, sap, or oil buildup. This will help prevent clogs and ensure smooth functioning during your next project.

| Step | Action |

|---|---|

| 1 | Disconnect the power source or remove the spark plug for safety. |

| 2 | Use a soft brush or cloth to wipe down the exterior surfaces and remove dust and grime. |

| 3 | Clean the air filter regularly to ensure proper airflow; replace if damaged. |

| 4 | Check the chain tension and lubricate it to prevent wear and tear. |

| 5 | Inspect the bar and remove any debris lodged in the groove. |

| 6 | Store the chainsaw in a dry place, ideally in a protective case to prevent dust accumulation. |

Following these steps will not only keep your equipment in top shape but also enhance your safety while using it. Regular maintenance is key to enjoying a reliable and efficient chainsaw for years to come.

Understanding the Poulan Pro 295 Specs

This section delves into the essential specifications of a well-known chainsaw model, highlighting its features and capabilities. Understanding these details is crucial for users to ensure they are equipped for effective operation and maintenance.

Key specifications include:

- Engine Type: A two-stroke engine known for its efficiency and power.

- Displacement: The engine’s capacity is significant for determining performance levels.

- Power Output: Measured in horsepower, this indicates the tool’s cutting ability.

- Bar Length: The length of the guide bar affects cutting depth and overall usability.

- Weight: A lighter model enhances maneuverability during extended use.

- Fuel Capacity: This impacts operational time before refueling is needed.

- Chain Speed: The speed at which the chain moves is crucial for cutting efficiency.

These features contribute to the tool’s performance in various tasks, from light trimming to more demanding cutting jobs. Familiarizing oneself with these specifications ensures a better understanding of how to utilize the equipment effectively.

Expert Tips for Long-Lasting Use

Ensuring the longevity of your equipment involves a combination of proper maintenance and mindful usage. By following expert advice, you can enhance performance and prolong the lifespan of your tools.

- Regular Cleaning: Keep your device free from dirt and debris. Regularly remove any buildup that may affect functionality.

- Proper Lubrication: Use high-quality lubricants to minimize friction and wear. Follow the manufacturer’s recommendations for lubrication intervals.

- Safe Storage: Store your equipment in a dry, cool place to prevent rust and damage. Utilize protective covers when not in use.

- Inspect Components: Regularly check for wear and tear on essential parts. Replace any damaged components promptly to avoid further issues.

- Follow Usage Guidelines: Adhere to the operational guidelines provided by the manufacturer to prevent misuse that could lead to premature failure.

- Fuel Quality: Use clean and appropriate fuel. Contaminated or incorrect fuel types can lead to significant performance issues.

By implementing these strategies, you can ensure your tools remain efficient and reliable for years to come. Consistent care will lead to optimal performance, making your investment worthwhile.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing the right components is crucial for optimal performance and longevity. Various avenues exist for obtaining these essential parts, ensuring that your tools remain in peak condition. Below are some reliable options to consider for finding suitable replacements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides a dedicated section for parts, allowing you to browse by model and specifications. |

| Authorized Dealers | Local or online dealers recognized by the manufacturer can offer genuine components and expert advice. |

| Online Retailers | Major e-commerce platforms frequently have a wide selection of parts, often accompanied by customer reviews and ratings. |

| Local Repair Shops | Community repair shops may stock parts or assist in ordering what you need, often with the added benefit of professional installation. |

| Salvage Yards | For those looking for budget-friendly options, salvage yards can be treasure troves of used components in good condition. |